Professional Documents

Culture Documents

GRavimétrica GA 210

GRavimétrica GA 210

Uploaded by

Paty GoicocheaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GRavimétrica GA 210

GRavimétrica GA 210

Uploaded by

Paty GoicocheaCopyright:

Available Formats

Data sheet | 104.05.05 | Copyright © The right to alterations is reserved.

PROCESSING

GRAVITY SEPARATOR

GA 210

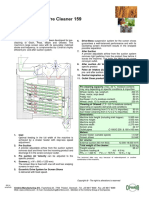

GENERAL

Brand Cimbria

Designation Gravity separator

Model GA 210

Use Industry

Application 5b. Bagging-off type hopper for design with base

Grains or particles of almost identical size are fed structure (required, if bagging-off type hoppers

continuously on the separating deck surface of the instead of discharge hopper will be supplied).

separator, providing a uniform bed of material over the 6. Cyclofan

deck surface. 7. Exhaust fan

With motor, without support structure.

Design 8. Dust separating cyclone with rotary valve.

The deck is fluidised by a completely uniform pressurised

air system stratifying the light material to the top of the

product bed and allowing the heavy material to contact

the deck surface. The deck is inclined from side to side and

inlet end to discharge end at adjustable angles.

Working mode

The deck itself is powered by a well-balanced eccentric

drive which moves the deck at low amplitude and high

frequency up hill. The heavy material contacting a specially

designed square wire deck surface moves up hill, while the

light material fluidised by the air system moves down hill

due to gravitational pull. A typically separation pattern is

depicted below.

1. Intake pre-storage hopper

For intake adjustment between feeder-elevator and

electro-magnetic feeder SP 18 incl. three level

indicator switches.

Delivery with or without supporting legs.

2. Electro-magnetic feeder type SP 18 Technical data

For a trouble-free, continuous feeding of the Capacity

machines. Corn, wheat soybeans 10.0 t/h

3a. Intake dust-aspiration hopper Beans 4.8 t/h

Light dust and fine removals from the product to be Clover 3.0 t/h

Coffee (green) 6.7 t/h

cleaned. Connection to central dust exhaust unit.

Screen area 3.4 m²

Air requirement: 12 m³/min, 300 Pa.

Motors: (standard)

3b. Partial dust hood

Fan drive 11.0 kW

In case of heavy dust formation, for the removal of

Reciprocating drive 1.1 kW

dust from the incoming material and the light

Air volume:

produce area. Connection to central dust exhaust Air requirements 470 m³/min.

or individual cyclone and ventilator. Incl. Intake dust- Dimensions

aspiration hopper and frame. Length 3 288 mm

Air requirement: 210 m³/min, 300 Pa. Width 1 850 mm

3c. Full dust hood complete closed; suction over the Height 1 440 mm

whole table area. With frame. Total weight of separator

Air requirement: 550 m³/min, 300 Pa. Net 1 830 kg

4a. Discharge hopper for heavy product. Dynamic loading at 7–12 Hz:

4b. Vibrating discharge trough for heavy product with PH=+/- 450 N PV=+/- 160 N (10N = 1 kg)

stone trap. Technical data can vary for certain of the above due to continued

5a. Vibrating discharge trough for light product. development or a different machine composition.

Cimbria.com | 2021 September | Page 1 of 1

Cimbria Heid GmbH. | 2000 Stockerau | Austria | +43 2266 699 | cimbria-heid@agcocorp.com

You might also like

- Deliria-Faerie Tales For A New Millennium PDFDocument344 pagesDeliria-Faerie Tales For A New Millennium PDFJuan Del Desierto100% (4)

- COMACO LB1000-Asphalt Mixing PlantDocument12 pagesCOMACO LB1000-Asphalt Mixing PlantHermawan Septian Adittya100% (1)

- Tech Specs TM RS - 750D SF - 16 T - IndlDocument2 pagesTech Specs TM RS - 750D SF - 16 T - IndlB Manoranjan0% (1)

- ET673 Assingment2 - Air PollutionDocument3 pagesET673 Assingment2 - Air PollutionLee MinkNo ratings yet

- SPJ150 English ManualDocument22 pagesSPJ150 English ManualtuchidanNo ratings yet

- TS180S - Destoner - 1040902 - GB - DESPEDREGADORA 7.5TnDocument1 pageTS180S - Destoner - 1040902 - GB - DESPEDREGADORA 7.5TnJimmy SanchezNo ratings yet

- Bag HouseDocument55 pagesBag HousegovardhanNo ratings yet

- BM-S25L 3-5gallon Bottle Blow Molding MachineDocument11 pagesBM-S25L 3-5gallon Bottle Blow Molding MachineMohamed BayoumiNo ratings yet

- Bulk Feeding MachineDocument11 pagesBulk Feeding MachineSamuel NababanNo ratings yet

- Technical Specification - Palm Oil Processing PlantDocument22 pagesTechnical Specification - Palm Oil Processing PlantsfagroindustriiesNo ratings yet

- An Underestimated Technology?: Cyclone Dust CollectorsDocument1 pageAn Underestimated Technology?: Cyclone Dust CollectorsWONG TSNo ratings yet

- CIMBRIA - Pre Cleaner 159Document1 pageCIMBRIA - Pre Cleaner 159JOSE RICARDO DURANNo ratings yet

- DS AnimalFeedMilling ZA 1214 ENGDocument2 pagesDS AnimalFeedMilling ZA 1214 ENGThoa Tran VanNo ratings yet

- Quotations of 80tph Continous Drum Asphalt Plant With Wet Dust Catcher-CJME2023.12.11Document5 pagesQuotations of 80tph Continous Drum Asphalt Plant With Wet Dust Catcher-CJME2023.12.11fernandomelendezfmiNo ratings yet

- Sova Gunite MachineDocument2 pagesSova Gunite MachineThiền Quang NguyễnNo ratings yet

- 2014 Al Mining Institute Mathews PDFDocument39 pages2014 Al Mining Institute Mathews PDFbeemasundarNo ratings yet

- ESA IB BNDD Technical InformationDocument2 pagesESA IB BNDD Technical InformationdiogosaborNo ratings yet

- Petkus K541Document2 pagesPetkus K541balitaroloNo ratings yet

- Air Separators: Infinity For Cement EquipmentDocument36 pagesAir Separators: Infinity For Cement EquipmentNaveen Kumar NadendlaNo ratings yet

- RIO Article 8134Document16 pagesRIO Article 8134gustavo dela espriellaNo ratings yet

- HP Gearless Ball Mill Drive in Cement-Why Not! PDFDocument15 pagesHP Gearless Ball Mill Drive in Cement-Why Not! PDFRajuNo ratings yet

- KGU - App - Drying CapacityDocument25 pagesKGU - App - Drying CapacitySukallan DharNo ratings yet

- Zuther Reinigungstechnik ENDocument12 pagesZuther Reinigungstechnik ENpios.helectorNo ratings yet

- Biermann's Handbook of Pulp and Paper - Cap 06Document22 pagesBiermann's Handbook of Pulp and Paper - Cap 06chau_riberNo ratings yet

- Basic System Concepts-Nol-TecDocument7 pagesBasic System Concepts-Nol-TecpneuconNo ratings yet

- Highly Efficient Coating MachineDocument6 pagesHighly Efficient Coating MachineShuja Ur RehmanNo ratings yet

- Instruction Manual for Impulse Bag Cyclone Dust RemoverDocument31 pagesInstruction Manual for Impulse Bag Cyclone Dust Removersojo josephNo ratings yet

- CDM6225Cummins, Imported HYDDocument1 pageCDM6225Cummins, Imported HYDBruno AzevedoNo ratings yet

- Venturi Chamber Baghouse Filter Electrostatic PrecipitationDocument3 pagesVenturi Chamber Baghouse Filter Electrostatic PrecipitationLee MinkNo ratings yet

- SZR IV D Technical InformationDocument2 pagesSZR IV D Technical InformationdiogosaborNo ratings yet

- 4082WWT Grit RemovalDocument21 pages4082WWT Grit Removalahmedmagdi2009No ratings yet

- Parker RoadStar 1500 Jul19Document2 pagesParker RoadStar 1500 Jul19habtamuNo ratings yet

- Finishing EquipmentDocument8 pagesFinishing EquipmentDas and DasNo ratings yet

- HoseDocument4 pagesHoseBhayu Senoaji Dwi PrimasanjoyoNo ratings yet

- Terrajet EngDocument4 pagesTerrajet Eng77ztfNo ratings yet

- 76 Band Dryers PDFDocument1 page76 Band Dryers PDFPhilip WalkerNo ratings yet

- Lecture 2: Introduction and Types of Driers (Cont.) : 4.2.2 Drum DryerDocument1 pageLecture 2: Introduction and Types of Driers (Cont.) : 4.2.2 Drum DryerPooja ThaparNo ratings yet

- Spesifikasi Komponen Terkait VpaDocument8 pagesSpesifikasi Komponen Terkait VpaAgung Prasetya ChandranenaNo ratings yet

- Quotation of ADP40 Stationary Drum Mix Asphalt PlantDocument7 pagesQuotation of ADP40 Stationary Drum Mix Asphalt PlantChandra Prakash Karki100% (1)

- 23-01-18 Offer Lintec 240 To. Asphalt Batch Plant - Duo AsphaltDocument19 pages23-01-18 Offer Lintec 240 To. Asphalt Batch Plant - Duo Asphaltjamalhabbas742No ratings yet

- Charcoal Briquette Production Line 2-3tonDocument32 pagesCharcoal Briquette Production Line 2-3tonБат-Эрдэнэ ЭрдэнэчулуунNo ratings yet

- Brochure XE215SLLDocument2 pagesBrochure XE215SLLFernanda RizaldoNo ratings yet

- AW3000 Brochure PDFDocument6 pagesAW3000 Brochure PDFOscar CastleNo ratings yet

- WES CNG PackageDocument20 pagesWES CNG Packagehadmadi nurlatifNo ratings yet

- Quotation of MADP-40 Mobile Drum Mix Asphalt PlantDocument9 pagesQuotation of MADP-40 Mobile Drum Mix Asphalt PlantChandra Prakash KarkiNo ratings yet

- Dust Collector Fact BookDocument8 pagesDust Collector Fact BookDifbya WicaksanaNo ratings yet

- ZKG Dic12 p46-54 PDFDocument7 pagesZKG Dic12 p46-54 PDFRICARDOALEXBORGES100% (1)

- Wam 400 Dust CollectorDocument1 pageWam 400 Dust CollectorW Morales100% (1)

- Flyer VN AG Roaster AeroRoast BEBA USLtrDocument2 pagesFlyer VN AG Roaster AeroRoast BEBA USLtrAlexandruNo ratings yet

- Engine Gross Power: 510 KW (684 HP) Operating WeightDocument9 pagesEngine Gross Power: 510 KW (684 HP) Operating WeightNova kurniawan 34100% (1)

- Ash HandlingDocument3 pagesAsh HandlingAi VietNo ratings yet

- Airmax 266 PJDocument1 pageAirmax 266 PJmyonlyoneisyouNo ratings yet

- Product Group Industrial Vacuum Cleaners, 0415-156Document8 pagesProduct Group Industrial Vacuum Cleaners, 0415-156هبال حمزةNo ratings yet

- MOTTCORP - Application Briefs - Fiber Elements For Surface FiltrationDocument2 pagesMOTTCORP - Application Briefs - Fiber Elements For Surface FiltrationDragoslav DzolicNo ratings yet

- C200 WML 204Document9 pagesC200 WML 204Luis AlfonsoNo ratings yet

- M/V Bore Bay: - Member of Spliethoff GroupDocument2 pagesM/V Bore Bay: - Member of Spliethoff GroupJeff TrinidadNo ratings yet

- Engine Gross Power: 510 KW (684 HP) Operating WeightDocument9 pagesEngine Gross Power: 510 KW (684 HP) Operating Weightmohan100% (1)

- Wam Silo Top 266 Dust CollectorDocument1 pageWam Silo Top 266 Dust CollectorW MoralesNo ratings yet

- Bag HouseDocument23 pagesBag HouseTarak A Positive100% (2)

- The Machinery of Hay Harvesting - With Information on the Equipment and Methods Mowing, Raking and BailingFrom EverandThe Machinery of Hay Harvesting - With Information on the Equipment and Methods Mowing, Raking and BailingNo ratings yet

- Application of Buoyancy-Power Generator For Compressed Air Energy Storage Using A Fluid-Air Displacement System - ScienceDirectDocument7 pagesApplication of Buoyancy-Power Generator For Compressed Air Energy Storage Using A Fluid-Air Displacement System - ScienceDirectJoel Stanley TylerNo ratings yet

- Optimal Design of Low-Cost and Reliable Hybrid Renewable Energy System Considering Grid BlackoutsDocument7 pagesOptimal Design of Low-Cost and Reliable Hybrid Renewable Energy System Considering Grid BlackoutsNelson Andres Entralgo MaldonadoNo ratings yet

- HG-G9 Module 7 RTP PDFDocument10 pagesHG-G9 Module 7 RTP PDFDaniel Robert BuccatNo ratings yet

- ME-458 Turbomachinery: Muhammad Shaban Lecturer Department of Mechanical EngineeringDocument113 pagesME-458 Turbomachinery: Muhammad Shaban Lecturer Department of Mechanical EngineeringAneeq Raheem50% (2)

- Bydf3 ElectricDocument61 pagesBydf3 ElectricIvan Avila100% (1)

- The Little Magazine RamRamDocument5 pagesThe Little Magazine RamRamJasdeep SinghNo ratings yet

- Rikki Tikki Tavi Story Lesson PlanDocument3 pagesRikki Tikki Tavi Story Lesson Planapi-248341220No ratings yet

- Biogas ProductionDocument7 pagesBiogas ProductionFagbohungbe MichaelNo ratings yet

- MSFS Cessna Citation CJ4 Model 525C Operator's Guide (v1)Document92 pagesMSFS Cessna Citation CJ4 Model 525C Operator's Guide (v1)Matheus RochaNo ratings yet

- UNIT HistoryDocument2 pagesUNIT HistorySanders StephenNo ratings yet

- InnerFiles Current Year PDF 2023Document687 pagesInnerFiles Current Year PDF 2023shravanibagul04No ratings yet

- Development of TOSRA (Test of Science Related Attitudes) Instrument For Science Related Attitude Studies in Sindh ProvinceDocument16 pagesDevelopment of TOSRA (Test of Science Related Attitudes) Instrument For Science Related Attitude Studies in Sindh ProvinceYhann Buyan GeverolaNo ratings yet

- Teachers' Interview PDFDocument38 pagesTeachers' Interview PDFlalitNo ratings yet

- Ascariasis Ada GambarDocument4 pagesAscariasis Ada GambarninaNo ratings yet

- Lesson Plan: I've Got Two SistersDocument5 pagesLesson Plan: I've Got Two SistersBianca BybyNo ratings yet

- Comm 130 PortfolioDocument23 pagesComm 130 PortfolioSami MossNo ratings yet

- Gershwin George Rhapsody in Blue For Sax Quartet 64734Document113 pagesGershwin George Rhapsody in Blue For Sax Quartet 64734Jessica HowardNo ratings yet

- Empower B2 Unit 10 QuizDocument2 pagesEmpower B2 Unit 10 QuizGuidance Teuku Nyak Arif Fatih Bilingual SchoolNo ratings yet

- Optimizing The Lasing Quality of Diode Lasers by Anti-Reflective CoatingDocument21 pagesOptimizing The Lasing Quality of Diode Lasers by Anti-Reflective CoatingDannyNo ratings yet

- Oma TS MLP V3 - 2 20110719 ADocument128 pagesOma TS MLP V3 - 2 20110719 AkennychanklNo ratings yet

- Final Simple Research (BS CRIM. 1-ALPHA)Document5 pagesFinal Simple Research (BS CRIM. 1-ALPHA)Julius VeluntaNo ratings yet

- Ai-Ai ResumeDocument3 pagesAi-Ai ResumeNeon True BeldiaNo ratings yet

- Questionnaire For Technical AssistantDocument4 pagesQuestionnaire For Technical AssistantHabtamu Ye Asnaku LijNo ratings yet

- Stable Fixed Points of Card Trick FunctionsDocument10 pagesStable Fixed Points of Card Trick FunctionsDerekNo ratings yet

- Panasonic TH-P42C10M, S, T, K, DDocument122 pagesPanasonic TH-P42C10M, S, T, K, DEliel PinheiroNo ratings yet

- SBT Sekolah Berprestasi Tinggi (HPS) High Performing SchoolsDocument14 pagesSBT Sekolah Berprestasi Tinggi (HPS) High Performing SchoolsAminNo ratings yet

- Autumn Activity BookDocument33 pagesAutumn Activity Bookbuzuleacnadya100% (3)

- Whittington 22e Solutions Manual Ch14Document14 pagesWhittington 22e Solutions Manual Ch14潘妍伶No ratings yet

- ESSAYDocument7 pagesESSAYKaren OliveraNo ratings yet