Professional Documents

Culture Documents

Extended Shelf Life Egg Processing: Process Technology Bullet 9962

Extended Shelf Life Egg Processing: Process Technology Bullet 9962

Uploaded by

exergy 33Copyright:

Available Formats

You might also like

- Tetra Therm Aseptic FlexDocument4 pagesTetra Therm Aseptic FlexHossam Abdel Aziz100% (1)

- Pasteurization HTSTDocument20 pagesPasteurization HTSTSangeetha H100% (2)

- Differentiate Between Disturbed and Undisturbed Sample and Give 3 Type of Sampler For Each SampleDocument8 pagesDifferentiate Between Disturbed and Undisturbed Sample and Give 3 Type of Sampler For Each SampleNaqib Levis Sol100% (2)

- How To Bond Zirconia - The APC Concept PDFDocument9 pagesHow To Bond Zirconia - The APC Concept PDFKelly Katherine0% (1)

- Frozen Food Pre-Cooling: Process Technology Bullet 9960Document2 pagesFrozen Food Pre-Cooling: Process Technology Bullet 9960exergy 33No ratings yet

- Aseptic Juice Processing With Pulp: Process Technology Bullet 9810Document2 pagesAseptic Juice Processing With Pulp: Process Technology Bullet 9810exergy 33No ratings yet

- 9603 Salsa Pasta SauceDocument2 pages9603 Salsa Pasta Sauceexergy 33No ratings yet

- Tetra Pak Pasteurizer BF PDDocument6 pagesTetra Pak Pasteurizer BF PDTanvir BhagatNo ratings yet

- Pasteurizer BF TETRA PAKDocument4 pagesPasteurizer BF TETRA PAKLeo ZunigaNo ratings yet

- Continuous Production of Barbeque Sauce: Process DescriptionDocument2 pagesContinuous Production of Barbeque Sauce: Process Descriptionexergy 33No ratings yet

- Pd10016 Tetra Therm Lacta 1Document4 pagesPd10016 Tetra Therm Lacta 1Omar ArguelloNo ratings yet

- Tetra Therm Aseptic VTIS PD Hi 180702Document6 pagesTetra Therm Aseptic VTIS PD Hi 180702Muhammad RehmanNo ratings yet

- Long-Life MilkDocument34 pagesLong-Life MilkM Umer SaeedNo ratings yet

- Unit 3Document92 pagesUnit 3Kishore KumarNo ratings yet

- 8 UHT ProcessingDocument20 pages8 UHT ProcessingZacky Husada AchmadNo ratings yet

- HTST PasteurizerDocument2 pagesHTST PasteurizerChapa KaziNo ratings yet

- Aseptic Fruit Puree Processing: Process Technology Bullet 9821Document2 pagesAseptic Fruit Puree Processing: Process Technology Bullet 9821exergy 33No ratings yet

- Tetra Pak Indirect UHT Unit PFF SSHE - PDDocument4 pagesTetra Pak Indirect UHT Unit PFF SSHE - PDLotfi JeffaliNo ratings yet

- Tetra Therm Aseptic Visco SSHEDocument4 pagesTetra Therm Aseptic Visco SSHEsudheendracvkNo ratings yet

- Uht Pasteurization FinalDocument4 pagesUht Pasteurization FinalZacky Husada AchmadNo ratings yet

- Tetra Pak Pasteurizer BC: Highlights Working PrincipleDocument6 pagesTetra Pak Pasteurizer BC: Highlights Working PrincipleSoledad RodriguezNo ratings yet

- UHT ProcessingDocument12 pagesUHT ProcessingMohammad Ashraf Paul100% (1)

- Tetra Pak Indirect UHT Unit DC - PDDocument4 pagesTetra Pak Indirect UHT Unit DC - PDKhánh HồNo ratings yet

- Pasteurization: Pasteurizer For Aseptic Cold Filling of Fruit JuicesDocument3 pagesPasteurization: Pasteurizer For Aseptic Cold Filling of Fruit JuicesWmScheu1100% (1)

- Pasteur IzerDocument12 pagesPasteur Izerkhaoula100% (1)

- 05 PasteurisationDocument52 pages05 PasteurisationSadhan PadhiNo ratings yet

- Tetra Pak Pasteurizer D BaseDocument4 pagesTetra Pak Pasteurizer D BaseDorina CotoarăNo ratings yet

- PasturizationDocument28 pagesPasturizationTamizh TamizhNo ratings yet

- TIS-113-Prime Surface Heat ExchangerDocument0 pagesTIS-113-Prime Surface Heat Exchangerhappale2002No ratings yet

- HF PrincipalsThermal ProcessDocument76 pagesHF PrincipalsThermal ProcessAisarya DasNo ratings yet

- FDE311 Module9Document31 pagesFDE311 Module9dilaraaaydiin742No ratings yet

- Krones: Varioflash and VarioaseptDocument13 pagesKrones: Varioflash and VarioaseptHoa XaNo ratings yet

- Pasteurization and BlanchingDocument53 pagesPasteurization and Blanchingdmttapia-1No ratings yet

- Wa0003.Document4 pagesWa0003.muraliammu900No ratings yet

- PasturizersDocument13 pagesPasturizersAnkit BiholaNo ratings yet

- Milk PasteurizationDocument5 pagesMilk PasteurizationSatish PatilNo ratings yet

- Batch Pasteurizer For MilkDocument8 pagesBatch Pasteurizer For MilkMustafa AmroNo ratings yet

- PasteurisationDocument21 pagesPasteurisationRANIT sarkarNo ratings yet

- Thermal SolutionsDocument14 pagesThermal SolutionsManuel J. Vílchez FrancoNo ratings yet

- Heat Transfer Application. 413Document38 pagesHeat Transfer Application. 413Aronn SiamNo ratings yet

- Process Plant TrainerDocument7 pagesProcess Plant TrainerNatashah AshrafNo ratings yet

- FDE311 Module8Document27 pagesFDE311 Module8dilaraaaydiin742No ratings yet

- Tetra Therm Aseptic Drink 1: Efficient Pasteurization For Aseptic or Hot-Fill Beverage ProductionDocument3 pagesTetra Therm Aseptic Drink 1: Efficient Pasteurization For Aseptic or Hot-Fill Beverage ProductionAndrés Torres SandovalNo ratings yet

- Thermal Treatment: Tecnología Agroalimentaria I Moisés ViacavaDocument74 pagesThermal Treatment: Tecnología Agroalimentaria I Moisés ViacavaLuis EnriqueNo ratings yet

- Varioasept: Microbiological Safety For Your ProductsDocument6 pagesVarioasept: Microbiological Safety For Your Productsمصطفى- القرقعيNo ratings yet

- Pasteurization of Milk: Course: Dairy and Food EngineeringDocument12 pagesPasteurization of Milk: Course: Dairy and Food Engineeringdelapan is bakirNo ratings yet

- Evaporation TechnologyDocument24 pagesEvaporation TechnologymetashriNo ratings yet

- Internship Report: Submitted ToDocument32 pagesInternship Report: Submitted Toharis ilyasNo ratings yet

- Pignat S.A.S.: Computerized PasteurizationDocument4 pagesPignat S.A.S.: Computerized Pasteurizationlusoegyi 1919No ratings yet

- Drinking Milk TechnologyDocument25 pagesDrinking Milk TechnologySura C. JirNo ratings yet

- 8 UHT ProcessingDocument5 pages8 UHT ProcessingZacky Husada AchmadNo ratings yet

- Milk Processing Carried Out in Dairy Industry & Implementation of Industrial Automation in Milk ProcessingDocument20 pagesMilk Processing Carried Out in Dairy Industry & Implementation of Industrial Automation in Milk ProcessingRavi KashyapNo ratings yet

- ThermalDocument51 pagesThermalsadbad6No ratings yet

- Steam Powered Absorption Chiller Installation and Operation Manual TTDocument44 pagesSteam Powered Absorption Chiller Installation and Operation Manual TTromi_hamdani0% (1)

- Sop HRSGDocument23 pagesSop HRSGshameer_febi100% (1)

- Aseptic/Extended Life Surge Tank: Process Technology Bullet 9606Document2 pagesAseptic/Extended Life Surge Tank: Process Technology Bullet 9606exergy 33No ratings yet

- Falling Film Evap For DairyDocument8 pagesFalling Film Evap For DairysamirdudhandeNo ratings yet

- FARM - Vat PasteurizationDocument12 pagesFARM - Vat Pasteurizationford62bNo ratings yet

- Milk Factory Visit ReportDocument10 pagesMilk Factory Visit ReportshubhamrasalNo ratings yet

- Instant Pot Cookbook: The Ultimate Guide Plus 101 Delicious RecipesFrom EverandInstant Pot Cookbook: The Ultimate Guide Plus 101 Delicious RecipesRating: 3.5 out of 5 stars3.5/5 (2)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Hot Water Heater Installation and Repair: A Step-by-Step Guide to DIY Installation, Maintenance, and Troubleshooting for Homeowners: Homeowner Plumbing Help, #4From EverandHot Water Heater Installation and Repair: A Step-by-Step Guide to DIY Installation, Maintenance, and Troubleshooting for Homeowners: Homeowner Plumbing Help, #4No ratings yet

- 01 Muzeul National I 1974Document366 pages01 Muzeul National I 1974exergy 33100% (1)

- Kemp Russian Travellers To India and Persia 1625 1798Document150 pagesKemp Russian Travellers To India and Persia 1625 1798exergy 33No ratings yet

- Tapper-Nomads in IranDocument38 pagesTapper-Nomads in Iranexergy 33No ratings yet

- Religion and Persian Minature During TheDocument21 pagesReligion and Persian Minature During Theexergy 33No ratings yet

- Fluid-Mineral Equilibrium of Spring Waters at Cuitzeo Basin (Mexico) Geothermal ZoneDocument7 pagesFluid-Mineral Equilibrium of Spring Waters at Cuitzeo Basin (Mexico) Geothermal Zoneexergy 33No ratings yet

- COV - Sedimentation of Particles in Water or AirDocument9 pagesCOV - Sedimentation of Particles in Water or Airexergy 33No ratings yet

- GreenDocument86 pagesGreenexergy 33No ratings yet

- Artisan Rototherm Dries Lecithin: by Perry Alasti, VP, Food Processing Technologies, Artisan Industries IncDocument4 pagesArtisan Rototherm Dries Lecithin: by Perry Alasti, VP, Food Processing Technologies, Artisan Industries Incexergy 330% (1)

- 1 2 3 4Document217 pages1 2 3 4exergy 33No ratings yet

- RheologyDocument24 pagesRheologyexergy 33No ratings yet

- Untitled 12Document1 pageUntitled 12exergy 33No ratings yet

- Jim Witcher, Geothermal Greenhouse 042909Document15 pagesJim Witcher, Geothermal Greenhouse 042909exergy 33No ratings yet

- Csi 20040412Document11 pagesCsi 20040412exergy 33No ratings yet

- Asf Weatherly Ammonium-Nitrate 2022marDocument2 pagesAsf Weatherly Ammonium-Nitrate 2022marexergy 33No ratings yet

- Hwsoln 02Document7 pagesHwsoln 02exergy 33No ratings yet

- Ball MillDocument4 pagesBall Millexergy 33No ratings yet

- Ti 85 300 10 GeDocument2 pagesTi 85 300 10 Geexergy 33No ratings yet

- Advance To Driving With BiodieselDocument3 pagesAdvance To Driving With Biodieselexergy 33No ratings yet

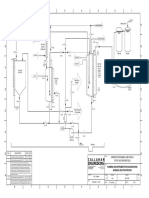

- State Line Biofuels Engineering Schematic - 12 - 07Document1 pageState Line Biofuels Engineering Schematic - 12 - 07exergy 33No ratings yet

- p0593500030441 IF9MFDocument4 pagesp0593500030441 IF9MFexergy 33No ratings yet

- Aseptic/Extended Life Surge Tank: Process Technology Bullet 9606Document2 pagesAseptic/Extended Life Surge Tank: Process Technology Bullet 9606exergy 33No ratings yet

- Continuous Production of Barbeque Sauce: Process DescriptionDocument2 pagesContinuous Production of Barbeque Sauce: Process Descriptionexergy 33No ratings yet

- Aseptic Juice Processing With Pulp: Process Technology Bullet 9810Document2 pagesAseptic Juice Processing With Pulp: Process Technology Bullet 9810exergy 33No ratings yet

- Evaluation of The NH Removal Efficiency of An Aci-Wageningen University and Research 184988Document8 pagesEvaluation of The NH Removal Efficiency of An Aci-Wageningen University and Research 184988exergy 33No ratings yet

- Aseptic Fruit Puree Processing: Process Technology Bullet 9821Document2 pagesAseptic Fruit Puree Processing: Process Technology Bullet 9821exergy 33No ratings yet

- PB-9941 Chantilly CreamDocument2 pagesPB-9941 Chantilly Creamexergy 33No ratings yet

- Continuous Tomato Paste Standardization: Solids Reduction PhaseDocument2 pagesContinuous Tomato Paste Standardization: Solids Reduction Phaseexergy 33No ratings yet

- 9603 Salsa Pasta SauceDocument2 pages9603 Salsa Pasta Sauceexergy 33No ratings yet

- Frozen Food Pre-Cooling: Process Technology Bullet 9960Document2 pagesFrozen Food Pre-Cooling: Process Technology Bullet 9960exergy 33No ratings yet

- Pages From RA 1-6. Finaldoc BDocument1 pagePages From RA 1-6. Finaldoc Bexergy 33No ratings yet

- Aisi 409Document1 pageAisi 409sheinilaNo ratings yet

- 1 s2.0 S2214785320312967 MainDocument12 pages1 s2.0 S2214785320312967 MainMITUSHI AGRAWALNo ratings yet

- IF SteelsDocument20 pagesIF SteelsZubair AhmadNo ratings yet

- Astasantin HPLCDocument6 pagesAstasantin HPLCROBINNo ratings yet

- Modular Waste Lube Oil PDFDocument19 pagesModular Waste Lube Oil PDFAdeel Ahmed100% (2)

- Mapefloor FC 200 ME Submittal With UAE RefDocument50 pagesMapefloor FC 200 ME Submittal With UAE RefAhmed IbrahimNo ratings yet

- MortarDocument40 pagesMortargraphicsman123100% (2)

- 1.6 A Personal NoteDocument1 page1.6 A Personal Notekara_25No ratings yet

- G9 STE Q3 Biotechnology ReviewerDocument9 pagesG9 STE Q3 Biotechnology ReviewerJoyz Etneilas ArguillesNo ratings yet

- Compressive Strength For Cast-In-Place Concrete: Table 1.7Document23 pagesCompressive Strength For Cast-In-Place Concrete: Table 1.7Dave TalabocNo ratings yet

- Cauvery Institute of Technology: Experimental Study On Strength of Concrete Using Areca Fiber and Granite PowderDocument43 pagesCauvery Institute of Technology: Experimental Study On Strength of Concrete Using Areca Fiber and Granite PowderNithin BmNo ratings yet

- The Effect of Vanadium Micro Alloying and Hot Deformation Control On The Mechanical Properties of Structural SteelDocument4 pagesThe Effect of Vanadium Micro Alloying and Hot Deformation Control On The Mechanical Properties of Structural SteelHany KhalifaNo ratings yet

- Determination of Elastic Constants of Additive Manufactured Inconel 625 Specimens Using An Ultrasonic TechniqueDocument11 pagesDetermination of Elastic Constants of Additive Manufactured Inconel 625 Specimens Using An Ultrasonic TechniqueHamidreza JavidradNo ratings yet

- PHK724 IdnengDocument12 pagesPHK724 Idnengdian agustinaNo ratings yet

- Pressure VesselDocument16 pagesPressure VesselsrinivasNo ratings yet

- Density Functional Theory Investigations of Bismuth VanadateDocument7 pagesDensity Functional Theory Investigations of Bismuth VanadateNurSalahuddinNo ratings yet

- General Education: Biological Science and Physical ScienceDocument248 pagesGeneral Education: Biological Science and Physical Sciencedennis balbuenaNo ratings yet

- Dimethyl Disulfide: Safety Data SheetDocument15 pagesDimethyl Disulfide: Safety Data SheetMohamed KilanyNo ratings yet

- Radiographic TestingDocument4 pagesRadiographic Testingtechzones100% (1)

- Unit ViDocument69 pagesUnit ViRavichandran SekarNo ratings yet

- Klein,: Organic ChemistryDocument41 pagesKlein,: Organic ChemistryMark BakalanNo ratings yet

- Paint DefectsDocument17 pagesPaint DefectsAdriana JonesNo ratings yet

- New Solvent For Polyamide 66 and Its Use For Preparing Single-Polymer Composite Coated-FabricDocument24 pagesNew Solvent For Polyamide 66 and Its Use For Preparing Single-Polymer Composite Coated-FabricSSNo ratings yet

- Revision Notes For Checkpoint ChemistryDocument13 pagesRevision Notes For Checkpoint ChemistryKostas TampakisNo ratings yet

- Andrews' ExperimentsDocument3 pagesAndrews' ExperimentsRSLNo ratings yet

- Certificate of Analysis: RVSEB-2023 21-06-2019 20-06-2020Document2 pagesCertificate of Analysis: RVSEB-2023 21-06-2019 20-06-2020dhairyasheelNo ratings yet

- Pre-AP Chemistry Basic Thermochemistry Equilibrium and Organic Chemistry Notes Unit 112Document29 pagesPre-AP Chemistry Basic Thermochemistry Equilibrium and Organic Chemistry Notes Unit 112ChessmanRobbinsNo ratings yet

- J 1 PQR GMAW FCAW D1.1 2020 FormDocument2 pagesJ 1 PQR GMAW FCAW D1.1 2020 FormCristian Narro100% (1)

Extended Shelf Life Egg Processing: Process Technology Bullet 9962

Extended Shelf Life Egg Processing: Process Technology Bullet 9962

Uploaded by

exergy 33Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Extended Shelf Life Egg Processing: Process Technology Bullet 9962

Extended Shelf Life Egg Processing: Process Technology Bullet 9962

Uploaded by

exergy 33Copyright:

Available Formats

Process Technology

Bullet 9962 12-99

EXTENDED SHELF LIFE EGG PROCESSING

PROCESS DESCRIPTION:

Products to be processed are fed to the system’s product balance tank. A Waukesha positive displace-

ment booster pump transfers the product through the raw regenerator and pre-heater. The product then

flows to the Falling Stream Heater (FSH™) infusion chamber, where it is rapidly heated to pre-processing

temperature prior to the pre-treatment holding tube. From the holding tube, the product is flash cooled to

about the same temperature at which it entered the infusion chamber. This removes all the water that was

added in the steam infusion process, along with any undesirable flavor from the process’s heat treatment.

After flash cooling, the product is heated to pasteurizing temperature, held for the required time and

cooled to the desired packaging temperature. Product then flows to either an aseptic designed surge tank

or the packaging equipment.

BLOCK DIAGRAM:

FSH™

Product Raw Product Product Pre-treatment

Infusion

Balance Tank Regenerator Pre-Heater Holding Tube

Heater

Liquid Egg

Packaging Final Product Holding Product Vacuum

Equipment Cooler Tube Heater Flash Cooler

PROCESS SYSTEM FEATURES:

! Extends shelf life from days to weeks or months.

! Removes volatile off flavors or odors.

! Maximizes thermal treatment with minimal change in product characteristics.

! Extends run times between system flush/in-run CIP.

! Lower steam temperature and special FSH™ design yield longer run times than injectors and other

infusion chamber designs.

! Product never contacts hotter metal in infusion heater/flash cooler.

! System is CIP cleaned from balance tank.

! Programmable logic controls for repeatable product treatment.

EQUIPMENT REQUIRED: INFORMATION REQUIRED FOR QUOTATION:

! WCB plate or tubular heat exchangers ! Products _____________________________________

! WCB centrifugal and positive displace- ! Product flow rate _______________________________

ment pumps

! Product viscosity _______________________________

! WCB Falling Stream Heater infusion

chamber ! Product specific gravity __________________________

! WCB holding tubes ! Product pH ___________________________________

! WCB vacuum flash cooler ! Product inlet temperature ________________________

! WCB hot water sets

! Desired product holding temperatures ______________

! Balance tank

! Miscellaneous valves ! Desired holding times ___________________________

! Control system ! Desired fill temperature __________________________

! Electrical service available _______________________

PROCESS PARAMETERS:

! Capacities: up to 3000 GPH ! Steam service available _________________________

! Cooling media service available ___________________

You might also like

- Tetra Therm Aseptic FlexDocument4 pagesTetra Therm Aseptic FlexHossam Abdel Aziz100% (1)

- Pasteurization HTSTDocument20 pagesPasteurization HTSTSangeetha H100% (2)

- Differentiate Between Disturbed and Undisturbed Sample and Give 3 Type of Sampler For Each SampleDocument8 pagesDifferentiate Between Disturbed and Undisturbed Sample and Give 3 Type of Sampler For Each SampleNaqib Levis Sol100% (2)

- How To Bond Zirconia - The APC Concept PDFDocument9 pagesHow To Bond Zirconia - The APC Concept PDFKelly Katherine0% (1)

- Frozen Food Pre-Cooling: Process Technology Bullet 9960Document2 pagesFrozen Food Pre-Cooling: Process Technology Bullet 9960exergy 33No ratings yet

- Aseptic Juice Processing With Pulp: Process Technology Bullet 9810Document2 pagesAseptic Juice Processing With Pulp: Process Technology Bullet 9810exergy 33No ratings yet

- 9603 Salsa Pasta SauceDocument2 pages9603 Salsa Pasta Sauceexergy 33No ratings yet

- Tetra Pak Pasteurizer BF PDDocument6 pagesTetra Pak Pasteurizer BF PDTanvir BhagatNo ratings yet

- Pasteurizer BF TETRA PAKDocument4 pagesPasteurizer BF TETRA PAKLeo ZunigaNo ratings yet

- Continuous Production of Barbeque Sauce: Process DescriptionDocument2 pagesContinuous Production of Barbeque Sauce: Process Descriptionexergy 33No ratings yet

- Pd10016 Tetra Therm Lacta 1Document4 pagesPd10016 Tetra Therm Lacta 1Omar ArguelloNo ratings yet

- Tetra Therm Aseptic VTIS PD Hi 180702Document6 pagesTetra Therm Aseptic VTIS PD Hi 180702Muhammad RehmanNo ratings yet

- Long-Life MilkDocument34 pagesLong-Life MilkM Umer SaeedNo ratings yet

- Unit 3Document92 pagesUnit 3Kishore KumarNo ratings yet

- 8 UHT ProcessingDocument20 pages8 UHT ProcessingZacky Husada AchmadNo ratings yet

- HTST PasteurizerDocument2 pagesHTST PasteurizerChapa KaziNo ratings yet

- Aseptic Fruit Puree Processing: Process Technology Bullet 9821Document2 pagesAseptic Fruit Puree Processing: Process Technology Bullet 9821exergy 33No ratings yet

- Tetra Pak Indirect UHT Unit PFF SSHE - PDDocument4 pagesTetra Pak Indirect UHT Unit PFF SSHE - PDLotfi JeffaliNo ratings yet

- Tetra Therm Aseptic Visco SSHEDocument4 pagesTetra Therm Aseptic Visco SSHEsudheendracvkNo ratings yet

- Uht Pasteurization FinalDocument4 pagesUht Pasteurization FinalZacky Husada AchmadNo ratings yet

- Tetra Pak Pasteurizer BC: Highlights Working PrincipleDocument6 pagesTetra Pak Pasteurizer BC: Highlights Working PrincipleSoledad RodriguezNo ratings yet

- UHT ProcessingDocument12 pagesUHT ProcessingMohammad Ashraf Paul100% (1)

- Tetra Pak Indirect UHT Unit DC - PDDocument4 pagesTetra Pak Indirect UHT Unit DC - PDKhánh HồNo ratings yet

- Pasteurization: Pasteurizer For Aseptic Cold Filling of Fruit JuicesDocument3 pagesPasteurization: Pasteurizer For Aseptic Cold Filling of Fruit JuicesWmScheu1100% (1)

- Pasteur IzerDocument12 pagesPasteur Izerkhaoula100% (1)

- 05 PasteurisationDocument52 pages05 PasteurisationSadhan PadhiNo ratings yet

- Tetra Pak Pasteurizer D BaseDocument4 pagesTetra Pak Pasteurizer D BaseDorina CotoarăNo ratings yet

- PasturizationDocument28 pagesPasturizationTamizh TamizhNo ratings yet

- TIS-113-Prime Surface Heat ExchangerDocument0 pagesTIS-113-Prime Surface Heat Exchangerhappale2002No ratings yet

- HF PrincipalsThermal ProcessDocument76 pagesHF PrincipalsThermal ProcessAisarya DasNo ratings yet

- FDE311 Module9Document31 pagesFDE311 Module9dilaraaaydiin742No ratings yet

- Krones: Varioflash and VarioaseptDocument13 pagesKrones: Varioflash and VarioaseptHoa XaNo ratings yet

- Pasteurization and BlanchingDocument53 pagesPasteurization and Blanchingdmttapia-1No ratings yet

- Wa0003.Document4 pagesWa0003.muraliammu900No ratings yet

- PasturizersDocument13 pagesPasturizersAnkit BiholaNo ratings yet

- Milk PasteurizationDocument5 pagesMilk PasteurizationSatish PatilNo ratings yet

- Batch Pasteurizer For MilkDocument8 pagesBatch Pasteurizer For MilkMustafa AmroNo ratings yet

- PasteurisationDocument21 pagesPasteurisationRANIT sarkarNo ratings yet

- Thermal SolutionsDocument14 pagesThermal SolutionsManuel J. Vílchez FrancoNo ratings yet

- Heat Transfer Application. 413Document38 pagesHeat Transfer Application. 413Aronn SiamNo ratings yet

- Process Plant TrainerDocument7 pagesProcess Plant TrainerNatashah AshrafNo ratings yet

- FDE311 Module8Document27 pagesFDE311 Module8dilaraaaydiin742No ratings yet

- Tetra Therm Aseptic Drink 1: Efficient Pasteurization For Aseptic or Hot-Fill Beverage ProductionDocument3 pagesTetra Therm Aseptic Drink 1: Efficient Pasteurization For Aseptic or Hot-Fill Beverage ProductionAndrés Torres SandovalNo ratings yet

- Thermal Treatment: Tecnología Agroalimentaria I Moisés ViacavaDocument74 pagesThermal Treatment: Tecnología Agroalimentaria I Moisés ViacavaLuis EnriqueNo ratings yet

- Varioasept: Microbiological Safety For Your ProductsDocument6 pagesVarioasept: Microbiological Safety For Your Productsمصطفى- القرقعيNo ratings yet

- Pasteurization of Milk: Course: Dairy and Food EngineeringDocument12 pagesPasteurization of Milk: Course: Dairy and Food Engineeringdelapan is bakirNo ratings yet

- Evaporation TechnologyDocument24 pagesEvaporation TechnologymetashriNo ratings yet

- Internship Report: Submitted ToDocument32 pagesInternship Report: Submitted Toharis ilyasNo ratings yet

- Pignat S.A.S.: Computerized PasteurizationDocument4 pagesPignat S.A.S.: Computerized Pasteurizationlusoegyi 1919No ratings yet

- Drinking Milk TechnologyDocument25 pagesDrinking Milk TechnologySura C. JirNo ratings yet

- 8 UHT ProcessingDocument5 pages8 UHT ProcessingZacky Husada AchmadNo ratings yet

- Milk Processing Carried Out in Dairy Industry & Implementation of Industrial Automation in Milk ProcessingDocument20 pagesMilk Processing Carried Out in Dairy Industry & Implementation of Industrial Automation in Milk ProcessingRavi KashyapNo ratings yet

- ThermalDocument51 pagesThermalsadbad6No ratings yet

- Steam Powered Absorption Chiller Installation and Operation Manual TTDocument44 pagesSteam Powered Absorption Chiller Installation and Operation Manual TTromi_hamdani0% (1)

- Sop HRSGDocument23 pagesSop HRSGshameer_febi100% (1)

- Aseptic/Extended Life Surge Tank: Process Technology Bullet 9606Document2 pagesAseptic/Extended Life Surge Tank: Process Technology Bullet 9606exergy 33No ratings yet

- Falling Film Evap For DairyDocument8 pagesFalling Film Evap For DairysamirdudhandeNo ratings yet

- FARM - Vat PasteurizationDocument12 pagesFARM - Vat Pasteurizationford62bNo ratings yet

- Milk Factory Visit ReportDocument10 pagesMilk Factory Visit ReportshubhamrasalNo ratings yet

- Instant Pot Cookbook: The Ultimate Guide Plus 101 Delicious RecipesFrom EverandInstant Pot Cookbook: The Ultimate Guide Plus 101 Delicious RecipesRating: 3.5 out of 5 stars3.5/5 (2)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Hot Water Heater Installation and Repair: A Step-by-Step Guide to DIY Installation, Maintenance, and Troubleshooting for Homeowners: Homeowner Plumbing Help, #4From EverandHot Water Heater Installation and Repair: A Step-by-Step Guide to DIY Installation, Maintenance, and Troubleshooting for Homeowners: Homeowner Plumbing Help, #4No ratings yet

- 01 Muzeul National I 1974Document366 pages01 Muzeul National I 1974exergy 33100% (1)

- Kemp Russian Travellers To India and Persia 1625 1798Document150 pagesKemp Russian Travellers To India and Persia 1625 1798exergy 33No ratings yet

- Tapper-Nomads in IranDocument38 pagesTapper-Nomads in Iranexergy 33No ratings yet

- Religion and Persian Minature During TheDocument21 pagesReligion and Persian Minature During Theexergy 33No ratings yet

- Fluid-Mineral Equilibrium of Spring Waters at Cuitzeo Basin (Mexico) Geothermal ZoneDocument7 pagesFluid-Mineral Equilibrium of Spring Waters at Cuitzeo Basin (Mexico) Geothermal Zoneexergy 33No ratings yet

- COV - Sedimentation of Particles in Water or AirDocument9 pagesCOV - Sedimentation of Particles in Water or Airexergy 33No ratings yet

- GreenDocument86 pagesGreenexergy 33No ratings yet

- Artisan Rototherm Dries Lecithin: by Perry Alasti, VP, Food Processing Technologies, Artisan Industries IncDocument4 pagesArtisan Rototherm Dries Lecithin: by Perry Alasti, VP, Food Processing Technologies, Artisan Industries Incexergy 330% (1)

- 1 2 3 4Document217 pages1 2 3 4exergy 33No ratings yet

- RheologyDocument24 pagesRheologyexergy 33No ratings yet

- Untitled 12Document1 pageUntitled 12exergy 33No ratings yet

- Jim Witcher, Geothermal Greenhouse 042909Document15 pagesJim Witcher, Geothermal Greenhouse 042909exergy 33No ratings yet

- Csi 20040412Document11 pagesCsi 20040412exergy 33No ratings yet

- Asf Weatherly Ammonium-Nitrate 2022marDocument2 pagesAsf Weatherly Ammonium-Nitrate 2022marexergy 33No ratings yet

- Hwsoln 02Document7 pagesHwsoln 02exergy 33No ratings yet

- Ball MillDocument4 pagesBall Millexergy 33No ratings yet

- Ti 85 300 10 GeDocument2 pagesTi 85 300 10 Geexergy 33No ratings yet

- Advance To Driving With BiodieselDocument3 pagesAdvance To Driving With Biodieselexergy 33No ratings yet

- State Line Biofuels Engineering Schematic - 12 - 07Document1 pageState Line Biofuels Engineering Schematic - 12 - 07exergy 33No ratings yet

- p0593500030441 IF9MFDocument4 pagesp0593500030441 IF9MFexergy 33No ratings yet

- Aseptic/Extended Life Surge Tank: Process Technology Bullet 9606Document2 pagesAseptic/Extended Life Surge Tank: Process Technology Bullet 9606exergy 33No ratings yet

- Continuous Production of Barbeque Sauce: Process DescriptionDocument2 pagesContinuous Production of Barbeque Sauce: Process Descriptionexergy 33No ratings yet

- Aseptic Juice Processing With Pulp: Process Technology Bullet 9810Document2 pagesAseptic Juice Processing With Pulp: Process Technology Bullet 9810exergy 33No ratings yet

- Evaluation of The NH Removal Efficiency of An Aci-Wageningen University and Research 184988Document8 pagesEvaluation of The NH Removal Efficiency of An Aci-Wageningen University and Research 184988exergy 33No ratings yet

- Aseptic Fruit Puree Processing: Process Technology Bullet 9821Document2 pagesAseptic Fruit Puree Processing: Process Technology Bullet 9821exergy 33No ratings yet

- PB-9941 Chantilly CreamDocument2 pagesPB-9941 Chantilly Creamexergy 33No ratings yet

- Continuous Tomato Paste Standardization: Solids Reduction PhaseDocument2 pagesContinuous Tomato Paste Standardization: Solids Reduction Phaseexergy 33No ratings yet

- 9603 Salsa Pasta SauceDocument2 pages9603 Salsa Pasta Sauceexergy 33No ratings yet

- Frozen Food Pre-Cooling: Process Technology Bullet 9960Document2 pagesFrozen Food Pre-Cooling: Process Technology Bullet 9960exergy 33No ratings yet

- Pages From RA 1-6. Finaldoc BDocument1 pagePages From RA 1-6. Finaldoc Bexergy 33No ratings yet

- Aisi 409Document1 pageAisi 409sheinilaNo ratings yet

- 1 s2.0 S2214785320312967 MainDocument12 pages1 s2.0 S2214785320312967 MainMITUSHI AGRAWALNo ratings yet

- IF SteelsDocument20 pagesIF SteelsZubair AhmadNo ratings yet

- Astasantin HPLCDocument6 pagesAstasantin HPLCROBINNo ratings yet

- Modular Waste Lube Oil PDFDocument19 pagesModular Waste Lube Oil PDFAdeel Ahmed100% (2)

- Mapefloor FC 200 ME Submittal With UAE RefDocument50 pagesMapefloor FC 200 ME Submittal With UAE RefAhmed IbrahimNo ratings yet

- MortarDocument40 pagesMortargraphicsman123100% (2)

- 1.6 A Personal NoteDocument1 page1.6 A Personal Notekara_25No ratings yet

- G9 STE Q3 Biotechnology ReviewerDocument9 pagesG9 STE Q3 Biotechnology ReviewerJoyz Etneilas ArguillesNo ratings yet

- Compressive Strength For Cast-In-Place Concrete: Table 1.7Document23 pagesCompressive Strength For Cast-In-Place Concrete: Table 1.7Dave TalabocNo ratings yet

- Cauvery Institute of Technology: Experimental Study On Strength of Concrete Using Areca Fiber and Granite PowderDocument43 pagesCauvery Institute of Technology: Experimental Study On Strength of Concrete Using Areca Fiber and Granite PowderNithin BmNo ratings yet

- The Effect of Vanadium Micro Alloying and Hot Deformation Control On The Mechanical Properties of Structural SteelDocument4 pagesThe Effect of Vanadium Micro Alloying and Hot Deformation Control On The Mechanical Properties of Structural SteelHany KhalifaNo ratings yet

- Determination of Elastic Constants of Additive Manufactured Inconel 625 Specimens Using An Ultrasonic TechniqueDocument11 pagesDetermination of Elastic Constants of Additive Manufactured Inconel 625 Specimens Using An Ultrasonic TechniqueHamidreza JavidradNo ratings yet

- PHK724 IdnengDocument12 pagesPHK724 Idnengdian agustinaNo ratings yet

- Pressure VesselDocument16 pagesPressure VesselsrinivasNo ratings yet

- Density Functional Theory Investigations of Bismuth VanadateDocument7 pagesDensity Functional Theory Investigations of Bismuth VanadateNurSalahuddinNo ratings yet

- General Education: Biological Science and Physical ScienceDocument248 pagesGeneral Education: Biological Science and Physical Sciencedennis balbuenaNo ratings yet

- Dimethyl Disulfide: Safety Data SheetDocument15 pagesDimethyl Disulfide: Safety Data SheetMohamed KilanyNo ratings yet

- Radiographic TestingDocument4 pagesRadiographic Testingtechzones100% (1)

- Unit ViDocument69 pagesUnit ViRavichandran SekarNo ratings yet

- Klein,: Organic ChemistryDocument41 pagesKlein,: Organic ChemistryMark BakalanNo ratings yet

- Paint DefectsDocument17 pagesPaint DefectsAdriana JonesNo ratings yet

- New Solvent For Polyamide 66 and Its Use For Preparing Single-Polymer Composite Coated-FabricDocument24 pagesNew Solvent For Polyamide 66 and Its Use For Preparing Single-Polymer Composite Coated-FabricSSNo ratings yet

- Revision Notes For Checkpoint ChemistryDocument13 pagesRevision Notes For Checkpoint ChemistryKostas TampakisNo ratings yet

- Andrews' ExperimentsDocument3 pagesAndrews' ExperimentsRSLNo ratings yet

- Certificate of Analysis: RVSEB-2023 21-06-2019 20-06-2020Document2 pagesCertificate of Analysis: RVSEB-2023 21-06-2019 20-06-2020dhairyasheelNo ratings yet

- Pre-AP Chemistry Basic Thermochemistry Equilibrium and Organic Chemistry Notes Unit 112Document29 pagesPre-AP Chemistry Basic Thermochemistry Equilibrium and Organic Chemistry Notes Unit 112ChessmanRobbinsNo ratings yet

- J 1 PQR GMAW FCAW D1.1 2020 FormDocument2 pagesJ 1 PQR GMAW FCAW D1.1 2020 FormCristian Narro100% (1)