Professional Documents

Culture Documents

United States Patent (19) : Bock (45) Feb. 5, 1974

United States Patent (19) : Bock (45) Feb. 5, 1974

Uploaded by

gorgi0 ratings0% found this document useful (0 votes)

20 views7 pagesThis patent describes a redundant control system for stabilizing aircraft that have rotatable horizontal stabilizers and elevators. The system allows the stabilizer or elevators to still function if one becomes jammed. It uses multiple hydraulic actuators to drive the stabilizer and elevators independently. If one control surface jams, override devices in the input linkage absorb the motion to prevent jamming the entire system, while the remaining surfaces continue operating normally to stabilize the aircraft.

Original Description:

efrgv ef

Original Title

US3790108

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis patent describes a redundant control system for stabilizing aircraft that have rotatable horizontal stabilizers and elevators. The system allows the stabilizer or elevators to still function if one becomes jammed. It uses multiple hydraulic actuators to drive the stabilizer and elevators independently. If one control surface jams, override devices in the input linkage absorb the motion to prevent jamming the entire system, while the remaining surfaces continue operating normally to stabilize the aircraft.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

20 views7 pagesUnited States Patent (19) : Bock (45) Feb. 5, 1974

United States Patent (19) : Bock (45) Feb. 5, 1974

Uploaded by

gorgiThis patent describes a redundant control system for stabilizing aircraft that have rotatable horizontal stabilizers and elevators. The system allows the stabilizer or elevators to still function if one becomes jammed. It uses multiple hydraulic actuators to drive the stabilizer and elevators independently. If one control surface jams, override devices in the input linkage absorb the motion to prevent jamming the entire system, while the remaining surfaces continue operating normally to stabilize the aircraft.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 7

United States Patent (19) [11] 3,790,108

Bock (45) Feb. 5, 1974

54 REDUNDANT STABLIZER CONTROL 3,733,039 5/1973. O'Connor et al................. 244/83 D

(75) Inventor: John W. Bock, Long Beach, Calif.

73 Assignee: McDonnel Douglas Corporation, Primary Examiner-Duane A. Reger

Santa Monica, Calif. Assistant Examiner-Jesus D. Sotelo

Attorney, Agent, or Firm-Robert O. Richardson; Wal

22 Filed: Nov. 13, 1972 ter J. Jason; Donald L. Royer

(21) Appl. No.: 306,377

52 U.S. C. ................................. 24483 D, 74,469 ABSTRACT

51) int. Cl. ............................................ B6e 1304. A redundant control system for operating two flight

58 Field of Search.244/75, R, 83 A, 83B,83 C, control surfaces such as a rotatable stabilizer and an

244/83 D, 83 E, 86, 89; 74/469, 470, 471 R, elevator rotatably mounted thereon whereby in the

479, 480 R event of either control surface mechanically jamming,

References Cited

the preselected control system may still be used to ac

56 tuate the unjammed control surface.

UNITED STATES PATENTS

2,528,752 11/1950. Jacobus............................ 244/83 D 9 Claims, 5 Drawing Figures

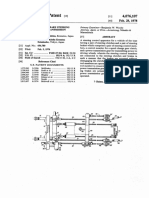

PATENTED FEB 51974 3,790,108

SHEET 1. Of 3

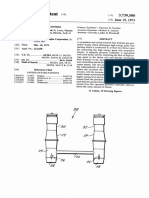

PATENTEDFEB 51974 3,790.108

SHEET 2 OF 3 aV

3,790, 108

2

REDUNDANT STABLEZER CONTROL or tabs. This method of accepting autopilot commands

at the actuators of individual elevators or tabs provides

BACKGROUND OF THE PRESENT INVENTION a simpler and more reliable autopilot control than is

likely if multiple inputs and a monitoring device is used

Most aircraft have horizontal stabilizers at the rear 5 to actuate a single stabilizer surface as in the case of

area of the aircraft. These stabilizers may be varied conventional stabilizer systems.

somewhat in their pitch attitude or angle of attack on

the airstream for trim purposes. These stabilizers have BRIEF DESCRIPTION OF THE DRAWINGS

a rear portion pivotally connected to them which are FIG. 1 is a schematic illustration of the controls with

called elevators. These elevators are the control sur O the stabilizer and elevator in phantom lines to show

faces normally operated by the pilot in the operation of their relationship,

the aircraft such as in takeoff, landing, ascending and FIGS. 2, 3 and 4 are perspective views of various

descending and for other maneuvers. forms of override jam compensating devices, and

SUMMARY OF THE PRESENT INVENTION 15

FIG. 5 is a block diagram illustration of the system.

In contrast to the conventional system which uses the

horizontal stabilizer for trim purposes and the elevators DETALED DESCRIPTION OF ILLUSTRATIVE

for control, the flying tail concept incorporating the EMBODIMENT

present invention uses the horizontal stabilizer for both In FIG. 1 there is shown in phantom lines the left sta

trim and control with the elevators geared to the stabi bilizer 10 with a pair of elevators 12, 14 pivotally con

lizer through a mechanical linkage. The horizontal sta nected on the trailing edge, and the right stabilizer 16

bilizer provides the elevator function and the elevators with a pair of elevators 18, 20 pivotally connected on

are used for trim purposes. There are advantages to the its trailing edge. There are appropriate stabilizer con

flying tail system, particularly in the STOL (short take nections 22 connecting the stabilizers so that their lead

off and landing) aircraft operation. It is within the fly 25

ing edges may be rotated together when the angle of at

ing tail system that the present invention is utilized and tack is adjusted as desired. This raising and lowering of

described in the following illustrative embodiment. the leading edges also changes the angle of the eleva

In this embodiment the stabilizer is driven by multi tors attached to the stabilizers. For safety purposes dual

ple hydraulic actuators and the elevators are also sets of controls are provided throughout the entire con

driven by hydraulic actuators. The input linkage from 30 trol system and override provisions are made so that in

the pilot to the actuators is such as to result in an eleva the event of jamming or malfunctioning of any of the

tor stabilizer program that would be identical to that of stabilizer or elevator structures, the remaining struc

conventional stabilizers. In the event of a jam of any tures not only will perform their functions but they will

one of the control surfaces, the input to the actuator is 35 also compensate for the non-workable ones.

taken up by an override spring and the remaining sur The control structure schematically shown in FIG. 1

faces continue to function. The redundant stabilizer

can best be described with reference to the functional

control system of the present invention includes a stabi block diagrams shown in FIG. 5. Starting with the pi

lizer driven by one or several actuators, one or several lot's control column 24 which initiates a fore and aft

elevator or tab surfaces driven by their own actuator or

actuators, a command system operated by the pilot, an 40 movement shown by double arrow 26, torsion rods 28,

override device in the input linkage to each actuator, 30 extend laterally to override devices 32, 34. These

an auto-control system (optional) with input to each devices are of the type shown in FIG. 2 which converts

elevator or tab actuator, and a feel device and trim de rotational movement to a longitudinal movement pro

vice with (optional) override spring between them and viding that a reactive longitudinal movement force (as

the remainder of the system. For pilot operation the pi 45 in a jam or malfunction) does not prevent such longitu

lot's command input is transmitted through cables or dinal movement. In the event such a force appears on

linkage to the stabilizer actuators and elevator or tab override device 34, for example, this force will not ap

actuators. If required to overcome control sensitivity pear in opposition to the rotational force on torsion rod

problems, the linkage may be non-linear to permit most 50

30, and does not interfere with the operability of the

of the initial movement to be provided by the elevator override device 32 that converts the rotation of rod 28

or tab. Load, feel and trim may be provided as desired. to a longitudinal force output. The structure of the

override devices will be described hereinafter with ref

In the event of a jam of the stabilizer or its actuators, erence to the structure shown in FIGS. 2, 3 and 4, but

the override devices between the pilot's command link the foregoing brief functional description is deemed ad

age and the stabilizer actuators absorbs the motion of equate in describing the systems in FIGS. and 5.

the pilot input and the remaining elevators or tabs con The output from overrides 32, 34 are longitudinal

tinue to be actuated to fly the airplane. The stabilizer movements of pushrods 36, 38 which cause rotation of

and all other surfaces continue to operate. Additional cranks 40, 42 by which cables 44, 46 and 48, 50 at

override devices may be used to protect the system 60

tached thereto are actuated. The other ends of cables

against jams of the feel and trim devices. As an option, 44, 46 are attached to sectors 52, and the other ends

the auto-control input may be to each individual eleva of cables 48, 50 are attached to sectors 54. These sec

tor or tab actuator. This input operates the effected ac tors are mounted on and cause rotation of torsion bars

tuator and its elevator or tab surface. This input also 56, 58. A variable load feel and trim unit 60, receiving

causes a motion of the pilot command linkage asso 65 signals from a load feel input device 62 and a trim input

ciated with the actuator. The linkage motion drives the device 64 also send rotational forces to the torsion bars.

stabilizer drive actuators, causing the stabilizer to move 56, 58 through override units 66 and 68. These over

as a result of autopilot input in addition to the elevators ride units provide torsion-to-torsion coupling as will be

3,790, 108

3 4.

explained hereinafter with reference to the override valve 154 is connected for actuation by pushrods 228,

unit in FIG. 4. 230, 232 and sectors 234, 236. Override device 238 in

Sector 54 initiates movement of the stabilizer by ac pushrod 230 is of the type shown in FIG. 3.

tuation of hydraulic cylinders 70, 72 attached between Reference is now made to the override device shown

aircraft cabin structure (not shown) at pivot points 74, in FIG. 2. Here a torque tube 240 which rotates as

76 and stabilizer connector 22 at pivot points 78, 80. shown by double arrow 242 is the input and pushrod

The elongation and contraction of piston rods 78, 80 244 which moves longitudinally as shown by double

within cylinders 70, 72 is accomplished by fluid flow arrow 246 is the output. Attached to torque tube 240

from hydraulic systems 82, 84 and 86, 88 regulated is a crank arm 248 having a crank pin 250 extending

through valves 90, 92. These valves are mechanically 10 therefrom. Pushrod 244 is pivotally mounted at one

controlled by linkages through override units 94, 96 end 250 to a crank 252 which rotates on axle 254. At

coupled to torsion bar 56 which is rotated by either or the other end 256 of crank 252 is a crank pin 258.

both of sectors 52 and 54. Override units 94, 96 are of Straddling pins 250 and 258 are a pair of retainer legs

the type to be described hereinafter with reference to 260,262 pivotally mounted at their top ends 264, 266

FIG. 2. 5 on axle 254 and held together at their bottom ends 268,

Linkage between valve 92 and override unit 96 con 270 by a connecting spring 272.

sists of pushrods 98, 100 angularly coupled through a In operation assume that torque tube 240 rotates

sector 102 pivotally connected at 104 to stabilizer con clockwise as does crank arm 248 and crank pin 250.

nector 22. Pushrod 98 is pivotally connected at 106 to This moves the lower end 268 of retainer leg 262 clock

link 108 of sector 102 and pushrod 100 is pivotally con wise. Spring 272 causes leg 260 to follow, moving

nected at 110 to link 112 of the sector. In this manner crank pin 258 in front of it. This causes lower end 256

horizontal longitudinal movement of pushrod 100 may of crank 252 to rotate clockwise, pulling pushrod 244

be translated to vertical longitudinal movement of to the right.

pushrod 98 for actuation of valve 92. This linkage, of 25 Now, suppose some movable structure to which

course, is only one of many forms of transmission of pushrod 244 is connected jams and pushrod 244 can

forces between override unit 96 and valve 92. Through not move. Crank pin 258 prevents rotation of leg 260

out the system other sectors and pushrods are shown and spring 272 stretches, permitting arm 262 to rotate

and will be briefly mentioned in their description since with the rotation of torque tube 240. Thus, a jam caus

they all function substantially in the same manner as 30 ing the output to be zero will still permit an input force

the linkage just described. to Occur.

The linkage between valve 90 and override unit 94 Briefly, the embodiments in FIGS. 3 and 4 are link

consists of pushrods 114, 116, 118, 120 interconnected to-link and torsion bar-to-torsion bar override devices

by sectors 122, 124 and 126, as shown, to provide a which operate in a manner similar to the unit in FIG.

change in direction as needed to make the connection. 35 2 just described. Thus a crank 274 with pushrod 276 is

Sectors 122, 124, 126 are pivotally mounted at pivot the input force in FIG.3 and torque tube 278 is the out

points 128, 130, 132 to some part of the stabilizer, not put force in FIG. 4. Otherwise the structure of these

shown. Thus it can be seen that either set of cables 44, override units is the same as that in FIG. 2.

46 or 48, 50 will cause actuation of either cylinder 70, Having thus described an illustrative embodiment of

72 to pivot the stabilizer connector 22 (and hence left the present invention, it is to be understood that modi

and right stabilizers 10 and 16) about pivot points 134, 40 fications thereof will become apparent to those skilled

136. in the art and that these deviations are to be construed

Elevators 12 and 14 are pivotally connected to left as part of the present invention.

stabilizer 10 along center line 138 and elevators 18 and I claim:

20 are pivotally connected to right stabilizer 16 along 45

1. A redundant stabilizer control system comprising:

center line 140. Hydraulic actuators 142, 144, 146 and

148 are adapted to pivot the elevators relative to the a stabilizer pivotally mounted to an aircraft,

stabilizers upon which they are mounted. Valves 150, stabilizer actuator means for raising and lowering the

152, 154 and 156 control actuators 142, 44, 146 and leading edge of said stabilizer,

148 respectively by regulating fluid flow from hydraulic 50

first linkage means for actuating said stabilizer actua

systems 158, 160, 162 and 164 respectively. tor means,

Signals from an autopilot for an auto-control input said linkage means having an override device therein

166, 168, 170, 172 may be used to control valves 150, to disrupt forces through said linkage means from

152, 154 and 156 or they may be controlled by torsion actuating said stabilizer when jamming of said sta

bar 58 through appropriate pushrods and sectors. 55 bilizer occurs,

Torsion bar 58 has a crank arm 174 to which valve said stabilizer having a plurality of elevator sections

150 is connected for actuation by pushrods 176, 178, attached thereto and adapted for relative move

180, 182 and sectors 184, 186 and 188. An override ment therewith,

device 190 of the type shown in FIG. 3 is placed in elevator actuator means for moving said elevator sec

pushrod 178. Torsion bar 58 has a crank arm 192 to 60 tions relative to said stabilizer,

which valve 152 is connected for actuation by pushrods Second linkage means for actuating said elevator ac

194, 196, 198, 200 and sectors 202, 204 and 206. tulator means,

Override device 208 of the type shown in FIG. 3 is said second linkage means having an override device

placed in pushrod 196. Torsion bar 58 has a crank arm therein to disrupt forces through said linkage

210 to which valve 156 is connected for actuation by 65 means from actuating said elevators when jamming

pushrods 212, 214, 216 and sectors 218 and 220. Over of said elevators occurs, and

ride device 222 in pushrod 214 is of the type shown in pilot control means for actuating both said linkage

FIG. 3. Torsion bar 58 has a crank arm 224 to which leaS.

3,790, 108

S 6

2. A redundant stabilizer control system as in claim movement pushrod linkage output, said one of said de

1 wherein said pilot control means includes vices including a pair of legs pivotally mounted at one

a torsion bar connected to said linkage means, of their ends and connected at the other of their ends

and by spring means, said rotational input causing one of

cable means operable to rotate said linkage means. 5 said legs to rotate, said spring means causing the other

3. A redundant stabilizer control system as in claim of said legs to rotate in the absence of opposing jam

1 wherein said second linkage means includes separate ming and malfunctioning forces, said other of said legs

linkages to each of said elevator sections and each of being connected to said pushrod linkage to cause longi

said linkages has an override device therein to disrupt tudinal movement thereof.

actuating forces to their corresponding associated ele 10 7. A redundant stabilizer control system as in claim

vator sections when opposing forces caused by jam 5 wherein at least one of said override devices is con

ming and malfunctioning oppose and exceed said actu nected to a pushrod linkage adapted for a longitudinal

ating forces. movement input, said one of said devices including a

4. A redundant stabilizer control system as in claim pair of legs pivotally mounted at one of their ends and

1 wherein said stabilizer actuator means includes a pair 15 connected at the other of their ends by spring means,

of actuators, each of said actuators being controlled said longitudinal movement input causing one of said

through separate linkages and each of said linkages has legs to rotate, said spring means causing the other of

an override device therein for disrupting actuating said legs to rotate in the absence of opposing jamming

forces through said linkages when jamming and mal and malfunctioning forces, and

functioning occurs. 20 means operable by said other of said legs to actuate

5. A redundant stabilizer control system as in claim control surfaces associated therewith.

1 wherein said override devices include a resilient con 8. A redundant stabilizer control system as in claim

nection which receives without transmitting actuating 7 wherein said means is a torsion rod adapted for rota

forces when there are opposing forces due to jamming tional movement.

and malfunctioning. 25 9. A redundnt stabilizer control system as in claim 7

6. A redundant stabilizer control system as in claim wherein said means is a pivotal crank for imparting lon

5 wherein at least one of said override devices is con gitudinal movementskto cka pushrod attached thereto.

nected to a rotational force input and a longitudinal sk Xk ck

35

40

45

50

55

60

65

You might also like

- Gulfstream IVDocument70 pagesGulfstream IVAnton100% (3)

- Starbucks Coffee Master Quiz Flashcards - QuizletDocument12 pagesStarbucks Coffee Master Quiz Flashcards - QuizletmuuayliiNo ratings yet

- Century Iii - Autopilot Flight System PDFDocument36 pagesCentury Iii - Autopilot Flight System PDFerik_x100% (1)

- 4 X 4Document2 pages4 X 4muhammad ali0% (1)

- ILS SystemDocument7 pagesILS SystemAneeb AhmedNo ratings yet

- Ata 27 FCS System OverviewDocument8 pagesAta 27 FCS System Overviewbnolasco0% (1)

- AUTOFLIGHTDocument17 pagesAUTOFLIGHTBonty MwashiNo ratings yet

- Towing TankDocument6 pagesTowing TankOdumoduChigozieUzomaNo ratings yet

- The Music in Stanley Kubrick's 2001: A Space OdysseyDocument27 pagesThe Music in Stanley Kubrick's 2001: A Space OdysseyJoris Daniel100% (1)

- United States Patent 119) : K / - :I - L I// SystemDocument6 pagesUnited States Patent 119) : K / - :I - L I// Systemrte678No ratings yet

- United States Patent (19) : Van DykeDocument5 pagesUnited States Patent (19) : Van DykegorgiNo ratings yet

- 1 Akalil Bin Sultan: Diploma of Engineering Technology in Aeroplane Maintenance Theory of Flight 5-6-16Document12 pages1 Akalil Bin Sultan: Diploma of Engineering Technology in Aeroplane Maintenance Theory of Flight 5-6-16Daniel JamilNo ratings yet

- United States Patent (19) : (45) June 24, 1975Document7 pagesUnited States Patent (19) : (45) June 24, 1975Rodrigo ContrerasNo ratings yet

- 5B-CIY, Levelmatic Operation and Service Instructions No. 3953Document15 pages5B-CIY, Levelmatic Operation and Service Instructions No. 3953mariosNo ratings yet

- Thrust Reverser Hook Latch System PatentDocument13 pagesThrust Reverser Hook Latch System PatentkevnwongNo ratings yet

- United States Patent (191: Rempfer Et A1. (451 Jan. 16,1973Document8 pagesUnited States Patent (191: Rempfer Et A1. (451 Jan. 16,1973rte678No ratings yet

- Basic Avionics Part 1 (ATA CH 22, 23, 31)Document109 pagesBasic Avionics Part 1 (ATA CH 22, 23, 31)kristian_rimbawanNo ratings yet

- US20140133980A1Document12 pagesUS20140133980A1雷黎明No ratings yet

- US4076107Document7 pagesUS4076107jai2009No ratings yet

- Cessna Citation X-Flight Controls PDFDocument26 pagesCessna Citation X-Flight Controls PDFAyrton NobileNo ratings yet

- Cessna Citation X-Flight Controls PDFDocument26 pagesCessna Citation X-Flight Controls PDFjuanNo ratings yet

- Unit - 1 A/C Control SystemDocument31 pagesUnit - 1 A/C Control Systemverma pavanNo ratings yet

- Pilot Guide Kfc250 BendixDocument28 pagesPilot Guide Kfc250 BendixJavier100% (1)

- ML C m2 c525mmc315Document10 pagesML C m2 c525mmc315Jessie DinoyNo ratings yet

- United States Patent: CarverDocument4 pagesUnited States Patent: CarverwewewewNo ratings yet

- Fligth Control SystemDocument4 pagesFligth Control SystemmecambNo ratings yet

- Us2703500 PDFDocument7 pagesUs2703500 PDFbelchior alvaroNo ratings yet

- Specific Applications: GuidanceDocument12 pagesSpecific Applications: Guidancealphaomega3744No ratings yet

- US3870253Document8 pagesUS3870253gorgiNo ratings yet

- Flight Controls: Operating ManualDocument94 pagesFlight Controls: Operating ManualTest TestNo ratings yet

- Process Instrumentation 2Document8 pagesProcess Instrumentation 2Aditya RasalNo ratings yet

- Meccanismo T.R.Document6 pagesMeccanismo T.R.Marco Raneo PezzanoNo ratings yet

- Syahmi Aem3 Assignment Flight ControlDocument24 pagesSyahmi Aem3 Assignment Flight Controlsyahmi samirNo ratings yet

- New 1Document12 pagesNew 1HshsjNo ratings yet

- Sistemas de Controle Do Onibus EspacialDocument9 pagesSistemas de Controle Do Onibus EspacialNathan Oliveira AssisNo ratings yet

- B737 - 300/400/500 A1, B2 ATA 27 Flight ControlsDocument124 pagesB737 - 300/400/500 A1, B2 ATA 27 Flight ControlsLetun_7686% (7)

- Assignment1Document2 pagesAssignment1Manoj KumarNo ratings yet

- 2023 - Mee 501 - NewDocument71 pages2023 - Mee 501 - NewWasiu OseiweNo ratings yet

- United States Patent: JennyDocument8 pagesUnited States Patent: JennygorgiNo ratings yet

- Opsmans608 FlightcontrolsDocument22 pagesOpsmans608 FlightcontrolsTyler BröggerNo ratings yet

- Simulation of Longitudinal Stability of Helicopter in Forward FlightDocument20 pagesSimulation of Longitudinal Stability of Helicopter in Forward FlightanmarhamidaliNo ratings yet

- 4 - Flight ControlsDocument9 pages4 - Flight ControlsBharath Kumar GoudNo ratings yet

- Easa Mod 13Document28 pagesEasa Mod 13Abdullah Jwifall100% (1)

- Pitch Control System Using LQR and Fuzzy Logic Controller: Nurbaiti@tganu - Uitm.edu - My Fuaad@fke - Utm.myDocument6 pagesPitch Control System Using LQR and Fuzzy Logic Controller: Nurbaiti@tganu - Uitm.edu - My Fuaad@fke - Utm.myStefania OliveiraNo ratings yet

- Flight Control SystemsDocument2 pagesFlight Control SystemsAnkita MundaNo ratings yet

- United States Patent (191 (11) Patent Number: 4,857,881Document9 pagesUnited States Patent (191 (11) Patent Number: 4,857,881Harish MahadevanNo ratings yet

- Automatic Turbine Run Up System 11.1: Fig. 11.1 Operation of Functional Group ControlDocument6 pagesAutomatic Turbine Run Up System 11.1: Fig. 11.1 Operation of Functional Group ControlAnonymous zMWvcTNo ratings yet

- Aircraft Control SystemDocument145 pagesAircraft Control Systemabdel4aliNo ratings yet

- Us2218760 PDFDocument3 pagesUs2218760 PDFbelchior alvaroNo ratings yet

- Simulation of Longitudinal Stability of Helicopter in Forward FlightDocument20 pagesSimulation of Longitudinal Stability of Helicopter in Forward FlightRahulNo ratings yet

- United States Patent: Forward-Reverse and BrakeDocument6 pagesUnited States Patent: Forward-Reverse and Brakejai2009No ratings yet

- Steering Gear SystemsDocument23 pagesSteering Gear SystemsEzy WaqaNo ratings yet

- 12-76. Typical Autopilot Controller.: Flight Director SystemsDocument25 pages12-76. Typical Autopilot Controller.: Flight Director SystemsAdrianNo ratings yet

- Presentation Auto Pilot 1Document59 pagesPresentation Auto Pilot 1Shandy AvisenaNo ratings yet

- Hydraulic Control SystemsDocument15 pagesHydraulic Control SystemsRon McIntyreNo ratings yet

- US5918832Document8 pagesUS5918832engine wangNo ratings yet

- Lecture No 33-37 Flight ControlsDocument65 pagesLecture No 33-37 Flight Controlsabdul masudNo ratings yet

- Aircraft Control SystemDocument125 pagesAircraft Control Systemabdel4aliNo ratings yet

- Aoa 737ngx Groundwork Primary Controls English TranscriptDocument10 pagesAoa 737ngx Groundwork Primary Controls English TranscriptKıvanc TerziogluNo ratings yet

- Helicopter Rotor System and DesignDocument27 pagesHelicopter Rotor System and DesignSumeet Ghodke78% (9)

- July 9, 1968 T M. A. Cardoso 3,391,746: Helicopter Control System Filed May 15, 1967 3 Sheets-Sheet 1Document7 pagesJuly 9, 1968 T M. A. Cardoso 3,391,746: Helicopter Control System Filed May 15, 1967 3 Sheets-Sheet 1rte678No ratings yet

- CL604 Thrust Reverser TroubleshootingDocument31 pagesCL604 Thrust Reverser TroubleshootingmguilbeaultNo ratings yet

- Q9.What Is The Purpose of Collective Control Lever?: Epe EpeDocument17 pagesQ9.What Is The Purpose of Collective Control Lever?: Epe EpeSunny SinghNo ratings yet

- United States Patent: Appl. No. 853,670Document9 pagesUnited States Patent: Appl. No. 853,670gorgiNo ratings yet

- United States Design Patent (10) Patent No.: US D444,512SDocument5 pagesUnited States Design Patent (10) Patent No.: US D444,512SgorgiNo ratings yet

- United States Patent (19) (11) Patent Number: Des. 356,990Document7 pagesUnited States Patent (19) (11) Patent Number: Des. 356,990gorgiNo ratings yet

- United States Patent: (75) Inventor: Robert E. Johnson, Alamitos, Calif., 33. Egm I. DADocument7 pagesUnited States Patent: (75) Inventor: Robert E. Johnson, Alamitos, Calif., 33. Egm I. DAgorgiNo ratings yet

- Patent Application Publication (10) Pub - No .: US 2021/0188423 A1Document20 pagesPatent Application Publication (10) Pub - No .: US 2021/0188423 A1gorgiNo ratings yet

- Patent Application Publication (10) Pub - No .: US 2021/0139140 A1Document69 pagesPatent Application Publication (10) Pub - No .: US 2021/0139140 A1gorgiNo ratings yet

- US3870253Document8 pagesUS3870253gorgiNo ratings yet

- United States Patent: 73) Assignee Mcdonnell Douglas CorporationDocument9 pagesUnited States Patent: 73) Assignee Mcdonnell Douglas CorporationgorgiNo ratings yet

- United States Patent (19) : (45) Sept. 16, 1975Document14 pagesUnited States Patent (19) : (45) Sept. 16, 1975gorgiNo ratings yet

- April 15, 1969: R. G., McintyreDocument9 pagesApril 15, 1969: R. G., McintyregorgiNo ratings yet

- United States Patent (19) : Propulsion System ControlDocument12 pagesUnited States Patent (19) : Propulsion System ControlgorgiNo ratings yet

- United States Patent: JennyDocument8 pagesUnited States Patent: JennygorgiNo ratings yet

- US3370810Document4 pagesUS3370810gorgiNo ratings yet

- European Patent Application: A Wing Tip DeviceDocument16 pagesEuropean Patent Application: A Wing Tip DevicegorgiNo ratings yet

- United States Patent (19) : (73) Assignee: Mcdonnell Douglas Corporation, STDocument13 pagesUnited States Patent (19) : (73) Assignee: Mcdonnell Douglas Corporation, STgorgiNo ratings yet

- ELOP Condor TAC: Tactical Aerial Reconnaissance Photography SystemDocument2 pagesELOP Condor TAC: Tactical Aerial Reconnaissance Photography SystemgorgiNo ratings yet

- ELOP Condor 2: Long Range Oblique Photography SystemDocument2 pagesELOP Condor 2: Long Range Oblique Photography SystemgorgiNo ratings yet

- TEPZZ 4 - 54 6B - T: European Patent SpecificationDocument24 pagesTEPZZ 4 - 54 6B - T: European Patent SpecificationgorgiNo ratings yet

- European Patent Specification B64D 1/06, B64D 7/08: Printed by Jouve, 75001 PARIS (FR)Document12 pagesEuropean Patent Specification B64D 1/06, B64D 7/08: Printed by Jouve, 75001 PARIS (FR)gorgiNo ratings yet

- United States Patent (19) : JohnsonDocument6 pagesUnited States Patent (19) : JohnsongorgiNo ratings yet

- European Patent Specification: Rotating Proprotor Arrangement For A Tiltrotor AircraftDocument23 pagesEuropean Patent Specification: Rotating Proprotor Arrangement For A Tiltrotor AircraftgorgiNo ratings yet

- TEPZZ 45 877B - T: European Patent SpecificationDocument32 pagesTEPZZ 45 877B - T: European Patent SpecificationgorgiNo ratings yet

- TEPZZ 99Z - 8B - T: European Patent SpecificationDocument29 pagesTEPZZ 99Z - 8B - T: European Patent SpecificationgorgiNo ratings yet

- European Patent Specification: Hybrid Propulsion Drive Train System For Tiltrotor AircraftDocument31 pagesEuropean Patent Specification: Hybrid Propulsion Drive Train System For Tiltrotor AircraftgorgiNo ratings yet

- European Patent Application: Foldable Wing Extensions For AircraftDocument16 pagesEuropean Patent Application: Foldable Wing Extensions For AircraftgorgiNo ratings yet

- Decision: Matter Of: Airbus Helicopters, Inc. File: DateDocument23 pagesDecision: Matter Of: Airbus Helicopters, Inc. File: DategorgiNo ratings yet

- A New Midcourse Guidance Design For Near Space Target InterceptorDocument10 pagesA New Midcourse Guidance Design For Near Space Target InterceptorgorgiNo ratings yet

- Elop Amps: Strategic ISR For Manned and Unmanned AircraftDocument2 pagesElop Amps: Strategic ISR For Manned and Unmanned AircraftgorgiNo ratings yet

- EP0807798A1Document10 pagesEP0807798A1gorgiNo ratings yet

- European Patent Application B64C 15/02, B64C 19/02Document46 pagesEuropean Patent Application B64C 15/02, B64C 19/02gorgiNo ratings yet

- Standard Bell Curve For Powerpoint: This Is A Sample Text Here. Insert Your Desired Text HereDocument5 pagesStandard Bell Curve For Powerpoint: This Is A Sample Text Here. Insert Your Desired Text HereGodson YogarajanNo ratings yet

- Notes On Modern PhilosophyDocument20 pagesNotes On Modern PhilosophyÜmit YılmazNo ratings yet

- ProposalDocument7 pagesProposalkarinaNo ratings yet

- 15001-Fanny CrosbyDocument16 pages15001-Fanny CrosbySharjin AuthorNo ratings yet

- Three Stages Sediment Filter and Uv Light Purifier: A Water Treatment SystemDocument36 pagesThree Stages Sediment Filter and Uv Light Purifier: A Water Treatment SystemMark Allen Tupaz MendozaNo ratings yet

- Self-Esteem, - God and The Bible - Who You Are in Christ Is What Counts, Not Your Own Self-Esteem or Accomplishments. - Doug Britton BooksDocument5 pagesSelf-Esteem, - God and The Bible - Who You Are in Christ Is What Counts, Not Your Own Self-Esteem or Accomplishments. - Doug Britton BooksAnonymous jlLBRMAr3ONo ratings yet

- United States Patent: (10) Patent No.: US 8,084,655 B2Document11 pagesUnited States Patent: (10) Patent No.: US 8,084,655 B2AdhityaEkoBagusNo ratings yet

- Difference Between Institute and University - Difference Between - Institute Vs UniversityDocument5 pagesDifference Between Institute and University - Difference Between - Institute Vs Universitytapar.dashNo ratings yet

- VO FinalDocument140 pagesVO Finalsudhasesh2000No ratings yet

- Installation Guide Water and SewerDocument84 pagesInstallation Guide Water and SewerMohammed sabatinNo ratings yet

- TFP321 03 2021Document4 pagesTFP321 03 2021Richard TorresNo ratings yet

- Argumentative Essay Conclusion ExampleDocument6 pagesArgumentative Essay Conclusion Exampleglzhcoaeg100% (2)

- Valerie Rosa Resume 3Document2 pagesValerie Rosa Resume 3api-715391361No ratings yet

- Instant Coffee With Natural Aroma by Spray-Drying.: January 1993Document8 pagesInstant Coffee With Natural Aroma by Spray-Drying.: January 1993Nhan NguyenNo ratings yet

- Full Case Crim ProDocument25 pagesFull Case Crim ProKrystle Hyacinth PescaderaNo ratings yet

- Zero Variance-Problem StatementDocument4 pagesZero Variance-Problem StatementR N Guru50% (2)

- Personal StatementDocument3 pagesPersonal Statementapi-354856949No ratings yet

- Lecture # 23Document14 pagesLecture # 23VaridGuptaNo ratings yet

- Quiz On Past Tenses With Awnsers, 9th GradeDocument2 pagesQuiz On Past Tenses With Awnsers, 9th GradeKristupas S100% (1)

- Ethics and The Three TrainingsDocument10 pagesEthics and The Three TrainingsJuan VizánNo ratings yet

- CH 2 - Electrostatic Potential - MCQDocument2 pagesCH 2 - Electrostatic Potential - MCQDeepali MalhotraNo ratings yet

- Summer Internship Program: "Report OnDocument79 pagesSummer Internship Program: "Report OnritikaNo ratings yet

- HonorariumDocument2 pagesHonorariumSherlock MalluNo ratings yet

- Set LP - 114719Document9 pagesSet LP - 114719Beverly SombiseNo ratings yet

- Gender RolesDocument2 pagesGender RolesВика УсачеваNo ratings yet

- Lecture 9 - Capcity and Level of Service - IIDocument43 pagesLecture 9 - Capcity and Level of Service - IIBasoz Arif AhmadNo ratings yet