Professional Documents

Culture Documents

Boot Strap System

Boot Strap System

Uploaded by

Subash Dhakal0 ratings0% found this document useful (0 votes)

51 views7 pagesThe bootstrap air cooling system uses two compressors to pressurize air in two stages before expanding it in a turbine. It uses ram air and two heat exchangers (an air cooler and after cooler) to cool the compressed air. This system is suitable for high speed aircraft where airflow from flight provides cooling. Ambient air is compressed, cooled in the air cooler using ram air, further compressed, cooled in the after cooler, expanded through the turbine, and supplied to the cabin at low temperature.

Original Description:

boot strap system

Original Title

boot strap system

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe bootstrap air cooling system uses two compressors to pressurize air in two stages before expanding it in a turbine. It uses ram air and two heat exchangers (an air cooler and after cooler) to cool the compressed air. This system is suitable for high speed aircraft where airflow from flight provides cooling. Ambient air is compressed, cooled in the air cooler using ram air, further compressed, cooled in the after cooler, expanded through the turbine, and supplied to the cabin at low temperature.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

51 views7 pagesBoot Strap System

Boot Strap System

Uploaded by

Subash DhakalThe bootstrap air cooling system uses two compressors to pressurize air in two stages before expanding it in a turbine. It uses ram air and two heat exchangers (an air cooler and after cooler) to cool the compressed air. This system is suitable for high speed aircraft where airflow from flight provides cooling. Ambient air is compressed, cooled in the air cooler using ram air, further compressed, cooled in the after cooler, expanded through the turbine, and supplied to the cabin at low temperature.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 7

BOOT-STRAP AIR COOLING SYSTEM

The term Bootstrap as used in Air Cycle Refrigeration

indicates a system in which the pressure of the working fluid is

raised in two levels by using two compressors, before the

working fluid which is air, expands in the turbine section

The main components of this system are:

• Two heat exchangers (air cooler and after cooler)

• A secondary compressor, which is driven by the turbine of the

cooling system

APPLICATION: This system is suitable for high speed aircraft,

where in the velocity of the aircraft provides the necessary

airflow for the heat exchangers

WORKING

• The air bled from the main compressor is first cooled by

the ram air in the first heat exchanger

• The air is then compressed to a higher pressure and

temperature in the compressor of the cooling turbine

• A substantial amount of heat of compression is removed

in the secondary heat exchanger and the air is cooled

further as it expands through the turbine section of the

cooling turbine

BOOT-STRAP AIR COOLING SYSTEM

• Ambient air state 1 is pressurized to

state 2 due to the ram effect

• This air is further compressed to state

3 in the main compressor

• The air is then cooled to state 4 in the

air cooler

• The heat rejected in the air cooler is

absorbed by the ram air at state 2

• The air from the air cooler is further

compressed from state 4 to state 5 in

the secondary compressor

• It is then cooled to state 6 in the after

T-s diagram for a boot-strap

cooler, expanded to cabin pressure in

air cooling system

the cooling turbine and is supplied to

the cabin at a low temperature T7

• If Q tonnes of refrigeration is the cooling load in the cabin, then the

quantity of air required for the refrigeration purpose will be

• Power required for the refrigeration system,

• C.O.P. of the refrigerating system,

ADVANTAGES

• The air is easily available and there is no cost of the

refrigerant

• The air is non-toxic and non-inflammable

• The leakage of air in small amounts is tolerable

• The air is light in weight per tonne of refrigeration

• The chilled air is directly used for cooling, there by

eliminating the cost of separate evaporator

• The pressure in the whole system is quite low, therefore

the piping, ducting etc. are quite simple to design,

fabricate and maintain

LIMITATIONS

• The basic system will cool the cabin when the airplane

is on the ground

• The Bootstrap system requires the airplane to be in

flight so that the ram air can cool the heat exchangers

• Since the system does not consist of a separate fan for

driving the air through the heat exchangers, it is not

suitable for ground cooling

You might also like

- The Basic Parts of An Airplane and Their FunctionsDocument4 pagesThe Basic Parts of An Airplane and Their FunctionsSubash DhakalNo ratings yet

- Anti IcingDocument17 pagesAnti IcingSubash Dhakal100% (1)

- PPT-1 For RAC Lect - GD SirDocument55 pagesPPT-1 For RAC Lect - GD SirKamal Kumar AgrawalNo ratings yet

- APHDocument59 pagesAPHBrijraj Pandey100% (5)

- Bootstrap Air Cooling System AerospaceDocument22 pagesBootstrap Air Cooling System AerospaceShambhavi LeolineLeveret100% (1)

- Mod - 2Document75 pagesMod - 2Kamadana thrilokNo ratings yet

- Gas Refrigeration System (Air Refrigeration)Document30 pagesGas Refrigeration System (Air Refrigeration)Ruturaj UmaranikarNo ratings yet

- Aircraft Refrigeration SystemDocument26 pagesAircraft Refrigeration Systemvinoth kumarNo ratings yet

- Air Cycle RefrigerationDocument15 pagesAir Cycle RefrigerationSyed Wajih Ul HassanNo ratings yet

- Air Refrigeration SystemDocument29 pagesAir Refrigeration SystemSumit KumarNo ratings yet

- Rac CH 2.3Document20 pagesRac CH 2.3Gemechu DelesaNo ratings yet

- Basics of Air ConditioningDocument28 pagesBasics of Air ConditioningdavinderNo ratings yet

- Components and Construction: LO3.2: Identify The Components of A Refrigeration SystemDocument50 pagesComponents and Construction: LO3.2: Identify The Components of A Refrigeration SystemBrianss AyangssNo ratings yet

- CH 3Document33 pagesCH 3beila.amu.22No ratings yet

- Topic 2 Refrigeration NotesDocument56 pagesTopic 2 Refrigeration NotesCia Lev LimNo ratings yet

- Compressor Controls Report CuagoDocument10 pagesCompressor Controls Report Cuagojoseph yatanNo ratings yet

- Marine Hvac SystemDocument58 pagesMarine Hvac SystemSiti Aishah Hussien100% (3)

- 502 CAC-Unit IIIDocument22 pages502 CAC-Unit IIIGauri ShindeNo ratings yet

- Unit 43 Heatpump Air.21FDocument48 pagesUnit 43 Heatpump Air.21FYuk man LawNo ratings yet

- TR 1 Air ConDocument6 pagesTR 1 Air ConLaarni De VeraNo ratings yet

- EME PPT (For 32 To 35) by DivyeshDocument24 pagesEME PPT (For 32 To 35) by DivyeshDivyesh ParmarNo ratings yet

- Systems 10 Pneumatic Systems PDFDocument21 pagesSystems 10 Pneumatic Systems PDFCemalettin öztoprakNo ratings yet

- Unit-2 Airplane Airconditioning SystemsDocument7 pagesUnit-2 Airplane Airconditioning SystemsJabez RichardsNo ratings yet

- ATA 21 - Air Conditioning and PressurizationDocument19 pagesATA 21 - Air Conditioning and PressurizationANIME TIMENo ratings yet

- Air CycleDocument30 pagesAir CycleSalokya KhandelwalNo ratings yet

- Module 5-Multi-Stage Air CompressorDocument26 pagesModule 5-Multi-Stage Air Compressoramit3184No ratings yet

- REf - Air Craft SystemDocument47 pagesREf - Air Craft Systemrag2604756437No ratings yet

- Gas Turbine ! ! ! !Document30 pagesGas Turbine ! ! ! !Faisal KhanNo ratings yet

- Air Craft Refrigeration GRP3Document13 pagesAir Craft Refrigeration GRP3Laka 98No ratings yet

- Bootstrap Air Cooling SystemDocument3 pagesBootstrap Air Cooling Systemsiddharth khattarNo ratings yet

- Pneumatics and Bleed AirDocument9 pagesPneumatics and Bleed AirlouisnathancraigNo ratings yet

- Lecture 30 Thermal Engineering II (22.09.2020)Document36 pagesLecture 30 Thermal Engineering II (22.09.2020)Dr. BIBIN CHIDAMBARANATHANNo ratings yet

- Gas Turbine 1Document25 pagesGas Turbine 1Muhammed SabeehNo ratings yet

- CH 3 Gas Refrigeration CycleDocument20 pagesCH 3 Gas Refrigeration CycleMeleseNo ratings yet

- Turbocharger and Supercharger 2Document36 pagesTurbocharger and Supercharger 2shoaibNo ratings yet

- Cooling SystemDocument18 pagesCooling SystemElFear P. NayawiNo ratings yet

- Power Plant EngineeringDocument158 pagesPower Plant EngineeringtamilvananirttNo ratings yet

- Psychrometric ChartDocument63 pagesPsychrometric ChartCutekarthik Subramanian100% (1)

- Gas Turbine Power Plant: By: Ms. Monika DeshwalDocument19 pagesGas Turbine Power Plant: By: Ms. Monika DeshwalKeshantSharma100% (2)

- Jet PropulsionDocument20 pagesJet PropulsionVeeranagireddyNo ratings yet

- TE 4th Module - Air CompressorDocument58 pagesTE 4th Module - Air Compressoralbin thomasNo ratings yet

- Air Conditioning (Temperature Control in Military Aircrafts)Document12 pagesAir Conditioning (Temperature Control in Military Aircrafts)AhmedAbdelZaherNo ratings yet

- Air-Conditioning System 1 (2024)Document31 pagesAir-Conditioning System 1 (2024)mohamed A.abdeltwabNo ratings yet

- Systems 11 Cabin Pressurisation S60 PDFDocument100 pagesSystems 11 Cabin Pressurisation S60 PDFCemalettin öztoprakNo ratings yet

- AIRCON - Powerpoint PresentationDocument64 pagesAIRCON - Powerpoint PresentationAnonymous zMXgZVENo ratings yet

- Air Refrigeration CycleDocument16 pagesAir Refrigeration Cyclesuraj singhNo ratings yet

- Gas Turbine: Olar LoungeDocument34 pagesGas Turbine: Olar Loungepkdevan68100% (1)

- Cooling System: Types of Collling Systems & ComponentsDocument12 pagesCooling System: Types of Collling Systems & ComponentsChudhary waseem asgharNo ratings yet

- Cooling of TransformersDocument15 pagesCooling of TransformersJatin YadavNo ratings yet

- Gas Turbine1Document29 pagesGas Turbine1swarg patelNo ratings yet

- Forced Draft Fan: by Justice. A. OfugaraDocument37 pagesForced Draft Fan: by Justice. A. OfugaraobisonandlawNo ratings yet

- Intro Gas Turbine Eng.Document57 pagesIntro Gas Turbine Eng.juniorowu12No ratings yet

- RAC - Unit 5 - Working of Window ACDocument11 pagesRAC - Unit 5 - Working of Window ACSAATVIK JAINNo ratings yet

- Unit Ii: Turboprop and TurbojetDocument55 pagesUnit Ii: Turboprop and TurbojetALAGANDULA NIKHIL0% (1)

- HVAC Equipment: MAE 406 Energy Conservation in Industry Stephen TerryDocument29 pagesHVAC Equipment: MAE 406 Energy Conservation in Industry Stephen TerrySuresh KumarNo ratings yet

- Automobile Engine Cooling System: Saad Ul Hasnain 2004-MECH-81 DMBDocument7 pagesAutomobile Engine Cooling System: Saad Ul Hasnain 2004-MECH-81 DMBtechcharmerNo ratings yet

- HVAC ControlsDocument24 pagesHVAC ControlsKunal DeshmukhNo ratings yet

- Oral and Practical Review: Reflections on the Part 147 CourseFrom EverandOral and Practical Review: Reflections on the Part 147 CourseNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Unit - I Part - ADocument108 pagesUnit - I Part - ASubash DhakalNo ratings yet

- Introduction To Lean ManufacturingDocument37 pagesIntroduction To Lean ManufacturingSubash DhakalNo ratings yet

- Six SigmaDocument25 pagesSix SigmaSubash DhakalNo ratings yet

- Cellular ManufacturingDocument42 pagesCellular ManufacturingSubash DhakalNo ratings yet

- Control Surfaces Notes PDFDocument12 pagesControl Surfaces Notes PDFSubash DhakalNo ratings yet

- Components of An AirplaneDocument8 pagesComponents of An AirplaneSubash DhakalNo ratings yet

- Flight InstrumentsDocument17 pagesFlight InstrumentsSubash DhakalNo ratings yet

- Gap Analysis ReportDocument19 pagesGap Analysis ReportBella Rizkiani100% (1)

- Ficha-Tecnica Bomba Sumergible 02-21 Tsurumi-Hs3.75sDocument2 pagesFicha-Tecnica Bomba Sumergible 02-21 Tsurumi-Hs3.75sSHARON CANO ORTEGANo ratings yet

- Belt Data Sheet - PhoenixDocument2 pagesBelt Data Sheet - PhoenixSeshuNo ratings yet

- Pneumatic ComponentsDocument30 pagesPneumatic ComponentsatertemizNo ratings yet

- Martillo Epiroc 2Document8 pagesMartillo Epiroc 2Robinson ReyesNo ratings yet

- Bombardier CRJ 00-Flight ControlsDocument58 pagesBombardier CRJ 00-Flight ControlsWilliam Jaldin CorralesNo ratings yet

- SJJ Series Compulsive Extrusion MixerDocument4 pagesSJJ Series Compulsive Extrusion MixerNicolas MolinaNo ratings yet

- Doorma Caba Door HardwaresDocument34 pagesDoorma Caba Door HardwaresjunaidNo ratings yet

- SW Pipe Fittings DimensionsDocument1 pageSW Pipe Fittings DimensionsManigandan RNo ratings yet

- Column With Biaxial MomentDocument18 pagesColumn With Biaxial MomentvibishnanNo ratings yet

- Department of Mechanical Engineering, RTU VII - SEM-AUTOCAD Lab - Internal Quiz MM - 20 Name: Roll NoDocument2 pagesDepartment of Mechanical Engineering, RTU VII - SEM-AUTOCAD Lab - Internal Quiz MM - 20 Name: Roll Norohit guptaNo ratings yet

- AGITATOR DRAWINGS-ModelDocument1 pageAGITATOR DRAWINGS-ModelMonty KushwahaNo ratings yet

- Ins. Overhead CraneDocument4 pagesIns. Overhead CranePetrusNo ratings yet

- NigataDocument2 pagesNigataArief utamaNo ratings yet

- Resume For The Post of Tank /welding / Piping Inspector.Document28 pagesResume For The Post of Tank /welding / Piping Inspector.AJMAL KAREEMNo ratings yet

- HFY-3800-0000-GEN-PD-0013 - 0 Welding and Welding Consumable Control Procedure-Code ADocument14 pagesHFY-3800-0000-GEN-PD-0013 - 0 Welding and Welding Consumable Control Procedure-Code ANashaat DhyaaNo ratings yet

- Filtrec F160 SeriesDocument8 pagesFiltrec F160 Serieshkhan10No ratings yet

- Instrolex Instrumentation SWADocument2 pagesInstrolex Instrumentation SWANima MoaddeliNo ratings yet

- Elastomod Kit Installation PDFDocument20 pagesElastomod Kit Installation PDFishakNo ratings yet

- R125lcr-9a R125lcrd-9a Demo PDFDocument37 pagesR125lcr-9a R125lcrd-9a Demo PDFsonjisahuri100% (1)

- Module 2 - CmatsDocument10 pagesModule 2 - CmatsreesespufffNo ratings yet

- Strip PAD: Fabrication AI02571 AI01651 AI01046 AI02525 OF AI02252 Finish AI02719Document1 pageStrip PAD: Fabrication AI02571 AI01651 AI01046 AI02525 OF AI02252 Finish AI02719Isaías AguilarNo ratings yet

- DI-EDC-PTP-553-002 REV. A - SUPPORT C2-A-C2-B - ApprDocument2 pagesDI-EDC-PTP-553-002 REV. A - SUPPORT C2-A-C2-B - ApprMc Dowell CampangNo ratings yet

- Turbine Q&ADocument7 pagesTurbine Q&AVijay KumarNo ratings yet

- Pes Gun Manual - A5 Printable 2Document20 pagesPes Gun Manual - A5 Printable 2Ruban GeorgeNo ratings yet

- Concept Design and Development of Semi Automated Potato Slicing Machine PDFDocument4 pagesConcept Design and Development of Semi Automated Potato Slicing Machine PDFjunaidadilNo ratings yet

- Circuit Setter: Calibrated Balance Valves With Flanged ConnectionsDocument2 pagesCircuit Setter: Calibrated Balance Valves With Flanged ConnectionsJulio MorenoNo ratings yet

- SEW Operating Instructions 2008 EnglishDocument132 pagesSEW Operating Instructions 2008 EnglishEmerson IpialesNo ratings yet

- Failures Modes of Riveted JointsDocument5 pagesFailures Modes of Riveted JointsGokul Goku SanthiNo ratings yet

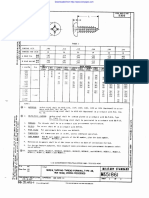

- MS51861ADocument3 pagesMS51861AbaluchiifNo ratings yet