Professional Documents

Culture Documents

Esd2400 Series: Ngine Overning Ystems

Esd2400 Series: Ngine Overning Ystems

Uploaded by

Anas BasarahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Esd2400 Series: Ngine Overning Ystems

Esd2400 Series: Ngine Overning Ystems

Uploaded by

Anas BasarahCopyright:

Available Formats

ENGINE ESD2400 SERIES

GOVERNING

SYSTEMS SPEED CONTROL UNIT

INSTALLATION ADJUSTMENTS

The speed control unit is hard potted and rugged Before Starting Engine

enough to be placed in a control cabinet or engine Check to insure the GAIN and STABILITY

mounted enclosure with other dedicated control adjustments, and if applied, the external SPEED TRIM

equipment. If water, mist, or condensation may come in CONTROL are set to mid position.

contact with the controller, it should be mounted

vertically. This will allow the fluid to drain away from the S t a r t Engine

speed control unit. Extreme heat should be avoided. The speed control unit governed speed setting is factory

set at approximately engine idle speed. (1000 Hz.,

speed sensor signal)

WARNING

Crank the engine with DC power applied to the

An overspeed shutdown device, independent of the governor system. The actuator will energize to the

governor system, should be provided to prevent loss of maximum fuel position until the engine starts. The

engine control, which may cause personal injury or governor system should control the engine at a low idle

equipment damage. speed. If the engine is unstable after starting, turn the

GAIN and STABILITY adjustments counterclockwise

WIRING until the engine is stable.

Basic electrical connections are illustrated in Diagram Governor Speed S e t t i n g

1. Actuator and battery connections to Terminals F, G, H, The governed speed set point is increased by

and J should be #16 AWG (1.3 mm sq.) or larger. Long clockwise rotation of the SPEED adjustment pot.

cables require an increased wire size to minimize Remote speed adjustment can be obtained with an

voltage drops. The battery positive (+) input, Terminal F, optional 5K Speed Trim Control. (See Diagram 1. )

should be fused for 15 amps as illustrated in Diagram 1.

Governor Performance

Magnetic speed sensor wires connected to Terminals Once the engine is at operating speed and at no load,

D and E MUST BE TWISTED AND/OR SHIELDED for the following governor performance adjustment can be

their entire length. The speed sensor cable shield made.

should ideally be connected as shown in Diagram 1. The

shield should be insulated to insure no other part of the A. Rotate the GAIN adjustment clockwise until

shield comes in contact with engine ground, otherwise instability develops. Gradually move the adjustment

stray speed signals may be introduced into the speed counterclockwise until stability returns. Move the

control unit. With the engine stopped, adjust the gap adjustment one division further counterclockwise to

between the magnetic speed sensor and the ring gear insure stable performance (270° pot).

teeth. The gap should not be any smaller than 0.020

in. (0.45 mm). Usually, backing out the speed sensor B. Rotate the STABILITY adjustment clockwise until

3/4 turn after touching the ring gear teeth will achieve a instability develops. Gradually move the adjustment

satisfactory air gap. The magnetic speed sensor counterclockwise until stability returns. Move the

voltage should be at least 1V AC RMS during adjustment one division further to insure stable

cranking. performance (270° pot).

C. Gain and stability adjustments may require minor

changes after engine load is applied. Normally,

adjustments made at no load achieve satisfactory

performance. A strip chart recorder can be used to

further optimize the adjustments.

Governors America Corp. 720 Silver St. Agawam, MA 01001

Tel: 413-786-5600 Fax: 413-789-7736 Web: http://www.governors-america.com E-mail: info@governors-america.com

Page 1 of 6 * ABOVE INFORMATION IS SUBJECT TO CHANGE WITHOUT NOTICE * PIB1023 Rev. A

If instability cannot be corrected or further performance clockwise rotation of the IDLE adjustment control.

improvements are required, refer to the SYSTEM When the engine is at idle speed, the speed control unit

TROUBLESHOOTING section. applies droop to the governor system to insure stable

operation.

Idle Speed Setting

After the governor speed setting has been adjusted,

place the optional external selector switch in the IDLE

position. The idle speed set point is increased by

SPECIFICATIONS

Performance

Isochronous Operation/Steady State Stability ............................................................................................± 0.25% or Better

Speed Range/Governor ......................................................................................................................................... 1kHz - 7.5KHz

Continuous Speed Drift with Temperature ................................................................................................. Typically < +0.5%

Speed Trim Range......................................................................................................................................... ±250Hz Typical

Idle Range..................................................................................................................... 500 5000Hz with trim pot installed

Environmental

Ambient Operating Temperature Range ................................................................................ -40°F to +180°F (-40°C to +85°C)

Relative Humidity (Non-condensing) ................................................................................................................... Up to 100%

All Surface Finishes ......................................................................................................Fungus Proof & Corrosion Resistant

Input Power

Supply .................................................................-12; 8-20V DC, -24; 16-32V DC (Transient and Reverse Voltage Protected)*

Polarity ...................................................................................................................................... Negative Ground (Case Isolated)

Power Consumption................................................................................................. 60mA Continuous plus actuator current

Maximum Actuator Current at 77°F (25°C) .................................................................................................10 Amps Continuous

Speed Sensor Signal........................................................................................................................... 0.50 V AC - 50 V AC RMS

Reliability

Vibration ............................................................................................................................................................... 5G @ 20-500Hz

Testing ............................................................................................................................................................ Functionally Tested

Physical

Dimensions ............................................................................................................................................. See Outline (Diagram 1)

Weight ..........................................................................................................................................................................12oz (347g)

Mounting ............................................................................................................................. Any Position (Vertical Preferred)

*Reverse voltage is protected against by a parallel diode in 12V units and a series diode in 24V units.

A 15A fuse must be installed in the positive battery lead. See Diagram 1.

Governors America Corp. 720 Silver St. Agawam, MA 01001

Tel: 413-786-5600 Fax: 413-789-7736 Web: http://www.governors-america.com E-mail: info@governors-america.com

Page 2 of 6 * ABOVE INFORMATION IS SUBJECT TO CHANGE WITHOUT NOTICE * PIB1023 Rev. A

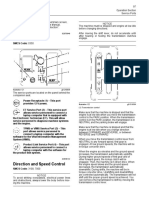

DIAGRAM 1. SYSTEM WIRING/OUTLINE

Governors America Corp. 720 Silver St. Agawam, MA 01001

Tel: 413-786-5600 Fax: 413-789-7736 Web: http://www.governors-america.com E-mail: info@governors-america.com

Page 3 of 6 * ABOVE INFORMATION IS SUBJECT TO CHANGE WITHOUT NOTICE * PIB1023 Rev. A

SYSTEM TROUBLESHOOTING

System Inoperative

If the engine governing system does not function, the fault may be determined by performing the voltage tests described

in Steps 1 through 4. Positive (+) and negative (-) refer to meter polarity. Should normal values be indicated during

troubleshooting steps, and then the fault may be with the actuator or the wiring to the actuator. Tests are performed with

battery power on and the engine off, except where noted. See actuator publication for testing procedure on the actuator.

Step Terminals Normal Reading Probable Cause of Abnormal Reading

1 F(-) & G(+) Battery Supply Voltage (12, 24, or 32 V DC) 1. DC battery power not connected. Check for blown fuse

2. Low battery voltage.

3. Wiring error.

2 B(+) & C(-) 0-2.7 with speed trim 1. Speed trim shorted or mis-wired.

4.8-5.4 without speed trim 2. Defective unit.

3 D(+) & E(-) 1.0 V AC RMS min. while cranking 1. Gap between speed sensor and gear teeth too great.

Check gap.

2. Improper or defective wiring to the speed sensor.

Resistance should be between 30 to 1200 ohms.

3. Defective speed sensor.

4 J(-) & F(+) 0.5-1.5 V DC while cranking 1. Wiring error to actuator.

2. Defective speed control unit.

3. Defective actuator.

Unsatisfactory Performance

If the governing system functions poorly, perform the following tests.

Symptom Test Probable Fault

Engine overspeed 1. Do Not Crank. Apply DC power to the 1. Actuator goes to full fuel. Then disconnect the

governor system. speed sensor wires. If actuator still at full fuel-

speed control unit defective. If actuator at

minimum fuel position erroneous speed signal.

Check speed sensor cable.

2. Manually hold the engine at the desired 1. If the voltage reading is 0.5 to 1.5 V DC,

running speed. Measure the DC a) SPEED adjustment set above desired speed.

voltage between Terminal J(-) & F(+) b) Defective speed control unit.

on the speed control unit. 2. If the voltage reading is above 1.5 V DC, actuator

or linkage binding.

3. Set point of overspeed shutdown set too low.

4. If the voltage reading is below 0.5 V DC,

defective speed control unit.

Actuator does not energize 1. Measure the DC voltage between 1. Replace the battery if weak or undersized.

fully while cranking. Terminals J(-) & F(+) on the speed 2. Actuator wiring incorrect.

control unit. Should be 0.8 to 1.5V DC. 3. If voltage is less than 1.5V, SPEED set too low

If not:

2. Momentarily connect Terminal F and J. 1. Actuator or battery wiring in error.

The actuator should move to the full 2. Actuator or linkage binding.

fuel position. 3. Defective actuator.

Engine remains below 1. Measure the actuator output, Terminals 1. If voltage measurement is with 1.5V or more of

desired governed speed H & J, while running under governor the battery supply voltage level, then fuel control

control. restricted from reaching full fuel position. Possibly

due to mechanical governor, carburetor spring, or

linkage interference.

2. If not, increase speed setting.

Governors America Corp. 720 Silver St. Agawam, MA 01001

Tel: 413-786-5600 Fax: 413-789-7736 Web: http://www.governors-america.com E-mail: info@governors-america.com

Page 4 of 6 * ABOVE INFORMATION IS SUBJECT TO CHANGE WITHOUT NOTICE * PIB1023 Rev. A

SYSTEM TROUBLESHOOTING Instability

Instability in a closed loop speed control system can be

Insufficient Magnetic Speed Signal categorized into two general types. PERIODIC appears to

A strong magnetic speed sensor signal will eliminate the be sinusoidal and at a regular rate. NON-PERIODIC is a

possibility of missed or extra pulses. The speed control unit random wandering or an occasional deviation from a steady

will govern well with 0.5 volts RMS speed sensor signal. A state band for no apparent reason.

speed sensor signal of 3 volts RMS or greater at governed

speed is recommended. Measurement of the signal is The PERIODIC type can be further classified as fast or

made at Terminals D and E. slow instability. Fast instability is a 3 Hz. or faster

irregularity of the speed and is usually a jitter. Slow periodic

The amplitude of the speed sensor signal can be raised by instability is below 3Hz., can be very slow, and is

reducing the gap between the speed sensor tip and the sometimes violent.

engine ring gear. The gap should not be any smaller than

0.020 in (0.45 mm). With the engine is stopped, back the If fast instability occurs, this is typically the governor

speed sensor out by 3/4 turn after touching the ring gear responding to engine firings. Raising the engine speed

tooth to achieve a satisfactory air gap. increases the frequency of instability and vice versa. In

this case, cutting the jumper from E1 to E2 will reduce this

Electro magnetic Compatibility ( EMC) tendency. In extreme cases, the removal of the E1 to E2

EMI SUSCEPTIBILITY - The governor system can be jumper may not take all the jitter out of the system. A

adversely affected by large interfering signals that are second jumper, E4 to E5, may be removed to further

conducted through the cabling or through direct radiation stabilize the system. Post locations are illustrated in

into the control circuits. Diagram 1. Interference from powerful electrical signals

can also be the cause. Turn off the battery chargers or

All GAC speed control sensors contain filters and shielding other electrical equipment to see if the system instability

designed to protect the unit s sensitive circuits from disappears.

moderate external interfering sources.

Slow instability can have many causes. Adjustment of the

Although it is difficult to predict levels of interference, GAIN and STABILITY usually cures most situations by

applications that include magnetos, solid sate ignition matching the speed control unit dynamics. If this is

systems, radio transmitters, voltage regulators or battery unsuccessful, the dead time compensation can be

chargers should be considered suspect as possible modified. Add a capacitor from posts E2 to E3 (negative

interfering sources. on E2). Post locations are illustrated in Diagram 1. Start

with 10mfds and increase until instability is eliminated. The

If it is suspected that external fields, either those that are control system can also be optimized for best

radiated or conducted, are or will affect the governor performance by following this procedure.

systems operation, it is recommended to use shielded

cable for all external connections. Be sure that only one If slow instability is unaffected by this procedure, evaluate

end of the shields, including the speed sensor shield, is the fuel system and engine performance. Check the fuel

connected to a single point on the case of the speed system linkage for binding, high friction, or poor linkage. Be

control unit. Mount the speed control to a grounded metal sure to check linkage during engine operation. Also look at

back plate or place it in a sealed metal box. the engine fuel system. Irregularities with carburetion or

fuel injection systems can change engine power with a

Radiation is when the interfering signal is radiated directly constant throttle setting. This can result in speed

through space to the governing system. To isolate the deviations beyond the control of the governor system.

governor system electronics from this type of interference Adding a small amount of droop can help stabilize the

source, a metal shield or a solid metal container is usually system for troubleshooting.

effective.

NON-PERIODIC instability should respond to the GAIN

Conduction is when the interfering signal is conducted control. If increasing the gain reduces the instability, then

through the interconnecting wiring to the governor system the problem is probably with the engine. Higher gain

electronics. Shielded cables and installing filters are allows the governor to respond faster and correct for

common remedies. disturbance. Look for engine misfiring, an erratic fuel

system, or load changes on the engine generator set

In severe, high-energy interference locations, such as when voltage regulator. If the throttle is slightly erratic, but

the governor system is directly in the field of a powerful performance is fast, removing the jumper from E4 to E5 will

transmitting source, the shielding may require to be a tend to steady the system.

special EMI class shielding. For these conditions, contact

GAC application engineering for specific If unsuccessful in solving instability, contact GAC for

recommendations. assistance.

Governors America Corp. 720 Silver St. Agawam, MA 01001

Tel: 413-786-5600 Fax: 413-789-7736 Web: http://www.governors-america.com E-mail: info@governors-america.com

Page 5 of 6 * ABOVE INFORMATION IS SUBJECT TO CHANGE WITHOUT NOTICE * PIB1023 Rev. A

Declaration of Conformity

Application to Council Directives Heavy and Light Industrial Applications

Standard to which Conformity is Declared EN55011, EN50081-2, and EN50082-2

Manufacturer's Name GOVERNORS AMERICA CORP.

Manufacturer's Address Agawam, MA 01001 USA

Importer's Name

Importer's Address

Type of Equipment Electronic Speed Control Unit

Model Number ESD2400 Series

Serial Number Above T10429

Year of Manufacture 1999 and later

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and

Standards.

Place: Agawam, MA USA Full Name: Mr. William Ferry

Date: May 6,1999 Position: President and CEO

In order to be in compliance with the above directives, the installer is obligated to install the equipment in strict

accordance with the following special instructions and guidelines.

1. The speed control unit must be mounted against the metal ground plane with two bolts, which make positive

electrical connections between the case and the back plane.

2. The magnetic pickup must be connected to the speed control using shielded cable as shown in the wiring diagram.

3. All shielded cable connections to the speed control must be connected to the case at the corner threaded

connection per the wiring diagram.

4. Shielded cable for the actuator is recommended to minimize the actuator s slight movement during fast high voltage

transients. The installer s choice of not using shielded cable may cause the actuator to move more than slightly

during these transients. However, no failures should be experienced.

The installer must refer to the wiring diagram in the literature for proper electrical connections.

Governors America Corp. 720 Silver St. Agawam, MA 01001

Tel: 413-786-5600 Fax: 413-789-7736 Web: http://www.governors-america.com E-mail: info@governors-america.com

Page 6 of 6 * ABOVE INFORMATION IS SUBJECT TO CHANGE WITHOUT NOTICE * PIB1023 Rev. A

You might also like

- Manual Regulador de Velocidade Gac Esd 5111Document2 pagesManual Regulador de Velocidade Gac Esd 5111Paulo Alves100% (2)

- Workshopman 03Document33 pagesWorkshopman 03Mohand Oubélaid Ait HammouNo ratings yet

- Tarjeta VelocidadDocument9 pagesTarjeta Velocidaddiego100% (1)

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Introduction To Video EditingDocument4 pagesIntroduction To Video EditingrendezvousfrNo ratings yet

- Merlin Service Ops Ap1590 66-88 PDFDocument231 pagesMerlin Service Ops Ap1590 66-88 PDFPaolo Fontanazzi100% (2)

- Warning: ESD5200 Series Speed Control UnitDocument6 pagesWarning: ESD5200 Series Speed Control UnitAnas BasarahNo ratings yet

- Warning: ESD5100 Series Speed Control UnitDocument6 pagesWarning: ESD5100 Series Speed Control Unitinstrumentacion.hsrNo ratings yet

- Esd5500E Series Speed Control Tlnit: WarningDocument5 pagesEsd5500E Series Speed Control Tlnit: WarningKarla HolandaNo ratings yet

- Ngine Overning Ystems: Generator Frequency Sensing Speed Control UnitDocument6 pagesNgine Overning Ystems: Generator Frequency Sensing Speed Control Unitjuan narvaezNo ratings yet

- Warning: ESD5500E Series Speed Control UnitDocument6 pagesWarning: ESD5500E Series Speed Control UnitLuis Alberto Lopez100% (1)

- ESD5100 Series Speed Control UnitDocument2 pagesESD5100 Series Speed Control UnitJaimeCoelloNo ratings yet

- ESD-5550/5570 Series - Speed Control Unit: Technical InformationDocument12 pagesESD-5550/5570 Series - Speed Control Unit: Technical InformationCarlos Molina100% (1)

- ESD5100 Series Speed Control UnitDocument2 pagesESD5100 Series Speed Control Unitajcapetillog100% (2)

- Speed Control GAC ESD5500Document8 pagesSpeed Control GAC ESD5500Manuel Otero80% (5)

- Gac Ecc328 ManualDocument4 pagesGac Ecc328 ManualAnonymous d2ofVvJNo ratings yet

- Gac Esd5500Document7 pagesGac Esd5500christramNo ratings yet

- Esd5500E Series Speed Control Unit: Product Technical Information PTI 1002EDocument7 pagesEsd5500E Series Speed Control Unit: Product Technical Information PTI 1002EalstomNo ratings yet

- Reg. Velocidade GAC ESD 5550 5570Document8 pagesReg. Velocidade GAC ESD 5550 5570thyagoenerg100% (1)

- Electronic Governor CatalogDocument26 pagesElectronic Governor CatalogAung Mh100% (1)

- FSK-628D Gobernador Electronico de MotorDocument35 pagesFSK-628D Gobernador Electronico de Motorsoldadores motoresNo ratings yet

- CAT-777F-Direction and Speed ControlDocument2 pagesCAT-777F-Direction and Speed ControlCybergoNo ratings yet

- Generator Automatic Voltage Regulator Operation Manual: Tel: - Fax: - @Document8 pagesGenerator Automatic Voltage Regulator Operation Manual: Tel: - Fax: - @Syed Mohammad Naveed100% (1)

- 2110 V1.0 ESD 5330 Technical Information 09 07 10 MH en PDFDocument13 pages2110 V1.0 ESD 5330 Technical Information 09 07 10 MH en PDFSamir KhanNo ratings yet

- GOB EG1065x Manual en PDFDocument8 pagesGOB EG1065x Manual en PDFRonaldCarrasquelNo ratings yet

- EG3000 ManualDocument7 pagesEG3000 ManualJose Armando Perez AcostaNo ratings yet

- Table 1.: InstallationDocument12 pagesTable 1.: InstallationRicardo MonteroNo ratings yet

- DYN1-10693-001-0-12 or DYN1-10693-001-0-24 PDFDocument8 pagesDYN1-10693-001-0-12 or DYN1-10693-001-0-24 PDFSyed Mohammad Naveed100% (1)

- E 391 Manual 1Document6 pagesE 391 Manual 1naruto akatcyNo ratings yet

- Detector Service ManualDocument4 pagesDetector Service Manualkhanh khanhNo ratings yet

- Manual Regulador de Velocidade Gac Esd 5111 PDFDocument2 pagesManual Regulador de Velocidade Gac Esd 5111 PDFGugui68100% (1)

- EG1065X Governor McPhersonDocument7 pagesEG1065X Governor McPhersonOrlando GalvanNo ratings yet

- 6.teste e Ajustes G3500 PDFDocument102 pages6.teste e Ajustes G3500 PDFrony silvaNo ratings yet

- Candy Differential: Infinitely Adjustable Rotary PositionerDocument6 pagesCandy Differential: Infinitely Adjustable Rotary PositionerVinay Prasad NNo ratings yet

- Eg1069x Manual en PDFDocument24 pagesEg1069x Manual en PDFtecnigenelecNo ratings yet

- Esd-5200 DS en 03.2011 V1.0Document4 pagesEsd-5200 DS en 03.2011 V1.0BryanLeonardoOspinoReinaNo ratings yet

- Manual Del Regulador Electrónico de Velocidad DGC-2007Document7 pagesManual Del Regulador Electrónico de Velocidad DGC-2007pevare100% (1)

- DYN1-10693-001-0-12 or DYN1-10693-001-0-24 PDFDocument8 pagesDYN1-10693-001-0-12 or DYN1-10693-001-0-24 PDFSyed Mohammad NaveedNo ratings yet

- ADB120E4Document3 pagesADB120E4abuzer1981No ratings yet

- ht-hsg100 Ds en 04-2014 v1-1Document4 pagesht-hsg100 Ds en 04-2014 v1-1Basaveswar KorlaNo ratings yet

- Gen Stepper CTRLDocument1 pageGen Stepper CTRLsparky1No ratings yet

- VOLVO Speed Governor ESD 5500E Technical InformationDocument10 pagesVOLVO Speed Governor ESD 5500E Technical Informationdaniel_ting_1No ratings yet

- Pti1000 Esd5100 SeriesDocument2 pagesPti1000 Esd5100 SeriesRamon Thales DomeniconiNo ratings yet

- DTN0004 PID Idle ControlDocument3 pagesDTN0004 PID Idle ControlshayNo ratings yet

- BPM24RT100BL Specspecifications UpdateDocument8 pagesBPM24RT100BL Specspecifications UpdatemalleNo ratings yet

- Ecm Gain SettingDocument2 pagesEcm Gain SettingMuomen FarooqNo ratings yet

- Esd5111 enDocument4 pagesEsd5111 enRicardo MonteroNo ratings yet

- YSD-FSK639D Governor-Usermanual enDocument19 pagesYSD-FSK639D Governor-Usermanual enMohamed A.AlbadriNo ratings yet

- ESD-5500E Series: Analogue Speed GovernorsDocument4 pagesESD-5500E Series: Analogue Speed GovernorsVasil Stoianov100% (1)

- Woodward Speed Droop PDFDocument8 pagesWoodward Speed Droop PDFedgarlimas100% (2)

- Sensorless Vector ControlDocument6 pagesSensorless Vector ControlDavid MartinNo ratings yet

- EG3000 Manual PDFDocument7 pagesEG3000 Manual PDFrepelindNo ratings yet

- Product Information: DYNA ControllersDocument4 pagesProduct Information: DYNA ControllersmarceloNo ratings yet

- ESD5522E Generator Speed Control UnitDocument2 pagesESD5522E Generator Speed Control UnitKhaled KamelNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- 6ctaa8 3-G2Document5 pages6ctaa8 3-G2Anas BasarahNo ratings yet

- Product Change Notice 45xx MKII June 19Document2 pagesProduct Change Notice 45xx MKII June 19Anas BasarahNo ratings yet

- Nta855 G4Document5 pagesNta855 G4Anas BasarahNo ratings yet

- PDF - Circutor - Self Reclosing Overcurrent Earth Leakage Protection - 11644 492317.htmlDocument2 pagesPDF - Circutor - Self Reclosing Overcurrent Earth Leakage Protection - 11644 492317.htmlAnas BasarahNo ratings yet

- Masterpact NT RETURN Masterpact NW RETURN NS1600b... 3200 RETURN NS630b... 1600 RETURN NSX100... 250 RETURN NSX400... 630 54444Document1 pageMasterpact NT RETURN Masterpact NW RETURN NS1600b... 3200 RETURN NS630b... 1600 RETURN NSX100... 250 RETURN NSX400... 630 54444Anas BasarahNo ratings yet

- Masterpact NW 48608Document1 pageMasterpact NW 48608Anas BasarahNo ratings yet

- Masterpact NW 48599Document1 pageMasterpact NW 48599Anas BasarahNo ratings yet

- DSE 3110 SymbolsDocument1 pageDSE 3110 SymbolsAnas BasarahNo ratings yet

- Masterpact NT RETURN NS630b... 1600 33648Document1 pageMasterpact NT RETURN NS630b... 1600 33648Anas BasarahNo ratings yet

- Masterpact NT RETURN Masterpact NW RETURN NS630b... 1600 33170Document1 pageMasterpact NT RETURN Masterpact NW RETURN NS630b... 1600 33170Anas BasarahNo ratings yet

- NH FuseDocument1 pageNH FuseAnas BasarahNo ratings yet

- DSEServicetool Software ManualDocument16 pagesDSEServicetool Software ManualAnas BasarahNo ratings yet

- Dse43xx Installation InstructionsDocument2 pagesDse43xx Installation InstructionsAnas BasarahNo ratings yet

- ShieldsysDocument2 pagesShieldsysAnas BasarahNo ratings yet

- DSE 710-720 Data SheetDocument2 pagesDSE 710-720 Data SheetAnas BasarahNo ratings yet

- EasyLogic PM1000 Series - METSEDM6200Document3 pagesEasyLogic PM1000 Series - METSEDM6200Anas BasarahNo ratings yet

- Sample MakerDocument2 pagesSample MakerAnas BasarahNo ratings yet

- Product 13215Document3 pagesProduct 13215Anas BasarahNo ratings yet

- Re17Ramu: Product DatasheetDocument4 pagesRe17Ramu: Product DatasheetAnas BasarahNo ratings yet

- HCI4EDocument8 pagesHCI4EAnas BasarahNo ratings yet

- LG22FDDocument1 pageLG22FDAnas BasarahNo ratings yet

- TC220TDocument4 pagesTC220TAnas BasarahNo ratings yet

- 1503544774Document5 pages1503544774Anas BasarahNo ratings yet

- SC27G900D2 DatasheetDocument3 pagesSC27G900D2 DatasheetAnas BasarahNo ratings yet

- Load Sharer: Application FunctionDocument4 pagesLoad Sharer: Application FunctionAnas BasarahNo ratings yet

- Fi Computermagic 03Document2 pagesFi Computermagic 03Anas BasarahNo ratings yet

- DSE 7210 - Installation - InstructionsDocument2 pagesDSE 7210 - Installation - InstructionsAnas BasarahNo ratings yet

- MINCO F2 Engine Controller Operating Instruction ManualDocument10 pagesMINCO F2 Engine Controller Operating Instruction ManualAnas BasarahNo ratings yet

- Lightning Arrester Lightningcontroller MC 125-B/Npe: Operation and Fields of ApplicationDocument2 pagesLightning Arrester Lightningcontroller MC 125-B/Npe: Operation and Fields of ApplicationAnas BasarahNo ratings yet

- Dse 7110-20 UkDocument4 pagesDse 7110-20 UkAnas BasarahNo ratings yet

- Learn Green Building Compliance and Energy Simulation SoftwareDocument3 pagesLearn Green Building Compliance and Energy Simulation SoftwareSMEC TimetableNo ratings yet

- Selwico CS4000 User ManualDocument46 pagesSelwico CS4000 User Manualcostica100% (4)

- FPi-2300 Brochure 071913 PDFDocument4 pagesFPi-2300 Brochure 071913 PDFLudi AdeNo ratings yet

- Pharma 4Document5 pagesPharma 4Uday kumarNo ratings yet

- 281 Info PopDocument2 pages281 Info PopLuis David GarcíaNo ratings yet

- Saep 334Document48 pagesSaep 334jubairNo ratings yet

- SER Eference UideDocument26 pagesSER Eference Uide曾龙No ratings yet

- COMPREHENSION PASSAGE 2022 3rd AND 4THDocument4 pagesCOMPREHENSION PASSAGE 2022 3rd AND 4THSumit RajkumarNo ratings yet

- Forms Review 4956119 303913649Document12 pagesForms Review 4956119 303913649yohoho97531No ratings yet

- DS TALEXX C003 enDocument2 pagesDS TALEXX C003 enPhilNo ratings yet

- GDTP Certification Application FormDocument4 pagesGDTP Certification Application FormNatarajan RamamoorthyNo ratings yet

- Transmittal: Design Document Transmittal Document No Rev Titles StatusDocument2 pagesTransmittal: Design Document Transmittal Document No Rev Titles Statushasan shahriarNo ratings yet

- Galileo 616 Ds PDFDocument4 pagesGalileo 616 Ds PDFCodinasound CaNo ratings yet

- Liferay PresentationDocument33 pagesLiferay Presentationshabbir_ahmed5023No ratings yet

- Lecture 23: Port and Vulnerability Scanning, Packet Sniffing, Intrusion Detection, and Penetration TestingDocument71 pagesLecture 23: Port and Vulnerability Scanning, Packet Sniffing, Intrusion Detection, and Penetration TestingUnsharp DevNo ratings yet

- Gla University (Mathura) Bca 2nd Semester Operating System PDFDocument156 pagesGla University (Mathura) Bca 2nd Semester Operating System PDFtoxicNo ratings yet

- FADEC PresentationDocument76 pagesFADEC PresentationWeerapat Siri100% (1)

- HUAWEI B311-520 Product Description - (V100R001 - 01, English)Document27 pagesHUAWEI B311-520 Product Description - (V100R001 - 01, English)lsalazmaNo ratings yet

- D. A and B TrueDocument2 pagesD. A and B TrueAkbar FalladikaNo ratings yet

- How To Choose The Right Data VisualizationDocument18 pagesHow To Choose The Right Data VisualizationMandar GadkariNo ratings yet

- IR400 Data SheetDocument2 pagesIR400 Data SheetimranNo ratings yet

- Appendix 11 Design FMEA ChecklistDocument16 pagesAppendix 11 Design FMEA ChecklistDearRed FrankNo ratings yet

- KGEN For SAGA IN DETAILDocument9 pagesKGEN For SAGA IN DETAILKhan Abdul BasitNo ratings yet

- PFC Max-Prospect ISKRADocument2 pagesPFC Max-Prospect ISKRAedcooNo ratings yet

- Comunicador Hart Yokogawa YHC5150XDocument99 pagesComunicador Hart Yokogawa YHC5150XFrancisco Navarro BarrientosNo ratings yet

- Readme WinCC Professional V11 SP2Document52 pagesReadme WinCC Professional V11 SP2breynneroNo ratings yet

- Catalogue 2018: Magnetic Thickness Detector (MTD)Document2 pagesCatalogue 2018: Magnetic Thickness Detector (MTD)wesam tetouhaNo ratings yet

- TransactionSummary 920020060866153 051023033316Document3 pagesTransactionSummary 920020060866153 051023033316gaurav sondhiNo ratings yet