Professional Documents

Culture Documents

Agip OSO: Characteristics (Typical Figures)

Agip OSO: Characteristics (Typical Figures)

Uploaded by

Luis Carlos Lagos SalinasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Agip OSO: Characteristics (Typical Figures)

Agip OSO: Characteristics (Typical Figures)

Uploaded by

Luis Carlos Lagos SalinasCopyright:

Available Formats

Agip OSO

PRODUCT DATA SHEET

Hydraulic oils based on mineral oil with components against corrosion, oil ageing and wear.

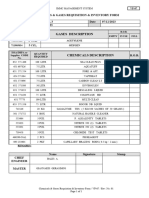

Characteristics (typical figures):

Agip OSO Unit 10 15 22 32 46 68 100 150 Test method

Kin. Viscosity at 40°C mm²/s 10,7 14,3 21,5 30 45 68 100 150 ASTM D 445

at 100°C mm²/s 2,8 3,3 4,2 5,3 6,7 8,67 11,1 14,7 DIN 51 550

Viscosity index 98 98 98 100 105 98 95 95 DIN ISO 2909

3

Density at 15°C kg/m 853 858 865 874 880 886 900 900 ASTM D 1298

Flashpoint o. C. °C 145 190 190 210 215 225 225 235 ASTM D 92

Pourpoint °C -30 -30 -27 -27 -27 -21 -21 -21 ASTM D 97

Designation HLP HLP HLP HLP HLP HLP HLP HLP DIN 51 524T.2

ISO-VG-grade 10 15 22 32 46 68 100 150 DIN 51 524T.2

Properties and Performance:

Agip OSO - types guarantee an untainted operation due to the high Viscosity index, also with

larger variations of the ambient temperatures. The low Pourpoint ensures immediate

operational readiness of the equipment at low ambient temperatures. Additionally these oils

have an excellent wear protection and very good oxidation stability as well as superior

corrosion protection properties. The excellent water rejection capability prevents the formation

of an emulsion and the good air release capability and anti-foam behaviour cause a fast

release of air. They are compatible with the common sealing materials and internal varnishes.

Applications:

Agip OSO - types are pneumatic fluids for hydraulic power transmission systems and control

devices under all operational conditions and highest pressures. The used oil viscosity has to be

in accordance with the manufacturer's specifications. These oils are also suitable as lubricating

oil (CL resp. CLP according to DIN 51 502) for splash and circular lubrication of bearings and

gearboxes.

Due to the good corrosion protection these oils are especially suitable for mobile hydraulic

systems.

Please observe the manufacturer’s specifications when selecting products.

eni S.p.A. Eni Schmiertechnik GmbH TK3

Refining & Marketing Division Paradiesstraße 14 04/2012

Via Laurentina 449, 00142 Rome 97080 Würzburg 0620e,621e,622e,623e,624e,

Standard Phone +39 06 5988.1 Tel. 0931 90098-0 625e,627e,630e

www.eni.com Seite 1 von 2

Agip OSO

PRODUCT DATA SHEET

Additional physical-technical data:

Agip OSO Unit 10 15 22 32 46 68 100 150 Test method

Neutral.-Number (s) mgKOH/g 0,9 0,9 0,9 1,2 1,3 1,2 1,2 1,2 DIN 51 558T.1

Ageing behaviour mgKOH/g --- 0,2 0,2 0,2 0,5 0,2 0,2 0,3 DIN 51 587

increase of the NN after

1000 h

Water hazardous class WGK 1 accord. VwVwS

Corrosion effect on Corr. grade 1 - 100 A 3 DIN 51 759

copper

Corrosion protection Corr. grade 0 - A DIN 51 585 Verf. A

properties against steel

Demulsifying behaviour

54°C min. 5 5 n.b. 10 15 15 --- ---

82°C min. --- --- --- --- --- --- 5 20 DIN 51 559

Air release capacity at

50°C min. 2 2 3 3 5 8 10 17 DIN 51 381

FZG-Test A/8,3/90

load stage --- --- > 12 11 > 12 > 12 > 12 > 12 DIN 51 354

spec. change of weight mg/KW --- --- < 0,2 < 0,2 < 0,2 < 0,2 < 0,2 < 0,2 Part 2

Vickersp.-test

Ring weight loss --- --- < 120 < 120 < 120 < 120 < 120 < 120 DIN 51 389

Vane weight loss --- --- < 30 < 30 < 30 < 30 < 30 < 30

Behaviour against (comparable with

sealing materials Nitrile SRE NBR1), DIN

% +3,4 --- +6 +0,6 +0,6 -0,6 3,2 -0,8

88, NBR101 7d/100°C, 53 538T.1u. DIN

rel. change of volume 53 521

Change of SHORE-A-

SH -2 --- -3 0 -4 0 -1 0 DIN 53 505

hardness

Designation CLP 10 CLP 15 CLP 22 CLP 32 CLP 46 --- --- --- DIN 51 502T.3

SRE NBR 1 7d/100°C

Specifications:

DIN 51 502 HLP BS 4231 HSD

DIN 51 524 T.2 ETON Vickes I-286-S3

ISOL-HM Denison HF 2A

VDMA 24 318 AFNOR NF 600 HM

CETOP RP 91 HM Parker Hannifin DENISON HF-0

SAUR DANFOSS REXROTH RE 90220-1/11.02

ATOS Tab. P002-01 Danielli Standard

eni S.p.A. Eni Schmiertechnik GmbH TK3

Refining & Marketing Division Paradiesstraße 14 04/2012

Via Laurentina 449, 00142 Rome 97080 Würzburg 0620e,621e,622e,623e,624e,

Standard Phone +39 06 5988.1 Tel. 0931 90098-0 625e,627e,630e

www.eni.com Seite 2 von 2

You might also like

- GN 48-005 - HAZOP - of - Flare - and - ReliefDocument26 pagesGN 48-005 - HAZOP - of - Flare - and - ReliefMuhammad.Saim100% (8)

- Doosan DL200 Electrical System Schematic Manual-1Document101 pagesDoosan DL200 Electrical System Schematic Manual-1Ariel CarranzaNo ratings yet

- Gear Compound Plus Iso - 68 - enDocument1 pageGear Compound Plus Iso - 68 - enSedin MurtićNo ratings yet

- Gear Compound Plus Iso - 68 - enDocument1 pageGear Compound Plus Iso - 68 - enSedin MurtićNo ratings yet

- Optimus Turbine Oil 2Document1 pageOptimus Turbine Oil 2kennethNo ratings yet

- Hydroflux Ep tcm14-62558Document1 pageHydroflux Ep tcm14-62558Azis GPBNo ratings yet

- Eni BlasiaDocument2 pagesEni BlasiaranjanguptNo ratings yet

- Renolin CLP - enDocument7 pagesRenolin CLP - enDANE80No ratings yet

- Epic Hydraulic Range TdsDocument2 pagesEpic Hydraulic Range Tdsapi-375685829No ratings yet

- Renolin Eterna (Governor Oil)Document2 pagesRenolin Eterna (Governor Oil)JohanNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- 4376 Industrial Gear Oil CLP 320Document1 page4376 Industrial Gear Oil CLP 320ralish12No ratings yet

- Renolin PA 320 GBDocument3 pagesRenolin PA 320 GBdnoaisapsNo ratings yet

- Agip Arnica S: Characteristics (Typical Figures)Document2 pagesAgip Arnica S: Characteristics (Typical Figures)AMAZING AGNo ratings yet

- Repsol Telex HVLP 32Document2 pagesRepsol Telex HVLP 32ibrahim maulanaNo ratings yet

- AGIP Arnica SDocument2 pagesAGIP Arnica SRZW RNo ratings yet

- L-TSA Classic Turbine OilDocument3 pagesL-TSA Classic Turbine OilQuy NguyenNo ratings yet

- Gulf Geartek - Hd-Sept2021 - 20211102102844Document1 pageGulf Geartek - Hd-Sept2021 - 20211102102844magadali7814No ratings yet

- 5010 5020 5030 5040 5070 5100 5090 2110 HYDRAULIC OIL AW PDS Vesion 3Document2 pages5010 5020 5030 5040 5070 5100 5090 2110 HYDRAULIC OIL AW PDS Vesion 3tauhidrockNo ratings yet

- Cofran Mecanep 220 enDocument2 pagesCofran Mecanep 220 enMATHEW JOSENo ratings yet

- Repsol Telex E 46,68Document2 pagesRepsol Telex E 46,68ibrahim maulanaNo ratings yet

- Renolin CLP - PIDocument6 pagesRenolin CLP - PIDương LêNo ratings yet

- Gulf EP Lubricant HDDocument1 pageGulf EP Lubricant HDatripathi2009No ratings yet

- Alphasyn GSDocument2 pagesAlphasyn GScool_ddNo ratings yet

- TORK HLPDocument1 pageTORK HLPWassim LounissiNo ratings yet

- S-Oil Hydro Fluid Aw: Product DescriptionDocument1 pageS-Oil Hydro Fluid Aw: Product DescriptionJonhNo ratings yet

- Carter EpDocument2 pagesCarter EpNguyễn Quang HưngNo ratings yet

- L-TSA Turbine OilDocument3 pagesL-TSA Turbine OilQuy NguyenNo ratings yet

- TDS Castrol Perfecto XPG - Power VersionDocument2 pagesTDS Castrol Perfecto XPG - Power VersionTeguh SNo ratings yet

- Eni Ote GT 32 Tds 7755 - EnuDocument2 pagesEni Ote GT 32 Tds 7755 - EnumvanzijpNo ratings yet

- Mak Hydrol HLPDocument2 pagesMak Hydrol HLPAbhimanyaNo ratings yet

- Maker Tauro enDocument2 pagesMaker Tauro enibrahim maulanaNo ratings yet

- Aral Degol BG 220: Gear Oil Type CLPDocument1 pageAral Degol BG 220: Gear Oil Type CLPdungdhtsNo ratings yet

- Zic Supervis AwDocument2 pagesZic Supervis AwMohammed Abdul GhafoorNo ratings yet

- Product Data Energol THB: DescriptionDocument2 pagesProduct Data Energol THB: Descriptionkarim karimNo ratings yet

- Shell Corena Oil P 150Document2 pagesShell Corena Oil P 150Secundar UtilizatorNo ratings yet

- Renolit CXI 2Document2 pagesRenolit CXI 2dnoaisapsNo ratings yet

- Q8 El Greco 220 - enDocument1 pageQ8 El Greco 220 - enDeepak YadavNo ratings yet

- Tds Atlantic Hydraulic OilsDocument1 pageTds Atlantic Hydraulic Oilsmgamal1080No ratings yet

- 2611 Gulf EP Lubricant HD 220Document1 page2611 Gulf EP Lubricant HD 220Jasper ShaonNo ratings yet

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- Ina Lis 1 2 and 3 111344Document1 pageIna Lis 1 2 and 3 111344Pero Plemeniti SimicNo ratings yet

- Product Data Sheet: Gulfsea Gear Oil SeriesDocument2 pagesProduct Data Sheet: Gulfsea Gear Oil SeriesObydur RahmanNo ratings yet

- Repsol Tauro PDFDocument1 pageRepsol Tauro PDFrandiNo ratings yet

- Ficha Tecnica Castrol Optigear BM RangeDocument3 pagesFicha Tecnica Castrol Optigear BM RangeVictor Manuel Gonzalez PerezNo ratings yet

- Hydraulic Oils Pds 0915Document1 pageHydraulic Oils Pds 0915Mohamed FersiNo ratings yet

- 3289310Document2 pages3289310Philippe VelhaNo ratings yet

- HO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)Document2 pagesHO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)azimchemNo ratings yet

- PDS - Addinol Gear Oil CLP 10, 68, 100, 150, 220, 320, 460, 680Document2 pagesPDS - Addinol Gear Oil CLP 10, 68, 100, 150, 220, 320, 460, 680LeoNo ratings yet

- PU SEAL Jed-337 008 en ADocument4 pagesPU SEAL Jed-337 008 en Aரஞ்சன் ஞானயோளிNo ratings yet

- Abs 70Document2 pagesAbs 70mohamad mostafaviNo ratings yet

- PDS - GulfSea Hydraulic AW Series-1Document2 pagesPDS - GulfSea Hydraulic AW Series-1Zaini YaakubNo ratings yet

- WL Hydrex Fully Synthetic PDSDocument1 pageWL Hydrex Fully Synthetic PDSAung Myat ThuNo ratings yet

- SMD291AX50T3Document2 pagesSMD291AX50T3Jonatan SmithNo ratings yet

- 3048421Document2 pages3048421Philippe VelhaNo ratings yet

- Ficha Tecnica Castrol Perfecto X RangeDocument3 pagesFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezNo ratings yet

- Shell Omala HD: High Performance Synthetic Industrial Gear and Bearing OilsDocument2 pagesShell Omala HD: High Performance Synthetic Industrial Gear and Bearing Oilsabdul ahhadNo ratings yet

- Gulf Harmony AW Plus: Premium Quality Anti-Wear Hydraulic OilDocument2 pagesGulf Harmony AW Plus: Premium Quality Anti-Wear Hydraulic OilHarsh AiwaleNo ratings yet

- Gengear Series SPL-A Up To 320Document3 pagesGengear Series SPL-A Up To 320Hakim AmmorNo ratings yet

- The SQUID Handbook: Fundamentals and Technology of SQUIDs and SQUID SystemsFrom EverandThe SQUID Handbook: Fundamentals and Technology of SQUIDs and SQUID SystemsNo ratings yet

- Kiln Stop Due To Cooling Water Low Level (Utility) : Holcim IndonesiaDocument3 pagesKiln Stop Due To Cooling Water Low Level (Utility) : Holcim IndonesiaSafrin SangiaNo ratings yet

- Blank Sticker Tabs TemplateDocument3 pagesBlank Sticker Tabs TemplateHina OdaNo ratings yet

- Line ProportionersDocument2 pagesLine ProportionersAhmed Said IbrahimNo ratings yet

- F 395 - 02 - Rjm5ns1sruqDocument3 pagesF 395 - 02 - Rjm5ns1sruqDylkanWingsNo ratings yet

- SCIENCE 8 Q3 - WEEK 3 - LAS 2 EvaporationDocument2 pagesSCIENCE 8 Q3 - WEEK 3 - LAS 2 EvaporationGlin BarrientosNo ratings yet

- Quat N Eq Xxxn-V-006 Dat001 001b-Equalizer VesselDocument1 pageQuat N Eq Xxxn-V-006 Dat001 001b-Equalizer VesselAhmed Abd ElmegeedNo ratings yet

- Refrigeration Air Conditioning Mechanical GATE IES PSU Study MaterialDocument12 pagesRefrigeration Air Conditioning Mechanical GATE IES PSU Study Materiall8o8r8d8s8i8v8No ratings yet

- Comprimo® Sulfur Solutions: ApplicationsDocument1 pageComprimo® Sulfur Solutions: ApplicationsPrasad ChakkarapaniNo ratings yet

- Feu Hydraulics PreboardDocument2 pagesFeu Hydraulics PreboardEla Macabante100% (1)

- ESP Excel PAD Rev01 - 5628121 - 01Document37 pagesESP Excel PAD Rev01 - 5628121 - 01Geraldo Soemaschris SoewarnoNo ratings yet

- Gaseous State Essay EMDocument2 pagesGaseous State Essay EMThilanka LiyanageNo ratings yet

- Gay Lussac Combined Avogadro Ideal Gas Law ApplicationDocument28 pagesGay Lussac Combined Avogadro Ideal Gas Law ApplicationAlexandra Venice Ann M. PerezNo ratings yet

- VP-07 05.23 Rev.01 (Chemicals Gases Req. and Inventory Form)Document1 pageVP-07 05.23 Rev.01 (Chemicals Gases Req. and Inventory Form)Mohamed FathyNo ratings yet

- Student Exploration: Boyle's Law and Charles's LawDocument14 pagesStudent Exploration: Boyle's Law and Charles's LawStephanie ValienteNo ratings yet

- Che Calculations 1 2014 - 20152 StudentsDocument2 pagesChe Calculations 1 2014 - 20152 StudentsAudreyWalangareDimalibotNo ratings yet

- Mah 402Document55 pagesMah 402Himanshu PanchalNo ratings yet

- Poster Marking ExDocument1 pagePoster Marking ExFridolin DanielNo ratings yet

- Family Tree: Positive Displacement PumpDocument20 pagesFamily Tree: Positive Displacement PumpMuhammad Qasim SajidNo ratings yet

- Incompressible Flow in A Duct: The Venturi and Low-Speed Wind Tunnel Sec 3.3Document14 pagesIncompressible Flow in A Duct: The Venturi and Low-Speed Wind Tunnel Sec 3.3jerome deiparineNo ratings yet

- Formulas: P V P V PV NRT T T "R" Values: 0.0821 Atm L 62.4 MMHG L 8.31 Kpa L Mol K Mol K Mol KDocument2 pagesFormulas: P V P V PV NRT T T "R" Values: 0.0821 Atm L 62.4 MMHG L 8.31 Kpa L Mol K Mol K Mol KmaxNo ratings yet

- FlowconME - Automatic Air VentDocument2 pagesFlowconME - Automatic Air VentKarim MakkiNo ratings yet

- Astm D7423Document9 pagesAstm D7423Gilson JoseNo ratings yet

- Fixed Bed Adsorption Column M7Document3 pagesFixed Bed Adsorption Column M7Mayank VashishthaNo ratings yet

- Safety Valve SelectionDocument56 pagesSafety Valve Selectionganesh82No ratings yet

- Dynamic Response of A U Tube ManometerDocument8 pagesDynamic Response of A U Tube ManometerRitikranjan YadavNo ratings yet

- Crude Oil - 2Document9 pagesCrude Oil - 2husseinNo ratings yet

- Assignment 5-1Document2 pagesAssignment 5-1ashutoshNo ratings yet

- Hydraulics Day 1 Properties of FluidsDocument13 pagesHydraulics Day 1 Properties of FluidszayarosspadillaNo ratings yet