Professional Documents

Culture Documents

TDS Fastflex - Eng - Rev.14 23 07 19 1

TDS Fastflex - Eng - Rev.14 23 07 19 1

Uploaded by

Swapnil JadhavOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS Fastflex - Eng - Rev.14 23 07 19 1

TDS Fastflex - Eng - Rev.14 23 07 19 1

Uploaded by

Swapnil JadhavCopyright:

Available Formats

Dr.

Fixit Fastflex

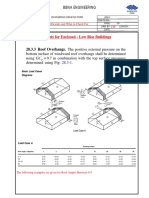

DR.FIXIT FASTFLEX

HIGH QUALITY POLYMER MODIFIED FLEXIBLE CEMENTITIOUS

WATERPROOFING MEMBRANE

Description

Dr. Fixit Fast Flex is a high elastic, waterproofing cement based material. With special

waterproofing properties, easy to use by plastering, applying by using a brush and roller or trowel.

Can be painted or overlaid. Use with waterproofing for non-toxic water tanks, can be used with

drinking water. (Passed the water quality test on toxic substances (heavy metals) of the Water

Quality Control Department) Provincial Waterworks Authority. After mixing the two parts together,

the liquid material can be applied on the desired surface. After drying, it looks like a rubber sheet. It

TECHNICAL DATA SHEET

has the property to prevent water seeping through, seamless and flexible, not cracking. Japanese

standard

Dr. Fixit Fastflex is a 2-component cement-based waterproofing material, which is powdered (fine

sand, sizing), liquid (modified acrylic polymer) and nontoxic substances, environmentally friendly -

free Volatile Organic Compound (VOC), excellent waterproofing property - no leakage up to 10 m.

hydrostatic pressure

Area of Application

Concrete foundations, basements wall and lift pits.

Swimming pools, water tanks and reservoirs.

Concealed roofs, parking decks, bathroom, toilet, kitchen, balconies and planters.

Any other concrete, cement or masonry surface subject to damage from moisture.

Rate of uses

* Theoretical consumption without allowance for loss.

Rate of uses

Kg/m2 m2/set (48 kg)

Standard

1 coats 1.10 43

2 coats 1.10 43

Total 2 coats 2.20 21

*Depending on surface conditions

Thickness

Thickness (micron)

Standard At Least At Most

1 coats 425 350 500

2 coats 425 350 500

Total 2 coats 850 700 1,000

S-PI-001 Rev.EN14 23 July, 2019 P 1/5

Dr. Fixit Fastflex

DR.FIXIT FASTFLEX

HIGH QUALITY POLYMER MODIFIED FLEXIBLE CEMENTITIOUS

WATERPROOFING MEMBRANE

Method of Application

1. Surface Preparation

Allow new concrete and masonry substrate to fully cure prior application.

All surfaces must be free from oil, grease, wax, dirt or any other form of foreign matter which

might effect adhesion.

Spalled Concrete must be sound before applied.

TECHNICAL DATA SHEET

Substrate should be reach a "Saturated Surface Dry" (SSD) condition (damp, without standing

water)

2. Mixing

Use Portland cement mechanical mixer at slow speed; add product powder part to liquid part in

a clean container until a smooth and homogenous slurry mixture is achieved.

Allow the mixed slurry to stand for 5-10 minutes for releasing air-trapped during the mixing

prior to application.

Mixing material must be use within recommend pot life.

3. Applications

Dr. Fixit Fastflex slurry can be applied by brush or roller. DO NOT dilute with water.

Recommend Coverage rate is approximately 1.1 kg./m2/coat for 1 mm. (Minimum 2 coat.).

Allow the slurry to cure for at least 15-30 min. before applying second coat. Do not leave the

first coat to dry longer than 8 hours.

For tile adhesive application on surface allow surface to cure for 3 days prior.

If first coat was cure over 8 hours, fix surface by applying 2 to 3 coats of Dr.Fixit Pidifin 2K

for desire waterproof surface thickness or fix by applying Dr.Fixit Fevimate XL tile adhesive

to act as top coat protection for Dr.Fixit Fastflex.

4. Curing

For maximum protection, allow 12 to 24 hours curing time after second coat.

Leave Dr. Fixit Fastflex at least 7 days to cure before filling or sealing water to test leaks.

S-PI-001 Rev.EN14 23 July, 2019 P 2/5

Dr. Fixit Fastflex

DR.FIXIT FASTFLEX

HIGH QUALITY POLYMER MODIFIED FLEXIBLE CEMENTITIOUS

WATERPROOFING MEMBRANE

Technical Information

Specification /

Properties Results

Standard

Mix Component (powder : liquid) Mix Ratio 1.4 : 1 by weight

Polymer Content by TGA

Polymeric substance, % 25.0

TECHNICAL DATA SHEET

ASTM D 6370

Organic substance, % 8.3

Ash, % 66.7

Proprietary Polymer by FTIR ASTM D3677 High quality modified acrylic polymer

Polymer/Cement Ratio 50-65% based on wet weight

Time of setting, hrs. ASTM C 191 41.5

Tensile Strength ASTM D 412

-as cast (Dumbbell die C)

2.63 N/mm.2

-after 2 week aging at 50 oC

3.70 N/mm.2

-72 hrs at 23oC immerse in 0.5% NaOCl

3.00 N/mm.2

-72 hrs at 23oC immerse in 1.25%

3.00 N/mm.2

NH40H

3.50 N/mm.2

-72 hrs at 23oC immerse in 3.7% HCl

Elongation at Break ASTM D 412

-as cast 152.5 %

-after 2 week aging at 50 oC 52 %

-72 hrs immerse in 0.5% NaOCl 41 %

-72 hrs immerse in 1.25% NH40H 44 %

-72 hrs immerse in 3.7% HCl 37 %

Adhesion in peel on mortar,

ASTM C 794 72.9

N/width (25mm)

Crack Bridging ASTM C 836

2 mm. width Passed

1 mm. width after 10 cycles Passed

Resistance to water penetration DIN 1048: Pt5:1991 No Water Penetration

Durometer Hardness, shore A ASTM D2240 93

Chloride Content Not detected - Chloride BS EN 480

free 0.007

(D.L < 0.01%) No Corrosion effect

Water Absorption - < 3%

Dry Film Thickness - 1000 Microns

Vibration durability test against JIS C 60068-2-59 No water leak after all test.

earthquake

Intensity level of earthquake JIS C 60068-2-59 Upper 6

Adhesion to Substrate,

ASTM D4541 1.6 N/mm2

N/mm2

Adhesion to Concrete 7 day

ASTM D4541 1.25 N/mm2

N/mm2

Immersion in Water

ASTM D4541 1.90 N/mm2

Adhesion to Concrete 7 day

S-PI-001 Rev.EN14 23 July, 2019 P 3/5

Dr. Fixit Fastflex

DR.FIXIT FASTFLEX

HIGH QUALITY POLYMER MODIFIED FLEXIBLE CEMENTITIOUS

WATERPROOFING MEMBRANE

Drying and Curing time

Substrate temperature 10 oC 25 oC 30 oC 40 oC

Surface (touch) dry, hrs. 3 1,30 1 0,45

12 6 3 2

TECHNICAL DATA SHEET

Dry to over coat, minimum, hrs.

Dried/cured for service, day 7 5 4 3

Thickness Recommend, mm

At least 0.7 mm

At most 1 mm

Drying and curing times are determined under controlled temperatures and relative

humidity below 65%, and at average of the DFT range for the product.

Surface (touch) dry: The state of drying when slight pressure with a finger does not leave an imprint or reveal

tackiness.

Dry to over coat, minimum: The recommended shortest time before the next coat can be applied.

Dried/cured for service: Minimum time before the coating can be permanently exposed to the intended

environment/medium

Packaging

48 kg/set

Powder 28 kg.

Liquid 20 kg.

Precautions & Limitations

Dr. Fixit Fastflex is not suitable for traffic area application.

Dr. Fixit Fastflex is a premeasure package, do not dilute with water or add more sand or

cement.

Dr. Fixit Fastflex material should have topcoat coating over it. Do not leave it bare to the sun

at all times.

Do not leave first coat dry longer than 8 hours.

S-PI-001 Rev.EN14 23 July, 2019 P 4/5

Dr. Fixit Fastflex

DR.FIXIT FASTFLEX

HIGH QUALITY POLYMER MODIFIED FLEXIBLE CEMENTITIOUS

WATERPROOFING MEMBRANE

Storage

12 month storage in sealed container and room temperature.

Health & Safety Precautions

TECHNICAL DATA SHEET

Non Flammable.

Avoid contact with skin and eyes. Any splashes to the skin or eyes should be washed off with

clean water.

Wear mask when mixing.

Wear protective gloves and eye protection when applied.

Disclaimer

The product information and the recommendations relating to the application and end-use of Dr.Fixit products, are based

on Dr.Fixit’s current knowledge and experience of the products when properly stored, handled and applied under normal

conditions in accordance with Dr.Fixit’s recommendations. In practice, the differences in materials, substrates and actual

site conditions are such that no warranty in respect of merchantability or of fitness for a particular purpose, nor any liability

arising out of any legal relationship whatsoever, can be inferred either from this information, or from any written

recommendations, or from any other advice offered. The user of the product must test the product’s suitability for the

intended application and purpose. Dr.Fixit reserves the right to change the properties of its products without notice, so the

company does not assume liability of any legal from this product information.

Pidilite Bamco Limited (A group company of Pidilite Industries Ltd.)

699 ModernformTower 15,17 FL.,Srinakarin Rd.,Pattanakarn, Suan Luang, Bangkok 10250, THAILAND.

T. +662 722-8535 F. +662 722-8381

Website: www.dr-fixit.co.th

E-mail: sales@pidilitebamco.com

Helpline Call +662 722 8535 #101

S-PI-001 Rev.EN14 23 July, 2019 P 5/5

You might also like

- Section PropertiesDocument50 pagesSection PropertiesSkyler PamatmatNo ratings yet

- The Empire Engineering Guide To Offshore Wind FoundationsDocument38 pagesThe Empire Engineering Guide To Offshore Wind FoundationsNam Hoai LeNo ratings yet

- TDS Pidifin 2K Eng Rev.09 23 07 19Document3 pagesTDS Pidifin 2K Eng Rev.09 23 07 19Sumit SinhaNo ratings yet

- B03 EMIX Putty Product SheetDocument3 pagesB03 EMIX Putty Product SheetAnthony Al LakissNo ratings yet

- TDS Super Latex - Eng - Rev.02 28 08 19Document3 pagesTDS Super Latex - Eng - Rev.02 28 08 19Pallavi ChoudharyNo ratings yet

- Technical Data Sheet: Epoguard EnamelDocument3 pagesTechnical Data Sheet: Epoguard Enameltrường phạmNo ratings yet

- TBI11N02-CIVIL-MPA-AEI-081 - 1 MPA Coating EpoxyDocument8 pagesTBI11N02-CIVIL-MPA-AEI-081 - 1 MPA Coating Epoxyachmaddevy setiawanNo ratings yet

- Polydek: Elastomeric, Single Component Water-Based Waterproofing MembraneDocument4 pagesPolydek: Elastomeric, Single Component Water-Based Waterproofing MembraneprasadNo ratings yet

- Protective & Marine Coatings: Heavy Duty Block FillerDocument4 pagesProtective & Marine Coatings: Heavy Duty Block FillerAna CabreraNo ratings yet

- Flexamat Spec SheetDocument5 pagesFlexamat Spec SheetJamesNo ratings yet

- Quicseal 104: Flexible Cementitious Waterproofing MembraneDocument3 pagesQuicseal 104: Flexible Cementitious Waterproofing MembraneJet ToledoNo ratings yet

- Techothane-Pu: High Build Elastomeric Bituminous Polyurethane Based Waterproofing MembraneDocument5 pagesTechothane-Pu: High Build Elastomeric Bituminous Polyurethane Based Waterproofing Membraneannayya.chandrashekar Civil EngineerNo ratings yet

- 113 DR Fixit FastflexDocument3 pages113 DR Fixit FastflexreshmitapallaNo ratings yet

- FLEXICOAT PU (I) LatestDocument3 pagesFLEXICOAT PU (I) Latestmathewsujith31No ratings yet

- TDS Nitocote EPU Saudi ArabiaDocument4 pagesTDS Nitocote EPU Saudi ArabiaShaikhRizwan100% (1)

- PDS STRATA EPOXY HT 35590 en-GB PDFDocument3 pagesPDS STRATA EPOXY HT 35590 en-GB PDFMohamed Nouzer0% (1)

- Barrier 77: Technical DataDocument4 pagesBarrier 77: Technical DatakikoNo ratings yet

- Sika Raintite: Liquid Membrane Waterproofing SystemDocument2 pagesSika Raintite: Liquid Membrane Waterproofing SystemMoatz HamedNo ratings yet

- Marathon XHBDocument5 pagesMarathon XHBakbarNo ratings yet

- PDS STRATA EPOXY MT 45520 en-GB PDFDocument2 pagesPDS STRATA EPOXY MT 45520 en-GB PDFMohamed NouzerNo ratings yet

- LFTD Panel MSDS (Updated)Document5 pagesLFTD Panel MSDS (Updated)Ernane RitaNo ratings yet

- Nitocote NT550: Flexible Protecting Coating, Based On A Hybrid Resin SystemDocument3 pagesNitocote NT550: Flexible Protecting Coating, Based On A Hybrid Resin SystemTayyab AchakzaiNo ratings yet

- DESMOFLEX TOP COΑΤ v2 ENDocument3 pagesDESMOFLEX TOP COΑΤ v2 ENprestigebuild888No ratings yet

- Technical Data: Plastic Steel 5-Minute Putty (SF)Document4 pagesTechnical Data: Plastic Steel 5-Minute Putty (SF)Hoàng DũngNo ratings yet

- Sikadur - 31 C: 2-Part Epoxy Adhesive For Sikadur - Combiflex SystemDocument4 pagesSikadur - 31 C: 2-Part Epoxy Adhesive For Sikadur - Combiflex SystemhemantrulzNo ratings yet

- Ikote CM 50X TDS (02-April-2024) V1.3Document2 pagesIkote CM 50X TDS (02-April-2024) V1.3nguyen hoang AnhNo ratings yet

- Nitocote ET402 : Coal Tar Extended Epoxy Resin CoatingDocument4 pagesNitocote ET402 : Coal Tar Extended Epoxy Resin CoatingmaninambiramNo ratings yet

- 13-Spec-Corrosion Protection System For Marine STRDocument3 pages13-Spec-Corrosion Protection System For Marine STRsunilbauchkarNo ratings yet

- E-Mix - Flowment 550 PDFDocument4 pagesE-Mix - Flowment 550 PDFngNo ratings yet

- Renderoc S: Constructive SolutionsDocument4 pagesRenderoc S: Constructive SolutionstalatzahoorNo ratings yet

- Nitocote ET402 : Constructive SolutionsDocument4 pagesNitocote ET402 : Constructive Solutionsnoto.sugiartoNo ratings yet

- PDS - Bostik NC WP - V5Document2 pagesPDS - Bostik NC WP - V5jasondouglas1810workNo ratings yet

- Fosroc Nitocote NT550: Constructive SolutionsDocument4 pagesFosroc Nitocote NT550: Constructive SolutionsVincent JavateNo ratings yet

- Belzona 1321: Product Specification SheetDocument2 pagesBelzona 1321: Product Specification Sheetmehdi kamaliNo ratings yet

- Aquaarm Spu SPL Ver 8 1Document3 pagesAquaarm Spu SPL Ver 8 1Paladi RaviNo ratings yet

- PDS Sikacrete 113 PPDocument4 pagesPDS Sikacrete 113 PPKoh HanNo ratings yet

- TD Self-LevellingDocument6 pagesTD Self-LevellingMeliany SariNo ratings yet

- iKOTE AC 40 (DEC-2023) V1.3Document2 pagesiKOTE AC 40 (DEC-2023) V1.3nguyen hoang AnhNo ratings yet

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- 63db379fced6e DF Fastflex Brochure PDFDocument4 pages63db379fced6e DF Fastflex Brochure PDFEr Shashank SharmaNo ratings yet

- 112 DR Fixit Pidifin 2kDocument3 pages112 DR Fixit Pidifin 2kreshmitapallaNo ratings yet

- TDS Contite FCW 010 Jul11Document4 pagesTDS Contite FCW 010 Jul11พศิน จันทะสิมNo ratings yet

- (Sika) Sikacem 133 Gunite Safety Data SheetDocument5 pages(Sika) Sikacem 133 Gunite Safety Data Sheet_at_to_No ratings yet

- Sikalastic®-632: Product Data SheetDocument5 pagesSikalastic®-632: Product Data SheetShanaei MiskinNo ratings yet

- Urethane Coating 165 PWDocument3 pagesUrethane Coating 165 PWANIBALLOPEZVEGANo ratings yet

- Acrylic WaterProofing Liquide TDSDocument3 pagesAcrylic WaterProofing Liquide TDSMohamed MagdiNo ratings yet

- 4.07 Fast Roof Pu 570Document4 pages4.07 Fast Roof Pu 570Nadeem Ahmed MirzaNo ratings yet

- Nitocote EpuDocument4 pagesNitocote EpumohamedbossilyNo ratings yet

- Chemflake Special: Technical Data SheetDocument5 pagesChemflake Special: Technical Data SheetSalmanNo ratings yet

- Fosroc Conbextra HF TDSDocument4 pagesFosroc Conbextra HF TDSRicky JayaNo ratings yet

- Kirloskar Corrocoat GFC CaseStudyDocument35 pagesKirloskar Corrocoat GFC CaseStudyAbhishek SharmaNo ratings yet

- MORTH 1600 2 Acrylic Elastomeric CoatingDocument4 pagesMORTH 1600 2 Acrylic Elastomeric CoatingRameshNo ratings yet

- SaueResisen-EPOXY EXPANSION JOINT COMPOUNDSDocument2 pagesSaueResisen-EPOXY EXPANSION JOINT COMPOUNDSSrihariKyatamNo ratings yet

- Nitocote PE135 : Constructive SolutionsDocument2 pagesNitocote PE135 : Constructive SolutionsMPS KALIBARUNo ratings yet

- TDS Renderoc TG Saudi ArabiaDocument4 pagesTDS Renderoc TG Saudi Arabiaumn_mlkNo ratings yet

- Conbextra EP120 TDS PDFDocument3 pagesConbextra EP120 TDS PDFzulfikarNo ratings yet

- E-Mix - EASI Screed PDFDocument3 pagesE-Mix - EASI Screed PDFngNo ratings yet

- IsmailiyahDocument3 pagesIsmailiyahanumfatimah313No ratings yet

- Marathon: Technical Data SheetDocument5 pagesMarathon: Technical Data SheetOkinawa TeakNo ratings yet

- Flexcrete 400: Epoxy Polysulfide Elastomeric Coating For Potable Water TanksDocument2 pagesFlexcrete 400: Epoxy Polysulfide Elastomeric Coating For Potable Water TanksSuresh YadavNo ratings yet

- Hempaflor Decorate 600Document2 pagesHempaflor Decorate 600Riian Apriansyah100% (1)

- 1 OnlineDocument12 pages1 OnlineSurajNo ratings yet

- Introduction & Free Body Diagrams: Luke Macdonald, Masc., P.Eng. Luke - Macdonald@Smu - CaDocument7 pagesIntroduction & Free Body Diagrams: Luke Macdonald, Masc., P.Eng. Luke - Macdonald@Smu - CaasifNo ratings yet

- 26 Units PDFDocument9 pages26 Units PDFMilsonNo ratings yet

- Rheology Unit 2Document69 pagesRheology Unit 2Shivani SinghNo ratings yet

- Ae6007 FafDocument3 pagesAe6007 FafYokesvaran K100% (1)

- Canopy Wind Coefficients - What To Check For ASCEDocument4 pagesCanopy Wind Coefficients - What To Check For ASCEAngelica OrnelasNo ratings yet

- Applied Thermal Engineering: J. Blondeau, R. Kock, J. Mertens, A.J. Eley, L. HolubDocument6 pagesApplied Thermal Engineering: J. Blondeau, R. Kock, J. Mertens, A.J. Eley, L. HolubArdhi Angga SNo ratings yet

- Department of Education: Republic of The PhilippinesDocument1 pageDepartment of Education: Republic of The PhilippinesJari CruzNo ratings yet

- MTH 30105/MTH 30605 Mathematics: TOPIC 4 - Integration - 2Document32 pagesMTH 30105/MTH 30605 Mathematics: TOPIC 4 - Integration - 2MishaalanNo ratings yet

- Richter Fouad - Guidelines For Thermography in Architecture and Civil Engineering Theory Application Areas Practical Implementation PDFDocument185 pagesRichter Fouad - Guidelines For Thermography in Architecture and Civil Engineering Theory Application Areas Practical Implementation PDFTomi Gánn100% (2)

- Mud ViscosityDocument5 pagesMud Viscosityhindn162No ratings yet

- Direct Current Machines + Summarised NotesDocument21 pagesDirect Current Machines + Summarised NotesElisha NissiNo ratings yet

- 12 Reflections PDFDocument4 pages12 Reflections PDFCleofe SobiacoNo ratings yet

- Instruction Manual: RA 0160 D, RA 0202 D, RA 0250 D, RA 0302 DDocument28 pagesInstruction Manual: RA 0160 D, RA 0202 D, RA 0250 D, RA 0302 DYunisNo ratings yet

- Product Data Sheet 400 400vp Contacting Conductivity Sensors Rosemount en 73038 PDFDocument16 pagesProduct Data Sheet 400 400vp Contacting Conductivity Sensors Rosemount en 73038 PDFsaifurrahman binyulismanNo ratings yet

- Air Conditioning System DesignDocument39 pagesAir Conditioning System DesignWaheed MidoNo ratings yet

- 03 Uppercat Free Upcat KeyDocument40 pages03 Uppercat Free Upcat Keyadrian suppNo ratings yet

- Energy Transfers Versus Energy Transformations: Newton's Cradle Is A Device That Combines Both Energy Transfers andDocument2 pagesEnergy Transfers Versus Energy Transformations: Newton's Cradle Is A Device That Combines Both Energy Transfers andmarteylNo ratings yet

- Improving Color Sensor Lux Accuracy: Application NoteDocument8 pagesImproving Color Sensor Lux Accuracy: Application NoteChen WinnieNo ratings yet

- This Study Resource Was: Nature's Numbers (Chapter 1 - 4)Document2 pagesThis Study Resource Was: Nature's Numbers (Chapter 1 - 4)Mico SantosNo ratings yet

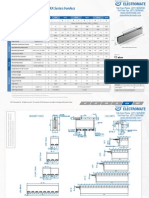

- Tecnotion UXA Series SpecsheetDocument2 pagesTecnotion UXA Series SpecsheetElectromateNo ratings yet

- Energy Healing Through Reiki - Distance Healing Specialist HandbookDocument99 pagesEnergy Healing Through Reiki - Distance Healing Specialist HandbookCLAUDIA100% (1)

- MCQ Unit I PHY110Document27 pagesMCQ Unit I PHY110GaganNo ratings yet

- 275 Instruction ManualDocument56 pages275 Instruction Manualsanjith bugwandeenNo ratings yet

- Pinch Class 1Document181 pagesPinch Class 1Bryan Badillo RamosNo ratings yet

- 5250286Document309 pages5250286james-hallakNo ratings yet

- Reliability of BiodexDocument13 pagesReliability of BiodexMattNo ratings yet

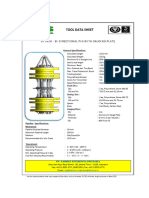

- B.6. 3. E. BiDi Pig With Gauging PlateDocument2 pagesB.6. 3. E. BiDi Pig With Gauging PlateAndre SuryadiNo ratings yet