Professional Documents

Culture Documents

G Stor Pro Spec Sheet 2018

G Stor Pro Spec Sheet 2018

Uploaded by

GOLDEN CNG TESTING CENTRE0 ratings0% found this document useful (0 votes)

11 views2 pagesOriginal Title

G-Stor-Pro-spec-sheet-2018

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

11 views2 pagesG Stor Pro Spec Sheet 2018

G Stor Pro Spec Sheet 2018

Uploaded by

GOLDEN CNG TESTING CENTRECopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

G-Stor Pro ™

Type 3 Cylinders

Luxfer’s G-Stor Pro Type 3 composite

cylinders are the highest-volume,

lightest-weight cylinders in the alternative

fuel industry and are designed to reduce

overall vehicle curb weight and thereby

increasing range.

Available in an extensive range of sizes, G-Stor Pro cylinders

consist of a Luxfer-manufactured aluminum liner fully

over-wrapped with carbon fiber. During a fast fill, the high

thermal conductivity of the aluminum liner helps dissipate

generated heat from the gas, providing a more complete fill

every time. Thoroughly tested to applicable global design

standards and regulations, G-Stor Pro cylinders are used in a

variety of CNG applications around the world such as: transit

buses; light, medium and heavy-duty trucks; refuse vehicles and

bulk gas transportation modules.

G-Stor Pro Type 3 Cylinders ™

Thanks to our unique liner processing technology, G-Stor Pro Benefits:

cylinders are the highest capacity, lightest-weight Type 3 AF

cylinders in the world. • Highest-volume, lightest-weight composite cylinder in its

Because they are 66 percent lighter than Type 1 all-steel diameter class.

cylinders and up to 16 percent lighter than other composite

cylinders in the NGV industry, these Luxfer cylinders offer fleet • Available with Luxfer’s exclusive fast-venting, reliable

operators greatly improved fuel economy, extended range pressure-relief devices (PRDs).

and a significant reduction in vehicle maintenance costs due

to lessened wear on vehicle brakes, tires and suspension • Zero gas permeability through the cylinder wall.

systems.

On retrofit applications, using G-Stor Pro cylinders reduces • Aluminum liner technology provides fast-fill capability,

suspension system alterations and improves vehicle handling. allowing near-complete capacity utilization in less time.

Benefits of Compressed Natural Gas:

• Significantly safer to store than liquid fuels – Leaks disperse into the air instead of on the ground.

• Field-proven deployment – There are over 25 million natural gas-powered vehicles and over 30 thousand

refueling stations around the world. (Source: ngvglobal.org).

• Sealed systems produce no evaporative emissions.

• Cleanest burning transportation fuel on the market today.

• Renewable Natural Gas (RNG) in the transportation sector is the only solution that is carbon net-negative.

This means that carbon emissions are reduced by over 100 percent.

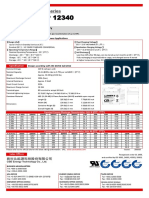

CNG Total weight, Water DGE GGE

Diameter Length Weight Neck Part

capacity tank and fuel volume equivalent equivalent

mount number

in mm in mm ft3 m³ lb kg lb kg l US gallon US gallon

10.8 274 60.0 1524 717.9 20.3 30.7 27.2 90.4 41.0 69.0 5.2 5.8 No L069

12.7 323 72.0 1829 1,188.6 33.7 106.0 48.1 156.4 71.0 114.2 8.6 9.6 No A1134D

13.0 330 108.3 2751 1,188.6 54.2 125.7 57.0 156.4 93.8 184.0 8.6 9.6 Yes Q184

14.2 361 120.0 3048 1,952.8 72.7 120.0 79.8 202.7 129.2 246.8 14.0 15.7 Yes A2523C

35.4 900 1,188.6 21.8 63.9 29.0 153.4 43.8 74.0 8.6 9.6 No V074**

77.6 1970 1,831.2 51.9 125.7 57.0 203.3 92.2 176.0 13.2 14.8 Yes V176

15.2 387 100.1 2542 2,434.7 68.9 167.6 76.0 270.8 122.8 234.0 17.5 19.6 Yes V234

120.0 3048 2,965.3 84.0 198.4 90.0 324.1 147.0 285.0 21.3 23.9 Yes V285

123.1 3128 3,059.0 86.6 205.0 93.0 334.7 151.8 294.0 22.0 24.7 Yes V294

34.0 864 790.8 22.4 75.0 34.0 108.5 49.2 76.0 5.7 6.4 No W076

42.0 1067 1,019.7 28.9 81.6 37.0 124.8 56.6 98.0 7.3 8.2 No W098

46.5 1181 1,178.0 33.4 100.1 45.4 150.0 68.1 113.2 8.5 9.5 No A1159D

52.0 1321 1,311.0 37.1 97.0 44.0 152.6 69.2 126.0 9.4 10.6 No W126

60.2 1528 1,581.6 44.8 117.6 53.4 184.7 83.8 152.0 11.4 12.8 No A1586C/W150†

63.3 1608 1,602.5 45.4 126.1 57.2 194.0 88.0 154.0 11.5 12.9 Yes A1575C

77.5 1969 2,016.4 57.1 147.9 67.1 233.4 105.9 193.8 14.5 16.3 Yes A1991C

15.9 404 77.8 1975 2,122.6 60.1 153.0 69.4 243.0 110.2 204.0 15.3 17.1 No A2085D

80.7 2051 2,101.8 59.5 150.9 68.5 240.0 108.9 202.0 15.1 16.9 Yes A2085C/W200†

83.1 2110 2,133.0 60.4 152.1 69.0 242.6 110.0 205.0 15.3 17.2 Yes W205

85.8 2179 2,281.8 64.6 169.1 76.7 265.8 120.6 219.3 16.4 18.4 Yes A2235C

99.8 2536 2,627.2 74.4 183.2 83.1 597.1 270.9 252.5 18.9 21.2 Yes A2602C/W250M†

120.0 3048 3,300.6 93.5 230.4 104.5 370.3 168.0 317.2 23.7 26.6 Yes A3238C

120.0 3048 3,396.1 96.2 233.9 106.1 377.9 171.4 326.4 24.4 27.4 No A3332D

123.1 3126 3,362.8 95.2 227.7 103.3 370.3 168.0 323.2 24.2 27.1 Yes A3332C/W320†

All parts have a service pressure of 248 bar.

Density of CNG = 0.0424 lb/cu-ft. 1 U.S. gallon of diesel/gasoline = 139/124 scf of CNG.

All cylinders are dual-ported, unless otherwise noted, with boss thread connection = 1 1/8 - 12 UNF - 2B.

Other sizes and custom cylinder lengths and size configurations are available upon request with minimum order. Approved pressure relief device must be used for fire protection.

Cylinder specifications are nominal values and are subject to change without notice.

Call +1 800 764 0366 to place your order

or visit www.luxfercylinders.com for more information

MLA102REV01DEC2018

You might also like

- Delivering Safety Nuros ApproachDocument33 pagesDelivering Safety Nuros Approachahawkins8223100% (4)

- DID 180 Standard Roller Chain: Roller Chains For Power TransmissionDocument1 pageDID 180 Standard Roller Chain: Roller Chains For Power TransmissionJhampol Rosales MuñozNo ratings yet

- Metering Pumps: Models A and BDocument5 pagesMetering Pumps: Models A and Bbmanojkumar16No ratings yet

- Moyno Pump 2000 Dimensions g2Document3 pagesMoyno Pump 2000 Dimensions g2ACCA PumpsNo ratings yet

- GB4065 2015-08 Relay Gel Battery Specifications - 0Document4 pagesGB4065 2015-08 Relay Gel Battery Specifications - 0camono2000No ratings yet

- Terminal: Drawing:: Part Number VPC 1 H 2 H 3 H 4 H 5 H 6 H 7 H 8 H 10 H 20 H 40 H 60 H 80 H 100 H 120 HDocument2 pagesTerminal: Drawing:: Part Number VPC 1 H 2 H 3 H 4 H 5 H 6 H 7 H 8 H 10 H 20 H 40 H 60 H 80 H 100 H 120 Hluis albornozNo ratings yet

- Data Sheet 12MVR155LDocument2 pagesData Sheet 12MVR155LIgors SpaskisNo ratings yet

- B1 PowerSafe TS Range SummaryDocument4 pagesB1 PowerSafe TS Range Summarylostris234No ratings yet

- GP Series: Valve Regulated Lead Acid BatteryDocument1 pageGP Series: Valve Regulated Lead Acid BatteryOscar MorenoNo ratings yet

- Gre Pipe 1Document7 pagesGre Pipe 1stephenNo ratings yet

- C Purlin Data SheetDocument6 pagesC Purlin Data SheetAkhil VN100% (1)

- VBW12121 - 300PSI Wafer Butterfly ValveDocument1 pageVBW12121 - 300PSI Wafer Butterfly ValveErickNo ratings yet

- Butt Weld FittingsDocument15 pagesButt Weld FittingsRoberto OliveiraNo ratings yet

- Dimensions of Steel Beams Type IPE European Standard EN 10025-1/2Document1 pageDimensions of Steel Beams Type IPE European Standard EN 10025-1/2Petar Topic100% (1)

- IPNDocument1 pageIPNarianto32No ratings yet

- GP Series: Valve Regulated Lead Acid BatteryDocument1 pageGP Series: Valve Regulated Lead Acid BatteryBrayanNo ratings yet

- Durbar Safe LoadDocument1 pageDurbar Safe LoadМилан БурсаћNo ratings yet

- Safe Load Table: Specifically For Platforms and Other Large Floor AreasDocument1 pageSafe Load Table: Specifically For Platforms and Other Large Floor AreasМилан БурсаћNo ratings yet

- Debut An IzerDocument42 pagesDebut An IzerRizadz AhmadNo ratings yet

- Tubos PVCDocument4 pagesTubos PVCcesar paitanNo ratings yet

- Steel Pipe-Unit WeightDocument3 pagesSteel Pipe-Unit Weightsujan daraiNo ratings yet

- Weld Consumable CalculatorDocument7 pagesWeld Consumable CalculatorQuality TeamNo ratings yet

- Hdpe Spec Sheet Pe4710Document5 pagesHdpe Spec Sheet Pe4710thanguctNo ratings yet

- Tecumseh RD 0003 e - Rev 1 Service Guidelines HCFC r22 To HFC Blends - Oct2017Document8 pagesTecumseh RD 0003 e - Rev 1 Service Guidelines HCFC r22 To HFC Blends - Oct2017Bazin TsegayeNo ratings yet

- Sieve Analysis of Fine Aggregates: Materials Testing #1Document4 pagesSieve Analysis of Fine Aggregates: Materials Testing #1Maryll TapiaNo ratings yet

- Thread Standard BSPDocument7 pagesThread Standard BSPĐạt TrầnNo ratings yet

- Victaulic OGS-200 Grooved End Fittings: 1.0 Product DescriptionDocument13 pagesVictaulic OGS-200 Grooved End Fittings: 1.0 Product DescriptionCinthya Yesenia Cruz MedinaNo ratings yet

- 920-920R NR SizingDocument2 pages920-920R NR SizingKonrad SzwedoNo ratings yet

- 2020 Dwyer Catalog - Rev.12 PDFDocument500 pages2020 Dwyer Catalog - Rev.12 PDFVu Duc ThuongNo ratings yet

- Drill Pipe PDFDocument3 pagesDrill Pipe PDFebrahimNo ratings yet

- ANSI Flange DimensnioDocument3 pagesANSI Flange Dimensniohon choong chongNo ratings yet

- Operational Theory Force On Crosshead GuidesDocument2 pagesOperational Theory Force On Crosshead GuidesArun SNo ratings yet

- Weight CalculationDocument17 pagesWeight Calculationmiteshpatel191No ratings yet

- Option SD (L+R) Inv Cost Monthly Mean Monthly Std. Dev. Lead Time Reorder Interval Safety Stock Average InventoryDocument6 pagesOption SD (L+R) Inv Cost Monthly Mean Monthly Std. Dev. Lead Time Reorder Interval Safety Stock Average InventoryRahul PrasadNo ratings yet

- Calcium Chloride TG: Product DataDocument2 pagesCalcium Chloride TG: Product DataIqbal batchaNo ratings yet

- Tabela Torques de ApertoDocument8 pagesTabela Torques de ApertoEduardo Figueiredo BertassoNo ratings yet

- Heavy Hex Bolt DimensionsDocument6 pagesHeavy Hex Bolt DimensionsSUJIT PATEL100% (1)

- Res Minggu 1Document55 pagesRes Minggu 1Gh4n113 IdNo ratings yet

- Drilling 1 AutoRecoveredDocument52 pagesDrilling 1 AutoRecoveredKhaled AdelNo ratings yet

- S Series PumpDocument12 pagesS Series Pumptim.qwamNo ratings yet

- Section - Properties - Steel - Profiles Rev 2 4Document10 pagesSection - Properties - Steel - Profiles Rev 2 4Francisco Javier Alvarez GarzaNo ratings yet

- TABLA2Document4 pagesTABLA2Daniel Espino QuirogaNo ratings yet

- HDPE Spec Sheet 3608 PDFDocument5 pagesHDPE Spec Sheet 3608 PDFfrnandoxNo ratings yet

- 67745048-Weld-Consumable-CalculatorDocument7 pages67745048-Weld-Consumable-CalculatorAlzaki AbdullahNo ratings yet

- VictaulicDocument6 pagesVictaulicdeep manNo ratings yet

- Tools TipsExtensionsDocument4 pagesTools TipsExtensionsSolina AlunorteNo ratings yet

- ShacklesDocument9 pagesShacklesMuhammad Najam AbbasNo ratings yet

- General Heat ExchangerDocument8 pagesGeneral Heat ExchangerPaolo GNo ratings yet

- Suntech Thrust Pad Cata 18-19Document16 pagesSuntech Thrust Pad Cata 18-19ARKA technocorpNo ratings yet

- Weld Consumable Calculator, Butt and Fillet WeldsDocument7 pagesWeld Consumable Calculator, Butt and Fillet WeldsMiguel HermosaNo ratings yet

- Meatsupplies 14sep23iiDocument33 pagesMeatsupplies 14sep23iiliuzhileeNo ratings yet

- Flange Weight ChartDocument1 pageFlange Weight Chartabhishek198327No ratings yet

- Table: Frame Section Properties 01 - General Sectionname Material Shape Autotype Totalwt TotalmassDocument5 pagesTable: Frame Section Properties 01 - General Sectionname Material Shape Autotype Totalwt TotalmassJose Alejandrino MendozaNo ratings yet

- Lab 2 CV321 s11184759 FinalDocument18 pagesLab 2 CV321 s11184759 Finalshraddha NadanNo ratings yet

- The Dryfit Range For Modular Performance Adaption.: Sonnenschein A412 / 120 FTDocument2 pagesThe Dryfit Range For Modular Performance Adaption.: Sonnenschein A412 / 120 FTglukkerNo ratings yet

- 90 Elbow Long RadiusDocument1 page90 Elbow Long RadiusAkash AdamNo ratings yet

- 90 Elbow Long RadiusDocument1 page90 Elbow Long RadiusRazwan SanjahNo ratings yet

- 12 MVR 125Document1 page12 MVR 125Ionut BirlicaNo ratings yet

- Table H1 Total Final Energy Consumption in Australia, by Fuel, Energy Units ADocument5 pagesTable H1 Total Final Energy Consumption in Australia, by Fuel, Energy Units AChunwai LiongNo ratings yet

- Teshi Butt-Weld-Fittings Product CatalogueDocument15 pagesTeshi Butt-Weld-Fittings Product Cataloguesayan.teshiNo ratings yet

- RTL Compiler SynthesisDocument22 pagesRTL Compiler Synthesissureg7No ratings yet

- s7300 fm352 Operating Instructions en en-US PDFDocument226 pagess7300 fm352 Operating Instructions en en-US PDFABNo ratings yet

- Daden Newsletter 1407Document2 pagesDaden Newsletter 1407David BurdenNo ratings yet

- Capstone Project ReportDocument25 pagesCapstone Project ReportRupesh AkulaNo ratings yet

- Andrew HBXX 3817tb1 VTM HBXX 3817tb1 A2mDocument3 pagesAndrew HBXX 3817tb1 VTM HBXX 3817tb1 A2manna.bNo ratings yet

- GHT 200048 PDFDocument14 pagesGHT 200048 PDFMuzzammil NazeerNo ratings yet

- Chapter 1 Introduction To POM PDFDocument19 pagesChapter 1 Introduction To POM PDFakankaroraNo ratings yet

- Revised List of Online Courses For Fourth and Sixth Semester Through SWAYAM and NPTEL 21 Jan 2021 1Document9 pagesRevised List of Online Courses For Fourth and Sixth Semester Through SWAYAM and NPTEL 21 Jan 2021 1vinay DeshmukhNo ratings yet

- Route CommandDocument5 pagesRoute Commandkapil514No ratings yet

- Activity Guide - Functions Make - Unit 4 Lesson 11Document3 pagesActivity Guide - Functions Make - Unit 4 Lesson 11Devin PhillipsNo ratings yet

- MS Samsung Slim Duct PDFDocument2 pagesMS Samsung Slim Duct PDFMacSparesNo ratings yet

- DB224-B Product SpecificationsDocument2 pagesDB224-B Product SpecificationsTo VT3No ratings yet

- The Wharf Residence Brochure 1Document1 pageThe Wharf Residence Brochure 1Sun XinNo ratings yet

- Design of Active Filters Using A New Active Device CdbaDocument130 pagesDesign of Active Filters Using A New Active Device Cdbaersan turkmanNo ratings yet

- M12-2 Installation GuideDocument146 pagesM12-2 Installation GuideAdrian Gabriel GhiţăNo ratings yet

- Agile Unit 3Document46 pagesAgile Unit 3SaHiLNo ratings yet

- Agreement ProtocolsDocument17 pagesAgreement ProtocolsYash AgrawalNo ratings yet

- Fire Classif & ChecklistDocument8 pagesFire Classif & ChecklistAtulNo ratings yet

- VCET 12 PRJ02 Student ProjectPlanDocument2 pagesVCET 12 PRJ02 Student ProjectPlanshodhanNo ratings yet

- Autopipe Variante PDFDocument4 pagesAutopipe Variante PDFLe Thanh HaiNo ratings yet

- M. Karthikeyan - 139556013Document3 pagesM. Karthikeyan - 139556013madhubaddapuriNo ratings yet

- Log Cat 1689561665052Document79 pagesLog Cat 1689561665052Salman WahidNo ratings yet

- Chapter07-Computer Based Training MethodDocument13 pagesChapter07-Computer Based Training MethodFakhrulrazi IbrahimNo ratings yet

- Thesis On Adaptive FilterDocument10 pagesThesis On Adaptive Filtershannongutierrezcorpuschristi100% (2)

- Photo Math PolicyDocument36 pagesPhoto Math PolicyRose Ann MalinaoNo ratings yet

- Senior Project Manager ERP in New York NY Resume Raymond RzasaDocument3 pagesSenior Project Manager ERP in New York NY Resume Raymond RzasaRaymondRzasaNo ratings yet

- 2b3 SmartUP Parts Manual, 24472102 Rev.B Mar.2013Document42 pages2b3 SmartUP Parts Manual, 24472102 Rev.B Mar.2013Izabela SantanaNo ratings yet

- Claude E. Shannon, N.J.A. Sloane, Aaron D. Wyner - Collected Papers of Claude E. Shannon (1993, IEEE Press) PDFDocument954 pagesClaude E. Shannon, N.J.A. Sloane, Aaron D. Wyner - Collected Papers of Claude E. Shannon (1993, IEEE Press) PDFCarlos Eduardo Correa Roque100% (2)