Professional Documents

Culture Documents

Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001

Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001

Uploaded by

neerajOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001

Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001

Uploaded by

neerajCopyright:

Available Formats

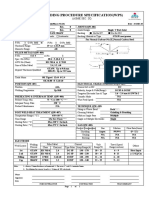

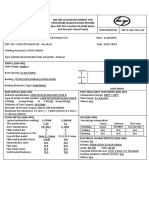

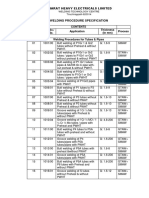

Larsen & Toubro Minerals & Metals

NMDC Nagarnar 2 MTPA pellet plant, Jagdalpur – 494001.

WELDING PROCEDURE SPECIFICATIONS (WPS)

Welding Procedure Specification No. WPS/01 Date: Qualified to: IS 7307 Part-I

Supporting PQR No.(s) PQR /01 Dated

Welding Process(es): SMAW Type(s) : Manual

Prepared By: Neeraj Dubey

JOINTS (QW-403) Details

Joints Design: As per production Drawing

Root Spacing : As per production Drawing

AS PER PRODUCTION DRAWING

Backing : No For Root run &Yes for Hot passes

Backing Material (Type) : Weld Metal

Retainers: NA

□ Metal □ Nonfusing Metal

□ Non metallic □ Other

BASE METALS (QW-403)

P.No.:1, Group No.: 1 TO P.No.:1, Group No.: 1 (Without Impact)

OR

Specification and type / grade or UNS Number : IS2062 or Equivalent

to Specification and type / grade or UNS Number : IS2062 or Equivalent

Thickness Range:

Base Metal: Groove: 5.0 to 200.00 mm Fillet: All

Maximum Pass Thickness ≤ ½ in. (13mm) Yes

T Limits : Not Applicable

FILLER METALS (QW- 404) SMAW

Spec. No. (SFA) 5.1

AWS No. (Class) E7018

F.NO. 4

A.NO. 1

Size of Filler Metals. ɸ3.15, 4.0 & 5.0 mm

Filler Metal Product Form. Not Applicable

Supplemental Filler Metal. None

Consumable Insert None

Weld Metal

Thickness Range

Groove 200.00 mm (Max.)

Fillet All

Flux NA

Flux Trade Name NA

Other With filler metal only

Positions (QW 405) Post weld Heat Treatment (QW 407)

Position(s) of Groove : All Temperature Range : NA

Soaking Time Range: NA

Welding Progression: Uphill if vertical T Limits: NA

Other : Nil

Position(s) of Fillet : All

Other :Nil

PREHEAT (QW 406)

Preheat Temp. Min. :100C

Inter pass Temp. Max. : 2500C

Preheat Maintenance : None

Other : Nil

Gas (QW 408) Percent Composition

Gas (es) (Mixture) Flow rate

Shielding Nil Nil Nil

(GTAW)

Trailing Nil Nil Nil

Backing Nil Nil Nil

Other Nil

Electrical Characteristics (QW 409)

Filler Metal Current Volts Travel Speed Other (e.g., Remarks,

Weld Classification Diameter Type and Amp (Range) (Range) mm Comments, Hot wire

Pass(es) Process (mm) Polarity (Range) Addition, Technique, Torch

Angle etc.)

All SMAW E7018 3.15MM DCEP 70-140 10-14 As Required

Passes SMAW E7018 4.0MM DCEP 70-90 12-14 As Required

SMAW E7018 5.0MM DCEP 80-100 12-16 As Required

Nil

Pulsing Current : Not Used Heat Input (max.) : NA

Tungsten Electrode Size and Type: None

Mode of Metal Transfer for GWAW (FCAW) : NA

Electrode Wire feed speed range: NA

Other : Nil

TECHNIQUE (QW 410) SMAW

String or Weave Bead Weave

Orifice or Gas Cup Size 6.25 to 10mm

Method of Cleaning Brushing & Grinding

Method of Back Gouging Grinding

Oscillation NA

Closed to Out chamber NA

Multiple or Single Pass Multiple

Multiple or Single Electrodes: Single

Manual or Automatic Manual

Electrode Spacing NA

Peening: Not Allowed

Use of Thermal Processes Not Applicable

Other: 1.This Procedure Shall be used for Tacking, Welding & Weld Repair.

You might also like

- QW-482 201.1Document2 pagesQW-482 201.1Barwin CruzNo ratings yet

- Asme Ix - WPS - Gtaw Fcaw Gmaw PDFDocument1 pageAsme Ix - WPS - Gtaw Fcaw Gmaw PDFThe Welding Inspections CommunityNo ratings yet

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- PQR A106 HAL-1Document1 pagePQR A106 HAL-1Budi Setia RahmanNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- WPS BhelDocument2 pagesWPS BhelpradhankruhsnaNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- Welding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionDocument2 pagesWelding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionTrudie0% (1)

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDocument11 pagesEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaNo ratings yet

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Welding Procedure Welding Procedure Specification SpecificationDocument2 pagesWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- Welder I.D CardDocument2 pagesWelder I.D Cardvhung TranNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- Sa 516 WPQDocument1 pageSa 516 WPQElgen IgloriaNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- WPS - 006Document13 pagesWPS - 006MAT-LIONNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad Pathan100% (1)

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Document1 pageWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- WPS - 023Document10 pagesWPS - 023MAT-LION0% (1)

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Emmanuel Loayza100% (1)

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS Format For ASME IX - PQR-AllDocument3 pagesWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- WPQR2Document3 pagesWPQR2Thanasis KyrgiazoglouNo ratings yet

- Premier Engineering Industries: List of WPS/PQRDocument1 pagePremier Engineering Industries: List of WPS/PQRBalkishan DyavanapellyNo ratings yet

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- Slamet WPQRDocument1 pageSlamet WPQRChandra Bintang W.PNo ratings yet

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- WPS PQR FormatDocument1 pageWPS PQR FormatJatin Kamdar100% (2)

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Preliminary Welding Procedure Specification (PWPS)Document1 pagePreliminary Welding Procedure Specification (PWPS)AzriNo ratings yet

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- 111 - Atom Isi Wps3Document1 page111 - Atom Isi Wps3burakNo ratings yet

- Form Qw-483 Suggested Format For Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code) Record Actual Variables Used To Weld Test CouponDocument2 pagesForm Qw-483 Suggested Format For Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code) Record Actual Variables Used To Weld Test CouponMijanur Rahman100% (1)

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- Material P NumberDocument11 pagesMaterial P NumberChaitanya Sai TNo ratings yet

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit Ghosh100% (1)

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- WPS 1Document1 pageWPS 1janardan.sfeNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- TICKETDocument2 pagesTICKETneerajNo ratings yet

- Indian Standard: Approval Tests For Welding ProceduresDocument22 pagesIndian Standard: Approval Tests For Welding ProceduresneerajNo ratings yet

- Indian Standard: Approval Tests For Welding ProceduresDocument22 pagesIndian Standard: Approval Tests For Welding ProceduresneerajNo ratings yet

- Larsen & Toubro Minerals & MetalsDocument2 pagesLarsen & Toubro Minerals & MetalsneerajNo ratings yet

- Kapil Dev Singh: Leave LV:8.000 Loan:0.00Document3 pagesKapil Dev Singh: Leave LV:8.000 Loan:0.00neerajNo ratings yet

- Adobe Scan Aug 19, 2022Document3 pagesAdobe Scan Aug 19, 2022neerajNo ratings yet