Professional Documents

Culture Documents

Installation Instructions: Harley-Davidson Softail Big Shots Staggered PART# 17941 / 47941

Installation Instructions: Harley-Davidson Softail Big Shots Staggered PART# 17941 / 47941

Uploaded by

David Noriega de SotoCopyright:

Available Formats

You might also like

- Electrical Current Flow Diagrams Amarok Diesel 2012 2.0 PDFDocument1,117 pagesElectrical Current Flow Diagrams Amarok Diesel 2012 2.0 PDFDirceo Sulca Sanchez79% (19)

- Br710-A2 Engine DescriptionDocument19 pagesBr710-A2 Engine Descriptionmuters100% (1)

- MLT629Rev 05-03Document1,068 pagesMLT629Rev 05-03Razvan Mitru50% (2)

- KB 7636 U - Drawing PDFDocument1 pageKB 7636 U - Drawing PDFhugoheloNo ratings yet

- 12 Volt Hydraulic Pump Mte 4850 PDFDocument1 page12 Volt Hydraulic Pump Mte 4850 PDFpurnomo100% (1)

- p94 1425Document5 pagesp94 1425Luis Eduardo Corzo Enriquez100% (1)

- Yfz450 Service Manaual PDFDocument355 pagesYfz450 Service Manaual PDFDavid McQuownNo ratings yet

- LTM 1060Document4 pagesLTM 1060ayman akrabNo ratings yet

- Answer 2004 Skareb Service Manual PDFDocument23 pagesAnswer 2004 Skareb Service Manual PDFEzequiel Acosta García0% (1)

- Blow Off Valves DescriptionDocument12 pagesBlow Off Valves DescriptionParmeshwar Nath TripathiNo ratings yet

- Installation Instructions: 2018 Harley-Davidson Softail Stainless Hi-Output 2-1 PART# 27631/47631Document11 pagesInstallation Instructions: 2018 Harley-Davidson Softail Stainless Hi-Output 2-1 PART# 27631/47631Kurt LeadbeaterNo ratings yet

- Installation Instructions: 2017 Harley-Davidson Touring Power Duals PART# 16871/46871Document7 pagesInstallation Instructions: 2017 Harley-Davidson Touring Power Duals PART# 16871/46871febriNo ratings yet

- AS3 / AS6: SAE-Flange / Weld ButtDocument5 pagesAS3 / AS6: SAE-Flange / Weld ButtHuy NguyễnNo ratings yet

- Ariel Corporation - Arielcorp - Com22Document1 pageAriel Corporation - Arielcorp - Com22Anwar SadatNo ratings yet

- B 2457 AA - DrawingDocument1 pageB 2457 AA - DrawinghugoheloNo ratings yet

- Illustrated Parts List MODEL NO. 96041041000 Customer Catalog No. Ts 142L PRODUCT NO. 960 41 04-10Document18 pagesIllustrated Parts List MODEL NO. 96041041000 Customer Catalog No. Ts 142L PRODUCT NO. 960 41 04-10Saman SafdarNo ratings yet

- Lycoming PartsDocument140 pagesLycoming PartsRaul DeonarainNo ratings yet

- Installation Instructions: Harley-Davidson Touring Power Duals PART# 16371Document7 pagesInstallation Instructions: Harley-Davidson Touring Power Duals PART# 16371Salazar LeoNo ratings yet

- AC SystemDocument1 pageAC SystemDavid AnberlinNo ratings yet

- NEXT GEN HEX - SERVICE PARTS REFERENCE GUIDE - 2017 - revised10OCT2017Document8 pagesNEXT GEN HEX - SERVICE PARTS REFERENCE GUIDE - 2017 - revised10OCT2017Aldo MaranonNo ratings yet

- Zapasnye Chasti Traktor Husqvarna Ts 142t 9604104-32 Sadovyy Traktor Husqvarna Ts 142t 3495648729Document18 pagesZapasnye Chasti Traktor Husqvarna Ts 142t 9604104-32 Sadovyy Traktor Husqvarna Ts 142t 3495648729JánosNo ratings yet

- RMQLP-4120-H10 (Assembly)Document3 pagesRMQLP-4120-H10 (Assembly)Debabrata SahaNo ratings yet

- Manual Maquina GluteoDocument8 pagesManual Maquina Gluteoluisalberto89No ratings yet

- Illustrated Parts List MFG Id No. 944.605130 Customer Catalog No. 60513Document18 pagesIllustrated Parts List MFG Id No. 944.605130 Customer Catalog No. 60513golfgolfgolf212121No ratings yet

- Vue Eclatee m125 97Document18 pagesVue Eclatee m125 97Rémi GrangeNo ratings yet

- Installation Instructions: Harley-Davidson Sportster Mini Grenades PART# 16874 / 46874Document6 pagesInstallation Instructions: Harley-Davidson Sportster Mini Grenades PART# 16874 / 46874raymond malletNo ratings yet

- Pioneer Vsx-c301-s Rrv2846 SupplementDocument10 pagesPioneer Vsx-c301-s Rrv2846 SupplementSörös EndreNo ratings yet

- B 2458 S - Drawing PDFDocument1 pageB 2458 S - Drawing PDFhugoheloNo ratings yet

- Motorola 7vt1 7vt2 7vt5 Sams 83 6Document21 pagesMotorola 7vt1 7vt2 7vt5 Sams 83 6jpineteNo ratings yet

- Publication PDFDocument112 pagesPublication PDFкостя костяNo ratings yet

- Stop Directional Valves 2.5in Thru 3in F 93 5140 PrintDocument1 pageStop Directional Valves 2.5in Thru 3in F 93 5140 PrintEmad SalamaNo ratings yet

- Rotorcorp Air Conditioning KitDocument2 pagesRotorcorp Air Conditioning KitHolman OrjuelaNo ratings yet

- Tcu A650E Harness: Powertrain Control Solutions, LLCDocument3 pagesTcu A650E Harness: Powertrain Control Solutions, LLCromoNo ratings yet

- PARI2010 AAaa 532438299Document18 pagesPARI2010 AAaa 532438299jonNo ratings yet

- CL4 - Column - Assembly - Rev 00Document1 pageCL4 - Column - Assembly - Rev 00Mohamed MounirNo ratings yet

- NS50 Aerox R Water PumpDocument1 pageNS50 Aerox R Water PumptsimposthomasNo ratings yet

- ED1140158-900 (30082016 DCA Review)Document2 pagesED1140158-900 (30082016 DCA Review)mycopteraviationNo ratings yet

- DespieceDocument18 pagesDespiecejgsp0912No ratings yet

- Electronic Copy of Original Generated On Jul 11, 2014 7:01 AMDocument1 pageElectronic Copy of Original Generated On Jul 11, 2014 7:01 AMJuan OrtegaNo ratings yet

- Despiece Tecnico Technical Parts: Lavavajillas de Capota Pass-Through DishwashersDocument39 pagesDespiece Tecnico Technical Parts: Lavavajillas de Capota Pass-Through Dishwashersrafael cuellarNo ratings yet

- M18 018 eDocument3 pagesM18 018 eFalgon IslamNo ratings yet

- Part List - bd05s1100-1200 - Door Latch AssyDocument4 pagesPart List - bd05s1100-1200 - Door Latch Assyskrohilla1673No ratings yet

- JC Parts 967-0220Document85 pagesJC Parts 967-0220phoenixpowerandcontrolNo ratings yet

- TAP-NP (Assembly)Document2 pagesTAP-NP (Assembly)Ragnar RokiNo ratings yet

- Installation and Parts Manual: FOR Caterpillar D8T & D9T TractorsDocument28 pagesInstallation and Parts Manual: FOR Caterpillar D8T & D9T TractorsJusaNadaNo ratings yet

- IPL, Husqvarna, TS 142T, 96041043200, 2019-10Document18 pagesIPL, Husqvarna, TS 142T, 96041043200, 2019-10Frank ColaciuriNo ratings yet

- TU-045 - AS-RBP - 9-5.8 inDocument4 pagesTU-045 - AS-RBP - 9-5.8 inAtom InsideNo ratings yet

- Part Remove & Instaaal EngineDocument2 pagesPart Remove & Instaaal Engineb3go ideotNo ratings yet

- RTG Range.: Ready To Go StockDocument56 pagesRTG Range.: Ready To Go StockFercomil S.A.SNo ratings yet

- SEC5Document12 pagesSEC5SKLANTNo ratings yet

- Dch-164s & Dch-165s CatalogDocument4 pagesDch-164s & Dch-165s CatalogajajsainNo ratings yet

- QPQPJQ: Block Junction Tee Code 61 or 62 Block Pads / Block Flange or PadDocument4 pagesQPQPJQ: Block Junction Tee Code 61 or 62 Block Pads / Block Flange or PadHuy NguyễnNo ratings yet

- IPL, Partner, P185107HRB, 96061017700, 2007-01, TractorDocument18 pagesIPL, Partner, P185107HRB, 96061017700, 2007-01, TractorKriszekNo ratings yet

- Denso CR Injector Repair Kits 2015 PDF 1481112829Document22 pagesDenso CR Injector Repair Kits 2015 PDF 1481112829reza100% (1)

- John DreeDocument118 pagesJohn DreeHồng Sơn NguyễnNo ratings yet

- Lobatse Water Supply Master Plan - Work Package 1Document3 pagesLobatse Water Supply Master Plan - Work Package 1KIMBERLY HILLNo ratings yet

- D20S-5 Sb1109e12 PDFDocument848 pagesD20S-5 Sb1109e12 PDFGORD100% (1)

- B-2372-S Drawing ARIELDocument1 pageB-2372-S Drawing ARIELhugoheloNo ratings yet

- Pioneer djm-800 rrv3474 SupplementDocument2 pagesPioneer djm-800 rrv3474 SupplementjaanvanbrabantNo ratings yet

- 2 Inch Demco Relief Valves Replacement PartsDocument1 page2 Inch Demco Relief Valves Replacement Partsjose villalbaNo ratings yet

- SS 810 2 6PR 20160Document1 pageSS 810 2 6PR 20160armin_kunosic9871No ratings yet

- Gun Grey 350 BSIV 28112017Document12 pagesGun Grey 350 BSIV 28112017mrinal halder100% (1)

- PB02-STG-001 Steam Turbine System (A10-P-2001)Document1 pagePB02-STG-001 Steam Turbine System (A10-P-2001)zhangNo ratings yet

- IPL, Partner, P145107HRB, 96061017501, 2007-11, TractorDocument19 pagesIPL, Partner, P145107HRB, 96061017501, 2007-11, TractormkontossNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Rigging HandbookDocument123 pagesRigging Handbookhelp100% (2)

- Three-Phase Asynchronous Motors BN-BE-BX SeriesDocument102 pagesThree-Phase Asynchronous Motors BN-BE-BX Seriesamulya68No ratings yet

- 2022 Kocher D-Id enDocument2 pages2022 Kocher D-Id enmohamed alwanNo ratings yet

- Transmission Gear OilDocument1 pageTransmission Gear OilDouglas CortezziNo ratings yet

- Roof Fans Roof FansDocument32 pagesRoof Fans Roof Fansvvukmirovic_2No ratings yet

- Axles RT Crane MM10101Document73 pagesAxles RT Crane MM10101Marco AchinaNo ratings yet

- Solidworks Student Edition. For Academic Use Only.: 1911 Simplex EngineDocument30 pagesSolidworks Student Edition. For Academic Use Only.: 1911 Simplex Engineapi-273572571No ratings yet

- RodDocument24 pagesRodYebrail Mojica RuizNo ratings yet

- Dyna 1997-1998Document426 pagesDyna 1997-1998John HendersonNo ratings yet

- CV Carb Tuning ProceduresDocument4 pagesCV Carb Tuning ProceduresheartofdixieNo ratings yet

- Mechmate Gear, Resolution, Speed & Mach Frequency CalculatorDocument2 pagesMechmate Gear, Resolution, Speed & Mach Frequency CalculatorgfgfNo ratings yet

- Pos Tag ServiceDocument48 pagesPos Tag ServiceWajdi MansourNo ratings yet

- PD300-01 SpecSheetDocument4 pagesPD300-01 SpecSheetJeremy DruffelNo ratings yet

- Crochets Combine250TDocument8 pagesCrochets Combine250TsalemNo ratings yet

- Vibration ChartDocument1 pageVibration Chartairframer1981No ratings yet

- Microcontrolled Electromagnetic Engine: Atul Kumar Singh, Prabhat Ranjan TripathiDocument4 pagesMicrocontrolled Electromagnetic Engine: Atul Kumar Singh, Prabhat Ranjan TripathiTarun SinghNo ratings yet

- 1000 SERIES: 3 Stage Mast Parts ManualDocument46 pages1000 SERIES: 3 Stage Mast Parts ManualSifawSifaxBoudaoudNo ratings yet

- Transport, Assembly, Commissioning and Maintenance of Air Handling UnitsDocument50 pagesTransport, Assembly, Commissioning and Maintenance of Air Handling UnitsHoang TungNo ratings yet

- Treinamento de Servicos Lg958 Eng Rev1 2010 PDFDocument148 pagesTreinamento de Servicos Lg958 Eng Rev1 2010 PDFChandia Sagredo0% (1)

- ALGB142Document44 pagesALGB142MahaManthra100% (1)

- Types of Electrical Protection Relays or Protective Relays - Electrical Engineering PDFDocument6 pagesTypes of Electrical Protection Relays or Protective Relays - Electrical Engineering PDFRohan RustagiNo ratings yet

- FS1325A-R CNC RouterDocument6 pagesFS1325A-R CNC RouterBengkel WojojoyoNo ratings yet

- M8S5 Manual TransmissionDocument47 pagesM8S5 Manual TransmissionHai VanNo ratings yet

Installation Instructions: Harley-Davidson Softail Big Shots Staggered PART# 17941 / 47941

Installation Instructions: Harley-Davidson Softail Big Shots Staggered PART# 17941 / 47941

Uploaded by

David Noriega de SotoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Instructions: Harley-Davidson Softail Big Shots Staggered PART# 17941 / 47941

Installation Instructions: Harley-Davidson Softail Big Shots Staggered PART# 17941 / 47941

Uploaded by

David Noriega de SotoCopyright:

Available Formats

INSTALLATION INSTRUCTIONS:

HARLEY-DAVIDSON SOFTAIL

BIG SHOTS STAGGERED

PART# 17941 / 47941

Congratulations, you have purchased the finest exhaust system available for your motorcycle. Your Vance & Hines exhaust

is designed and crafted for performance, quality, and style. Please follow the instructions below, check exhaust system for

missing or damaged

7 parts and if you need

6 any assistance please

5 contact our technical4 support line (562) 921-7461.

3

RE

REV. ECO

01 -

3

2

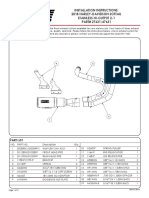

PARTS LIST

NO. PART NO. Description Qty. 8 A826HW 3/8-16 x 2.25 SHCS 2

1 D1125FC Header Assembly 1 9 A260HW 3/8-16 x 1 Hex Bolt 2

2 D1124HC/D1324HP Front Heat Shield 1 10 A240HW 5/16-18 x 5/8 FHS 4

3 D1125HC/D1325HP Rear Heat Shield 1 11 A270HW No. 20 Hose Clamp 3

4 A644ST O2 Adaptor 2 12 A272HW No. 28 Hose Clamp 4

5 A740ST-P Controls Spacer 2 13 A195HW Nut Plate 2

THE INFORMATION CONTAINED IN THIS DRAWIN

DISCLOSED TO OTHERS FOR MANUFACTURE OR FO

UNLESS OTHERWISE SPECIFIED

6 A745HW-P Lever Spacer 1 14 1103-P Bracket Spacer INTERPRET DIMENSIONS

AND TOLERANCES

PER ANSI Y14.5M

1 DIMENSIONS ARE INCHES

TOLERANCES ARE:

CAD

S. G

DRAW

FRACTIONAL: 1/16"

15 1143-P Mount Bracet 1

S. G

7 A739HW 5/16-24x 1.25BHCS 1

THIRD ANGLE PROJECTION ANGULAR: 2 CHEC

X.X 0.030"

B.

X.XX 0.015"

X.XXX 0.010" APPR

MATERIAL

SEE INDIV. DWGS

FINISH

CHROME, SEE INDIV. DWG

7 6 5 4 3

Page 1 of 6 D802IN RevB

HARDWARE

4 5 6 7 8 9 10 11 12 13

14 15

TOOLS REQUIRED

Flat Head Screwdriver 5/16 Nut Driver

Combination Wrench: 3/8” Drive Ratchet w/ 4” extension

1/2” &14mm 1/2”& 3/4” Socket,

1/2” Deep Socket

5/32”, 3/16”, 5/16” Allen Sockets THE INFORMATION CON

DISCLOSED TO OTHERS FOR

UNLESS OTHERWISE S

INTERPRET DIMENSIONS

AND TOLERANCES DIMENS

TOLE

Allen Wrenches: 3/16”, Snap Ring Pliers

PER ANSI Y14.5M

FRAC

THIRD ANGLE PROJECTION ANGU

5/16”

X.X

X.XX

X.XXX

MATERIAL

SEE

FINISH

CHROME

6 5 4 3

Page 2 of 6 D802IN RevB

STOCK EXHAUST SYSTEM REMOVAL

1. Locate the rear O2 sensor connector. Remove the two bolts holding the right side

cover in place and gently pull cover off bike. NOTE: Pay attention to the wire routing

for re-installation.

2. Locate the front O2 sensor connector. Unplug the sensor and feed the end of the wire

through the frame, freeing it from the motorcycle.

3. On Floor board models, loosen the right-hand floor board mounting bolts to gain

clearance for the exhaust removal and installation.

4. On Mid Mount models remove the forward brake rod bolt and remove the mid mount

foot peg bracket.

5. Loosen the heat shield clamps on both the front and rear exhaust pipes.

6. Remove the two mounting nuts from each head pipe, located at the cylinder head.

7. Remove the bolts attaching the mufflers to the mounting bracket.

8. Remove the entire exhaust system and set it aside.

9. Remove the stock mounting bracket.

10. Carefully remove the exhaust port flanges and circlips from the stock exhaust system

using the snap ring pliers. NOTE: Replace bent or damaged circlips.

11. Carefully remove the O2 sensors from the stock head pipes and save for re-use with the

new system.

12. Check the condition of the exhaust gasket and replace if worn or damaged. Harley

Davidson part number 65324-83B.

Page 3 of 6 D802IN RevB

VANCE & HINES EXHAUST INSTALLATION

1. Install the supplied mounting bracket, 1143-P. Using the supplied hardware 3/8-16 x

1” Hex bolt. Place the bracket spacer 1103-P in-between the frame and the 1143-P

bracket. Torque the mounting bracket bolts to 30-33 Ft./Lbs.

2. Remove head pipes from their protective packaging and install circlips and flanges

from the stock system onto both new head pipes.

3. Apply a small amount of anti-seize compound to the threads of the O2 sensors and

install them into the new head pipe. Install supplied 18mm to 12mm oxygen sensor

adapter then install 12mm oxygen sensors.

4. Remove heat shields from their protective packaging. Note: Removal of the end cap

may be required. Place each heat shield on a non-abrasive surface such as a blanket

or carpet. For chrome, use a felt tip pen and for black systems, use a pencil. Lightly

mark the outside edge of each heat shield to show location of mounting clips where

hose clamps will loop through. NOTE: Pencil marks can be erased if care is taken not to

harm coating.

5. Lay headers into the heat shields tail end first.

6. Install the end caps (if removal was necsarry) into the tail end of each heat shield

engaging head pipe and heat shield. Align mounting hole with the end cap hole.

Install and tight 1/4-20 button head screws. Note: Removable thread locking

compound is recommended.

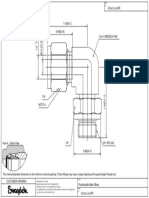

7. Loosely intall hose clamps by feeding the tail end of the clamp into the heat shields

clips. Use #20 hose clamps for head pipes areas and #28 hose clamps for muffler

areas. Take note of the screw direction. Figure 1. Screw head should be accessible

when system is installed on motorcycle for adjustment purposes. Note Do not tighten at

this time.

8. Using stock flange nuts, carefully install the head pipes into exhaust ports. Do not

tighten the nuts at this time.

9. Attach the mufflers to the mounting bracket. Using the two supplied nut plates and

5/16-18 flange bolts. Slide the nut plates inside the brackets that are welded to the

backside of each muffler.

10. Make sure to align the head pipes and heatshields then tighten the cylinder port

exhaust flange nuts on front and rear cylinders. See Figure 2.

11. On floor board models, re-install and tighten the floor board mounting bolts.

12. On mid mount models re-install mid mount foot peg bracket with spacers and new

hardware.

13. Re-install forward brake rod with spacer between brake rod and brake pedal support.

14. For models with passenger foot peg attached to the stock exhaust bracket, remove

the upper plug on the frame and re-install the left and right side passenger foot pegs

into the upper mounting holes. Figure 5.

15. Tighten the hose clamp heat shields.

16. Route the O2 sensor and reconnect O2 sensors to the wire harness.

17. Be sure to tighten all hardware before staring the motorcycle.

Page 4 of 6 D802IN RevB

D

FIGURE 1

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF VANCE & HI

DISCLOSED TO OTHERS FOR MANUFACTURE OR FOR ANY OTHER PURPOSE, UNLESS SPECIF

A UNLESS OTHERWISE SPECIFIED NAME DATE

CAD SANTA FE SP

INTERPRET DIMENSIONS

AND TOLERANCES DIMENSIONS ARE INCHES S. GUTIERREZ 8/27/2018 BROWNSB

PER ANSI Y14.5M TOLERANCES ARE: DRAWN www.vanceand

FRACTIONAL: 1/16" S. GUTIERREZ 8/27/2018

ANGULAR: 2

201

THIRD ANGLE PROJECTION PROJECT

CHECKED

X.X 0.030"

B. JOHNSON 8/27/2018

X.XX 0.015"

X.XXX 0.010" APPROVED

TITLE

FIGURE 2

MATERIAL

SEE INDIV. DWGS SIZE PART #

FINISH B

CHROME, SEE INDIV. DWGS WT. 19.053 LB

8 7 6 5 4 3 2

Page 5 of 6 D802IN RevB

EXHAUST CARE

1. When installing a new set of chrome pipes, make sure your hands are clean and free of

oil. After installation, thoroughly clean pipes with a soft cloth and cleaning solvent that

will leave no residue before starting the motorcycle.

2. Avoid long periods of idling as this can cause discoloration.

3. Intake leaks can cause the engine to run lean and overheat, this could lead to

discoloration.

4. Make sure there are no exhaust leaks at the junction of the exhaust pipes and cylinder

head. We recommend replacing gaskets if they are worn.

EXHAUST CARE (BLACK)

1. When installing a new set of black pipes, make sure your hands are clean and free of

oil. After installation, thoroughly clean pipes with a warm soapy water and a soft cloth.

Dry with a clean towel to remove any residue before starting the motorcycle. Do NOT

use anything abrasive to clean the pipes.

2. Avoid long periods of idling as this can cause discoloration.

3. Intake leaks can cause the engine to run lean and overheat, this could lead to

discoloration.

4. Make sure there are no exhaust leaks at the junction of the exhaust pipes and cylinder

head. We recommend replacing gaskets if they are worn.

Emissions Notice:

In California, in order to meet Air Resources Board emissions requirements, certain aftermarket part applications

have been identified as replacements, and others have received ARB Executive Orders. All other emissions

related aftermarket parts are for competition use only. A list of replacement parts and EO parts, and

corresponding fitment is provided at vanceandhines.com/California.

Warranty:

All Vance & Hines products are warranted against defects in material and workmanship for a period of 90 days.

This warranty does not cover discoloration or rust. This warranty shall be limited to the repair or replacement of

the product, which may be proven defective under normal use. Vance & Hines will not warranty any system

that has been abused, misused, improperly installed or modified.

Dealers or distributors are not authorized to make dispositions binding upon Vance & Hines. Vance & Hines will

not be responsible for any labor charges incurred in removing or replacing any system under warranty. A return

authorization number and a copy of the original purchase invoice must accompany all returns. Parts returned

without a return authorization may be refused.

13861 ROSECRANS AVENUE / SANTA FE SPRINGS, CA 90670

SALES: (562) 921-5388

TECHNICAL: (562) 926-5291

FAX: (562) 802-0110

Page 6 of 6

You might also like

- Electrical Current Flow Diagrams Amarok Diesel 2012 2.0 PDFDocument1,117 pagesElectrical Current Flow Diagrams Amarok Diesel 2012 2.0 PDFDirceo Sulca Sanchez79% (19)

- Br710-A2 Engine DescriptionDocument19 pagesBr710-A2 Engine Descriptionmuters100% (1)

- MLT629Rev 05-03Document1,068 pagesMLT629Rev 05-03Razvan Mitru50% (2)

- KB 7636 U - Drawing PDFDocument1 pageKB 7636 U - Drawing PDFhugoheloNo ratings yet

- 12 Volt Hydraulic Pump Mte 4850 PDFDocument1 page12 Volt Hydraulic Pump Mte 4850 PDFpurnomo100% (1)

- p94 1425Document5 pagesp94 1425Luis Eduardo Corzo Enriquez100% (1)

- Yfz450 Service Manaual PDFDocument355 pagesYfz450 Service Manaual PDFDavid McQuownNo ratings yet

- LTM 1060Document4 pagesLTM 1060ayman akrabNo ratings yet

- Answer 2004 Skareb Service Manual PDFDocument23 pagesAnswer 2004 Skareb Service Manual PDFEzequiel Acosta García0% (1)

- Blow Off Valves DescriptionDocument12 pagesBlow Off Valves DescriptionParmeshwar Nath TripathiNo ratings yet

- Installation Instructions: 2018 Harley-Davidson Softail Stainless Hi-Output 2-1 PART# 27631/47631Document11 pagesInstallation Instructions: 2018 Harley-Davidson Softail Stainless Hi-Output 2-1 PART# 27631/47631Kurt LeadbeaterNo ratings yet

- Installation Instructions: 2017 Harley-Davidson Touring Power Duals PART# 16871/46871Document7 pagesInstallation Instructions: 2017 Harley-Davidson Touring Power Duals PART# 16871/46871febriNo ratings yet

- AS3 / AS6: SAE-Flange / Weld ButtDocument5 pagesAS3 / AS6: SAE-Flange / Weld ButtHuy NguyễnNo ratings yet

- Ariel Corporation - Arielcorp - Com22Document1 pageAriel Corporation - Arielcorp - Com22Anwar SadatNo ratings yet

- B 2457 AA - DrawingDocument1 pageB 2457 AA - DrawinghugoheloNo ratings yet

- Illustrated Parts List MODEL NO. 96041041000 Customer Catalog No. Ts 142L PRODUCT NO. 960 41 04-10Document18 pagesIllustrated Parts List MODEL NO. 96041041000 Customer Catalog No. Ts 142L PRODUCT NO. 960 41 04-10Saman SafdarNo ratings yet

- Lycoming PartsDocument140 pagesLycoming PartsRaul DeonarainNo ratings yet

- Installation Instructions: Harley-Davidson Touring Power Duals PART# 16371Document7 pagesInstallation Instructions: Harley-Davidson Touring Power Duals PART# 16371Salazar LeoNo ratings yet

- AC SystemDocument1 pageAC SystemDavid AnberlinNo ratings yet

- NEXT GEN HEX - SERVICE PARTS REFERENCE GUIDE - 2017 - revised10OCT2017Document8 pagesNEXT GEN HEX - SERVICE PARTS REFERENCE GUIDE - 2017 - revised10OCT2017Aldo MaranonNo ratings yet

- Zapasnye Chasti Traktor Husqvarna Ts 142t 9604104-32 Sadovyy Traktor Husqvarna Ts 142t 3495648729Document18 pagesZapasnye Chasti Traktor Husqvarna Ts 142t 9604104-32 Sadovyy Traktor Husqvarna Ts 142t 3495648729JánosNo ratings yet

- RMQLP-4120-H10 (Assembly)Document3 pagesRMQLP-4120-H10 (Assembly)Debabrata SahaNo ratings yet

- Manual Maquina GluteoDocument8 pagesManual Maquina Gluteoluisalberto89No ratings yet

- Illustrated Parts List MFG Id No. 944.605130 Customer Catalog No. 60513Document18 pagesIllustrated Parts List MFG Id No. 944.605130 Customer Catalog No. 60513golfgolfgolf212121No ratings yet

- Vue Eclatee m125 97Document18 pagesVue Eclatee m125 97Rémi GrangeNo ratings yet

- Installation Instructions: Harley-Davidson Sportster Mini Grenades PART# 16874 / 46874Document6 pagesInstallation Instructions: Harley-Davidson Sportster Mini Grenades PART# 16874 / 46874raymond malletNo ratings yet

- Pioneer Vsx-c301-s Rrv2846 SupplementDocument10 pagesPioneer Vsx-c301-s Rrv2846 SupplementSörös EndreNo ratings yet

- B 2458 S - Drawing PDFDocument1 pageB 2458 S - Drawing PDFhugoheloNo ratings yet

- Motorola 7vt1 7vt2 7vt5 Sams 83 6Document21 pagesMotorola 7vt1 7vt2 7vt5 Sams 83 6jpineteNo ratings yet

- Publication PDFDocument112 pagesPublication PDFкостя костяNo ratings yet

- Stop Directional Valves 2.5in Thru 3in F 93 5140 PrintDocument1 pageStop Directional Valves 2.5in Thru 3in F 93 5140 PrintEmad SalamaNo ratings yet

- Rotorcorp Air Conditioning KitDocument2 pagesRotorcorp Air Conditioning KitHolman OrjuelaNo ratings yet

- Tcu A650E Harness: Powertrain Control Solutions, LLCDocument3 pagesTcu A650E Harness: Powertrain Control Solutions, LLCromoNo ratings yet

- PARI2010 AAaa 532438299Document18 pagesPARI2010 AAaa 532438299jonNo ratings yet

- CL4 - Column - Assembly - Rev 00Document1 pageCL4 - Column - Assembly - Rev 00Mohamed MounirNo ratings yet

- NS50 Aerox R Water PumpDocument1 pageNS50 Aerox R Water PumptsimposthomasNo ratings yet

- ED1140158-900 (30082016 DCA Review)Document2 pagesED1140158-900 (30082016 DCA Review)mycopteraviationNo ratings yet

- DespieceDocument18 pagesDespiecejgsp0912No ratings yet

- Electronic Copy of Original Generated On Jul 11, 2014 7:01 AMDocument1 pageElectronic Copy of Original Generated On Jul 11, 2014 7:01 AMJuan OrtegaNo ratings yet

- Despiece Tecnico Technical Parts: Lavavajillas de Capota Pass-Through DishwashersDocument39 pagesDespiece Tecnico Technical Parts: Lavavajillas de Capota Pass-Through Dishwashersrafael cuellarNo ratings yet

- M18 018 eDocument3 pagesM18 018 eFalgon IslamNo ratings yet

- Part List - bd05s1100-1200 - Door Latch AssyDocument4 pagesPart List - bd05s1100-1200 - Door Latch Assyskrohilla1673No ratings yet

- JC Parts 967-0220Document85 pagesJC Parts 967-0220phoenixpowerandcontrolNo ratings yet

- TAP-NP (Assembly)Document2 pagesTAP-NP (Assembly)Ragnar RokiNo ratings yet

- Installation and Parts Manual: FOR Caterpillar D8T & D9T TractorsDocument28 pagesInstallation and Parts Manual: FOR Caterpillar D8T & D9T TractorsJusaNadaNo ratings yet

- IPL, Husqvarna, TS 142T, 96041043200, 2019-10Document18 pagesIPL, Husqvarna, TS 142T, 96041043200, 2019-10Frank ColaciuriNo ratings yet

- TU-045 - AS-RBP - 9-5.8 inDocument4 pagesTU-045 - AS-RBP - 9-5.8 inAtom InsideNo ratings yet

- Part Remove & Instaaal EngineDocument2 pagesPart Remove & Instaaal Engineb3go ideotNo ratings yet

- RTG Range.: Ready To Go StockDocument56 pagesRTG Range.: Ready To Go StockFercomil S.A.SNo ratings yet

- SEC5Document12 pagesSEC5SKLANTNo ratings yet

- Dch-164s & Dch-165s CatalogDocument4 pagesDch-164s & Dch-165s CatalogajajsainNo ratings yet

- QPQPJQ: Block Junction Tee Code 61 or 62 Block Pads / Block Flange or PadDocument4 pagesQPQPJQ: Block Junction Tee Code 61 or 62 Block Pads / Block Flange or PadHuy NguyễnNo ratings yet

- IPL, Partner, P185107HRB, 96061017700, 2007-01, TractorDocument18 pagesIPL, Partner, P185107HRB, 96061017700, 2007-01, TractorKriszekNo ratings yet

- Denso CR Injector Repair Kits 2015 PDF 1481112829Document22 pagesDenso CR Injector Repair Kits 2015 PDF 1481112829reza100% (1)

- John DreeDocument118 pagesJohn DreeHồng Sơn NguyễnNo ratings yet

- Lobatse Water Supply Master Plan - Work Package 1Document3 pagesLobatse Water Supply Master Plan - Work Package 1KIMBERLY HILLNo ratings yet

- D20S-5 Sb1109e12 PDFDocument848 pagesD20S-5 Sb1109e12 PDFGORD100% (1)

- B-2372-S Drawing ARIELDocument1 pageB-2372-S Drawing ARIELhugoheloNo ratings yet

- Pioneer djm-800 rrv3474 SupplementDocument2 pagesPioneer djm-800 rrv3474 SupplementjaanvanbrabantNo ratings yet

- 2 Inch Demco Relief Valves Replacement PartsDocument1 page2 Inch Demco Relief Valves Replacement Partsjose villalbaNo ratings yet

- SS 810 2 6PR 20160Document1 pageSS 810 2 6PR 20160armin_kunosic9871No ratings yet

- Gun Grey 350 BSIV 28112017Document12 pagesGun Grey 350 BSIV 28112017mrinal halder100% (1)

- PB02-STG-001 Steam Turbine System (A10-P-2001)Document1 pagePB02-STG-001 Steam Turbine System (A10-P-2001)zhangNo ratings yet

- IPL, Partner, P145107HRB, 96061017501, 2007-11, TractorDocument19 pagesIPL, Partner, P145107HRB, 96061017501, 2007-11, TractormkontossNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Rigging HandbookDocument123 pagesRigging Handbookhelp100% (2)

- Three-Phase Asynchronous Motors BN-BE-BX SeriesDocument102 pagesThree-Phase Asynchronous Motors BN-BE-BX Seriesamulya68No ratings yet

- 2022 Kocher D-Id enDocument2 pages2022 Kocher D-Id enmohamed alwanNo ratings yet

- Transmission Gear OilDocument1 pageTransmission Gear OilDouglas CortezziNo ratings yet

- Roof Fans Roof FansDocument32 pagesRoof Fans Roof Fansvvukmirovic_2No ratings yet

- Axles RT Crane MM10101Document73 pagesAxles RT Crane MM10101Marco AchinaNo ratings yet

- Solidworks Student Edition. For Academic Use Only.: 1911 Simplex EngineDocument30 pagesSolidworks Student Edition. For Academic Use Only.: 1911 Simplex Engineapi-273572571No ratings yet

- RodDocument24 pagesRodYebrail Mojica RuizNo ratings yet

- Dyna 1997-1998Document426 pagesDyna 1997-1998John HendersonNo ratings yet

- CV Carb Tuning ProceduresDocument4 pagesCV Carb Tuning ProceduresheartofdixieNo ratings yet

- Mechmate Gear, Resolution, Speed & Mach Frequency CalculatorDocument2 pagesMechmate Gear, Resolution, Speed & Mach Frequency CalculatorgfgfNo ratings yet

- Pos Tag ServiceDocument48 pagesPos Tag ServiceWajdi MansourNo ratings yet

- PD300-01 SpecSheetDocument4 pagesPD300-01 SpecSheetJeremy DruffelNo ratings yet

- Crochets Combine250TDocument8 pagesCrochets Combine250TsalemNo ratings yet

- Vibration ChartDocument1 pageVibration Chartairframer1981No ratings yet

- Microcontrolled Electromagnetic Engine: Atul Kumar Singh, Prabhat Ranjan TripathiDocument4 pagesMicrocontrolled Electromagnetic Engine: Atul Kumar Singh, Prabhat Ranjan TripathiTarun SinghNo ratings yet

- 1000 SERIES: 3 Stage Mast Parts ManualDocument46 pages1000 SERIES: 3 Stage Mast Parts ManualSifawSifaxBoudaoudNo ratings yet

- Transport, Assembly, Commissioning and Maintenance of Air Handling UnitsDocument50 pagesTransport, Assembly, Commissioning and Maintenance of Air Handling UnitsHoang TungNo ratings yet

- Treinamento de Servicos Lg958 Eng Rev1 2010 PDFDocument148 pagesTreinamento de Servicos Lg958 Eng Rev1 2010 PDFChandia Sagredo0% (1)

- ALGB142Document44 pagesALGB142MahaManthra100% (1)

- Types of Electrical Protection Relays or Protective Relays - Electrical Engineering PDFDocument6 pagesTypes of Electrical Protection Relays or Protective Relays - Electrical Engineering PDFRohan RustagiNo ratings yet

- FS1325A-R CNC RouterDocument6 pagesFS1325A-R CNC RouterBengkel WojojoyoNo ratings yet

- M8S5 Manual TransmissionDocument47 pagesM8S5 Manual TransmissionHai VanNo ratings yet