Professional Documents

Culture Documents

High Running Solid Solvent-Based Laminating Adhesive

High Running Solid Solvent-Based Laminating Adhesive

Uploaded by

alfredoCopyright:

Available Formats

You might also like

- Fiber Analysis: Qualitative: AATCC Test Method 20-2013Document20 pagesFiber Analysis: Qualitative: AATCC Test Method 20-2013Milagros Wieczorek100% (1)

- The Powder Coaters ManualDocument209 pagesThe Powder Coaters ManualOvation Audio Labs100% (4)

- High Running Solid Solvent-Based Laminating AdhesiveDocument2 pagesHigh Running Solid Solvent-Based Laminating Adhesivealfredo100% (1)

- Technical Data Sheet: Regalrez™ 1085 Hydrocarbon ResinDocument2 pagesTechnical Data Sheet: Regalrez™ 1085 Hydrocarbon ResinPaul TsaiNo ratings yet

- Cardolite Ultra LITE 2009: Epoxy Curing Agent Technical DatasheetDocument2 pagesCardolite Ultra LITE 2009: Epoxy Curing Agent Technical Datasheettrường phạmNo ratings yet

- Crestomer-1152PA ENG TDS Feb18Document3 pagesCrestomer-1152PA ENG TDS Feb18fernando machadoNo ratings yet

- Technical Data Sheet: Regalrez™ 1094 Hydrocarbon ResinDocument2 pagesTechnical Data Sheet: Regalrez™ 1094 Hydrocarbon ResinPaul TsaiNo ratings yet

- 419 - Composites Catalogue-AtulDocument12 pages419 - Composites Catalogue-AtulVaittianathan Mahavapillai100% (1)

- Lubricants: Unoba EPDocument2 pagesLubricants: Unoba EPQC RegianNo ratings yet

- Ali Goger IngeniaDocument16 pagesAli Goger IngeniaMiguel Angel Perez EsparzaNo ratings yet

- Bond Polymers International BrochureDocument9 pagesBond Polymers International Brochuregabriel oliveira monteiroNo ratings yet

- PDS CST820 CO enDocument2 pagesPDS CST820 CO enm.onderolaganNo ratings yet

- ADCOTE 548-81R + Coreactant F (TDS)Document4 pagesADCOTE 548-81R + Coreactant F (TDS)Wasif AzimNo ratings yet

- 4408 Fully Synthetic Heavy Duty Industrial Gear OilDocument3 pages4408 Fully Synthetic Heavy Duty Industrial Gear OilYoong TanNo ratings yet

- 95-812 Series 95-812 Series 95-812 Series 95-812 Series Pitthane® Ultra Pitthane® Ultra Pitthane® UltraDocument2 pages95-812 Series 95-812 Series 95-812 Series 95-812 Series Pitthane® Ultra Pitthane® Ultra Pitthane® Ultramiguel angel lopezNo ratings yet

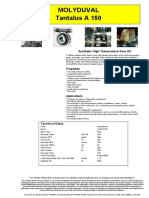

- Tantalus A 150Document1 pageTantalus A 150Selçuk MerterNo ratings yet

- Whitmore Det-900 GreaseDocument1 pageWhitmore Det-900 GreaseDon HowardNo ratings yet

- TDS - Soluryl - 80 - HanwhaDocument1 pageTDS - Soluryl - 80 - Hanwhaichsan hakimNo ratings yet

- Dow 177 03747 HPR900 So4 LDocument4 pagesDow 177 03747 HPR900 So4 LAditya RifNo ratings yet

- RTC Flexible Packaging - EngDocument25 pagesRTC Flexible Packaging - EngthuylienNo ratings yet

- ExxonMobil Vistamaxx 6202Document2 pagesExxonMobil Vistamaxx 6202Rajiv DubeyNo ratings yet

- Synthetic Food Grade Grease Synthetic Food Grade Grease: (NSF Certified (NSF Certified, Category H1, REGN NO. 147065)Document2 pagesSynthetic Food Grade Grease Synthetic Food Grade Grease: (NSF Certified (NSF Certified, Category H1, REGN NO. 147065)mayurghule19100% (1)

- Permax 230Document1 pagePermax 230Catalin VelcsovNo ratings yet

- Everlube 620 ATDSDocument2 pagesEverlube 620 ATDSValentinNo ratings yet

- Technical Data Sheet (TDS) PDFDocument3 pagesTechnical Data Sheet (TDS) PDFSabuj SaikiaNo ratings yet

- Polywithe® - 8000 CLDocument1 pagePolywithe® - 8000 CLsébastien cardinaleNo ratings yet

- 4 - EPS - Biobased Polymer For Furniture Applications and Waterborne Polymers For Corrosion Resistance Up To C5 ClassDocument43 pages4 - EPS - Biobased Polymer For Furniture Applications and Waterborne Polymers For Corrosion Resistance Up To C5 ClassIzabela MarchewkaNo ratings yet

- Biodegradable Wire Rope Coating GreaseDocument2 pagesBiodegradable Wire Rope Coating GreasedhowardjNo ratings yet

- Polytone: ABR Series/Thermoplastic Acrylic ResinsDocument7 pagesPolytone: ABR Series/Thermoplastic Acrylic ResinsAdhvik PuriNo ratings yet

- Estane 54610 TPU: Advancing MaterialsDocument2 pagesEstane 54610 TPU: Advancing MaterialsRonaldo CamargoNo ratings yet

- Polylon 1900 (3853091)Document4 pagesPolylon 1900 (3853091)JOCELYN MEDINANo ratings yet

- Shield - Euro Tech 1Document2 pagesShield - Euro Tech 1Ali KhalidNo ratings yet

- Thermolite 890F TDS Rev v3Document3 pagesThermolite 890F TDS Rev v3Qwerty RoyalNo ratings yet

- Cloverdale Tds 83570 eDocument4 pagesCloverdale Tds 83570 eErnesto Javier Martín RosabalNo ratings yet

- TPS Eva 3641 2Document1 pageTPS Eva 3641 2Juthi RahmanNo ratings yet

- NC-558 TDS enDocument2 pagesNC-558 TDS enniteshacharya100% (1)

- Aesthetic Topcoat Guide SWDocument8 pagesAesthetic Topcoat Guide SWjennifergiannouNo ratings yet

- Palmester 2083 2088 2090: Biolubricant Base OilsDocument2 pagesPalmester 2083 2088 2090: Biolubricant Base OilsVandewalleNo ratings yet

- ExxonMobil Enable 20-05HHDocument2 pagesExxonMobil Enable 20-05HHHung TranNo ratings yet

- 8090Document2 pages8090dost369No ratings yet

- Performance Coatings Product Data Sheet Lubrijet™ T800 Polyurethane DispersionDocument2 pagesPerformance Coatings Product Data Sheet Lubrijet™ T800 Polyurethane DispersionPedro Duplaa Soares FerreiraNo ratings yet

- 118 01806 01 Carbowax Polyethylene Glycol Peg 8000 TdsDocument2 pages118 01806 01 Carbowax Polyethylene Glycol Peg 8000 TdsrickthetrickstertrickyNo ratings yet

- Polyurethane Dispersions Product GuideDocument4 pagesPolyurethane Dispersions Product GuideAn PhungNo ratings yet

- Bentone 2018Document2 pagesBentone 2018Victor ZhicayNo ratings yet

- Ecoalube642TDS PDFDocument2 pagesEcoalube642TDS PDFDkC gunsNo ratings yet

- Prometheus Sa 20 HVDocument1 pagePrometheus Sa 20 HVMassimiliano VolaNo ratings yet

- PET Processing V4 1 PDFDocument48 pagesPET Processing V4 1 PDFwoongs73100% (1)

- Polymer Modification Hydrophobic EN May2021 USDocument4 pagesPolymer Modification Hydrophobic EN May2021 USManish DobariyaNo ratings yet

- Lubricants: Cable LubeDocument2 pagesLubricants: Cable LubeVictor ZhicayNo ratings yet

- TDS Abitol E Hydroabietyl AlcoholDocument2 pagesTDS Abitol E Hydroabietyl AlcoholCaio OliveiraNo ratings yet

- Sapphire Spray Grease - GBDocument2 pagesSapphire Spray Grease - GBdiegogsouzzaNo ratings yet

- TDS DuraCoat 11 60 Rhino IndustrialDocument2 pagesTDS DuraCoat 11 60 Rhino IndustrialDonnie WeltyNo ratings yet

- Lite 3060 - TdsDocument2 pagesLite 3060 - TdsJuan Sebastián Fernández RamírezNo ratings yet

- Prometheus A 00 LMDocument1 pagePrometheus A 00 LMMassimiliano VolaNo ratings yet

- Alphasyn Ep 220Document2 pagesAlphasyn Ep 220Atika AtikaNo ratings yet

- Optimelt Phc7005, PDFDocument10 pagesOptimelt Phc7005, PDFrotti_gururajNo ratings yet

- Cardolite Ultra LITE 513: Epoxy Reactive Diluent Technical DatasheetDocument2 pagesCardolite Ultra LITE 513: Epoxy Reactive Diluent Technical Datasheettrường phạmNo ratings yet

- TechnicalDataSheet (TDS) TulsionA-2XMP English 01042018Document3 pagesTechnicalDataSheet (TDS) TulsionA-2XMP English 01042018hamdani sceNo ratings yet

- Bpxe B6ctalDocument2 pagesBpxe B6ctalVusal HasanovNo ratings yet

- 124826carboset® CR-785Document17 pages124826carboset® CR-785ForeverNo ratings yet

- QA Manual 2020 Pi Tape Texas LLCDocument21 pagesQA Manual 2020 Pi Tape Texas LLCalfredoNo ratings yet

- BS en Iso 00105-E05-2010Document12 pagesBS en Iso 00105-E05-2010alfredoNo ratings yet

- Hydrostatic TestDocument6 pagesHydrostatic TestalfredoNo ratings yet

- BS en Iso 00105-E04-2013Document14 pagesBS en Iso 00105-E04-2013alfredoNo ratings yet

- BS en Iso 00105-J01-2000Document22 pagesBS en Iso 00105-J01-2000alfredoNo ratings yet

- BS en Iso 00105-E02-2013Document14 pagesBS en Iso 00105-E02-2013alfredoNo ratings yet

- Wide Ranging Tie Layer PerformanceDocument7 pagesWide Ranging Tie Layer PerformancealfredoNo ratings yet

- BS en Iso 00105-J02-2000Document16 pagesBS en Iso 00105-J02-2000alfredoNo ratings yet

- Hot Tack Heatsealer: Data SheetDocument2 pagesHot Tack Heatsealer: Data SheetalfredoNo ratings yet

- BS en Iso 00105-J03-2009Document18 pagesBS en Iso 00105-J03-2009alfredoNo ratings yet

- Solutions For Shrink Packaging FilmsDocument2 pagesSolutions For Shrink Packaging FilmsalfredoNo ratings yet

- Wintest Analysis English PDFDocument54 pagesWintest Analysis English PDFalfredoNo ratings yet

- Dow Products For Fibers, Nonwovens and Barrier FilmsDocument2 pagesDow Products For Fibers, Nonwovens and Barrier FilmsalfredoNo ratings yet

- Eco-Friendly Laminating Adhesive SolutionDocument2 pagesEco-Friendly Laminating Adhesive SolutionalfredoNo ratings yet

- Food Safe Packaging Hot Melt AdhesivesDocument4 pagesFood Safe Packaging Hot Melt AdhesivesalfredoNo ratings yet

- High Running Solid Solvent-Based Laminating AdhesiveDocument2 pagesHigh Running Solid Solvent-Based Laminating Adhesivealfredo100% (1)

- Coating of Polyester Film With Thin Wax LayersDocument37 pagesCoating of Polyester Film With Thin Wax LayersalfredoNo ratings yet

- Protocol For Sample Collection - Interlaboratorial - WVTR - ObenDocument3 pagesProtocol For Sample Collection - Interlaboratorial - WVTR - ObenalfredoNo ratings yet

- Durosan 03 Exterior Matt (I) : Technical Data SheetDocument3 pagesDurosan 03 Exterior Matt (I) : Technical Data Sheetمحمد عزتNo ratings yet

- 19 - J Mater Chem 2009-19-5027Document6 pages19 - J Mater Chem 2009-19-5027Christhy Vanessa Ruiz MadroñeroNo ratings yet

- Additives For Crop Protection EvonikDocument20 pagesAdditives For Crop Protection EvonikAlfredo MéndezNo ratings yet

- Material Selection Task - Wind TurbineDocument12 pagesMaterial Selection Task - Wind TurbineVishwajit GaunsNo ratings yet

- States of Matter NotesDocument14 pagesStates of Matter NotesAreeba EjazNo ratings yet

- Aslan700 DatasheetDocument1 pageAslan700 Datasheetaditarian .pNo ratings yet

- Ficha Tecnica y Certificado de Bituminoso MartinDocument2 pagesFicha Tecnica y Certificado de Bituminoso MartinPasion Argentina EliuNo ratings yet

- Maintenance and Repair of Heat Exchangers PDFDocument73 pagesMaintenance and Repair of Heat Exchangers PDFTehman Alam100% (2)

- Hdpe Conduit SystemsDocument10 pagesHdpe Conduit SystemsKevinNo ratings yet

- 2013 Furniture CatalogueDocument28 pages2013 Furniture Cataloguesevens7No ratings yet

- Construction Chemicals 17.06.08Document27 pagesConstruction Chemicals 17.06.08Kanupriya JainNo ratings yet

- 304 Stainless Steel: Form of SupplyDocument3 pages304 Stainless Steel: Form of SupplyDeepak SinghNo ratings yet

- YSLY-JZ DatasheetDocument6 pagesYSLY-JZ DatasheetreliableplacementNo ratings yet

- 1110 ChemistryDocument6 pages1110 ChemistryPatrickNo ratings yet

- Hardness of Tempered Martensite in Carbon and Low-Alloy SteelsDocument11 pagesHardness of Tempered Martensite in Carbon and Low-Alloy Steelsjose antonio100% (1)

- Sintering and Related Phenomena - Proceedings of The Third International Conference On Sintering and Related Phenomena, Held at The University of Notre Dame, June 5-7, 1972 PDFDocument450 pagesSintering and Related Phenomena - Proceedings of The Third International Conference On Sintering and Related Phenomena, Held at The University of Notre Dame, June 5-7, 1972 PDFbicky180No ratings yet

- Sigmaprime® 200 Series: Product Data SheetDocument7 pagesSigmaprime® 200 Series: Product Data SheetkaleshNo ratings yet

- When Was Cement First UsedDocument9 pagesWhen Was Cement First UsedHareesh HariNo ratings yet

- Proposed Residential House To Be Built at Block 00X, Plot 00Y, Kampala UgandaDocument25 pagesProposed Residential House To Be Built at Block 00X, Plot 00Y, Kampala UgandaGLOVIS MACNo ratings yet

- EDUS391100 F6 FXAQ PVJU Wall Mounted Engineering DataDocument42 pagesEDUS391100 F6 FXAQ PVJU Wall Mounted Engineering DataIbnuyusoff77No ratings yet

- 10 CRKT Retail PL A EbookDocument16 pages10 CRKT Retail PL A EbookcaceresortegaNo ratings yet

- We Know How: Product RangeDocument5 pagesWe Know How: Product RangeMohamed RaafatNo ratings yet

- Effects of Cationic Surfactant During The Precipitation of Calcium Carbonate Nano-Particles On Their Size, Morphology, and OtherDocument8 pagesEffects of Cationic Surfactant During The Precipitation of Calcium Carbonate Nano-Particles On Their Size, Morphology, and OtherSORIN AVRAMESCUNo ratings yet

- Surat Synthetic Industry: Anshumala, Saurabh, Suruchi, Anil Balai, Raghav SharmaDocument30 pagesSurat Synthetic Industry: Anshumala, Saurabh, Suruchi, Anil Balai, Raghav SharmaNitin KohliNo ratings yet

- Flyer - Astm A252Document3 pagesFlyer - Astm A252PT. Pakuhaji Naga PerkasaNo ratings yet

- Elasto-Seal-Pro Bullbond Tds 2017rDocument4 pagesElasto-Seal-Pro Bullbond Tds 2017rMark VillafloresNo ratings yet

- Obtaining Pure Acetanilide From Crude Acetanilide by Recrystallization ProcessDocument5 pagesObtaining Pure Acetanilide From Crude Acetanilide by Recrystallization ProcessCharlot NavarroNo ratings yet

- Bentofix: Advantages of Needle-PunchedDocument4 pagesBentofix: Advantages of Needle-PunchedKamal LatifNo ratings yet

- Me-666 ADocument4 pagesMe-666 ATherese SalvioNo ratings yet

High Running Solid Solvent-Based Laminating Adhesive

High Running Solid Solvent-Based Laminating Adhesive

Uploaded by

alfredoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High Running Solid Solvent-Based Laminating Adhesive

High Running Solid Solvent-Based Laminating Adhesive

Uploaded by

alfredoCopyright:

Available Formats

ADCOTETM 795/796

High Running Solid Solvent–based Laminating Adhesive

ADCOTE™ 795/796 adhesive is a two component, high application Adhesive Viscosity compared to Application Solids:

solids (50%) dry bond solvent–based laminating adhesive system. ADCOTE™ 795/796 compared to Solvent–based Benchmark

This adhesive system adheres to a variety of substrates with excellent

heat and chemical resistance. Adhesive Viscosity compared to Application Solids – Ford Cup B-4

140

ADCOTE™ 795/796 adhesive is designed for laminating aluminum 120

Viscosity in secs

foil and a variety of polyester, polyolefin and coextruded films typically

100

used in food, medical, and industrial packaging applications.

80

Key Value Highlights of ADCOTE™ 795/796: 60

• Good machinability with 50% application solids 40

• Sustainability and cost saving with 10-15% solvent reductions 20

• Faster line speed on metalized structures

0

• Long pot life with high bond strength and adhesion to key films 35% 40% 50% 60%

• Less solvent retention for final laminates

ADCOTE™ 795/796 Solvent–based Benchmark

Typical Applications for ADCOTE™ 795/796:

Bond Strength

Applications Laminating Structures

Milk powder, Snack food, PET (ink) / AI Foil; Comparative Bond Strength across various structures

Biscuits, Noodles, Salt, Tea, PET (ink) / Met.PET; 600

Candy, Confectionary, BOPP (ink) / Met.BOPP;

Bond Strength, N15mm

500

Cereals packaging etc. PET (ink) / Met.CPP

400

Typical Physical Properties: 300

Property ADCOTE™ 795 CR 796 Isocynate 200

Polyol 100

Solids (%) 75% 85% 0

PET/PE-40 PET/MBOPP PET/MPET (PET/Foil)/

Viscosity (cps) 1200 +/- 300 cps 345 cps PE-40

Weight/Gallon 10.1 lb (1.21 g/cc) 9.5 lb (1.14 g/cc) ADCOTE™ 795/796 Solvent–based Benchmark

Solvent Ethyl Acetate Ethyl Acetate

Mix Ratio 100 pbw 28pbw

Diluents Urethane Grade Ethyl Urethane Grade Ethyl

Acetate Acetate

Shelf Life 360 days 360 days

*These properties are typical but do not constitute specifications.

Recommended Operating Conditions

Application Method Gravure

Application Cylinder 130-200 line/in (50 – 80 line/cm)

Application Solids 50%

Dry Adhesive Weight 1.5-3.0 lb/ream, (2.4-4.8 gsm)

Dry Web Temperature 150-180° F / 65-82° C

Lamination Temperature 160 – 220° F / 71-104° C

Cure Time 3-5 days at 70° F / 21° C

Cleaning Solvent Methyl Ethyl Ketone, Ethyl Acetate

Freeze/Thaw Stability Protect from freezing

For more information on products, innovations, expertise, and other services available to you from

Dow’s Plastics business group, visit www.dowplastics.com and choose your region, or contact us

as indicated below.

North America Europe/Middle East +800-3694-6367

U.S. & Canada 1-800-441-4369 +31-11567-2626

1-989-832-1426 Italy

Mexico +1-800-441-4369 +800-783-825

Latin America South Africa +800-99-5078

Argentina +54-11-4319-0100

Brazil +55-11-5188-9000 Asia Pacific +800-7776-7776

Colombia +57-1-219-6000 +86-21-3851-4988

Mexico +52-55-5201-4700 +400-889-0789 (China only)

The principles of Responsible Care® and Sustainable Development influence the production of printed

literature for The Dow Chemical Company (“Dow”). As a contribution towards the protection of our environment,

Dow’s printed literature is produced in small quantities and on paper containing recovered/post-consumer fiber

and using 100 percent soy-based ink whenever possible.

NOTICE: Any photographs of end-use applications in this document represent potential end-use applications

but do not necessarily represent current commercial applications, nor do they represent an endorsement by

The Dow Chemical Company (“Dow”) of the actual products. Further, these photographs are for illustration

purposes only and do not reflect either an endorsement or sponsorship of any other manufacturer for a specific

potential end-use product or application, or for Dow, or for specific products manufactured by Dow.

NOTICE: No freedom from infringement of any patent owned by Dow or others is to be inferred. Because use

conditions and applicable laws may differ from one location to another and may change with time, the Customer

is responsible for determining whether products and the information in this document are appropriate for the

Customer’s use and for ensuring that the Customer’s workplace and disposal practices are in compliance with

applicable laws and other governmental enactments. Dow assumes no obligation or liability for the information

in this document. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

NOTICE: If products are described as “experimental” or “developmental”: (1) product specifications may not

be fully determined; (2) analysis of hazards and caution in handling and use are required; (3) there is greater

potential for Dow to change specifications and/or discontinue production; and (4) although Dow may from time

to time provide samples of such products, Dow is not obligated to supply or otherwise commercialize such

products for any use or application whatsoever.

NOTICE REGARDING MEDICAL APPLICATION RESTRICTIONS: Dow will not knowingly sell or sample any

product or service (“Product”) into any commercial or developmental application that is intended for:

a. long-term or permanent contact with internal bodily fluids or tissues. “Long-term” is contact which exceeds

72 continuous hours;

b. use in cardiac prosthetic devices regardless of the length of time involved (“cardiac prosthetic devices”

include, but are not limited to, pacemaker leads and devices, artificial hearts, heart valves, intra-aortic

balloons and control systems, and ventricular bypass-assisted devices);

c. use as a critical component in medical devices that support or sustain human life; or

d. use specifically by pregnant women or in applications designed specifically to promote or interfere with

human reproduction.

Dow requests that customers considering use of Dow products in medical applications notify Dow so that

appropriate assessments may be conducted.

Dow does not endorse or claim suitability of its products for specific medical applications. It is the responsibility

of the medical device or pharmaceutical manufacturer to determine that the Dow product is safe, lawful, and

technically suitable for the intended use. DOW MAKES NO WARRANTIES, EXPRESS OR IMPLIED,

CONCERNING THE SUITABILITY OF ANY DOW PRODUCT FOR USE IN MEDICAL APPLICATIONS.

This document is intended for use within ASIA PACIFIC.

Published September 2014. Printed in Singapore.

© 2014 The Dow Chemical Company

®™

Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow Form No. 901-00351-0914SP

You might also like

- Fiber Analysis: Qualitative: AATCC Test Method 20-2013Document20 pagesFiber Analysis: Qualitative: AATCC Test Method 20-2013Milagros Wieczorek100% (1)

- The Powder Coaters ManualDocument209 pagesThe Powder Coaters ManualOvation Audio Labs100% (4)

- High Running Solid Solvent-Based Laminating AdhesiveDocument2 pagesHigh Running Solid Solvent-Based Laminating Adhesivealfredo100% (1)

- Technical Data Sheet: Regalrez™ 1085 Hydrocarbon ResinDocument2 pagesTechnical Data Sheet: Regalrez™ 1085 Hydrocarbon ResinPaul TsaiNo ratings yet

- Cardolite Ultra LITE 2009: Epoxy Curing Agent Technical DatasheetDocument2 pagesCardolite Ultra LITE 2009: Epoxy Curing Agent Technical Datasheettrường phạmNo ratings yet

- Crestomer-1152PA ENG TDS Feb18Document3 pagesCrestomer-1152PA ENG TDS Feb18fernando machadoNo ratings yet

- Technical Data Sheet: Regalrez™ 1094 Hydrocarbon ResinDocument2 pagesTechnical Data Sheet: Regalrez™ 1094 Hydrocarbon ResinPaul TsaiNo ratings yet

- 419 - Composites Catalogue-AtulDocument12 pages419 - Composites Catalogue-AtulVaittianathan Mahavapillai100% (1)

- Lubricants: Unoba EPDocument2 pagesLubricants: Unoba EPQC RegianNo ratings yet

- Ali Goger IngeniaDocument16 pagesAli Goger IngeniaMiguel Angel Perez EsparzaNo ratings yet

- Bond Polymers International BrochureDocument9 pagesBond Polymers International Brochuregabriel oliveira monteiroNo ratings yet

- PDS CST820 CO enDocument2 pagesPDS CST820 CO enm.onderolaganNo ratings yet

- ADCOTE 548-81R + Coreactant F (TDS)Document4 pagesADCOTE 548-81R + Coreactant F (TDS)Wasif AzimNo ratings yet

- 4408 Fully Synthetic Heavy Duty Industrial Gear OilDocument3 pages4408 Fully Synthetic Heavy Duty Industrial Gear OilYoong TanNo ratings yet

- 95-812 Series 95-812 Series 95-812 Series 95-812 Series Pitthane® Ultra Pitthane® Ultra Pitthane® UltraDocument2 pages95-812 Series 95-812 Series 95-812 Series 95-812 Series Pitthane® Ultra Pitthane® Ultra Pitthane® Ultramiguel angel lopezNo ratings yet

- Tantalus A 150Document1 pageTantalus A 150Selçuk MerterNo ratings yet

- Whitmore Det-900 GreaseDocument1 pageWhitmore Det-900 GreaseDon HowardNo ratings yet

- TDS - Soluryl - 80 - HanwhaDocument1 pageTDS - Soluryl - 80 - Hanwhaichsan hakimNo ratings yet

- Dow 177 03747 HPR900 So4 LDocument4 pagesDow 177 03747 HPR900 So4 LAditya RifNo ratings yet

- RTC Flexible Packaging - EngDocument25 pagesRTC Flexible Packaging - EngthuylienNo ratings yet

- ExxonMobil Vistamaxx 6202Document2 pagesExxonMobil Vistamaxx 6202Rajiv DubeyNo ratings yet

- Synthetic Food Grade Grease Synthetic Food Grade Grease: (NSF Certified (NSF Certified, Category H1, REGN NO. 147065)Document2 pagesSynthetic Food Grade Grease Synthetic Food Grade Grease: (NSF Certified (NSF Certified, Category H1, REGN NO. 147065)mayurghule19100% (1)

- Permax 230Document1 pagePermax 230Catalin VelcsovNo ratings yet

- Everlube 620 ATDSDocument2 pagesEverlube 620 ATDSValentinNo ratings yet

- Technical Data Sheet (TDS) PDFDocument3 pagesTechnical Data Sheet (TDS) PDFSabuj SaikiaNo ratings yet

- Polywithe® - 8000 CLDocument1 pagePolywithe® - 8000 CLsébastien cardinaleNo ratings yet

- 4 - EPS - Biobased Polymer For Furniture Applications and Waterborne Polymers For Corrosion Resistance Up To C5 ClassDocument43 pages4 - EPS - Biobased Polymer For Furniture Applications and Waterborne Polymers For Corrosion Resistance Up To C5 ClassIzabela MarchewkaNo ratings yet

- Biodegradable Wire Rope Coating GreaseDocument2 pagesBiodegradable Wire Rope Coating GreasedhowardjNo ratings yet

- Polytone: ABR Series/Thermoplastic Acrylic ResinsDocument7 pagesPolytone: ABR Series/Thermoplastic Acrylic ResinsAdhvik PuriNo ratings yet

- Estane 54610 TPU: Advancing MaterialsDocument2 pagesEstane 54610 TPU: Advancing MaterialsRonaldo CamargoNo ratings yet

- Polylon 1900 (3853091)Document4 pagesPolylon 1900 (3853091)JOCELYN MEDINANo ratings yet

- Shield - Euro Tech 1Document2 pagesShield - Euro Tech 1Ali KhalidNo ratings yet

- Thermolite 890F TDS Rev v3Document3 pagesThermolite 890F TDS Rev v3Qwerty RoyalNo ratings yet

- Cloverdale Tds 83570 eDocument4 pagesCloverdale Tds 83570 eErnesto Javier Martín RosabalNo ratings yet

- TPS Eva 3641 2Document1 pageTPS Eva 3641 2Juthi RahmanNo ratings yet

- NC-558 TDS enDocument2 pagesNC-558 TDS enniteshacharya100% (1)

- Aesthetic Topcoat Guide SWDocument8 pagesAesthetic Topcoat Guide SWjennifergiannouNo ratings yet

- Palmester 2083 2088 2090: Biolubricant Base OilsDocument2 pagesPalmester 2083 2088 2090: Biolubricant Base OilsVandewalleNo ratings yet

- ExxonMobil Enable 20-05HHDocument2 pagesExxonMobil Enable 20-05HHHung TranNo ratings yet

- 8090Document2 pages8090dost369No ratings yet

- Performance Coatings Product Data Sheet Lubrijet™ T800 Polyurethane DispersionDocument2 pagesPerformance Coatings Product Data Sheet Lubrijet™ T800 Polyurethane DispersionPedro Duplaa Soares FerreiraNo ratings yet

- 118 01806 01 Carbowax Polyethylene Glycol Peg 8000 TdsDocument2 pages118 01806 01 Carbowax Polyethylene Glycol Peg 8000 TdsrickthetrickstertrickyNo ratings yet

- Polyurethane Dispersions Product GuideDocument4 pagesPolyurethane Dispersions Product GuideAn PhungNo ratings yet

- Bentone 2018Document2 pagesBentone 2018Victor ZhicayNo ratings yet

- Ecoalube642TDS PDFDocument2 pagesEcoalube642TDS PDFDkC gunsNo ratings yet

- Prometheus Sa 20 HVDocument1 pagePrometheus Sa 20 HVMassimiliano VolaNo ratings yet

- PET Processing V4 1 PDFDocument48 pagesPET Processing V4 1 PDFwoongs73100% (1)

- Polymer Modification Hydrophobic EN May2021 USDocument4 pagesPolymer Modification Hydrophobic EN May2021 USManish DobariyaNo ratings yet

- Lubricants: Cable LubeDocument2 pagesLubricants: Cable LubeVictor ZhicayNo ratings yet

- TDS Abitol E Hydroabietyl AlcoholDocument2 pagesTDS Abitol E Hydroabietyl AlcoholCaio OliveiraNo ratings yet

- Sapphire Spray Grease - GBDocument2 pagesSapphire Spray Grease - GBdiegogsouzzaNo ratings yet

- TDS DuraCoat 11 60 Rhino IndustrialDocument2 pagesTDS DuraCoat 11 60 Rhino IndustrialDonnie WeltyNo ratings yet

- Lite 3060 - TdsDocument2 pagesLite 3060 - TdsJuan Sebastián Fernández RamírezNo ratings yet

- Prometheus A 00 LMDocument1 pagePrometheus A 00 LMMassimiliano VolaNo ratings yet

- Alphasyn Ep 220Document2 pagesAlphasyn Ep 220Atika AtikaNo ratings yet

- Optimelt Phc7005, PDFDocument10 pagesOptimelt Phc7005, PDFrotti_gururajNo ratings yet

- Cardolite Ultra LITE 513: Epoxy Reactive Diluent Technical DatasheetDocument2 pagesCardolite Ultra LITE 513: Epoxy Reactive Diluent Technical Datasheettrường phạmNo ratings yet

- TechnicalDataSheet (TDS) TulsionA-2XMP English 01042018Document3 pagesTechnicalDataSheet (TDS) TulsionA-2XMP English 01042018hamdani sceNo ratings yet

- Bpxe B6ctalDocument2 pagesBpxe B6ctalVusal HasanovNo ratings yet

- 124826carboset® CR-785Document17 pages124826carboset® CR-785ForeverNo ratings yet

- QA Manual 2020 Pi Tape Texas LLCDocument21 pagesQA Manual 2020 Pi Tape Texas LLCalfredoNo ratings yet

- BS en Iso 00105-E05-2010Document12 pagesBS en Iso 00105-E05-2010alfredoNo ratings yet

- Hydrostatic TestDocument6 pagesHydrostatic TestalfredoNo ratings yet

- BS en Iso 00105-E04-2013Document14 pagesBS en Iso 00105-E04-2013alfredoNo ratings yet

- BS en Iso 00105-J01-2000Document22 pagesBS en Iso 00105-J01-2000alfredoNo ratings yet

- BS en Iso 00105-E02-2013Document14 pagesBS en Iso 00105-E02-2013alfredoNo ratings yet

- Wide Ranging Tie Layer PerformanceDocument7 pagesWide Ranging Tie Layer PerformancealfredoNo ratings yet

- BS en Iso 00105-J02-2000Document16 pagesBS en Iso 00105-J02-2000alfredoNo ratings yet

- Hot Tack Heatsealer: Data SheetDocument2 pagesHot Tack Heatsealer: Data SheetalfredoNo ratings yet

- BS en Iso 00105-J03-2009Document18 pagesBS en Iso 00105-J03-2009alfredoNo ratings yet

- Solutions For Shrink Packaging FilmsDocument2 pagesSolutions For Shrink Packaging FilmsalfredoNo ratings yet

- Wintest Analysis English PDFDocument54 pagesWintest Analysis English PDFalfredoNo ratings yet

- Dow Products For Fibers, Nonwovens and Barrier FilmsDocument2 pagesDow Products For Fibers, Nonwovens and Barrier FilmsalfredoNo ratings yet

- Eco-Friendly Laminating Adhesive SolutionDocument2 pagesEco-Friendly Laminating Adhesive SolutionalfredoNo ratings yet

- Food Safe Packaging Hot Melt AdhesivesDocument4 pagesFood Safe Packaging Hot Melt AdhesivesalfredoNo ratings yet

- High Running Solid Solvent-Based Laminating AdhesiveDocument2 pagesHigh Running Solid Solvent-Based Laminating Adhesivealfredo100% (1)

- Coating of Polyester Film With Thin Wax LayersDocument37 pagesCoating of Polyester Film With Thin Wax LayersalfredoNo ratings yet

- Protocol For Sample Collection - Interlaboratorial - WVTR - ObenDocument3 pagesProtocol For Sample Collection - Interlaboratorial - WVTR - ObenalfredoNo ratings yet

- Durosan 03 Exterior Matt (I) : Technical Data SheetDocument3 pagesDurosan 03 Exterior Matt (I) : Technical Data Sheetمحمد عزتNo ratings yet

- 19 - J Mater Chem 2009-19-5027Document6 pages19 - J Mater Chem 2009-19-5027Christhy Vanessa Ruiz MadroñeroNo ratings yet

- Additives For Crop Protection EvonikDocument20 pagesAdditives For Crop Protection EvonikAlfredo MéndezNo ratings yet

- Material Selection Task - Wind TurbineDocument12 pagesMaterial Selection Task - Wind TurbineVishwajit GaunsNo ratings yet

- States of Matter NotesDocument14 pagesStates of Matter NotesAreeba EjazNo ratings yet

- Aslan700 DatasheetDocument1 pageAslan700 Datasheetaditarian .pNo ratings yet

- Ficha Tecnica y Certificado de Bituminoso MartinDocument2 pagesFicha Tecnica y Certificado de Bituminoso MartinPasion Argentina EliuNo ratings yet

- Maintenance and Repair of Heat Exchangers PDFDocument73 pagesMaintenance and Repair of Heat Exchangers PDFTehman Alam100% (2)

- Hdpe Conduit SystemsDocument10 pagesHdpe Conduit SystemsKevinNo ratings yet

- 2013 Furniture CatalogueDocument28 pages2013 Furniture Cataloguesevens7No ratings yet

- Construction Chemicals 17.06.08Document27 pagesConstruction Chemicals 17.06.08Kanupriya JainNo ratings yet

- 304 Stainless Steel: Form of SupplyDocument3 pages304 Stainless Steel: Form of SupplyDeepak SinghNo ratings yet

- YSLY-JZ DatasheetDocument6 pagesYSLY-JZ DatasheetreliableplacementNo ratings yet

- 1110 ChemistryDocument6 pages1110 ChemistryPatrickNo ratings yet

- Hardness of Tempered Martensite in Carbon and Low-Alloy SteelsDocument11 pagesHardness of Tempered Martensite in Carbon and Low-Alloy Steelsjose antonio100% (1)

- Sintering and Related Phenomena - Proceedings of The Third International Conference On Sintering and Related Phenomena, Held at The University of Notre Dame, June 5-7, 1972 PDFDocument450 pagesSintering and Related Phenomena - Proceedings of The Third International Conference On Sintering and Related Phenomena, Held at The University of Notre Dame, June 5-7, 1972 PDFbicky180No ratings yet

- Sigmaprime® 200 Series: Product Data SheetDocument7 pagesSigmaprime® 200 Series: Product Data SheetkaleshNo ratings yet

- When Was Cement First UsedDocument9 pagesWhen Was Cement First UsedHareesh HariNo ratings yet

- Proposed Residential House To Be Built at Block 00X, Plot 00Y, Kampala UgandaDocument25 pagesProposed Residential House To Be Built at Block 00X, Plot 00Y, Kampala UgandaGLOVIS MACNo ratings yet

- EDUS391100 F6 FXAQ PVJU Wall Mounted Engineering DataDocument42 pagesEDUS391100 F6 FXAQ PVJU Wall Mounted Engineering DataIbnuyusoff77No ratings yet

- 10 CRKT Retail PL A EbookDocument16 pages10 CRKT Retail PL A EbookcaceresortegaNo ratings yet

- We Know How: Product RangeDocument5 pagesWe Know How: Product RangeMohamed RaafatNo ratings yet

- Effects of Cationic Surfactant During The Precipitation of Calcium Carbonate Nano-Particles On Their Size, Morphology, and OtherDocument8 pagesEffects of Cationic Surfactant During The Precipitation of Calcium Carbonate Nano-Particles On Their Size, Morphology, and OtherSORIN AVRAMESCUNo ratings yet

- Surat Synthetic Industry: Anshumala, Saurabh, Suruchi, Anil Balai, Raghav SharmaDocument30 pagesSurat Synthetic Industry: Anshumala, Saurabh, Suruchi, Anil Balai, Raghav SharmaNitin KohliNo ratings yet

- Flyer - Astm A252Document3 pagesFlyer - Astm A252PT. Pakuhaji Naga PerkasaNo ratings yet

- Elasto-Seal-Pro Bullbond Tds 2017rDocument4 pagesElasto-Seal-Pro Bullbond Tds 2017rMark VillafloresNo ratings yet

- Obtaining Pure Acetanilide From Crude Acetanilide by Recrystallization ProcessDocument5 pagesObtaining Pure Acetanilide From Crude Acetanilide by Recrystallization ProcessCharlot NavarroNo ratings yet

- Bentofix: Advantages of Needle-PunchedDocument4 pagesBentofix: Advantages of Needle-PunchedKamal LatifNo ratings yet

- Me-666 ADocument4 pagesMe-666 ATherese SalvioNo ratings yet