Professional Documents

Culture Documents

Unit 5

Unit 5

Uploaded by

ranga0 ratings0% found this document useful (0 votes)

35 views59 pagesThe document discusses sludge management in wastewater treatment. It describes the different types of sludge generated - primary, secondary, and tertiary sludge - and their characteristics. The objectives of sludge treatment are to reduce volume and stabilize the organic content through processes like thickening, digestion, dewatering, and drying. Anaerobic digestion is commonly used for sludge stabilization, which breaks down organics into methane and carbon dioxide through a multi-step microbial process. Proper operation parameters and systems are required for effective anaerobic digestion of sludge.

Original Description:

Original Title

unit 5

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses sludge management in wastewater treatment. It describes the different types of sludge generated - primary, secondary, and tertiary sludge - and their characteristics. The objectives of sludge treatment are to reduce volume and stabilize the organic content through processes like thickening, digestion, dewatering, and drying. Anaerobic digestion is commonly used for sludge stabilization, which breaks down organics into methane and carbon dioxide through a multi-step microbial process. Proper operation parameters and systems are required for effective anaerobic digestion of sludge.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

35 views59 pagesUnit 5

Unit 5

Uploaded by

rangaThe document discusses sludge management in wastewater treatment. It describes the different types of sludge generated - primary, secondary, and tertiary sludge - and their characteristics. The objectives of sludge treatment are to reduce volume and stabilize the organic content through processes like thickening, digestion, dewatering, and drying. Anaerobic digestion is commonly used for sludge stabilization, which breaks down organics into methane and carbon dioxide through a multi-step microbial process. Proper operation parameters and systems are required for effective anaerobic digestion of sludge.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 59

Sludge Management

• The term sludge refers to the solids that are

settled and separated during wastewater

treatment.

• It is necessary to treat properly or dispose the

sludge generated during the various stages of

wastewater treatment like primary

sedimentation, secondary sedimentation and

sludge generated from advanced (tertiary)

treatment, if any.

Sludge Management

• The quantity of sludge generated depends

upon the degree of treatment or quality of

treated effluent required

i.e., higher the degree of wastewater

treatment, the larger the quantity of sludge to

be treated and handled

Sludge Management

• Because of strict rules and regulations

involving the handling and disposal of sludge,

it has become necessary to reduce the volume

of sludge in order to reduce the operating

costs (approximately 50% of the plant cost) of

treatment plants.

• Hence a properly designed and efficiently

operated sludge processing and disposal

system is essential to the overall success of

the wastewater treatment plant.

Sludge

characterization

• The sludge generated during the wastewater

treatment can be classified into three

categories:

1. Primary Sludge

2. Secondary Sludge

3. Tertiary Sludge

Characteristics of Primary

Sludge

• Sludge settled in primary settling tanks comes

under this category which contains

- 3% to 7% solids out of which approximately 60%

to 80% are organic.

• Primary sludge solids are usually gray in color,

slimy, fairly coarse, and with highly obnoxious

odors.

• This type of sludge can be digested readily by

aerobic or anaerobic bacteria under favorable

operating conditions.

Characteristics of Secondary

Sludge

• This type of sludge from secondary settling tanks

has commonly a brownish, flocculent appearance

and an earthy odor.

• It consists mainly of microorganism containing

75% to 90% organic fraction and remaining inert

materials.

• The organic matter may be assumed to have a

specific gravity of 1.01 to 1.05, depending on its

source, whereas the inorganic particles have high

a specific gravity of about 2.5.

Characteristics of Tertiary

Sludge

• The nature of sludge from the tertiary

(advanced) treatment process depends on the

unit process followed like membrane

processes or chemical methods, etc.

• Chemical sludge from phosphorus removal is

difficult to handle and treat.

• Tertiary sludge from biological nitrification

and denitrification is similar to waste

activated sludge.

Objectives of Sludge

Treatment

Sludge is stabilized to

(i)Reduce the organic content

ii)Reduce pathogens

ii)Eliminate odours

v)Reduce, or eliminate the potential for

decomposition

v)Improve dewatering characteristics of the sludge to

reduce volume for disposal.

vi)Safe and aesthetically acceptable disposal of sludge.

ii)By product of methane is used as fuel & and helps in

controlling temperature and also generates power.

Sludge

• The reduction in Treatment

volume of the sludge can be

achieved by

-thickening,

-dewatering and

-drying; and

• Stabilization of organic matter can be obtained

by employing

-digestion (aerobic or anaerobic),

- incineration,

- composting,

- heat treatment,

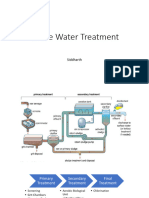

Flow sheet for biological

sludge treatment

Sludge

• Sludge thickeningThickening

or dewatering is adopted for

reducing the volume of sludge and increasing the

solid contents. This will help in following:

(i) increasing the loading on the digester, requiring

lesser digester volume,

(ii) increase feed solids concentration to vacuum

filters,

(iii) economize transport and handling cost of sludge

within the plant and final disposal,

(iv) minimize land required and handling cost for

final disposal of the digested sludge on land, and

Sludge

Thickening

• In sludge thickeners, greater amount of

water is removed from the sludge.

• The thickening of the sludge can be achieved

by 3 types of thickening units

1. Gravity thickener,

2. Floatation thickener

3. Centrifugal thickener

Gravity

thickener

• It consists of a small circular opening tank, like

sedimentation tank except that it is deeper to

accommodate a greater volume of sludge and

has a heavier raking mechanism.

• Slowly rotating rake mechanism, like deep truss

are provided to stir the sludge gently, opening

up channels for water to escape, thereby

promoting densification of sludge.

Anaerobic Sludge

Digestion

• In anaerobic digestion process the organic

material, in mixture of primary settled sludge

and biological sludge from secondary clarifier,

is converted to CH4 and CO2 under anaerobic

conditions.

• This is carried out in an air tight reactor in

absence of oxygen.

• Most microbes used in this digestion are

anaerobes or facultative type.

Anaerobic Sludge

Digestion

• During oxidation of organic matter

anaerobically following reaction occurs

• Organic matter CO2 + CH4+

(Anaerobic bacteria)

New cell + energy for cells + Other products

(H2S, H2, N2 etc.)

The process of anaerobic sludge

digestion

The process of anaerobic sludge

digestion

• The breakdown of three major organic matters

is shown below:

• Carbohydrates Simple sugarsAlcohols,

aldehydes Organic acids

•Proteins Amino acids Organic acids + NH3

•Fats and oils Organic acids

• Organic acids CO2 + CH4 + H2S, H2, N2 etc.

in traces (55-75%) (35-45%)

Anaerobic sludge

digestion

• The first group of microorganisms hydrolyzes the

complex organic substances to soluble end

products and is called as hydrolytic bacteria.

• The second group of microorganisms called

acidogenic bacteria converts the product of first

group of bacteria into simple end product

primarily VFA and alcohols.

• The third group called methanogenic bacteria

converts the produced acid by the second group

into methane and carbon dioxide.

Anaerobic sludge

• Alkalinity

digestion

present in the reactor should be

sufficient for proper functioning of the digester to

maintain the pH between 6.5 to 8.0.

• Temperature has got tremendous effect in the

functioning of a digester.

• It has been established that two types of

bacteria, mesophilic (20 to 40oC) and

thermophilic (45 to 65oC) are responsible for

biodegradation.

• Therefore, the digester can be operated either at

mesophilic or thermophilic temperature range.

Anaerobic Digestion Operating

• Temperature Parameters

– Optimum 98oF (35oC)

– General Operating Range 35 to 65oC

• pH

– Optimum 7.0 to 7.1

– General Limits 6.7 to 7.4

• Sludge Loading

– Recommended loadings for anaerobic digesters

that are mixed and heated are 3.2-7.2 kg

VS/m3/day.

– However loading rates of (0.5-0.6 kg VS/m3/day)

Anaerobic Digestion Operating

• Gas CompositionParameters

– Carbon Dioxide 65 to 69 percent

– Methane 31 to 35 percent

– Hydrogen Sulfide Trace

• Volatile Acids Concentration (as Acetic

Acid)

– Normal Operation 200 to 800 mg/L

– Maximum Approximately 2,000 mg/L

• Alkalinity Concentrations as CaCO3

– Normal Operation 2,000 to 3,500 mg/L

Products of Digestion

1. Gases

Methane (CH4) Carbon

Dioxide (CO2)

2. Scum

Lighter Solids

3. Supernatant

Liquid Removed

4. Digested Sludge

“Stabilized”

Anaerobic Digestion

• Single-Stage DigesterSystems

with a Floating Cover

(Standard Rate)

– Contents Unmixed and Unheated

– Td = 30 to 60 days

• Single-Stage High Rate Digestion System

– Contents Mixed and Heated

– Td = 15 days or less

• Two-Stage Anaerobic Digestion System

– Second Stage Can Function as a Solids

Separation Phase

– Additional Digestion Can also occur in this

Second Stage

Conventional Standard Rate Anaerobic

Digester

High Rate, Continuous-Flow, Stirred Tank

Single Stage Digester

Two-Stage Anaerobic

Digester

Tank

• Cylindrical: 20~125 ftDesign

in diameter, > 25 ft deep,

conical bottom with a min. slope of 1 vertical to 4

horizontal; a “waffle” shape bottom to minimize grit

accumulation and to reduce the need for digester

cleaning

• Rectangular: rarely used due to poor mixing and dead

zones

• Egg-shape: eliminate cleaning, better mixing, better

control of the scum layer, and smaller land area

requirements; steel or reinforced concrete; due to

better mixing devices, the use may not be justified.

• Provide ways of cleaning out grit and scum

• Door at ground level

Biogas

Recovery

• Guidelines for amount of biogas produced per

amount of organic material digested

• Sewage sludge: 0.75 – 1.12 Nm3 per kg of volatile

solids destroyed (typical value: 0.95 Nm3/kg)

• Organic solid waste:

– 0.38 – 0.42 Nm3 per kg of volatile solids added

(at a retention time of 14 days) for single- stage

processes

–Up to 0.6 Nm3 per kg of VS added for two- stage

processes

Biogas composition

• The methane fraction produced in the biogas varies

with the input material; as a rule of thumb:

• carbohydrates: approx. 50 vol.-% methane

• fats: approx. 70 vol.-% methane

• proteins: approx. 84 vol.-% methane

Compound Vol %

Methane 50-75

Carbon dioxide 25-50

Nitrogen <7

Oxygen <2

Hydrogen sulfide <1

Ammonia <1

Sludge Conditioning

• Sludge is conditioned to improve its dewatering

characteristics.

•Two methods are commonly used for sludge conditioning

(i) addition of chemicals and (ii) heat treatment.

•Chemical conditioning results in coagulation of the

solids and release of the absorbed water.

•Conditioning is used in advance of vacuum filtration

and centrifugation.

•Chemicals used include ferric chloride, lime, alum

and organic polymers.

•The chemical dosage required is determined in the

laboratory test.

•The sludgewhich is difficult to dewater requires

Sludge

Dewatering

• The digested sludge is applied on the sludge drying

beds, the water content of the sludge can be reduced

to around 70%.

• Sludge drying beds require large land area (nearly

40% of the total area required for sewage treatment

plant), hence at the places where land is not available

other alternatives such as, mechanical dewatering on

vacuum filters, filter press or centrifuge followed by

heat drying or incineration could be used after sludge

conditioning.

• In India, most of the parts of the country there is

favourable climate for open sludge drying, hence

sludge drying beds are preferred as an economical

Sludge Drying Beds

• This is used where land available is adequate and

the dried sludge is used for soil conditioning.

• The sludge is applied on the bed of sand, which is

supported on gravel.

• Major portion of the liquid drains off in the first

few hours after which drying occur due to

evaporation.

• Sludge cake shrinks, producing cracks which

further accelerate evaporation from the sludge

surface.

Sludge Drying Beds

• In dry region generally the sludge will get

dried within two weeks.

• The drying period will depend on sunshine,

rainfall, wind velocity, and relative humidity,

apart from sludge characteristics.

• Under adverse weather condition, it may take

up to four weeks.

• The sludge drying beds should be located at

least 100 m away from houses to avoid

smelling problem.

Design Criteria for Sludge Drying Beds

Area of beds:

•The land requirement can be substantial with the value of

0.1 to 0.25 m2/capita for anaerobically digested sludge.

•Generally the cycle time is up to 2 weeks for warmer

climate and 3 to 6 weeks.

The specifications for preparation of sludge drying beds are

as follows:

Underdrains:

•It is made from the open joined vitrified clay pipe or tiles of

at least 10 cm diameter.

•Pipe should not be laid more than 6 m apart from each

other.

•Arrangement should be made to return the drained water

Design Criteria for Sludge Drying Beds

Gravel:

•Gravel covers the under-drainage system.

•Graded gravel is placed around the under drains

in layers up to 30 cm, with minimum of 15 cm

above under drains (Figure 22.7).

•At least top 3 cm layer of gravel is of 3 to 6 mm

size.

Sand:

•Sand of effective size 0.5 to 0.75 mm and

uniformity coefficient not greater than 4 is used.

•The depth of the sand may vary from 20 to 30

Figure 22.7 Sectional elevation of

sludge drying beds

Design Criteria for Sludge Drying Beds

Dimensions:

•Sludge drying beds are commonly 6 to 8 m wide and

30 m long. With the bed slope of 0.5%.

Sludge Inlet:

•Pipe of minimum 20 cm diameter should be used for

sludge inlet pipe.

•This pipe should discharge sludge at minimum height

of 0.3 m above the sand bed.

Removal of Sludge:

•Dried sludge cake is removed by shovel or forks when

the moisture content is less than 70%.

•After removal of the dried sludge the sand bed is

prepared by leveling for next cycle of sludge

application.

DISPOSAL OF DIGESTED

SLUDGE

• Spreading on farm land

• Dumping ( in abandoned quarries)

• Land filling ( Sanitary)

• Sludge lagooning

• Composting

• Disposing in Inland water bodies or Sea.

Windrow Composting

Advances in Sludge Treatment and

• Sludge Thickeningdisposal

-Floatation thickener

-Centrifugal thickener

• Stabilization of organic matter can be

obtained by employing

-incineration,

-composting,

-heat treatment,

-chlorine oxidation or lime stabilization

• Dewatering

- Vacuum, pressure filters, or centrifuge

methods for removing water from the

solids.

Thank you!

You might also like

- Neom - Ncec - Esia - Airport West Solar PV Plant - Rev00!24!09-2022Document319 pagesNeom - Ncec - Esia - Airport West Solar PV Plant - Rev00!24!09-2022Mohamed Ali SalahNo ratings yet

- Eat 356/4 - Wastewater Engineering: Sludge Removal ManagementDocument33 pagesEat 356/4 - Wastewater Engineering: Sludge Removal Managementabas ibrahimNo ratings yet

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationFrom EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationRating: 3 out of 5 stars3/5 (1)

- Current Industrial Wastewater Treatment Processes: Dairy IndustriesDocument36 pagesCurrent Industrial Wastewater Treatment Processes: Dairy IndustriesMarlen TrejoNo ratings yet

- Biological Sludge Stabilization or DigestionDocument25 pagesBiological Sludge Stabilization or DigestionDr. Akepati Sivarami Reddy100% (1)

- Chapter 8.1Document14 pagesChapter 8.1Aakash MandalNo ratings yet

- Sludge Treatment & DisposalDocument78 pagesSludge Treatment & DisposalAirish Navera67% (3)

- Sludge ManagementDocument37 pagesSludge ManagementcivilkudumbamNo ratings yet

- Sludge TreatmentDocument17 pagesSludge TreatmentusmansherdinNo ratings yet

- MidsemDocument30 pagesMidsemSowmya TuragaNo ratings yet

- D. WWTP SecondaryDocument37 pagesD. WWTP Secondaryzairulh7No ratings yet

- Technical Skills Workshop On Effluent Treatment Plant At: HindustanDocument33 pagesTechnical Skills Workshop On Effluent Treatment Plant At: HindustanDuggineni RamakrishnaNo ratings yet

- Lecture 12 - Waste Water Treatment MethodsDocument41 pagesLecture 12 - Waste Water Treatment MethodsUsman KhalidNo ratings yet

- Domestic Waste and Waste TreatmentDocument42 pagesDomestic Waste and Waste TreatmenterhanzorerNo ratings yet

- Practical Thoery Sludge Treatment-P+TDocument20 pagesPractical Thoery Sludge Treatment-P+TsarfaNo ratings yet

- Waste Water TreatmentDocument17 pagesWaste Water TreatmentSOURABH GANGWARNo ratings yet

- Treatment Processes: ScreensDocument5 pagesTreatment Processes: ScreensSajil KrishnaNo ratings yet

- Physical, Chemical & Biological: Design of Facilities For Treatment of Waste WaterDocument118 pagesPhysical, Chemical & Biological: Design of Facilities For Treatment of Waste WaterAseem Vivek Masih100% (1)

- Lecture 1Document33 pagesLecture 1mahaks070No ratings yet

- Anaerobic Sludge Digester (ASD) : Ahmad Faris Bin Mohd Napi Muhd Baktiar Bin Razali Muhd Nasrun Bin Mohd RosdiDocument46 pagesAnaerobic Sludge Digester (ASD) : Ahmad Faris Bin Mohd Napi Muhd Baktiar Bin Razali Muhd Nasrun Bin Mohd RosdiAhmad FarisNo ratings yet

- WWTPPT 161203034016Document30 pagesWWTPPT 161203034016Lavish100% (1)

- L7-Sewage TreatmentF - For SpectrumDocument58 pagesL7-Sewage TreatmentF - For SpectrumWAN NURULAIN ARIBAH BINTI WAN HASSANNo ratings yet

- Unit 4 Distillery Industry Waste and Its TreatmentDocument21 pagesUnit 4 Distillery Industry Waste and Its TreatmentKhalilNo ratings yet

- Chapter 4b - Wastewater Treatment 2Document105 pagesChapter 4b - Wastewater Treatment 2Mazliah Zainal AbidinNo ratings yet

- Waste Water EngineeringDocument12 pagesWaste Water Engineeringsomeshshinde8855No ratings yet

- Lecture 6 - Waste Water Treatment MethodsDocument45 pagesLecture 6 - Waste Water Treatment MethodsHamza RiazNo ratings yet

- Effluent Treatment: Dr. Mayank Chaudhary Assistant Professor Department of Biotechnology MMEC, MM (DU), Mullana-AmbalaDocument13 pagesEffluent Treatment: Dr. Mayank Chaudhary Assistant Professor Department of Biotechnology MMEC, MM (DU), Mullana-AmbalaDr. Mayank ChaudharyNo ratings yet

- Biological Treatment Process: By, Adarsh SDocument60 pagesBiological Treatment Process: By, Adarsh Sadarsh sNo ratings yet

- Treatment: - Water and Waste WaterDocument32 pagesTreatment: - Water and Waste WaterNaresh ButaniNo ratings yet

- Physical, Chemical & Biological: Design of Facilities For Treatment of Waste WaterDocument118 pagesPhysical, Chemical & Biological: Design of Facilities For Treatment of Waste WaterAyahKenzieNo ratings yet

- Bioreactors For Wastewater TreatmentDocument40 pagesBioreactors For Wastewater TreatmentPatricia Jayshree Samuel JacobNo ratings yet

- Waste Water TreatmentDocument44 pagesWaste Water TreatmentSangeethika Madubashini T. Hettige100% (1)

- Slaughterhouse Waste Water TreatmentDocument16 pagesSlaughterhouse Waste Water TreatmentAleem Ahmed100% (1)

- Lectuer 15Document29 pagesLectuer 15deekshupapareddyNo ratings yet

- CHT 303 Module 3 To S5Document144 pagesCHT 303 Module 3 To S5jonasNo ratings yet

- Garbage RepDocument4 pagesGarbage RepNeerja HsNo ratings yet

- ETP - Basic - 01.08.2019Document31 pagesETP - Basic - 01.08.2019Hardik ShahNo ratings yet

- Sludge From Sewage Treatment Plants Agricultural Waste Animal ExcrementsDocument19 pagesSludge From Sewage Treatment Plants Agricultural Waste Animal ExcrementsAnas AsgharNo ratings yet

- Physical Unit OperationsDocument45 pagesPhysical Unit OperationsSeHa Hassan86% (7)

- Water TreamentDocument74 pagesWater TreamentCindy JavaNo ratings yet

- SEAA2922 Wastewater Engineering: Sludge Treatment and DisposalDocument28 pagesSEAA2922 Wastewater Engineering: Sludge Treatment and DisposalTzipporahNo ratings yet

- Biogas Reactors: (Anaerobic Digester)Document24 pagesBiogas Reactors: (Anaerobic Digester)Maham AzamNo ratings yet

- Sludge Managment 2 RJDDocument34 pagesSludge Managment 2 RJDiyi2010No ratings yet

- Lecture 7 - Class-Biomass Energy Conversion Technologies and Processes - Anaerobic DigestionDocument51 pagesLecture 7 - Class-Biomass Energy Conversion Technologies and Processes - Anaerobic DigestionBenard KalamboNo ratings yet

- Ecofriendly Methods of Pre Treatment Textile ProcessingDocument41 pagesEcofriendly Methods of Pre Treatment Textile ProcessingNikithaaNo ratings yet

- CHAPTER 2 - Wastewater Treatment 2Document145 pagesCHAPTER 2 - Wastewater Treatment 2PMNo ratings yet

- Disposal and Treatment of Sewagfe Unit-6Document43 pagesDisposal and Treatment of Sewagfe Unit-6Subhashish .DeyNo ratings yet

- Inorganic Solids: Coarser OrganicDocument13 pagesInorganic Solids: Coarser OrganicSemNo ratings yet

- Wastewater ExamDocument9 pagesWastewater ExamSanti PoNo ratings yet

- Industrial Wastewater Treatment-DisposalDocument37 pagesIndustrial Wastewater Treatment-DisposalSajedur Rahman SetuNo ratings yet

- I. Characteristics of WastewaterDocument59 pagesI. Characteristics of WastewaterEljay VinsonNo ratings yet

- Unit 2Document95 pagesUnit 2rangaNo ratings yet

- Sludge Management Fog Management Land Discharge of WastewaterDocument18 pagesSludge Management Fog Management Land Discharge of WastewaterNeil RyanNo ratings yet

- Anaerobic Treatment Systems Technical DesignDocument64 pagesAnaerobic Treatment Systems Technical DesignJizzlmanizzlNo ratings yet

- Biofilter DecisionsDocument23 pagesBiofilter DecisionsBokJrNo ratings yet

- Environmental Biotechnology3bDocument94 pagesEnvironmental Biotechnology3bFarrukh ZamanNo ratings yet

- Physical, Chemical & Biological: Design of Facilities For Treatment of Waste WaterDocument118 pagesPhysical, Chemical & Biological: Design of Facilities For Treatment of Waste Waterdrsalazar13No ratings yet

- Week 9-CHEM4015-CIVE4140-2023-2024Document44 pagesWeek 9-CHEM4015-CIVE4140-2023-2024Nitin RautNo ratings yet

- Sludge DigestionDocument13 pagesSludge Digestion1911O27 Prathikshaa KNo ratings yet

- Wastewater TreatmentDocument44 pagesWastewater TreatmentGiancarlo SantosNo ratings yet

- Bricks: Ce8391 Construction Materials Unit I Stones - Bricks - Concrete BlocksDocument17 pagesBricks: Ce8391 Construction Materials Unit I Stones - Bricks - Concrete BlocksrangaNo ratings yet

- Tests On BricksDocument13 pagesTests On BricksrangaNo ratings yet

- Unit 1Document250 pagesUnit 1rangaNo ratings yet

- Refractory Bricks: Ce8391 Construction MaterialsDocument22 pagesRefractory Bricks: Ce8391 Construction MaterialsrangaNo ratings yet

- Unit 2Document95 pagesUnit 2rangaNo ratings yet

- Manufacturing Process of BricksDocument26 pagesManufacturing Process of Bricksranga100% (1)

- Unit 4Document49 pagesUnit 4rangaNo ratings yet

- Surveying: Unit - 1: Session - 1: SLO - 1Document74 pagesSurveying: Unit - 1: Session - 1: SLO - 1rangaNo ratings yet

- Unit 3Document155 pagesUnit 3rangaNo ratings yet

- Air PollutionDocument11 pagesAir PollutionrangaNo ratings yet

- Non-Consumptive Water Use:: Ce 2031 Water Resources EngineeringDocument19 pagesNon-Consumptive Water Use:: Ce 2031 Water Resources EngineeringrangaNo ratings yet

- Prepared By, Shivrampachaiyappan Sankarmuniyappan: Operation of System of ReservoirsDocument22 pagesPrepared By, Shivrampachaiyappan Sankarmuniyappan: Operation of System of ReservoirsrangaNo ratings yet

- Svcet: Ce6501-Structural Analysis - Classical MethodDocument22 pagesSvcet: Ce6501-Structural Analysis - Classical MethodrangaNo ratings yet

- Basic Civil Engineering Questions and AnswersDocument18 pagesBasic Civil Engineering Questions and AnswersrangaNo ratings yet

- Nov Dec 2012 RRS - NoRestriction - NoRestrictionDocument2 pagesNov Dec 2012 RRS - NoRestriction - NoRestrictionrangaNo ratings yet

- 16CE303 - Surveying I: Unit - 3: Session - 3: SLO - 1Document6 pages16CE303 - Surveying I: Unit - 3: Session - 3: SLO - 1rangaNo ratings yet

- Theodolite TraversingDocument25 pagesTheodolite TraversingrangaNo ratings yet

- 16CE303 - Surveying I: Unit - 3: Session - 2: SLO - 2Document8 pages16CE303 - Surveying I: Unit - 3: Session - 2: SLO - 2rangaNo ratings yet

- 16CE303 - Surveying I: Unit - 3: Session - 1: SLO - 1Document19 pages16CE303 - Surveying I: Unit - 3: Session - 1: SLO - 1rangaNo ratings yet

- 16CE303 - Surveying I: Unit - 3: Session - 2: SLO - 1Document9 pages16CE303 - Surveying I: Unit - 3: Session - 2: SLO - 1rangaNo ratings yet

- Theodolite Traversing: Unit-VDocument110 pagesTheodolite Traversing: Unit-VrangaNo ratings yet

- Basic Civil Engineering Questions and AnswersDocument18 pagesBasic Civil Engineering Questions and AnswersrangaNo ratings yet

- Planning 3 DG FN-04Document28 pagesPlanning 3 DG FN-04GreenNo ratings yet

- 2023 Eng1503 - Question PaperDocument6 pages2023 Eng1503 - Question PaperAnelka AshleyNo ratings yet

- The Development of Passive Downdraught EvaporativeDocument7 pagesThe Development of Passive Downdraught Evaporative1SI17AT024 MOHAMMED AASIM ATIQNo ratings yet

- Water Resources MCQDocument25 pagesWater Resources MCQsiddesh mankar0% (1)

- gALIYAT sPRINGSDocument4 pagesgALIYAT sPRINGSbehzad afridiNo ratings yet

- What Is PlasticDocument2 pagesWhat Is PlasticJunaidahMubarakAliNo ratings yet

- Branches of ZoogeographyDocument12 pagesBranches of ZoogeographyHaris KhanNo ratings yet

- Clean Cooking Industry Snapshot: Second EditionDocument42 pagesClean Cooking Industry Snapshot: Second EditionShyam M CoutinhoNo ratings yet

- Ecocriticism (Mid)Document2 pagesEcocriticism (Mid)Saif Ur RahmanNo ratings yet

- Reasons Why We Should Care Our EnvironmentDocument2 pagesReasons Why We Should Care Our EnvironmentFatihah AdnanNo ratings yet

- CHRW Exercises 1Document6 pagesCHRW Exercises 1floramie GalarosaNo ratings yet

- Wildlife Protection Act 1972Document11 pagesWildlife Protection Act 1972ankitadbrmishraNo ratings yet

- Energy Engineering LabDocument9 pagesEnergy Engineering Labvjadhav JadhavNo ratings yet

- Sample Social Opportunity Recognition ToolDocument1 pageSample Social Opportunity Recognition ToolNicole SorianoNo ratings yet

- Passive Voice 1Document11 pagesPassive Voice 1Gian Carlo33% (3)

- PHD Course Work Syllabus GeologyDocument5 pagesPHD Course Work Syllabus Geologykpcvpkjbf100% (2)

- Safety Data Sheet: 1. Identification of The Substances/ Trade Name and CompanyDocument6 pagesSafety Data Sheet: 1. Identification of The Substances/ Trade Name and CompanymelvinkuriNo ratings yet

- Cirp Annals - Manufacturing TechnologyDocument23 pagesCirp Annals - Manufacturing TechnologyKailash C BhosaleNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument5 pagesSafety Data Sheet: 1. Product and Company Identificationkei iswandaNo ratings yet

- This Study Resource WasDocument3 pagesThis Study Resource WasNabila SedkiNo ratings yet

- SCIENCE Q1 LESSON 8 WASTE DISPOSAL. Beverly v. SantiagoDocument27 pagesSCIENCE Q1 LESSON 8 WASTE DISPOSAL. Beverly v. SantiagoAiza Tolentino-CarpioNo ratings yet

- Stormwater Drainage For Proposed Buildings ApplicationDocument3 pagesStormwater Drainage For Proposed Buildings Applicationsudip sharmaNo ratings yet

- The Return of The HuarangoDocument3 pagesThe Return of The HuarangoLiam EganNo ratings yet

- FDS Acido FosforicoDocument9 pagesFDS Acido FosforicoBlutch0No ratings yet

- Research ARDES417 JasminDocument13 pagesResearch ARDES417 JasminRata TreftNo ratings yet

- Porac J Pampanga ChentesDocument3 pagesPorac J Pampanga ChentesJahmae ChentesNo ratings yet

- 01 PDFDocument8 pages01 PDFAnonymous uCYIu1No ratings yet

- Activity 3.3.1 UtilitiesDocument5 pagesActivity 3.3.1 UtilitiesBlaine MNo ratings yet

- Pondicherry PDFDocument7 pagesPondicherry PDFHoney Dave100% (1)