Professional Documents

Culture Documents

Purpose Risk Identification Responsibilities Risk Assessment Risk Response Risk Mitigation Risk Contingency Planning

Purpose Risk Identification Responsibilities Risk Assessment Risk Response Risk Mitigation Risk Contingency Planning

Uploaded by

Quality Unit 1 Ajay PandeyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Purpose Risk Identification Responsibilities Risk Assessment Risk Response Risk Mitigation Risk Contingency Planning

Purpose Risk Identification Responsibilities Risk Assessment Risk Response Risk Mitigation Risk Contingency Planning

Uploaded by

Quality Unit 1 Ajay PandeyCopyright:

Available Formats

SILCOTECH BONNY PRODUCTS (INDIA) PVT. LTD.

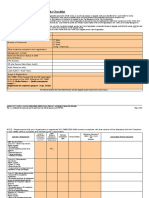

AUTOMOTIVE QUALITY Date of Issue: 01/07/2018

MANAGEMENT SYSTEM PROCEDURE FOR RISK Issue No. 01 .Rev. No. 01

IATF 16949:2016 MANAGEMENT Date of Rev.06/06/2018

(SBPIPL/OCP/08/01)

Procedure: Risk Management

Table of Contents

Summary

Purpose

Risk Identification

Responsibilities

Risk Assessment

Risk Response

Risk Mitigation

Risk Contingency Planning

Issued By : QC Head 1 Approved By : Director

SILCOTECH BONNY PRODUCTS (INDIA) PVT. LTD.

AUTOMOTIVE QUALITY Date of Issue: 01/07/2018

MANAGEMENT SYSTEM PROCEDURE FOR RISK Issue No. 01 .Rev. No. 01

IATF 16949:2016 MANAGEMENT Date of Rev.06/06/2018

(SBPIPL/OCP/08/01)

Summary:

Risk is defined as an event that has a probability of occurring, and could have either a positive

or negative impact to a project/process should that risk occur. A risk may have one or more

causes and, if it occurs, one or more impacts.

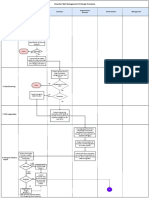

Risk management is an ongoing process that continues through the life of a project/process. It

includes processes for risk management planning, identification, analysis, monitoring and

control. Many of these processes are updated throughout the project/process lifecycle as new

risks can be identified at any time. It’s the objective of risk management to decrease the

probability and impact of events adverse to the project/process.

Purpose

This plan documents the processes, tools and procedures that will be used to manage and

control.

Risk Identification

A risk is any event that could prevent the project/process from progressing as planned, or from

successful completion. Risks can be identified from a number of different sources. Some may

be quite obvious and will be identified prior to project/process kickoff.

Others will be identified during the project/process lifecycle, and a risk can be identified by

anyone associated with the project/process. Some risk will be inherent to the project/process

itself, while others will be the result of external influences that are completely outside the control

of the project/process team.

The project/process manager will determine if any of the newly identified risk factors or events

warrant further evaluation. Those that do will undergo risk quantification and risk response

development, as appropriate, and the action item will be closed.

Risk Responsibilities

Director, Production Head, QC Head and all other departments head

Risk Assessment

Risk assessment is the act of determining the probability that a risk will occur and the impact

that event would have, should it occur. This is basically a “cause and effect” analysis. The

“cause” is the event that might occur, while the “effect” is the potential impact to a

project/process, should the event occur.

Issued By : QC Head 2 Approved By : Director

SILCOTECH BONNY PRODUCTS (INDIA) PVT. LTD.

AUTOMOTIVE QUALITY Date of Issue: 01/07/2018

MANAGEMENT SYSTEM PROCEDURE FOR RISK Issue No. 01 .Rev. No. 01

IATF 16949:2016 MANAGEMENT Date of Rev.06/06/2018

(SBPIPL/OCP/08/01)

Assessment of a risk involves two factors. First is the probability which is the measure of

certainty that an event, or risk, will occur.

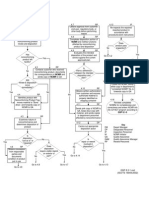

Risk Response

For each identified risk, a response must be identified. It is the responsibility of the

project/process team to select a risk response for each risk. The project/process team will need

the best possible assessment of the risk and description of the response options in order to

select the right response for each risk. The probability of the risk event occurring and the

impacts will be the basis for determining the degree to which the actions to mitigate the risk

should be taken. One way of evaluating mitigation strategies is to multiply the risk cost times the

probability of occurrence.

Risk Mitigation

Risk mitigation involves two steps: • Identifying the various activities, or steps, to reduce the

probability and/or impact of an adverse risk. • Creation of a Contingency Plan to deal with the

risk should it occur.

Taking early steps to reduce the probability of an adverse risk occurring may be more effective

and less costly than repairing the damage after a risk has occurred. However, some risk

mitigation options may simply be too costly in time or money to consider.

Mitigation activities should be linkage and documented in the COTO LOG and Risk Register,

and reviewed on a regular basis. They include: • Identification of potential failure points for each

risk mitigation solution. For each failure point, provide alternatives for correcting the failure.

Risk Contingency Planning

Contingency planning is the act of preparing a plan, or a series of activities, should an adverse

risk occur. Having a contingency plan in place forces the project/process team to think in

advance as to a course of action if a risk event takes place. • Identify the contingency plan

tasks (or steps) that can be performed to implement the mitigation strategy. • Identify the

necessary resources such as money, equipment and labor. • Develop a contingency plan

schedule.

Processes to Address Immediate Unforeseen Risks

The individual identifying the risk will immediately notify the project/process managers. The

individual notified will assess the risk situation. If required, the project/process managers will

identify a mitigating strategy, and assign resources as necessary work.

Record/Reference:

Issued By : QC Head 3 Approved By : Director

SILCOTECH BONNY PRODUCTS (INDIA) PVT. LTD.

AUTOMOTIVE QUALITY Date of Issue: 01/07/2018

MANAGEMENT SYSTEM PROCEDURE FOR RISK Issue No. 01 .Rev. No. 01

IATF 16949:2016 MANAGEMENT Date of Rev.06/06/2018

(SBPIPL/OCP/08/01)

COTO LOG-----------------

Risk Register---------------

Contingency Plan-----------

FMEA---------------------------

Issued By : QC Head 4 Approved By : Director

You might also like

- Global Pharmaceutical and Biologics Regulatory StrategyDocument270 pagesGlobal Pharmaceutical and Biologics Regulatory StrategyPranay Ghiya100% (2)

- Pye, D.-1968-The Nature and Art of WorkmanshipDocument22 pagesPye, D.-1968-The Nature and Art of WorkmanshipecoaletNo ratings yet

- Matrix CSRDocument6 pagesMatrix CSRDiego Jordan Hernández100% (1)

- Sop For Handling CCDocument14 pagesSop For Handling CCnataarajan praveenNo ratings yet

- Quality Tools: Failure Mode and Effects AnalysisDocument3 pagesQuality Tools: Failure Mode and Effects AnalysisAl RammohanNo ratings yet

- Supplier 8D FormDocument3 pagesSupplier 8D FormBen DesireNo ratings yet

- ANPQP - Supplier Feasibility Commitment: Renault Project: Document Reference No / VersionDocument1 pageANPQP - Supplier Feasibility Commitment: Renault Project: Document Reference No / Versionjefry sitorusNo ratings yet

- The Investment SettingDocument23 pagesThe Investment Settingnavin_singhNo ratings yet

- Management of Product Safety: 6) Esclation Process & Information FlowDocument2 pagesManagement of Product Safety: 6) Esclation Process & Information FlowrajarajanNo ratings yet

- 85-04, The BW Preventive Action Register.: Purpose and ScopeDocument2 pages85-04, The BW Preventive Action Register.: Purpose and Scopedanaka007No ratings yet

- 10.1 ImprovementDocument8 pages10.1 ImprovementVijayendran VijayNo ratings yet

- QA-072 Risk Management ProcedureDocument5 pagesQA-072 Risk Management ProcedureinsaanNo ratings yet

- Control of ChangesDocument9 pagesControl of ChangesRambir KaushikNo ratings yet

- DS-04-01 R0 Competency Requirements of Internal AuditorsDocument2 pagesDS-04-01 R0 Competency Requirements of Internal AuditorsDhinakaranNo ratings yet

- Sop Capa PDFDocument3 pagesSop Capa PDFnakul tiwariNo ratings yet

- Internal Audit Risk Scale and AssessmentDocument4 pagesInternal Audit Risk Scale and AssessmentWasim ArshadNo ratings yet

- Main Process Complaint ManagementDocument12 pagesMain Process Complaint Managementsafit_rhyNo ratings yet

- ISO 13485: 2016 Planner and Delta Checklist: InstructionsDocument10 pagesISO 13485: 2016 Planner and Delta Checklist: InstructionsYogesh H NarkhedeNo ratings yet

- 4.4.1 Product SafetyDocument5 pages4.4.1 Product SafetyVijayendran VijayNo ratings yet

- Rca SopDocument4 pagesRca SopShiva Prakasam PernetiNo ratings yet

- IATF IA CHecklistDocument2 pagesIATF IA CHecklistDamodaran RajanayagamNo ratings yet

- PFMEA Review - MOM FormatDocument2 pagesPFMEA Review - MOM FormatMASU BRAKE PADS QANo ratings yet

- Control PlanDocument4 pagesControl PlanRakesh PandeyNo ratings yet

- NCR Flow ChartDocument1 pageNCR Flow ChartPramod AthiyarathuNo ratings yet

- DFMEA ProcedureDocument16 pagesDFMEA ProcedureRushikesh KoshtiNo ratings yet

- Change Control Request FormDocument3 pagesChange Control Request FormSuleman FaizNo ratings yet

- CAPA Corrective and Preventive Action in PharmaceuticalDocument5 pagesCAPA Corrective and Preventive Action in PharmaceuticalRainMan75No ratings yet

- Application Area(s) :: Quality Risk Management Approach For Manufacturing and Control Processes and Associated GMP SystemsDocument18 pagesApplication Area(s) :: Quality Risk Management Approach For Manufacturing and Control Processes and Associated GMP SystemsBehrouz RostampourNo ratings yet

- Flow Chart Change ControlDocument2 pagesFlow Chart Change ControlJAGADISH PHARMACEUTICALSNo ratings yet

- Control Plan For Lighting ProductDocument6 pagesControl Plan For Lighting ProductpapplionNo ratings yet

- MD 010 Design Validation Sop 1 0 110905125013 Phpapp02Document1 pageMD 010 Design Validation Sop 1 0 110905125013 Phpapp02Omer ZiaNo ratings yet

- 01 Internal Auditing Technique Rev. 05 12 09 2018Document40 pages01 Internal Auditing Technique Rev. 05 12 09 2018Syed Maroof AliNo ratings yet

- QMS Risk IdentificationDocument6 pagesQMS Risk IdentificationyogshastriNo ratings yet

- ISO27k Nonconformity Corrective Preventive Action FormDocument3 pagesISO27k Nonconformity Corrective Preventive Action FormJasim's BhaignaNo ratings yet

- Vda Fmea TemplateDocument54 pagesVda Fmea Templatehmp90No ratings yet

- QMS-Process Risk Assessment ExampleDocument2 pagesQMS-Process Risk Assessment ExampleRavi ShankarNo ratings yet

- APQP or Advanced Product Quality Planning Standard, APQP Training, APQP Consulting, APQP SoftwareDocument2 pagesAPQP or Advanced Product Quality Planning Standard, APQP Training, APQP Consulting, APQP SoftwareselvamNo ratings yet

- (QSP-NPD-01) Process For Advanced Product Quality Planning (APQP)Document9 pages(QSP-NPD-01) Process For Advanced Product Quality Planning (APQP)Gourav SainiNo ratings yet

- TMT Procedure - Analysis of Data & Continuous Improvement P2Document1 pageTMT Procedure - Analysis of Data & Continuous Improvement P2sumanNo ratings yet

- Process Validation ConceptDocument6 pagesProcess Validation ConceptYousifNo ratings yet

- Flowchart New MOC-Copy of Page-1 (4) - 1Document3 pagesFlowchart New MOC-Copy of Page-1 (4) - 1Tevriyudha MardikaNo ratings yet

- Change Control ProcedureDocument2 pagesChange Control ProcedurePavan Kumar0% (1)

- 7 FmeaDocument25 pages7 Fmeaprx4177No ratings yet

- Quality Manual 2020 V5.0Document84 pagesQuality Manual 2020 V5.0KKSAT100% (1)

- QSP 06 - Preventive ActionDocument5 pagesQSP 06 - Preventive ActionVivek VNo ratings yet

- QP 73001 Rev 07 Product Design and Development ProcedureDocument8 pagesQP 73001 Rev 07 Product Design and Development ProcedurevinayNo ratings yet

- Malati Founders PVT Ltd. Risk Analysis For Rework Rev No Rev DateDocument1 pageMalati Founders PVT Ltd. Risk Analysis For Rework Rev No Rev DateDhananjay PatilNo ratings yet

- QSP Format Product SafetyDocument4 pagesQSP Format Product Safetydhir.ankurNo ratings yet

- Concept of Deviation & CAPA at Analytical Lab in Pharma IndustryDocument30 pagesConcept of Deviation & CAPA at Analytical Lab in Pharma Industryapoteker istnNo ratings yet

- COMP-OPP-01 Procedure For Control and Validation of ProductionDocument4 pagesCOMP-OPP-01 Procedure For Control and Validation of ProductionISODCC DSPINo ratings yet

- SOP Corrective Action: SOP As Approved by The Program Signing AuthorityDocument1 pageSOP Corrective Action: SOP As Approved by The Program Signing Authoritysudar1477No ratings yet

- Eop 45 01Document10 pagesEop 45 01Muhammad ArslanNo ratings yet

- Change Control Alaxan FR Capsule 2020Document6 pagesChange Control Alaxan FR Capsule 2020Rio FebriansyahNo ratings yet

- 15 (QSP-QA - 07) Process & Product AuditDocument3 pages15 (QSP-QA - 07) Process & Product AuditBASAVA ENGINEERING100% (1)

- Updates Dec09 AIAG FMEA-Ranking-TablesDocument3 pagesUpdates Dec09 AIAG FMEA-Ranking-TablesSuresh Velu100% (1)

- PFMEA Review PlanDocument1 pagePFMEA Review PlanKaran Malhi100% (1)

- ISO 13485 Quality Management System A Complete Guide - 2021 EditionFrom EverandISO 13485 Quality Management System A Complete Guide - 2021 EditionNo ratings yet

- Good Distribution Practice A Complete Guide - 2020 EditionFrom EverandGood Distribution Practice A Complete Guide - 2020 EditionNo ratings yet

- Corrective And Preventative Action A Complete Guide - 2020 EditionFrom EverandCorrective And Preventative Action A Complete Guide - 2020 EditionNo ratings yet

- Lu A Comparative Study of The Measurements of Perceived Risk Among Contractors in China 307 312Document6 pagesLu A Comparative Study of The Measurements of Perceived Risk Among Contractors in China 307 312Hanan Nur RahmahNo ratings yet

- Isms Policy ListDocument6 pagesIsms Policy ListAviraj SarkarNo ratings yet

- RaymondDocument12 pagesRaymondCharu SharmaNo ratings yet

- Pipeline Corroson Integrity Management EPGDocument9 pagesPipeline Corroson Integrity Management EPGJo AzzamNo ratings yet

- Integrated Performance Management For Sustained GrowthDocument24 pagesIntegrated Performance Management For Sustained Growthtdeviyan100% (1)

- Chapter 12 Risk and Refinements On CB: © 2012 Pearson Prentice Hall. All Rights ReservedDocument26 pagesChapter 12 Risk and Refinements On CB: © 2012 Pearson Prentice Hall. All Rights ReservedMyra NicdaoNo ratings yet

- Executive SummaryDocument3 pagesExecutive SummaryyogeshramachandraNo ratings yet

- Gregor Wadlewski Multi Level Marketing As A Business ModelDocument20 pagesGregor Wadlewski Multi Level Marketing As A Business ModelJoao Paulo MouraNo ratings yet

- Millet Expedition Project: 2015 RULESDocument9 pagesMillet Expedition Project: 2015 RULESRasLDKNo ratings yet

- CasingSeat ReportDocument12 pagesCasingSeat ReportZain-Alabdeen Haithem LaftaNo ratings yet

- ASI Design Guide - Wind Actions On Steel Sheds and GaragesDocument12 pagesASI Design Guide - Wind Actions On Steel Sheds and Garagesreynolds53489% (9)

- The International New Issues in Social SciencesDocument22 pagesThe International New Issues in Social Sciencessowyam saleNo ratings yet

- MacMillan - B&M 2012 PDFDocument154 pagesMacMillan - B&M 2012 PDFSelvaraj VillyNo ratings yet

- Agile Methodology From Growth Driven Development (GDD) ApproachDocument15 pagesAgile Methodology From Growth Driven Development (GDD) ApproachAayush PathakNo ratings yet

- Rita Gunther Mcgrath: Strategy Moving As Fast As Your Business (Harvard Business Review Press)Document16 pagesRita Gunther Mcgrath: Strategy Moving As Fast As Your Business (Harvard Business Review Press)Theo ConstantinNo ratings yet

- Nebosh IGC 3Document18 pagesNebosh IGC 3kishoryawaleNo ratings yet

- Wealth Maximization ObjectiveDocument8 pagesWealth Maximization ObjectiveNeha SharmaNo ratings yet

- Trucking Container RegulationDocument240 pagesTrucking Container RegulationKhoai Sai GonNo ratings yet

- Xva - Ma - D1S1Document30 pagesXva - Ma - D1S1guliguruNo ratings yet

- Pub - What Is A Disaster Perspectives On The QuestionDocument338 pagesPub - What Is A Disaster Perspectives On The QuestioncharlessNo ratings yet

- Safety Distances For Hydrogen Refuelling StationDocument8 pagesSafety Distances For Hydrogen Refuelling Station이응우No ratings yet

- Modern Slavery Statement 2022Document26 pagesModern Slavery Statement 2022Pedro VolkweisNo ratings yet

- Analisis Manajemen Risiko Pada Proyek Konstruksi Pelabuhan: Kajian Literatur SistematikDocument15 pagesAnalisis Manajemen Risiko Pada Proyek Konstruksi Pelabuhan: Kajian Literatur Sistematikhaidar khoirulNo ratings yet

- Fin TRM Comm RM 2Document12 pagesFin TRM Comm RM 2Sam KuNo ratings yet

- Reflection The TriumphDocument3 pagesReflection The TriumphNabila Abdul MukthiNo ratings yet

- Financial Management:: An Introduction To Risk and Return - History of Financial Market ReturnsDocument70 pagesFinancial Management:: An Introduction To Risk and Return - History of Financial Market Returnsfreakguy 313No ratings yet

- Control Environment Integrity and Ethical ValuesDocument2 pagesControl Environment Integrity and Ethical ValuesamitNo ratings yet