Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

50 viewsHSK78G Maintenance Schedule

HSK78G Maintenance Schedule

Uploaded by

Muhammad SohailCummins C2000N5CC HSK78G maintenance schedule

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Mechanical Engineering Internship Report by Job Lazarus Okello PDFDocument58 pagesMechanical Engineering Internship Report by Job Lazarus Okello PDFnufaza97100% (6)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Variable Frequency DriveDocument26 pagesVariable Frequency Driveashwinichodisetti_3771% (7)

- Seat Leon 2020 SSP177 - ENDocument76 pagesSeat Leon 2020 SSP177 - ENPaulo Marcelo100% (3)

- Đề Cương CHKII - 22.23 (Global)Document6 pagesĐề Cương CHKII - 22.23 (Global)loanlazy1807No ratings yet

- Nitrox 125 Picture Book 2010 12 09Document80 pagesNitrox 125 Picture Book 2010 12 09Gloria RamirezNo ratings yet

- Abdul Qadir Khan Contact InfoDocument4 pagesAbdul Qadir Khan Contact InfobhaskarNo ratings yet

- Char Lynn 104 2000 Series Motor Data SheetDocument28 pagesChar Lynn 104 2000 Series Motor Data Sheetsyahril boonieNo ratings yet

- Sistema de Combustible c15Document10 pagesSistema de Combustible c15Elmer Tintaya MamaniNo ratings yet

- Materials Handling EquipmentDocument58 pagesMaterials Handling Equipmentahmed jemalNo ratings yet

- Solid Waste Management in KolkataDocument9 pagesSolid Waste Management in KolkatavivekbhuchemNo ratings yet

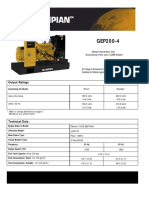

- Catalogo Gep200-4Document4 pagesCatalogo Gep200-4Felix PerezNo ratings yet

- Zero-Emission Bus and Truck Market in The United States and Canada: A 2020 UpdateDocument6 pagesZero-Emission Bus and Truck Market in The United States and Canada: A 2020 UpdateThe International Council on Clean TransportationNo ratings yet

- RAP MARYAM - R02 (Old)Document34 pagesRAP MARYAM - R02 (Old)Asad MuhammadNo ratings yet

- Dec 23 Sohar Oman North America Trading LLCDocument3 pagesDec 23 Sohar Oman North America Trading LLCsuleimanalhinai93No ratings yet

- Dynapac Pneumatic Tire Roller Cp1200 Operation and MaintenanceDocument8 pagesDynapac Pneumatic Tire Roller Cp1200 Operation and Maintenancemanuel100% (52)

- Program SEIKEN 2020 - REV.2Document3 pagesProgram SEIKEN 2020 - REV.2franzknievelNo ratings yet

- United Gear IntroductionDocument13 pagesUnited Gear IntroductionKOMATSU SHOVELNo ratings yet

- Accessories-6-Electric WiringDocument46 pagesAccessories-6-Electric WiringCarlos TecnicNo ratings yet

- Quick User GuideDocument43 pagesQuick User GuideEink SimNo ratings yet

- Fuel, Lubricants & Fluids SCANIA NTGDocument58 pagesFuel, Lubricants & Fluids SCANIA NTGcah ndeso channelNo ratings yet

- Foden Alpha 8 X 4 Steel Tipper 2002 Rj02 JwuDocument1 pageFoden Alpha 8 X 4 Steel Tipper 2002 Rj02 JwuOumarba Kamanda100% (1)

- SM2 Quiz 4Document10 pagesSM2 Quiz 4Ashlesha VermaNo ratings yet

- IATF - International Automotive Task Force: Rules For Achieving and Maintaining IATF Recognition IATF Rules 5 EditionDocument9 pagesIATF - International Automotive Task Force: Rules For Achieving and Maintaining IATF Recognition IATF Rules 5 EditionCarlos LimaNo ratings yet

- 50 TOP POWER ELECTRONICS Interview Questions and Answers PDF POWER ELECTRONICS Interview Questions PDFDocument10 pages50 TOP POWER ELECTRONICS Interview Questions and Answers PDF POWER ELECTRONICS Interview Questions PDFSIVAKAMINo ratings yet

- Advance Product Quality Planning Status ReportDocument30 pagesAdvance Product Quality Planning Status ReporttapanNo ratings yet

- Alessandrini Et Al. 2012 - Consumption Calculation of Vehicles Using OBD DataDocument18 pagesAlessandrini Et Al. 2012 - Consumption Calculation of Vehicles Using OBD DataPedro MunizNo ratings yet

- Pick and Place Robotic Arm Using PLC IJERTV8IS080268 PDFDocument4 pagesPick and Place Robotic Arm Using PLC IJERTV8IS080268 PDFDinesh PanickerNo ratings yet

- Volvo Transmission Oil LineDocument7 pagesVolvo Transmission Oil Lineᴀʙʜɪ JOHALNo ratings yet

- Sandvik RD5 Series Rock DrillsDocument17 pagesSandvik RD5 Series Rock Drillsroland100% (1)

- Traffic Management PLANDocument12 pagesTraffic Management PLANalla malikNo ratings yet

HSK78G Maintenance Schedule

HSK78G Maintenance Schedule

Uploaded by

Muhammad Sohail0 ratings0% found this document useful (0 votes)

50 views7 pagesCummins C2000N5CC HSK78G maintenance schedule

Original Title

HSK78G maintenance schedule

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCummins C2000N5CC HSK78G maintenance schedule

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

50 views7 pagesHSK78G Maintenance Schedule

HSK78G Maintenance Schedule

Uploaded by

Muhammad SohailCummins C2000N5CC HSK78G maintenance schedule

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 7

8.

2 One Time Only - C2000N5CD Maintenance Schedule C2000N5CD Maintenance Schedule

C1550P5CD, C1600N5CD, C1800N5CD, C2000N5CD 8 - Maintenance

8.1 C2000N5CD Maintenance Schedule - Daily Check

Perform daily, or every 8 hours

Task Daily Page

Check the cooling system level or pressure. X 334

Check the lubricating oil level. X 332

Check the air intake system plumbing for leaks. X 335

Check the exhaust system plumbing for leaks. X 336

Check for air filter restriction. X 335

Check hoses for signs of rubbing or damage. X 331

Check the fuel system for leaks. X 331

Check the harnesses and electrical

X 337

connections.

Check the operator panel for fault codes. X 248

Check the grease level in the automatic

X 338

regreaser.

Monitor the spark plug breakdown voltage. X 250

Check the wiring harnesses. X 337

Check the ignition system box air filter for

X

debris buildup.

8.2 C2000N5CD Maintenance Schedule - One Time Only

Task Hours Page

Replace the lubricating oil filters. 250

Measure the valve lash. 250

Sample the coolant. 250

Check the alternator drive end bearing

250

temperature.

Check the alternator non-drive end bearing

250

temperature.

Measure the supplemental coolant additive

250

concentration.

Replace the lubricating oil. 250

Check the alternator fan for damage. 250

Measure and record the baseline valve stem

250

height.

A059L026 (Issue 7) Page 303 © 2021 Cummins Inc.

C2000N5CD Maintenance Schedule 8.3 Routine Maintenance - C2000N5CD Maintenance

Schedule

8 - Maintenance C1550P5CD, C1600N5CD, C1800N5CD, C2000N5CD

8.3 C2000N5CD Maintenance Schedule - Routine Maintenance

Task Hours Month Years Page

Sample the lubricating oil. 250 1

Analyze the lubricating oil sample. 250 1

Replace the lubricating oil, refer to the

maintenance interval procedure for additional 1500 1

information.(As necessary)

Clean the ignition system box air filter.(As

1500 1

necessary)

Replace the lubricating oil filters, refer to the

maintenance interval procedure for additional 1500 1

information.(As necessary)

Measure the emissions. 3000 6

Replace the crankcase breather filter element

(closed crankcase ventilation), refer to the

3000 1

maintenance interval procedure for additional

information.(As necessary)

Test the local and remote emergency stops. 3000 6

Check the alternator fan for damage. 3000

Inspect the drive coupling rubber element. 3000 6

Clean the drive end bearing grease from the

3000

alternator adapter.

Replace the air filters, refer to the maintenance

interval procedure for additional information.(As 3000

necessary)

Check the lubricating oil circulating pump fan

3000 6

for debris buildup.

Check the starter batteries. 3000 6

Check the alternator non-drive end bearing

3000

temperature.

Check the alternator drive end bearing

3000

temperature.

Check the charging alternator drive belt for

3000

damage.

Measure the supplemental coolant additive

3000 6

concentration.

Measure the valve recession. 3000

Measure the spark plug gaps, refer to the

maintenance interval procedure for additional 3000

information.(As necessary)

Sample the coolant. 3000 6

© 2021 Cummins Inc. Page 304 A059L026 (Issue 7)

8.3 Routine Maintenance - C2000N5CD Maintenance C2000N5CD Maintenance Schedule

Schedule

C1550P5CD, C1600N5CD, C1800N5CD, C2000N5CD 8 - Maintenance

Task Hours Month Years Page

Clean the alternator non-drive end grease trap. 3000

Measure the valve lash. 3000

Replace the ignition system box air filter.(As

6000 6

necessary)

Replace the NOx sensors. 6000

Replace crankcase breather filter element

(open crankcase ventilation), refer to the

6000 1

maintenance interval procedure for additional

information.(As necessary)

Replace the exhaust gas oxygen sensors. 6000

Fill the automatic regreaser.(As necessary) 7500

Inspect the starter batteries. 7500 1

Check the lubricating oil heater operation.(If

7500 1

equipped)

Check the low temperature electric water

7500 1

pump motor fan for debris buildup.(If equipped)

Check the coolant heater assembly operation. 7500 1

Check the high temperature electric water

7500 1

pump motor fan for debris buildup.(If equipped)

Measure the charging alternator drive belt

7500 1

tension.

Replace the spark plugs, refer to the

maintenance interval procedure for additional 9000

information.

Check the exhaust system outlet connection

15000

bellows.

Replace the charging alternator drive belt. 15000

Clean the center chamber of the air filter

15000 2

housing.

Check the exhaust transfer connection

15000

bellows.

Service the turbochargers. 15000

Check the turbocharger wastegate bellows. 19500

Replace the coolant heater thermostat. 19500 3

Replace the coolant, refer to the maintenance

interval procedure for additional information.(As 19500 3

necessary)

Replace the wastegate valve assembly. 19500

Replace the lubricating oil circulating pump

19500

coupling.(If equipped)

A059L026 (Issue 7) Page 305 © 2021 Cummins Inc.

C2000N5CD Maintenance Schedule 8.4 Mid-Life Schedule - C2000N5CD Maintenance Schedule

8 - Maintenance C1550P5CD, C1600N5CD, C1800N5CD, C2000N5CD

8.4 C2000N5CD Maintenance Schedule - Mid-Life Schedule

Task Hours Page

Perform the insulation resistance test. 40000

Replace the exhaust manifold insulation.(As

40000

necessary)

Inspect the Control Batteries. 40000

Replace the connecting rod capscrews. 40000

Inspect the connecting rod. 40000

Replace the DC converter fan. 40000

Replace the ignition coils. 40000

Check the exhaust manifold transfer

40000

connection.

Check the turbocharger wastegate transfer

40000

connection.

Check the turbocharger turbine intake transfer

40000

connection.

Check the turbocharger wastegate transfer

40000

connections bellows.

Check the exhaust manifold bellows. 40000

Check the valve proving system filter for debris

40000

buildup.

Replace the exhaust transfer connection

40000

insulation.(As necessary)

Replace the wastegate valve assembly

40000

insulation.(As necessary)

Replace the ignition system box fan. 40000

Replace the prechamber insert. 40000

Replace the engine mount slip joint washers. 40000

Replace the mechanical water pump.(If

40000

equipped)

Replace the rear crankshaft seal. 40000

Replace the front crankshaft seal. 40000

Replace the cylinder liner. 40000

Replace the connecting rod bearings. 40000

Check the aftercooler assembly. 40000

Replace the drive coupling rubber element. 40000

Replace the anti-condensation heater. 40000

Replace the varistors. 40000

© 2021 Cummins Inc. Page 306 A059L026 (Issue 7)

8.5 Overhaul Schedule - C2000N5CD Maintenance Schedule C2000N5CD Maintenance Schedule

C1550P5CD, C1600N5CD, C1800N5CD, C2000N5CD 8 - Maintenance

Task Hours Page

Replace the diodes. 40000

Replace the alternator drive end bearing

40000

assembly.

Replace the alternator non-drive end bearing

40000

assembly.

Replace the cylinder heads. 40000

Check the exhaust manifolds. 40000

8.5 C2000N5CD Maintenance Schedule - Overhaul Schedule

Task Hours Page

Perform the insulation resistance test. 40000

Check the turbocharger wastegate transfer

40000

connection.

Replace the cylinder heads. 40000

Replace the wastegate valve assembly

40000

insulation.(As necessary)

Replace the exhaust transfer connection

40000

insulation.(As necessary)

Check the valve proving system filter for debris

40000

buildup.

Check the exhaust manifold bellows. 40000

Check the turbocharger wastegate transfer

40000

connections bellows.

Check the turbocharger turbine intake transfer

40000

connection.

Check the exhaust manifold transfer

40000

connection.

Replace the engine mount slip joint washers. 40000

Replace the ignition coils. 40000

Replace the DC converter fan. 40000

Inspect the connecting rod. 40000

Replace the connecting rod capscrews. 40000

Inspect the Control Batteries. 40000

Check the exhaust manifolds. 40000

Inspect the piston pin. 40000

Inspect the pistons. 40000

Replace the ignition system box fan. 40000

A059L026 (Issue 7) Page 307 © 2021 Cummins Inc.

C2000N5CD Maintenance Schedule 8.5 Overhaul Schedule - C2000N5CD Maintenance Schedule

8 - Maintenance C1550P5CD, C1600N5CD, C1800N5CD, C2000N5CD

Task Hours Page

Replace the exhaust manifold insulation.(As

40000

necessary)

Replace the varistors. 40000

Replace the connecting rod bearings. 40000

Replace the mechanical water pump.(If

40000

equipped)

Replace the rear crankshaft seal. 40000

Replace the front crankshaft seal. 40000

Replace the alternator non-drive end bearing

40000

assembly.

Replace the alternator drive end bearing

40000

assembly.

Replace the diodes. 40000

Replace the cylinder liner. 40000

Replace the anti-condensation heater. 40000

Replace the drive coupling rubber element. 40000

Replace flexible hoses.(As necessary) 80000

Inspect the crankshaft. 80000

Replace the camshaft bushings. 80000

Replace the pistons. 80000

Replace the piston pins. 80000

Inspect the engine lubricating oil pump idler

80000

gear thrust bearing.

Inspect the camshaft compound idler gear

80000

thrust bearing.

Inspect the crankshaft. 80000

Replace the camshaft thrust bearing. 80000

Inspect the push rods. 80000

Measure gear train backlash. 80000

Replace the rocker lever assembly. 80000

Replace the cam follower assemblies. 80000

Replace the viscous vibration damper. 80000

Replace the piston cooling nozzles. 80000

Replace the crankshaft thrust bearings. 80000

Replace the main bearings. 80000

Replace the lubricating oil pump assembly. 80000

Replace the gas fuel line seals. 80000

© 2021 Cummins Inc. Page 308 A059L026 (Issue 7)

8.6 Daily Check - C1800N5CD Maintenance Schedule C1800N5CD Maintenance Schedule

C1550P5CD, C1600N5CD, C1800N5CD, C2000N5CD 8 - Maintenance

Task Hours Page

Inspect the camshaft compound idler gear. 80000

Inspect the cylinder block. 80000

Replace the oil circulating pump. 80000

Inspect the camshaft. 80000

Replace the aftercooler core. 80000

Check the front camshaft gear. 80000

Inspect the water pump idler gear. 80000

Inspect the engine lubricating oil pump idler

80000

gear.

Inspect the water pump idler gear thrust

80000

bearing.

8.6 C1800N5CD Maintenance Schedule - Daily Check

Perform daily, or every 8 hours

Task Daily Page

Check the cooling system level or pressure. X 334

Check the lubricating oil level. X 332

Check the air intake system plumbing for leaks. X 335

Check the exhaust system plumbing for leaks. X 336

Check for air filter restriction. X 335

Check hoses for signs of rubbing or damage. X 331

Check the fuel system for leaks. X 331

Check the harnesses and electrical

X 337

connections.

Check the operator panel for fault codes. X 248

Check the grease level in the automatic

X 338

regreaser.

Monitor the spark plug breakdown voltage. X 250

Check the wiring harnesses. X 337

Check the ignition system box air filter for

X

debris buildup.

A059L026 (Issue 7) Page 309 © 2021 Cummins Inc.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Mechanical Engineering Internship Report by Job Lazarus Okello PDFDocument58 pagesMechanical Engineering Internship Report by Job Lazarus Okello PDFnufaza97100% (6)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Variable Frequency DriveDocument26 pagesVariable Frequency Driveashwinichodisetti_3771% (7)

- Seat Leon 2020 SSP177 - ENDocument76 pagesSeat Leon 2020 SSP177 - ENPaulo Marcelo100% (3)

- Đề Cương CHKII - 22.23 (Global)Document6 pagesĐề Cương CHKII - 22.23 (Global)loanlazy1807No ratings yet

- Nitrox 125 Picture Book 2010 12 09Document80 pagesNitrox 125 Picture Book 2010 12 09Gloria RamirezNo ratings yet

- Abdul Qadir Khan Contact InfoDocument4 pagesAbdul Qadir Khan Contact InfobhaskarNo ratings yet

- Char Lynn 104 2000 Series Motor Data SheetDocument28 pagesChar Lynn 104 2000 Series Motor Data Sheetsyahril boonieNo ratings yet

- Sistema de Combustible c15Document10 pagesSistema de Combustible c15Elmer Tintaya MamaniNo ratings yet

- Materials Handling EquipmentDocument58 pagesMaterials Handling Equipmentahmed jemalNo ratings yet

- Solid Waste Management in KolkataDocument9 pagesSolid Waste Management in KolkatavivekbhuchemNo ratings yet

- Catalogo Gep200-4Document4 pagesCatalogo Gep200-4Felix PerezNo ratings yet

- Zero-Emission Bus and Truck Market in The United States and Canada: A 2020 UpdateDocument6 pagesZero-Emission Bus and Truck Market in The United States and Canada: A 2020 UpdateThe International Council on Clean TransportationNo ratings yet

- RAP MARYAM - R02 (Old)Document34 pagesRAP MARYAM - R02 (Old)Asad MuhammadNo ratings yet

- Dec 23 Sohar Oman North America Trading LLCDocument3 pagesDec 23 Sohar Oman North America Trading LLCsuleimanalhinai93No ratings yet

- Dynapac Pneumatic Tire Roller Cp1200 Operation and MaintenanceDocument8 pagesDynapac Pneumatic Tire Roller Cp1200 Operation and Maintenancemanuel100% (52)

- Program SEIKEN 2020 - REV.2Document3 pagesProgram SEIKEN 2020 - REV.2franzknievelNo ratings yet

- United Gear IntroductionDocument13 pagesUnited Gear IntroductionKOMATSU SHOVELNo ratings yet

- Accessories-6-Electric WiringDocument46 pagesAccessories-6-Electric WiringCarlos TecnicNo ratings yet

- Quick User GuideDocument43 pagesQuick User GuideEink SimNo ratings yet

- Fuel, Lubricants & Fluids SCANIA NTGDocument58 pagesFuel, Lubricants & Fluids SCANIA NTGcah ndeso channelNo ratings yet

- Foden Alpha 8 X 4 Steel Tipper 2002 Rj02 JwuDocument1 pageFoden Alpha 8 X 4 Steel Tipper 2002 Rj02 JwuOumarba Kamanda100% (1)

- SM2 Quiz 4Document10 pagesSM2 Quiz 4Ashlesha VermaNo ratings yet

- IATF - International Automotive Task Force: Rules For Achieving and Maintaining IATF Recognition IATF Rules 5 EditionDocument9 pagesIATF - International Automotive Task Force: Rules For Achieving and Maintaining IATF Recognition IATF Rules 5 EditionCarlos LimaNo ratings yet

- 50 TOP POWER ELECTRONICS Interview Questions and Answers PDF POWER ELECTRONICS Interview Questions PDFDocument10 pages50 TOP POWER ELECTRONICS Interview Questions and Answers PDF POWER ELECTRONICS Interview Questions PDFSIVAKAMINo ratings yet

- Advance Product Quality Planning Status ReportDocument30 pagesAdvance Product Quality Planning Status ReporttapanNo ratings yet

- Alessandrini Et Al. 2012 - Consumption Calculation of Vehicles Using OBD DataDocument18 pagesAlessandrini Et Al. 2012 - Consumption Calculation of Vehicles Using OBD DataPedro MunizNo ratings yet

- Pick and Place Robotic Arm Using PLC IJERTV8IS080268 PDFDocument4 pagesPick and Place Robotic Arm Using PLC IJERTV8IS080268 PDFDinesh PanickerNo ratings yet

- Volvo Transmission Oil LineDocument7 pagesVolvo Transmission Oil Lineᴀʙʜɪ JOHALNo ratings yet

- Sandvik RD5 Series Rock DrillsDocument17 pagesSandvik RD5 Series Rock Drillsroland100% (1)

- Traffic Management PLANDocument12 pagesTraffic Management PLANalla malikNo ratings yet