Professional Documents

Culture Documents

Continuous Tomato Paste Standardization: Solids Reduction Phase

Continuous Tomato Paste Standardization: Solids Reduction Phase

Uploaded by

exergy 33Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Continuous Tomato Paste Standardization: Solids Reduction Phase

Continuous Tomato Paste Standardization: Solids Reduction Phase

Uploaded by

exergy 33Copyright:

Available Formats

Process Technology

Bullet 9629 9-97

CONTINUOUS TOMATO PASTE STANDARDIZATION

Solids Reduction Phase

PROCESS DESCRIPTION:

Tomato Paste (Solids Reduction)

The concentrated product is force-fed into a Waukesha positive displacement timing pump from the bag unloading

hopper which is designed with a twin screw auger. The timing pump has a variable frequency drive which serves to

control the paste dilution speed. From this pump, product flows through a centrifugal blending pump, which runs

at a higher rate than the timing pump. This pump enhances the dilution efficiency of the paste and water prior to

sending the diluted solution through the inline mixer. The tomato paste standardization tank, with scraper agitator

and dual counter rotating agitator, serves as the standardized product tank. Product flows from the product tank to

the batching system via the positive displacement batch feed pump. The water timing pump, in conjunction with

the product timing pump, standardized product circulation pump, Brix meter and associated valves closely con-

trols product consistency. These items compose a ratio control loop capable of standardizing the paste from

31% total solids to as low as 5% total solids.

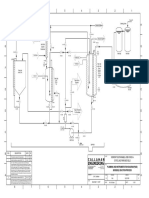

BLOCK FLOW DIAGRAM:

Twin WCB Positive WCB Positive WCB Centrifugal

Static Mixer

!

!

Screw Displacement Paste Displacement Recirculation

and In-Line Brix Meter

Hopper Timing Pump Water Timing Pump Blend Pump

!

To Batching System Tanks WCB Positive WCB Standardized

or Standardized Paste Displacement Batch

!

Recirculation Standardization Tank

!

!

Holding Tanks Feed Pump Positive Pump

PROCESS SYSTEM FEATURES:

!Maximizes solids recovery without use of bag rinse water.

!Reduces variability of standardized product through elimination of rinse water.

!Dilution capacity from 31% tomato paste to 5% single-strength juice.

!Optimum control of product consistency using in-line Brix meter, continuous blending and recirculation

verification.

!Programmable logic control for repeatable product consistency.

EQUIPMENT REQUIRED: INFORMATION REQUIRED

!Twin screw auger hopper FOR QUOTATION:

!WCB positive displacement pumps !Products __________________________________________

!WCB centrifugal pump !Total usage rate of standardized product ___________________

!Standardization tank !Total solids of bag to be dumped _________________________

!WCB valves and fittings !Specific gravity of unstandardized product _________________

!Automated control system !Viscosity of unstandardized product _____________________

!CIP system !Desired total solids after standardization ___________________

PROCESS PARAMETERS: !Specific gravity of standardized product ___________________

!Capacities of up to sixteen 300 gallon bag !Viscosity of standardized product _______________________

and box totes per hour !Product temperature __________________________________

!Capable of 6-to-1 dilution rate !Dilution water temperature _____________________________

!Can be used on products such as frozen

juice concentrates and pulp

You might also like

- EX70 SuperDocument217 pagesEX70 SuperKudanthai Senthilkumar86% (7)

- BOSCH Preferred Products CatalogDocument33 pagesBOSCH Preferred Products CatalogJamin SmtpngNo ratings yet

- Innopro Paramix C Blending System PDFDocument2 pagesInnopro Paramix C Blending System PDFvickysandaNo ratings yet

- Code Name Circuit Diagram. AL3201 Generator Circuit Diagram SCH01. BA3101 Battery 1 Circuit Diagram SCH01. BA3102 Battery 2 Circuit Diagram SCH01Document46 pagesCode Name Circuit Diagram. AL3201 Generator Circuit Diagram SCH01. BA3101 Battery 1 Circuit Diagram SCH01. BA3102 Battery 2 Circuit Diagram SCH01Arvis Žigalovs100% (1)

- PB-9941 Chantilly CreamDocument2 pagesPB-9941 Chantilly Creamexergy 33No ratings yet

- Aseptic Juice Processing With Pulp: Process Technology Bullet 9810Document2 pagesAseptic Juice Processing With Pulp: Process Technology Bullet 9810exergy 33No ratings yet

- Vacuum Tumbler SystemDocument2 pagesVacuum Tumbler SystemJANE JACOBSNo ratings yet

- APV CSD Sugar Dissolver 5401 01 03 2010 USDocument2 pagesAPV CSD Sugar Dissolver 5401 01 03 2010 USrudypqNo ratings yet

- Continuous Production of Barbeque Sauce: Process DescriptionDocument2 pagesContinuous Production of Barbeque Sauce: Process Descriptionexergy 33No ratings yet

- FPP 15 ChandramouliDocument6 pagesFPP 15 ChandramouliAbraham.CastilloNo ratings yet

- Tappi Controle de ConsitenciaDocument16 pagesTappi Controle de ConsitenciaFelipe WatanabeNo ratings yet

- Aseptic Fruit Puree Processing: Process Technology Bullet 9821Document2 pagesAseptic Fruit Puree Processing: Process Technology Bullet 9821exergy 33No ratings yet

- Sugar enDocument12 pagesSugar enakhmad zaenudinNo ratings yet

- Brochure, Teledyne Tekmar AutoMate-Q40 Automated QuEChERS PlatformDocument8 pagesBrochure, Teledyne Tekmar AutoMate-Q40 Automated QuEChERS PlatformNguyễn Khang LuânNo ratings yet

- VSSLM 2016 3Document2 pagesVSSLM 2016 3AKINMADE OLUWATOSINNo ratings yet

- Manual & Automatic Chemical ControlDocument36 pagesManual & Automatic Chemical ControlKhaled SaadnehNo ratings yet

- Frozen Food Pre-Cooling: Process Technology Bullet 9960Document2 pagesFrozen Food Pre-Cooling: Process Technology Bullet 9960exergy 33No ratings yet

- Emec V Series PumpsDocument3 pagesEmec V Series PumpsManutençãoNo ratings yet

- Frautech CatalogueDocument16 pagesFrautech CatalogueHicham EL KTAIBINo ratings yet

- FBBRCBSENbDocument7 pagesFBBRCBSENbbartekguzikNo ratings yet

- High Performance Liquid Chromatography (HPLC)Document22 pagesHigh Performance Liquid Chromatography (HPLC)abhijeetpadhi001No ratings yet

- Almix LV20Document2 pagesAlmix LV20anas lhabachiNo ratings yet

- Auxiliary Equipment (Latest)Document4 pagesAuxiliary Equipment (Latest)paancongoNo ratings yet

- Manual Bioseguridad LaboratorioDocument2 pagesManual Bioseguridad LaboratorioCorona CoronitaNo ratings yet

- Page 3Document7 pagesPage 3Jehangir PhoneNo ratings yet

- Pro Cip ManualDocument7 pagesPro Cip Manualmanue2912No ratings yet

- Data Sheet - Pharmed® BPT Biocompatible Peristaltic Pump Tubing PDFDocument3 pagesData Sheet - Pharmed® BPT Biocompatible Peristaltic Pump Tubing PDFildarNo ratings yet

- 2 B Biopharmproductoverview GB 03Document6 pages2 B Biopharmproductoverview GB 03Make it simpleNo ratings yet

- Tank Jet MixersDocument2 pagesTank Jet MixersGabriela Axinte100% (1)

- GEA Varipond Tcm11-42317Document14 pagesGEA Varipond Tcm11-42317Thang VuNo ratings yet

- Tank Jet MixersDocument2 pagesTank Jet MixersImtinan MohsinNo ratings yet

- Jacobi Ab Resinex Softening A4 Eng A0613Document2 pagesJacobi Ab Resinex Softening A4 Eng A0613Dzulkifli MuhamadNo ratings yet

- Poly Series: Polymer Preparation UnitDocument8 pagesPoly Series: Polymer Preparation UnitChalut YvesNo ratings yet

- 002 Ov Foam EquipmentDocument10 pages002 Ov Foam EquipmentHesti WulandariNo ratings yet

- 01.22.16 Coca Cola Process DescriptionDocument32 pages01.22.16 Coca Cola Process DescriptionHausland Const. Corp.No ratings yet

- B Dispensing Us 01Document12 pagesB Dispensing Us 01Vruno Velasquez LNo ratings yet

- Pre-Engineered Water Treatment SolutionsDocument2 pagesPre-Engineered Water Treatment SolutionsaminiislandNo ratings yet

- Sierra - BrochureDocument64 pagesSierra - BrochureKundaiNo ratings yet

- Sewage Treatment Plant Report For M/s Santla Devi Resorts Pvt. LTDDocument7 pagesSewage Treatment Plant Report For M/s Santla Devi Resorts Pvt. LTDSamNo ratings yet

- Dopag LSR Silcomix enDocument12 pagesDopag LSR Silcomix enChetan SharmaNo ratings yet

- Powder MaxDocument4 pagesPowder MaxABC - Angela GomezNo ratings yet

- Summary of FLUX Pump Series-2Document1 pageSummary of FLUX Pump Series-2barkahNo ratings yet

- Facet FG - Diesel BrochureDocument4 pagesFacet FG - Diesel BrochurechertanNo ratings yet

- Shear PumpDocument4 pagesShear PumpAnilNo ratings yet

- Emulsion Production and Optimizing ConditionsDocument45 pagesEmulsion Production and Optimizing ConditionsLucia SaezNo ratings yet

- PH Systems Design: Mark Girgenti - Director of Design Engineering and Business DevelopmentDocument46 pagesPH Systems Design: Mark Girgenti - Director of Design Engineering and Business Developmenthoangvubui4632No ratings yet

- Aseptic Filler Fillstar CX Brochure - tcm11 39652Document2 pagesAseptic Filler Fillstar CX Brochure - tcm11 39652Hossam Abdel AzizNo ratings yet

- Stuffer 420 VDocument4 pagesStuffer 420 VAndrés ValdomezNo ratings yet

- Contiflow enDocument19 pagesContiflow enMaxsilva85No ratings yet

- Thickeners and Clarifiers: Liquid / Solid SeparationDocument6 pagesThickeners and Clarifiers: Liquid / Solid Separationyounes1980No ratings yet

- Tre BP Super Tre BP Chain Solution 01 2019 EN LR 27157Document2 pagesTre BP Super Tre BP Chain Solution 01 2019 EN LR 27157xenec17151No ratings yet

- CHE EL2 Crystallization Part 2Document13 pagesCHE EL2 Crystallization Part 2Michelle MariposaNo ratings yet

- CHE 503 - Lecture 4Document31 pagesCHE 503 - Lecture 4sapphira lucielNo ratings yet

- CV Yuwana Bakti - 2023Document16 pagesCV Yuwana Bakti - 2023aditya pamungkasNo ratings yet

- CONTEX Continuous Extractor - tcm11-43006Document4 pagesCONTEX Continuous Extractor - tcm11-43006Diego ArroyaveNo ratings yet

- WP Bdi GB 1000 2012Document10 pagesWP Bdi GB 1000 2012prijepolje72No ratings yet

- 9603 Salsa Pasta SauceDocument2 pages9603 Salsa Pasta Sauceexergy 33No ratings yet

- Ficha Emec VCO - CompletoDocument12 pagesFicha Emec VCO - CompletoSandry Lara TorresNo ratings yet

- "V" Series Metering Pumps: Data SheetDocument6 pages"V" Series Metering Pumps: Data Sheetluis EscobedoNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Flow charts of pharmaceutical quality control tests for different dosage formsFrom EverandFlow charts of pharmaceutical quality control tests for different dosage formsNo ratings yet

- 01 Muzeul National I 1974Document366 pages01 Muzeul National I 1974exergy 33100% (1)

- Kemp Russian Travellers To India and Persia 1625 1798Document150 pagesKemp Russian Travellers To India and Persia 1625 1798exergy 33No ratings yet

- Tapper-Nomads in IranDocument38 pagesTapper-Nomads in Iranexergy 33No ratings yet

- Religion and Persian Minature During TheDocument21 pagesReligion and Persian Minature During Theexergy 33No ratings yet

- Fluid-Mineral Equilibrium of Spring Waters at Cuitzeo Basin (Mexico) Geothermal ZoneDocument7 pagesFluid-Mineral Equilibrium of Spring Waters at Cuitzeo Basin (Mexico) Geothermal Zoneexergy 33No ratings yet

- COV - Sedimentation of Particles in Water or AirDocument9 pagesCOV - Sedimentation of Particles in Water or Airexergy 33No ratings yet

- GreenDocument86 pagesGreenexergy 33No ratings yet

- Artisan Rototherm Dries Lecithin: by Perry Alasti, VP, Food Processing Technologies, Artisan Industries IncDocument4 pagesArtisan Rototherm Dries Lecithin: by Perry Alasti, VP, Food Processing Technologies, Artisan Industries Incexergy 330% (1)

- 1 2 3 4Document217 pages1 2 3 4exergy 33No ratings yet

- RheologyDocument24 pagesRheologyexergy 33No ratings yet

- Untitled 12Document1 pageUntitled 12exergy 33No ratings yet

- Jim Witcher, Geothermal Greenhouse 042909Document15 pagesJim Witcher, Geothermal Greenhouse 042909exergy 33No ratings yet

- Csi 20040412Document11 pagesCsi 20040412exergy 33No ratings yet

- Asf Weatherly Ammonium-Nitrate 2022marDocument2 pagesAsf Weatherly Ammonium-Nitrate 2022marexergy 33No ratings yet

- Hwsoln 02Document7 pagesHwsoln 02exergy 33No ratings yet

- Ball MillDocument4 pagesBall Millexergy 33No ratings yet

- Ti 85 300 10 GeDocument2 pagesTi 85 300 10 Geexergy 33No ratings yet

- Advance To Driving With BiodieselDocument3 pagesAdvance To Driving With Biodieselexergy 33No ratings yet

- State Line Biofuels Engineering Schematic - 12 - 07Document1 pageState Line Biofuels Engineering Schematic - 12 - 07exergy 33No ratings yet

- p0593500030441 IF9MFDocument4 pagesp0593500030441 IF9MFexergy 33No ratings yet

- Aseptic/Extended Life Surge Tank: Process Technology Bullet 9606Document2 pagesAseptic/Extended Life Surge Tank: Process Technology Bullet 9606exergy 33No ratings yet

- Continuous Production of Barbeque Sauce: Process DescriptionDocument2 pagesContinuous Production of Barbeque Sauce: Process Descriptionexergy 33No ratings yet

- Aseptic Juice Processing With Pulp: Process Technology Bullet 9810Document2 pagesAseptic Juice Processing With Pulp: Process Technology Bullet 9810exergy 33No ratings yet

- Evaluation of The NH Removal Efficiency of An Aci-Wageningen University and Research 184988Document8 pagesEvaluation of The NH Removal Efficiency of An Aci-Wageningen University and Research 184988exergy 33No ratings yet

- Aseptic Fruit Puree Processing: Process Technology Bullet 9821Document2 pagesAseptic Fruit Puree Processing: Process Technology Bullet 9821exergy 33No ratings yet

- PB-9941 Chantilly CreamDocument2 pagesPB-9941 Chantilly Creamexergy 33No ratings yet

- Extended Shelf Life Egg Processing: Process Technology Bullet 9962Document2 pagesExtended Shelf Life Egg Processing: Process Technology Bullet 9962exergy 33No ratings yet

- 9603 Salsa Pasta SauceDocument2 pages9603 Salsa Pasta Sauceexergy 33No ratings yet

- Frozen Food Pre-Cooling: Process Technology Bullet 9960Document2 pagesFrozen Food Pre-Cooling: Process Technology Bullet 9960exergy 33No ratings yet

- Pages From RA 1-6. Finaldoc BDocument1 pagePages From RA 1-6. Finaldoc Bexergy 33No ratings yet

- Zia 6000-8000 9CND TechnicalManual 5DTCNP20 EN v1-0Document93 pagesZia 6000-8000 9CND TechnicalManual 5DTCNP20 EN v1-0convofixNo ratings yet

- Pureit Excella User Manual PDFDocument31 pagesPureit Excella User Manual PDFabdulrehman999No ratings yet

- Multiphase - Pumps - Axel CalgaryDocument45 pagesMultiphase - Pumps - Axel CalgaryAlberto Enrique De Santa Anna CampderáNo ratings yet

- Instructiuni PACO Pumps KP, KPV GRUNDFOSDocument24 pagesInstructiuni PACO Pumps KP, KPV GRUNDFOSCristina HirtescuNo ratings yet

- Sauer DanfossDocument72 pagesSauer DanfossRoberto Gomez100% (2)

- 2022 10 12 313D2L Activacion - AnsulDocument13 pages2022 10 12 313D2L Activacion - AnsulCesar Miguel Gallardo TorrelNo ratings yet

- Self-Priming Centrifugal Pumps: "D" SeriesDocument12 pagesSelf-Priming Centrifugal Pumps: "D" Seriesjohn kenneth vasquez vasquezNo ratings yet

- Principle and Application of WEICHAI Electrical High Common Rail SystemDocument44 pagesPrinciple and Application of WEICHAI Electrical High Common Rail Systemheri setyonoNo ratings yet

- 2019 11 27.11.46.56 Hydrulics and Pneumatics (Syllabus)Document1 page2019 11 27.11.46.56 Hydrulics and Pneumatics (Syllabus)Harry HarryNo ratings yet

- 01 Vacon AC Drives Basic CourseDocument43 pages01 Vacon AC Drives Basic CourseKarthik Sriramakavacham100% (2)

- Alto Marine CatalogDocument35 pagesAlto Marine CatalogdavidNo ratings yet

- Storage and Handling Safety in LPG Plants: Onur ÖzutkuDocument5 pagesStorage and Handling Safety in LPG Plants: Onur ÖzutkuDavid RodriguesNo ratings yet

- Optimization of Electrosubmersible Pumps For Handling Heavy Foamy OilsDocument11 pagesOptimization of Electrosubmersible Pumps For Handling Heavy Foamy OilsrizalziNo ratings yet

- ECS002 - Calculation For The Orifice Plate On The AC Lube Oil SystemDocument9 pagesECS002 - Calculation For The Orifice Plate On The AC Lube Oil SystemPaul CarlyNo ratings yet

- Filter,: Type FIA 15 - 200 ( - 8 In.)Document12 pagesFilter,: Type FIA 15 - 200 ( - 8 In.)GogaNo ratings yet

- Caldera Columbia CT-25 Manual PDFDocument72 pagesCaldera Columbia CT-25 Manual PDFPharmalat MantenimientoNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- How Do Plant Pipe Strain Problems Affect My Pumping SystemsDocument5 pagesHow Do Plant Pipe Strain Problems Affect My Pumping SystemsKarimAboelmkaremNo ratings yet

- 3.0 Water Lines Preface: Bechtel ConfidentialDocument6 pages3.0 Water Lines Preface: Bechtel ConfidentialCristhianNo ratings yet

- Electric Sprayers: Graco's Complete Line of Professional Electric Airless SprayersDocument32 pagesElectric Sprayers: Graco's Complete Line of Professional Electric Airless SprayershyiredNo ratings yet

- Sulfuric Acid Plant Hydrogen ExplosionsDocument37 pagesSulfuric Acid Plant Hydrogen ExplosionsAbdelghani Massouri100% (1)

- 02 Chilled Water Piping Pumps PDFDocument64 pages02 Chilled Water Piping Pumps PDFbilal almelegyNo ratings yet

- CV For Adu-Ansere Fokuo Kwarteng 3Document6 pagesCV For Adu-Ansere Fokuo Kwarteng 3Adu Ansere FokuoNo ratings yet

- Manual de PropietarioDocument22 pagesManual de PropietarioSergioPortillaLastarria100% (2)

- Alpha 3Document4 pagesAlpha 3Alin Emil MuresanNo ratings yet

- Valve World Magazine June 2023Document88 pagesValve World Magazine June 2023Krishna KumarNo ratings yet

- Consulting - Specifying Engineer - NFPA 20 - Fire Pump Design 1Document15 pagesConsulting - Specifying Engineer - NFPA 20 - Fire Pump Design 1HSEI Jatim - NSU 2020No ratings yet

- Terex TC 20Document36 pagesTerex TC 20touran445No ratings yet