Professional Documents

Culture Documents

ENG... Air Conditioning (ENG GS6 022)

ENG... Air Conditioning (ENG GS6 022)

Uploaded by

翟庆祥Copyright:

Available Formats

You might also like

- Bot CookbookDocument149 pagesBot Cookbookdaniel monteroNo ratings yet

- CSHP Template For Residential - New (Repaired)Document5 pagesCSHP Template For Residential - New (Repaired)Jo An Valdez0% (1)

- Rooftop Service Manula (Heat Pump) - 190411Document151 pagesRooftop Service Manula (Heat Pump) - 190411Kyc IndustrialNo ratings yet

- Boracay Case StudyDocument12 pagesBoracay Case StudyJbrille Ubias0% (1)

- Sime Format 24 System Boiler InstDocument36 pagesSime Format 24 System Boiler InstJer CotterNo ratings yet

- McQuay Water Cooled Package MWCP-2004 PDFDocument40 pagesMcQuay Water Cooled Package MWCP-2004 PDFbluemojo75% (4)

- Service Manual MIH Series Condensing Units Heat Pump: 1.5 Tons To 5 TonsDocument30 pagesService Manual MIH Series Condensing Units Heat Pump: 1.5 Tons To 5 TonsHenry Javier RíosNo ratings yet

- Clinical Pharmacology For Nurses PDFDocument1 pageClinical Pharmacology For Nurses PDFgordon kevin0% (1)

- Especificaciones Tecnica LGH150H PDFDocument92 pagesEspecificaciones Tecnica LGH150H PDFRicardo Morán SilvaNo ratings yet

- Manejadora AHR Guia TecnicaDocument10 pagesManejadora AHR Guia TecnicaJulio JumboNo ratings yet

- Vac Works Technical Specifications Rev: 0 Date: February 2019 Sahid Kuta Life Style Resort - BaliDocument8 pagesVac Works Technical Specifications Rev: 0 Date: February 2019 Sahid Kuta Life Style Resort - Baliferdinand laiNo ratings yet

- Service Report - PMS of Line 2 Cooler Exhaust Fan and Raw Mill EP Fan - ACS600 VFDDocument8 pagesService Report - PMS of Line 2 Cooler Exhaust Fan and Raw Mill EP Fan - ACS600 VFDJunie V. TayrusNo ratings yet

- 32687-1 The Light Cinema-BanburyDocument9 pages32687-1 The Light Cinema-Banburyamith_kmNo ratings yet

- Aqcf851bu Service Manual PDFDocument42 pagesAqcf851bu Service Manual PDFreisubNo ratings yet

- Ac Units Technical Specifications Annex ADocument44 pagesAc Units Technical Specifications Annex Aengr.genaNo ratings yet

- TM - Modular Air Chiller (VRA, R410A, R22) - 1401Document54 pagesTM - Modular Air Chiller (VRA, R410A, R22) - 1401yusuf mohd sallehNo ratings yet

- Itaan Pharma Offer For HVAC - R0 - 27.05.22 (1) - 15Document2 pagesItaan Pharma Offer For HVAC - R0 - 27.05.22 (1) - 15Srikanth ChagantipatiNo ratings yet

- Techrite Controls Siemens Siemens Qgo20 Oxygen Sensor 1761 PDFDocument6 pagesTechrite Controls Siemens Siemens Qgo20 Oxygen Sensor 1761 PDFedy soryawanNo ratings yet

- IOM Water Modules 202007Document78 pagesIOM Water Modules 202007aha030185No ratings yet

- GOODMAN WALL MOUNT AIR HANDLER Awst - SeriesDocument12 pagesGOODMAN WALL MOUNT AIR HANDLER Awst - Seriespw20092No ratings yet

- Especificaciones Equipos Paquetes PDFDocument8 pagesEspecificaciones Equipos Paquetes PDFDavid BallenNo ratings yet

- 200-1013-06-003 RFQ Full Package and High Pressure Coil Design CalculationDocument15 pages200-1013-06-003 RFQ Full Package and High Pressure Coil Design CalculationBilel MahjoubNo ratings yet

- Kaukan Oil Cooler Instruction HandbookDocument14 pagesKaukan Oil Cooler Instruction HandbooksunhuynhNo ratings yet

- Procool Electronic Panel: Ako-17635-1 Ako-17635-2Document23 pagesProcool Electronic Panel: Ako-17635-1 Ako-17635-2Amic BanatNo ratings yet

- Operating Instructions: StreamlineDocument12 pagesOperating Instructions: StreamlineMarco AurélioNo ratings yet

- Maintenance Manual AK200Document31 pagesMaintenance Manual AK200Maxence Kouessi100% (6)

- Scroll Chillers - Record SpecificationDocument4 pagesScroll Chillers - Record SpecificationEagle MayNo ratings yet

- Installation, Use and Maintenance Manual: Chillers and Heat PumpsDocument68 pagesInstallation, Use and Maintenance Manual: Chillers and Heat PumpsesaNo ratings yet

- York Furnace ManualDocument8 pagesYork Furnace ManualToky100No ratings yet

- Hal Ahu BoqDocument16 pagesHal Ahu Boqmdalt9180100% (1)

- Uh Svx01a en - 09032008 (Trane Unit Heaters)Document60 pagesUh Svx01a en - 09032008 (Trane Unit Heaters)kayeleNo ratings yet

- Restek Methanizer For Agilent GCS: Instruction/ Operation ManualDocument44 pagesRestek Methanizer For Agilent GCS: Instruction/ Operation Manualginga716No ratings yet

- Bangalore Job OfferDocument25 pagesBangalore Job OfferPuneet AggarwalNo ratings yet

- Bard UP03Document12 pagesBard UP03Alan VazquezNo ratings yet

- A6V12118043 enDocument7 pagesA6V12118043 engobilgobilNo ratings yet

- Manejadora AhrDocument12 pagesManejadora AhrIsrael ArceoNo ratings yet

- Technical Guide: Single Piece Standard Ecm Air HandlersDocument14 pagesTechnical Guide: Single Piece Standard Ecm Air HandlersOmar CaceresNo ratings yet

- P P O I : Roject Rofile N NvertersDocument11 pagesP P O I : Roject Rofile N NvertersAshwani RanaNo ratings yet

- Cazan Installation-Manual-FbgDocument20 pagesCazan Installation-Manual-FbgCretu Stefan-DanielNo ratings yet

- Pp10 CCGT Power Station: Operation and Maintenance Manual Sootblower Seal Air FansDocument13 pagesPp10 CCGT Power Station: Operation and Maintenance Manual Sootblower Seal Air Fansanbesivam87_49857255No ratings yet

- GC Tips Tricks-Agilent (Compatibility Mode)Document43 pagesGC Tips Tricks-Agilent (Compatibility Mode)Sneha PatelNo ratings yet

- TM MAC (60Hz) 2011 PDFDocument28 pagesTM MAC (60Hz) 2011 PDFgio_flores_4No ratings yet

- Revised CotmatDocument7 pagesRevised CotmatMayuresh JagtapNo ratings yet

- AG HA Eng PDFDocument20 pagesAG HA Eng PDFΓεώργιος ΠαπαδόπουλοςNo ratings yet

- Service InstructionsDocument62 pagesService InstructionsShouzab AbbasNo ratings yet

- Manual de CompresorDocument56 pagesManual de CompresorDuberly Sarmiento SernaNo ratings yet

- Automatic Control System Technical SpecDocument6 pagesAutomatic Control System Technical Specferdinand laiNo ratings yet

- Wisb 72 1023Document20 pagesWisb 72 1023rsavallaNo ratings yet

- Maintenance Manual Rev2 - ENDocument30 pagesMaintenance Manual Rev2 - ENMartha BenavidesNo ratings yet

- Chiller Modular Inverter Engenharia - 200708044909000000Document39 pagesChiller Modular Inverter Engenharia - 200708044909000000Beuno LeiteNo ratings yet

- Bosch Greenstar ZWBR 7-25 A23 Gcno.46-311-44 Boiler Installation and Service ManualDocument36 pagesBosch Greenstar ZWBR 7-25 A23 Gcno.46-311-44 Boiler Installation and Service ManualMerlin1950No ratings yet

- Ceiling Concealed Chilled Water Fan Coil UnitDocument14 pagesCeiling Concealed Chilled Water Fan Coil UnitRodrigo Neira De FinoNo ratings yet

- PDFDocument17 pagesPDFDelovan CheikhoNo ratings yet

- Installation and Servicing InstructionsDocument56 pagesInstallation and Servicing Instructionssurya kundankumarNo ratings yet

- KT 15 AircooledDocument26 pagesKT 15 AircooledSEANSA SRLNo ratings yet

- 7000 Series CSA CertificateDocument3 pages7000 Series CSA Certificates bNo ratings yet

- LG Multi V SPECDocument21 pagesLG Multi V SPECJavier SordoNo ratings yet

- Chiller Technical ManualDocument87 pagesChiller Technical ManualElias GarciaNo ratings yet

- Godrej Split Ac Est#10026Document3 pagesGodrej Split Ac Est#10026Abdullah.N FAAliNo ratings yet

- The Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410ADocument12 pagesThe Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410AcarlosNo ratings yet

- Highlighted-VRF Specification-Crown Home ConsultantDocument41 pagesHighlighted-VRF Specification-Crown Home ConsultantneamatallahNo ratings yet

- Standard Updated-VRF Specification-Crown Home ConsultantDocument41 pagesStandard Updated-VRF Specification-Crown Home ConsultantneamatallahNo ratings yet

- 12 HP Ogeneral VRF Quotation For Proposed Residence 30 11 2023Document9 pages12 HP Ogeneral VRF Quotation For Proposed Residence 30 11 2023sonam gargNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- ENG... Distribution Transformer (ENG GS6 009)Document17 pagesENG... Distribution Transformer (ENG GS6 009)翟庆祥No ratings yet

- ENG... Distribution Transformer (ENG GS6 012)Document16 pagesENG... Distribution Transformer (ENG GS6 012)翟庆祥No ratings yet

- ENG... Elect Assesment Up To 650volt (ENG-GS6-E23-2)Document7 pagesENG... Elect Assesment Up To 650volt (ENG-GS6-E23-2)翟庆祥No ratings yet

- ENG... Electrical & Instrumentation Cables - (ENG-GS6-007)Document15 pagesENG... Electrical & Instrumentation Cables - (ENG-GS6-007)翟庆祥No ratings yet

- Ucrete MF Flooring - BASF Data Sheet ADocument4 pagesUcrete MF Flooring - BASF Data Sheet A翟庆祥No ratings yet

- Dairy IndustryDocument4 pagesDairy IndustrySOURAV GOYALNo ratings yet

- Seven Principles of Universal DesignDocument8 pagesSeven Principles of Universal DesignEricson Puig EuropaNo ratings yet

- 2021-2023 FO X RFR Tracker - KC NCDDP AFDocument147 pages2021-2023 FO X RFR Tracker - KC NCDDP AFJestoni Gonzales TortolaNo ratings yet

- 08CLecture - Welding Codes StandardsDocument15 pages08CLecture - Welding Codes StandardsDavid HuamanNo ratings yet

- Mobile Concrete Pumps 46-5 and 47-5 Underground Equipment: Tunneling and MiningDocument12 pagesMobile Concrete Pumps 46-5 and 47-5 Underground Equipment: Tunneling and MiningJonathan Guzmán MendozaNo ratings yet

- Building Maintenance ChecklistDocument5 pagesBuilding Maintenance ChecklistcajaroNo ratings yet

- Drug Study CefurexDocument2 pagesDrug Study CefurexJILLIAN MARIE BARREDONo ratings yet

- Crime Fighting and Crime Prevention (Criminal Justice)Document127 pagesCrime Fighting and Crime Prevention (Criminal Justice)Dimitrije Živković100% (1)

- Safari - 24 Apr 2020 at 1:57 AMDocument1 pageSafari - 24 Apr 2020 at 1:57 AMAgatha chilesheNo ratings yet

- AÇO A350 355 Tabela1Document8 pagesAÇO A350 355 Tabela1Roberto GomesNo ratings yet

- 13 Worksheet PKTDocument8 pages13 Worksheet PKTAllyza Alimeos SobosoboNo ratings yet

- Composite Materials CZ2BDocument20 pagesComposite Materials CZ2BVahid KamraninejadNo ratings yet

- Drugs Used During Pregnancy and LactationDocument21 pagesDrugs Used During Pregnancy and LactationHarsheethaNo ratings yet

- 306-Article Text-2098-1-10-20210428Document15 pages306-Article Text-2098-1-10-20210428Prasetiyo Eko LaksonoNo ratings yet

- Reologia Do Restylane FinesseDocument8 pagesReologia Do Restylane FinesseRhelvis1No ratings yet

- The Ultimate Azerbaijani Cookbook 111 Dishes From Azerbaijan To Cook Right Now Bodic All ChapterDocument67 pagesThe Ultimate Azerbaijani Cookbook 111 Dishes From Azerbaijan To Cook Right Now Bodic All Chapterfrank.claypool853100% (9)

- Construction MethodologyDocument102 pagesConstruction MethodologyDagnachew TassewNo ratings yet

- Lupus in Women - Informative SpeechDocument13 pagesLupus in Women - Informative Speechkayla leeNo ratings yet

- Furuno Installation ManualDocument35 pagesFuruno Installation ManualZakaria Chowdhury71% (7)

- Applied Chemistry: LESSON 1: Introduction To Organic ChemistryDocument3 pagesApplied Chemistry: LESSON 1: Introduction To Organic ChemistryMaja LucasNo ratings yet

- Introductory Topics HandoutDocument43 pagesIntroductory Topics HandoutGGuillorn100% (1)

- Anticancer Activity of Medicinal Plants ThesisDocument7 pagesAnticancer Activity of Medicinal Plants Thesislbbzfoxff100% (2)

- Rescission of Insurance ContractsDocument12 pagesRescission of Insurance ContractsCari Mangalindan MacaalayNo ratings yet

- USFS Mission - Tanzania - May 2009 - Water Resources in Tabora and Rukwa - For FRAMEDocument57 pagesUSFS Mission - Tanzania - May 2009 - Water Resources in Tabora and Rukwa - For FRAMERahul K Awade0% (1)

- Communication Skill For Assistance Umkm UpdatedDocument45 pagesCommunication Skill For Assistance Umkm UpdatedFadel TuasamuNo ratings yet

- Company Profile - PretechDocument26 pagesCompany Profile - PretechanandivmNo ratings yet

ENG... Air Conditioning (ENG GS6 022)

ENG... Air Conditioning (ENG GS6 022)

Uploaded by

翟庆祥Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ENG... Air Conditioning (ENG GS6 022)

ENG... Air Conditioning (ENG GS6 022)

Uploaded by

翟庆祥Copyright:

Available Formats

ENG-GS6-E20

Air Conditioning

General specification

Custodian: E&I Superintendent Revision number: 7.1

Approved Manager Engineering Services Effective date: 19 October 2015

Doc number: ENG-GS6-E20 Last revision date: 8 November 2015 Next revision date: 8 November 2018

Any printed document is an uncontrolled document Date printed:

2022/08/29

Palabora Copper (Pty) Ltd, is a subsidiary of Palabora Mining Company Page 1 of 7

Table of Contents

1. Scope................................................................................................................................2

2. General..............................................................................................................................2

3. Sub-stations.......................................................................................................................3

4. UPS and Control Rooms...................................................................................................3

5. Isolators.............................................................................................................................3

6. Piping.................................................................................................................................3

7. C.O.C.................................................................................................................................3

8. Installation.........................................................................................................................4

9. Maintenance......................................................................................................................6

10. Disposal.............................................................................................................................6

List of Figures

No table of figures entries found.

List of Tables

Table 1: Associated documents and its locations................................................................................5

Table 2: Table of changes................................................................................................................... 6

1. Scope

The scope of work includes the specification of all parts of air conditioners

2. General

Custodian: E&I Superintendent Revision number: 7.1

Approved Manager Engineering Services Effective date: 19 October 2015

Doc number: ENG-GS6-E20 Last revision date: 8 November 2015 Next revision date: 8 November 2018

Any printed document is an uncontrolled document Date printed:

2022/08/29

Palabora Copper (Pty) Ltd, is a subsidiary of Palabora Mining Company Page 2 of 7

All air-conditioner designs must be for Phalaborwa’s summer conditions and high ambient

temperatures.

Window / Wall units are no longer permitted.

Inverter Split units is the standard that will be installed.

Due to the procurement policy no brand name may be specified.

Any new air-conditioner installation must be approved by the Manager Engineering services.

Any new installation can be benchmark against the following standard and must the same or better.

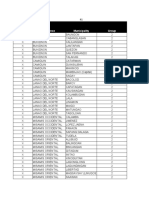

BTU Make Model

1200 Hisens

0 e AS-12UR4SVNVG2

1800 Hisens

0 e AS-18UR4SUVVG

2400 Hisens

0 e AS-24UR4SFJVG

3000 Hisens

0 e AS-30UR45LKVT

6000 Hisens

0 e AUD-60VG

3. Sub-stations

Industrial units used in electrical substations will be of the pressurised cooling energy

efficient technology with a built in air filtration system or pressurising air filter unit must be

installed in conjunction with these This is to ensure a filtered fresh air supply through the

substation to prevent dust ingress and condensation forming.

4. UPS and Control Rooms

Where units are installed in critical areas (UPS rooms, control/rack rooms, casting cabins,

overhead cranes, lunchrooms, line-up rooms, etc.) an auto start unit must be installed to

ensure that the unit will start automatically after a power dip/failure. In these critical areas it

is advisable to install two smaller units as opposed to one large unit which will prevent

equipment damage, urgency of repair if one unit fails, which will also mean better energy

efficiency.

5. Isolators

All 220 volt isolators for air conditioning will be at least of a 30 amp rating, where possible, be

mounted to the right hand side of the air conditioner with the isolator cover bottom side in line with the

bottom side of the air conditioner, not exceeding 1 metre from the air conditioner. If power skirting is

used the isolator will be fitted to the power skirting and the flex wire to the Air-conditioner run inside

white PVC trunking.

6. Piping

All piping will run in trunking with closing lids or protected to prevent inadvertent damage to the

piping.

7. C.O.C.

Custodian: E&I Superintendent Revision number: 7.1

Approved Manager Engineering Services Effective date: 19 October 2015

Doc number: ENG-GS6-E20 Last revision date: 8 November 2015 Next revision date: 8 November 2018

Any printed document is an uncontrolled document Date printed:

2022/08/29

Palabora Copper (Pty) Ltd, is a subsidiary of Palabora Mining Company Page 3 of 7

All electrical installations must comply with the Electrical Specifications G.S.6, SABS 10142-1 and a

certificate of compliance issued on completion of the installation. All electrical designs and

drawings must be approved by the Electrical Engineer before any construction will start.

8. Installation

Air conditioners must be installed in accordance with manufacturer’s instructions. However the

following must be adhered to:

The condensing unit must be placed on a concrete block or steel bracket at a height not less than

200mm above surrounding ground level.

The condensing unit must be at least 250mm from any structure.

Where the condensing unit is placed higher than the evaporator, a "P" type trap must be installed in

the suction line to ensure proper oil movement to the compressor. See drawing SK-0-9501.

Inter-connecting tubing must be of a size not smaller than the size of the fittings provided on the

unit.

Where tubing runs are longer than the maximum shown on the accompanied chart, the tubing size

is to be agreed with the air conditioning supervisor..

AIR CONDITIONER MAXIMUM RUN

MODEL

PIPE INSIDE DIAMETER METRES

LIQUID SUCTION LINE

12000BTU ¼" ½" 15

18000BTU ¼ ½" 25

24000BTU ¼" 5/8" 25

Only tubing of the proper refrigeration grade for the refrigerant must be used.

The inside of the tubing must be kept clean and dry at all times.

Custodian: E&I Superintendent Revision number: 7.1

Approved Manager Engineering Services Effective date: 19 October 2015

Doc number: ENG-GS6-E20 Last revision date: 8 November 2015 Next revision date: 8 November 2018

Any printed document is an uncontrolled document Date printed:

2022/08/29

Palabora Copper (Pty) Ltd, is a subsidiary of Palabora Mining Company Page 4 of 7

Bends in copper tubing must be kept to a minimum and must then be of a large as possible radius

and not less than 5 times the piping O.D.

The Interconnecting tubing for the liquid and suction lines must be insulated separately.

Insulation must be of the correct size for individual tubing.

Where the insulation joins, the ends must be glued together with Pliobond, Genkem or similar

adhesive to prevent it from creeping and creating a gap.

Pipes must be adequately supported inside the trunking with saddles if necessary. 13. The

electric cable between the condenser and evaporator must be strapped so that they are separated

from the piping.

Drain pipes must be extended to ground level. Where drains are close drain pipes must be

extended to discharge into them. Where a large number of units are installed close together a

40mm PVC drain must be installed and each units drain pipes extended to drain into this pipe.

The size of the individual conductors of the electrical cables must be correctly rated for the full load

current of the equipment they are supplying..

The supply cable to the wall socket-outlet, if too short must be replaced with a new cable connected

inside the unit and terminated according to PMC specifications. No joints are permitted.

Three pin plugs should NOT ordinarily be used but, if used, must be of the transparent base type

with a screw holding the two halves together.

The cable must be inserted into the plug in such a way that the two inserts grip the outer sheath

securely.

All new installations will be supplied with a 15amp cord-grip isolator.

All air conditioners will be installed, to ensure that excess water can drain away easily.

All condenser units shall be installed in such a way that maintenance or repair work, can be

conducted easily.

Custodian: E&I Superintendent Revision number: 7.1

Approved Manager Engineering Services Effective date: 19 October 2015

Doc number: ENG-GS6-E20 Last revision date: 8 November 2015 Next revision date: 8 November 2018

Any printed document is an uncontrolled document Date printed:

2022/08/29

Palabora Copper (Pty) Ltd, is a subsidiary of Palabora Mining Company Page 5 of 7

All new installations or replacements will have an installation report form completed with all the

necessary information. This is for ALL refrigeration equipment i.e. Water-coolers, ice machines,

fridges, etc.

End users must be supplied with a user manual and be given a basic demonstration of how the

unit/remote works.

9. Maintenance

New units will be serviced as per manufacturer specifications, for warranty purposes for the period of

such warranty. For maximum lifespan of the unit and to ensure Energy efficiency ALL units will be

serviced at regular intervals that will be determined by the Electrical and Instrumentation Department

based on:

Manufacturers recommendations

The criticality of the equipment where the unit is installed

The environment where the unit is fitted

Where the installation can affect the health and/or safety of personnel

Where the installation can affect production

Once the service intervals have been determined the information will be forwarded to the relevant

Departmental planners to have plans created in SAP for the creation of PM01’s at the required

intervals.

10. Disposal

All scrap units and parts remain the property of Palabora Copper and shall be returned to the salvage

yard. Disposal Of Company Property and Hazardous Substances MS 10 E5-OP-361 Annexure 2 form

must be filled in and approved for disposal by Palabora Copper Client representative. Where possible

all refrigerant will be reclaimed with an approved gas reclaim plant.

Table 1: Associated documents and its locations

Document Document name Location:

number Where the document is saved

Custodian: E&I Superintendent Revision number: 7.1

Approved Manager Engineering Services Effective date: 19 October 2015

Doc number: ENG-GS6-E20 Last revision date: 8 November 2015 Next revision date: 8 November 2018

Any printed document is an uncontrolled document Date printed:

2022/08/29

Palabora Copper (Pty) Ltd, is a subsidiary of Palabora Mining Company Page 6 of 7

Table 2: Table of changes

Reviewed by:

E&I Superintendent

(Normally the Custodian)

In consultation with:

Electrical Infrastructure Supervisor and Electrical protection Specialist

(Who were involved in the review)

Document approved by:

(Person/committee that did the final Manager Engineering Services

approval)

Date of approval: 11 November 2015

Revision number: 7.1

Effective date:

(This refers to the date on which the 16 November 2015

updated document is communicated)

Change history Only the latest changes applicable to this revision have to be included

Date Paragraph Comments (Detailed comments that indicate the changes (or not) made)

5 Nov 2015 Whole doc Replace GS6 – E020 With this one.

Custodian: E&I Superintendent Revision number: 7.1

Approved Manager Engineering Services Effective date: 19 October 2015

Doc number: ENG-GS6-E20 Last revision date: 8 November 2015 Next revision date: 8 November 2018

Any printed document is an uncontrolled document Date printed:

2022/08/29

Palabora Copper (Pty) Ltd, is a subsidiary of Palabora Mining Company Page 7 of 7

You might also like

- Bot CookbookDocument149 pagesBot Cookbookdaniel monteroNo ratings yet

- CSHP Template For Residential - New (Repaired)Document5 pagesCSHP Template For Residential - New (Repaired)Jo An Valdez0% (1)

- Rooftop Service Manula (Heat Pump) - 190411Document151 pagesRooftop Service Manula (Heat Pump) - 190411Kyc IndustrialNo ratings yet

- Boracay Case StudyDocument12 pagesBoracay Case StudyJbrille Ubias0% (1)

- Sime Format 24 System Boiler InstDocument36 pagesSime Format 24 System Boiler InstJer CotterNo ratings yet

- McQuay Water Cooled Package MWCP-2004 PDFDocument40 pagesMcQuay Water Cooled Package MWCP-2004 PDFbluemojo75% (4)

- Service Manual MIH Series Condensing Units Heat Pump: 1.5 Tons To 5 TonsDocument30 pagesService Manual MIH Series Condensing Units Heat Pump: 1.5 Tons To 5 TonsHenry Javier RíosNo ratings yet

- Clinical Pharmacology For Nurses PDFDocument1 pageClinical Pharmacology For Nurses PDFgordon kevin0% (1)

- Especificaciones Tecnica LGH150H PDFDocument92 pagesEspecificaciones Tecnica LGH150H PDFRicardo Morán SilvaNo ratings yet

- Manejadora AHR Guia TecnicaDocument10 pagesManejadora AHR Guia TecnicaJulio JumboNo ratings yet

- Vac Works Technical Specifications Rev: 0 Date: February 2019 Sahid Kuta Life Style Resort - BaliDocument8 pagesVac Works Technical Specifications Rev: 0 Date: February 2019 Sahid Kuta Life Style Resort - Baliferdinand laiNo ratings yet

- Service Report - PMS of Line 2 Cooler Exhaust Fan and Raw Mill EP Fan - ACS600 VFDDocument8 pagesService Report - PMS of Line 2 Cooler Exhaust Fan and Raw Mill EP Fan - ACS600 VFDJunie V. TayrusNo ratings yet

- 32687-1 The Light Cinema-BanburyDocument9 pages32687-1 The Light Cinema-Banburyamith_kmNo ratings yet

- Aqcf851bu Service Manual PDFDocument42 pagesAqcf851bu Service Manual PDFreisubNo ratings yet

- Ac Units Technical Specifications Annex ADocument44 pagesAc Units Technical Specifications Annex Aengr.genaNo ratings yet

- TM - Modular Air Chiller (VRA, R410A, R22) - 1401Document54 pagesTM - Modular Air Chiller (VRA, R410A, R22) - 1401yusuf mohd sallehNo ratings yet

- Itaan Pharma Offer For HVAC - R0 - 27.05.22 (1) - 15Document2 pagesItaan Pharma Offer For HVAC - R0 - 27.05.22 (1) - 15Srikanth ChagantipatiNo ratings yet

- Techrite Controls Siemens Siemens Qgo20 Oxygen Sensor 1761 PDFDocument6 pagesTechrite Controls Siemens Siemens Qgo20 Oxygen Sensor 1761 PDFedy soryawanNo ratings yet

- IOM Water Modules 202007Document78 pagesIOM Water Modules 202007aha030185No ratings yet

- GOODMAN WALL MOUNT AIR HANDLER Awst - SeriesDocument12 pagesGOODMAN WALL MOUNT AIR HANDLER Awst - Seriespw20092No ratings yet

- Especificaciones Equipos Paquetes PDFDocument8 pagesEspecificaciones Equipos Paquetes PDFDavid BallenNo ratings yet

- 200-1013-06-003 RFQ Full Package and High Pressure Coil Design CalculationDocument15 pages200-1013-06-003 RFQ Full Package and High Pressure Coil Design CalculationBilel MahjoubNo ratings yet

- Kaukan Oil Cooler Instruction HandbookDocument14 pagesKaukan Oil Cooler Instruction HandbooksunhuynhNo ratings yet

- Procool Electronic Panel: Ako-17635-1 Ako-17635-2Document23 pagesProcool Electronic Panel: Ako-17635-1 Ako-17635-2Amic BanatNo ratings yet

- Operating Instructions: StreamlineDocument12 pagesOperating Instructions: StreamlineMarco AurélioNo ratings yet

- Maintenance Manual AK200Document31 pagesMaintenance Manual AK200Maxence Kouessi100% (6)

- Scroll Chillers - Record SpecificationDocument4 pagesScroll Chillers - Record SpecificationEagle MayNo ratings yet

- Installation, Use and Maintenance Manual: Chillers and Heat PumpsDocument68 pagesInstallation, Use and Maintenance Manual: Chillers and Heat PumpsesaNo ratings yet

- York Furnace ManualDocument8 pagesYork Furnace ManualToky100No ratings yet

- Hal Ahu BoqDocument16 pagesHal Ahu Boqmdalt9180100% (1)

- Uh Svx01a en - 09032008 (Trane Unit Heaters)Document60 pagesUh Svx01a en - 09032008 (Trane Unit Heaters)kayeleNo ratings yet

- Restek Methanizer For Agilent GCS: Instruction/ Operation ManualDocument44 pagesRestek Methanizer For Agilent GCS: Instruction/ Operation Manualginga716No ratings yet

- Bangalore Job OfferDocument25 pagesBangalore Job OfferPuneet AggarwalNo ratings yet

- Bard UP03Document12 pagesBard UP03Alan VazquezNo ratings yet

- A6V12118043 enDocument7 pagesA6V12118043 engobilgobilNo ratings yet

- Manejadora AhrDocument12 pagesManejadora AhrIsrael ArceoNo ratings yet

- Technical Guide: Single Piece Standard Ecm Air HandlersDocument14 pagesTechnical Guide: Single Piece Standard Ecm Air HandlersOmar CaceresNo ratings yet

- P P O I : Roject Rofile N NvertersDocument11 pagesP P O I : Roject Rofile N NvertersAshwani RanaNo ratings yet

- Cazan Installation-Manual-FbgDocument20 pagesCazan Installation-Manual-FbgCretu Stefan-DanielNo ratings yet

- Pp10 CCGT Power Station: Operation and Maintenance Manual Sootblower Seal Air FansDocument13 pagesPp10 CCGT Power Station: Operation and Maintenance Manual Sootblower Seal Air Fansanbesivam87_49857255No ratings yet

- GC Tips Tricks-Agilent (Compatibility Mode)Document43 pagesGC Tips Tricks-Agilent (Compatibility Mode)Sneha PatelNo ratings yet

- TM MAC (60Hz) 2011 PDFDocument28 pagesTM MAC (60Hz) 2011 PDFgio_flores_4No ratings yet

- Revised CotmatDocument7 pagesRevised CotmatMayuresh JagtapNo ratings yet

- AG HA Eng PDFDocument20 pagesAG HA Eng PDFΓεώργιος ΠαπαδόπουλοςNo ratings yet

- Service InstructionsDocument62 pagesService InstructionsShouzab AbbasNo ratings yet

- Manual de CompresorDocument56 pagesManual de CompresorDuberly Sarmiento SernaNo ratings yet

- Automatic Control System Technical SpecDocument6 pagesAutomatic Control System Technical Specferdinand laiNo ratings yet

- Wisb 72 1023Document20 pagesWisb 72 1023rsavallaNo ratings yet

- Maintenance Manual Rev2 - ENDocument30 pagesMaintenance Manual Rev2 - ENMartha BenavidesNo ratings yet

- Chiller Modular Inverter Engenharia - 200708044909000000Document39 pagesChiller Modular Inverter Engenharia - 200708044909000000Beuno LeiteNo ratings yet

- Bosch Greenstar ZWBR 7-25 A23 Gcno.46-311-44 Boiler Installation and Service ManualDocument36 pagesBosch Greenstar ZWBR 7-25 A23 Gcno.46-311-44 Boiler Installation and Service ManualMerlin1950No ratings yet

- Ceiling Concealed Chilled Water Fan Coil UnitDocument14 pagesCeiling Concealed Chilled Water Fan Coil UnitRodrigo Neira De FinoNo ratings yet

- PDFDocument17 pagesPDFDelovan CheikhoNo ratings yet

- Installation and Servicing InstructionsDocument56 pagesInstallation and Servicing Instructionssurya kundankumarNo ratings yet

- KT 15 AircooledDocument26 pagesKT 15 AircooledSEANSA SRLNo ratings yet

- 7000 Series CSA CertificateDocument3 pages7000 Series CSA Certificates bNo ratings yet

- LG Multi V SPECDocument21 pagesLG Multi V SPECJavier SordoNo ratings yet

- Chiller Technical ManualDocument87 pagesChiller Technical ManualElias GarciaNo ratings yet

- Godrej Split Ac Est#10026Document3 pagesGodrej Split Ac Est#10026Abdullah.N FAAliNo ratings yet

- The Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410ADocument12 pagesThe Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410AcarlosNo ratings yet

- Highlighted-VRF Specification-Crown Home ConsultantDocument41 pagesHighlighted-VRF Specification-Crown Home ConsultantneamatallahNo ratings yet

- Standard Updated-VRF Specification-Crown Home ConsultantDocument41 pagesStandard Updated-VRF Specification-Crown Home ConsultantneamatallahNo ratings yet

- 12 HP Ogeneral VRF Quotation For Proposed Residence 30 11 2023Document9 pages12 HP Ogeneral VRF Quotation For Proposed Residence 30 11 2023sonam gargNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- ENG... Distribution Transformer (ENG GS6 009)Document17 pagesENG... Distribution Transformer (ENG GS6 009)翟庆祥No ratings yet

- ENG... Distribution Transformer (ENG GS6 012)Document16 pagesENG... Distribution Transformer (ENG GS6 012)翟庆祥No ratings yet

- ENG... Elect Assesment Up To 650volt (ENG-GS6-E23-2)Document7 pagesENG... Elect Assesment Up To 650volt (ENG-GS6-E23-2)翟庆祥No ratings yet

- ENG... Electrical & Instrumentation Cables - (ENG-GS6-007)Document15 pagesENG... Electrical & Instrumentation Cables - (ENG-GS6-007)翟庆祥No ratings yet

- Ucrete MF Flooring - BASF Data Sheet ADocument4 pagesUcrete MF Flooring - BASF Data Sheet A翟庆祥No ratings yet

- Dairy IndustryDocument4 pagesDairy IndustrySOURAV GOYALNo ratings yet

- Seven Principles of Universal DesignDocument8 pagesSeven Principles of Universal DesignEricson Puig EuropaNo ratings yet

- 2021-2023 FO X RFR Tracker - KC NCDDP AFDocument147 pages2021-2023 FO X RFR Tracker - KC NCDDP AFJestoni Gonzales TortolaNo ratings yet

- 08CLecture - Welding Codes StandardsDocument15 pages08CLecture - Welding Codes StandardsDavid HuamanNo ratings yet

- Mobile Concrete Pumps 46-5 and 47-5 Underground Equipment: Tunneling and MiningDocument12 pagesMobile Concrete Pumps 46-5 and 47-5 Underground Equipment: Tunneling and MiningJonathan Guzmán MendozaNo ratings yet

- Building Maintenance ChecklistDocument5 pagesBuilding Maintenance ChecklistcajaroNo ratings yet

- Drug Study CefurexDocument2 pagesDrug Study CefurexJILLIAN MARIE BARREDONo ratings yet

- Crime Fighting and Crime Prevention (Criminal Justice)Document127 pagesCrime Fighting and Crime Prevention (Criminal Justice)Dimitrije Živković100% (1)

- Safari - 24 Apr 2020 at 1:57 AMDocument1 pageSafari - 24 Apr 2020 at 1:57 AMAgatha chilesheNo ratings yet

- AÇO A350 355 Tabela1Document8 pagesAÇO A350 355 Tabela1Roberto GomesNo ratings yet

- 13 Worksheet PKTDocument8 pages13 Worksheet PKTAllyza Alimeos SobosoboNo ratings yet

- Composite Materials CZ2BDocument20 pagesComposite Materials CZ2BVahid KamraninejadNo ratings yet

- Drugs Used During Pregnancy and LactationDocument21 pagesDrugs Used During Pregnancy and LactationHarsheethaNo ratings yet

- 306-Article Text-2098-1-10-20210428Document15 pages306-Article Text-2098-1-10-20210428Prasetiyo Eko LaksonoNo ratings yet

- Reologia Do Restylane FinesseDocument8 pagesReologia Do Restylane FinesseRhelvis1No ratings yet

- The Ultimate Azerbaijani Cookbook 111 Dishes From Azerbaijan To Cook Right Now Bodic All ChapterDocument67 pagesThe Ultimate Azerbaijani Cookbook 111 Dishes From Azerbaijan To Cook Right Now Bodic All Chapterfrank.claypool853100% (9)

- Construction MethodologyDocument102 pagesConstruction MethodologyDagnachew TassewNo ratings yet

- Lupus in Women - Informative SpeechDocument13 pagesLupus in Women - Informative Speechkayla leeNo ratings yet

- Furuno Installation ManualDocument35 pagesFuruno Installation ManualZakaria Chowdhury71% (7)

- Applied Chemistry: LESSON 1: Introduction To Organic ChemistryDocument3 pagesApplied Chemistry: LESSON 1: Introduction To Organic ChemistryMaja LucasNo ratings yet

- Introductory Topics HandoutDocument43 pagesIntroductory Topics HandoutGGuillorn100% (1)

- Anticancer Activity of Medicinal Plants ThesisDocument7 pagesAnticancer Activity of Medicinal Plants Thesislbbzfoxff100% (2)

- Rescission of Insurance ContractsDocument12 pagesRescission of Insurance ContractsCari Mangalindan MacaalayNo ratings yet

- USFS Mission - Tanzania - May 2009 - Water Resources in Tabora and Rukwa - For FRAMEDocument57 pagesUSFS Mission - Tanzania - May 2009 - Water Resources in Tabora and Rukwa - For FRAMERahul K Awade0% (1)

- Communication Skill For Assistance Umkm UpdatedDocument45 pagesCommunication Skill For Assistance Umkm UpdatedFadel TuasamuNo ratings yet

- Company Profile - PretechDocument26 pagesCompany Profile - PretechanandivmNo ratings yet