Professional Documents

Culture Documents

Swift Mannual

Swift Mannual

Uploaded by

Praveen JosephOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Swift Mannual

Swift Mannual

Uploaded by

Praveen JosephCopyright:

Available Formats

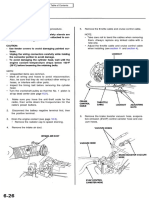

ENGINE ASSEMBLY REMOVAL AND INSTALLATION

REMOVAL 1. Relieve fuel pressure according to Fuel Pressure Relief Procedure 2. Disconnect negative and positive and negative cable of battery 3. Remove reservoir tank from battery tray 4. Disconnect ECM connector 5. Remove battery and tray 6. Remove engine hood after disconnecting windshield water hose 7. Drain engine oil 8. Drain transaxle oil 9. Drain coolant 10. Disconnect IAT sensor connector 11. Remove air cleaner case and resonator 12. Remove right and left side engine under covers 13. Remove A/C compressor belt 14. With hose connected , detach A/C compressor 15. Remove throttle body 16. Disconnect vacuum hose and then remove fuel pressure regulator from fuel delivery pipe 17. Disconnect the following electric wires *ECT sensor *EGR valve *CMP sensor * Purge valve * Ignition coil assembly *Injectors *Heated oxygen sensor *Engine oil pressure switch *CKP sensor *VSS * Back up light switch * Generator * Starting motor *Ground terminal from cylinder block *Battery ground cable from transaxle * Magnet clutch switch of A/C compressor (if equipped) *Each wire harness clamps

18. Disconnect the following cables

*Accelerator cable *Clutch cable *Gear select control cable * Gear shift control cable 19. Disconnect the following hoses * Brake booster hose from intake manifold * Radiator inlet and outlet hoses from each pipe * Heater inlet and outlet hoses from each pipe * Fuel feed hose from fuel feed pipe * Purge hose from purge valve 20. Disconnect right and left drive shaft joints from differential gear 21. Remove exhaust pipes 22. Install lifting device 23. Remove steering gear case assembly 24. Support engine and transaxle with jack 25. Remove engine left mounting bracket nuts and engine left mounting bolt 26. Before removing engine, recheck to make sure all hoses, electric wires and cables etc. disconnected from engine transaxle 27. Lower engine with transaxle from engine compartment 28. Disconnect transaxle from engine 29. Remove clutch cover and clutch disc CAUTION: Before lowering engine, to avoid damage to A/C compressor and clutch operating cylinder, make clearance by rising them. INSTALLATION 1. Install clutch cover and clutch disc 2. Connect transaxle to engine

3. Lift engine and transaxle into engine compartment with jack 4. Tighten engine left mounting bracket nuts and engine right mounting nuts to specified torque(55 Nm) 5. Install lifting device 6. Install steering gear case assembly 7. Remove lifting device 8. Install exhaust No. 1 , No. 2 and center pipes 9. Connect drive shaft joints 10. Connect disconnected hoses, cables, and electric wires noting the following Tighten nuts to specified torque (staring motor terminal nut: 11Nm Generator terminal nut: 6Nm) 11. Install fuel pressure regulator to fuel delivery pipe and then connect vacuum hoses 12. Install throttle body 13. Install air cleaner case and resonator 14. Install A/C compressor to its bracket 15. Adjust A/C compressor belt tension 16. Adjust accelerator cable play 17. For M/T model, adjust clutch cable play 18. Install battery and tray 19. Connect ECM connector. 20. Install reservoir tank to battery tray. 21. Check to ensure that all removed parts are back in place. 22. Refill cooling system with coolant 23. Refill engine with engine oil 24. Refill transaxle with transaxle oil 25. Connect positive and negative cable at battery 26. Verify that there is no fuel leakage, coolant leakage, oil leakage and exhaust gas leakage at each connection

You might also like

- 1997 Buick LeSabre Service Repair ManualDocument2,101 pages1997 Buick LeSabre Service Repair ManualJoseph Riccardo67% (3)

- Audi B6 AMB Engine Removing and Installing PDFDocument27 pagesAudi B6 AMB Engine Removing and Installing PDFjugoslavdjurdj100% (4)

- 4.2L Engine PDFDocument28 pages4.2L Engine PDFIvanov Hernandez Freire67% (3)

- KIA Sorento 3.3 V6 G6Db: Timing Chain: Removal/installationDocument16 pagesKIA Sorento 3.3 V6 G6Db: Timing Chain: Removal/installationIsaac Jesus Sotillo MarquezNo ratings yet

- Manual Motor Rover 75Document6 pagesManual Motor Rover 75Juan LombarderoNo ratings yet

- Engine K21 and K25 Engine FuelDocument19 pagesEngine K21 and K25 Engine FuelPablo Rojas Valenzuela100% (1)

- SM - VOLVO BL61 BACKHOE LOADER Service Repair ManualDocument24 pagesSM - VOLVO BL61 BACKHOE LOADER Service Repair ManualКонстантин Дубенко100% (2)

- 94 Isuzu Trooper Valve Cover RepairDocument5 pages94 Isuzu Trooper Valve Cover Repairturbopimp2000No ratings yet

- 4.0L V8 - VINS (K, U) Selected Block: Removal & InstallationDocument19 pages4.0L V8 - VINS (K, U) Selected Block: Removal & InstallationsixdownNo ratings yet

- 4.2L EngineDocument28 pages4.2L Engineadnmb100% (6)

- Chevrolet Lacetti - (Optra) 2005 1.4L-1.6Document45 pagesChevrolet Lacetti - (Optra) 2005 1.4L-1.6Hernan HernandezNo ratings yet

- 01-Engine - 2.8L DieselDocument211 pages01-Engine - 2.8L DieselGustavoNo ratings yet

- 2.4l 5 Cyl Vin 55Document25 pages2.4l 5 Cyl Vin 55Rogério MorenoNo ratings yet

- 2.5L 4-CYL - VIN (P) : 1993 Jeep CherokeeDocument19 pages2.5L 4-CYL - VIN (P) : 1993 Jeep CherokeeAlberto DelcastillooNo ratings yet

- Repair Manual PDFDocument784 pagesRepair Manual PDFwerles100% (1)

- 5.7l-Engine Repair ProcDocument21 pages5.7l-Engine Repair ProcfinjaegerNo ratings yet

- 1.9l 4 Cyl Vin A 2.0l Turbo 2.3l 4 CylDocument25 pages1.9l 4 Cyl Vin A 2.0l Turbo 2.3l 4 CylJosé Torcato AlmeidaNo ratings yet

- 2.4L 5-CYL VIN (55) : 1995 Volvo 850Document25 pages2.4L 5-CYL VIN (55) : 1995 Volvo 850apek1No ratings yet

- EC380D - Engine, RemovingDocument10 pagesEC380D - Engine, Removingmaintenance 2kpbNo ratings yet

- Engine 1.6L (Steem G16) PDFDocument18 pagesEngine 1.6L (Steem G16) PDFAry Duran0% (1)

- 00M12 PDFDocument6 pages00M12 PDFurania22000No ratings yet

- Removal and Install AssemblyDocument19 pagesRemoval and Install AssemblyNeeraj SengarNo ratings yet

- MazdaDocument30 pagesMazdagerber damianNo ratings yet

- Engine IdentificationDocument30 pagesEngine Identificationgerber damianNo ratings yet

- Engine, Removing and InstallingDocument16 pagesEngine, Removing and InstallingJohn OldfieldNo ratings yet

- Accelerator Control, Fuel & Exhaust Systems: Draining Water Fuel Filter CheckDocument22 pagesAccelerator Control, Fuel & Exhaust Systems: Draining Water Fuel Filter CheckDwight GeorgeNo ratings yet

- Engine Assembly Engine Assembly Removal and Installation: (QR25DE)Document33 pagesEngine Assembly Engine Assembly Removal and Installation: (QR25DE)Ioana BocaniciuNo ratings yet

- 2.2l 4 Cyl Diesel Vin SDocument19 pages2.2l 4 Cyl Diesel Vin SJosé Torcato AlmeidaNo ratings yet

- 2.4L Install InstructionsDocument13 pages2.4L Install InstructionskpepasNo ratings yet

- 980a0893&a376 PDFDocument51 pages980a0893&a376 PDFMichael DavenportNo ratings yet

- Engine, Removing: Información de ServicioDocument20 pagesEngine, Removing: Información de ServicioAlfonso BerRamNo ratings yet

- Accelerator Control, Fuel & Exhaust Systems: GI MADocument12 pagesAccelerator Control, Fuel & Exhaust Systems: GI MAaymendabNo ratings yet

- GA15 Engine DisassemblyDocument79 pagesGA15 Engine DisassemblyJohn Coxx100% (1)

- Aaz 1z Ahu Turbocharger SystDocument39 pagesAaz 1z Ahu Turbocharger Systboschit100% (1)

- Desmontaje de CulataDocument4 pagesDesmontaje de CulataJuan Carlos Casaboza XesspeNo ratings yet

- Procedure:-: Lab. I Engine Removal From A VehicleDocument1 pageProcedure:-: Lab. I Engine Removal From A VehicleMulugeta HamaroNo ratings yet

- Chapt 02Document144 pagesChapt 02Tony LoweNo ratings yet

- Induction Module Assembly 9.5: GeneralDocument10 pagesInduction Module Assembly 9.5: Generalvette512No ratings yet

- 2.0L ENGINE Chevy Tracker 1999Document52 pages2.0L ENGINE Chevy Tracker 1999andres german romeroNo ratings yet

- 4.1L V8 - Vin (7) & 4.5L V8 - Vin (5) : 1988 Cadillac DevilleDocument11 pages4.1L V8 - Vin (7) & 4.5L V8 - Vin (5) : 1988 Cadillac DevilleRobert TuckerNo ratings yet

- (PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 InglesDocument34 pages(PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 Inglesjorge Angel LopeNo ratings yet

- (PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 Ingles PDFDocument34 pages(PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 Ingles PDFtrastornadojhonNo ratings yet

- 980a1003 PDFDocument48 pages980a1003 PDFMichael DavenportNo ratings yet

- AVEO 2007-2010/wave - 07-10/engine Mechanical - 1.5L/Repair Instructions - On VehicleDocument86 pagesAVEO 2007-2010/wave - 07-10/engine Mechanical - 1.5L/Repair Instructions - On VehicleArley HernandezNo ratings yet

- 4G63 ManualDocument34 pages4G63 Manualfrinliwigo100% (4)

- ABSDocument40 pagesABSKomáromi LászlóNo ratings yet

- 1995 Nissan Datsun Sentra L4 1998cc 2.0L DOHC MFI SR20DEDocument8 pages1995 Nissan Datsun Sentra L4 1998cc 2.0L DOHC MFI SR20DEJhony Paredes AlfaroNo ratings yet

- Timing Chain EERDocument22 pagesTiming Chain EERNahuel CamberchioliNo ratings yet

- 980a3578 PDFDocument49 pages980a3578 PDFMichael Davenport100% (1)

- Manual de Servicio Isuzu 2.2lDocument24 pagesManual de Servicio Isuzu 2.2lChino PlagaNo ratings yet

- Manual - de - Servicio - Isuzu - 2.2l (LUV) PDFDocument24 pagesManual - de - Servicio - Isuzu - 2.2l (LUV) PDFLuis ValenzNo ratings yet

- Ranger 2000-2001 4.0Document47 pagesRanger 2000-2001 4.0testNo ratings yet

- Engine Identification: Vitara 5Document35 pagesEngine Identification: Vitara 5Saulo RodriguesNo ratings yet

- Manual Chevrolet LuminaDocument48 pagesManual Chevrolet Luminaluis marmoNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet