Professional Documents

Culture Documents

Uvc 102, 103: Dynamic Flow Control System With 2-Way or 3-Way Valve and Energy Monitoring, Evalveco

Uvc 102, 103: Dynamic Flow Control System With 2-Way or 3-Way Valve and Energy Monitoring, Evalveco

Uploaded by

Claudio ScacciatelliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uvc 102, 103: Dynamic Flow Control System With 2-Way or 3-Way Valve and Energy Monitoring, Evalveco

Uvc 102, 103: Dynamic Flow Control System With 2-Way or 3-Way Valve and Energy Monitoring, Evalveco

Uploaded by

Claudio ScacciatelliCopyright:

Available Formats

Product data sheet 2.1 57.

011

UVC 102, 103: Dynamic flow control system with 2-way or 3-

way valve and energy monitoring, eValveco

How energy efficiency is improved

The SAUTER eValveco flow control system is the energy-efficient solution for variable flow control

and energy monitoring

Features

• Pressure-independent variable flow control

• Dynamic hydronic balancing at full and partial load

• Energy monitoring

• Integrated flow measurement with feedback and temperature measurement

• Remote commissioning and troubleshooting

• With integrated LCD and operating panel

• Available as 2-way or 3-way ball valve version, DN15 ... DN50

• For variable-flow HVAC systems UVC102

M

Technical data

Electronic power supply

T

~

Power supply Uv: 24 V~ (±20%) 50 Hz

T

Power consumption during operation 2.5 W (3 VA)

Power consumption when idle 1.0 W (1.5 VA)

UVC103

Peak inrush current 6.4 A [3 ms]

Input signal Y1: 0...10 V= M

Ri ≥ 60 kΩ

Feedback signal1)

Feedback signal resolution

X1: 0...10 V= (max. 2 mA)

Approx. 100 mV

T

~

T

Volume flow control

Setpoint adjustment Analogue (Y1) or via Modbus or oper-

ating panel

Type of sensor TTM ultrasonic sensor, no moving

parts

Unit of measurement2) [m3/h], l/s, l/min, gpm (UK),

gpm (US)

Measuring accuracy3) ±3% of actual value

Minimum controllable flow 17...70 l/h

Readiness for operation 5-10 minutes after switching on

Valve and actuator

Nominal pressure PN16 (16 bar)

Differential pressure ∆p Max. 2.4 bar

Medium4) Water (glycol-free)

Temperature of medium 5 °C...90 °C

Leakage rate in % of Kvs 0.001 %

Temperature sensor

Measuring element Pt500 as per EN 60751, Class B

Interfaces and communication

Bus connector STP cable, 2x double twisted

BMS integration Protocol Modbus/RTU, slave

Connection RS-485 double twisted cable (with

shared lead)

Cable type Shielded 2-core cable, STP or FTP

Baud rate 9600, 19 200 or 38 400

1) In relation to the measured actual flow

2) Unit in [ ]: Factory setting

3) In relation to the measured actual flow

4) In accordance with VDI 2035 sheet 2

Right of amendment reserved © 2019 Fr. Sauter AG 1/11

Product data sheet 2.1 57.011

Terminating resistor 120 Ω both sides

Flow meter design

Housing material Polypropylene, steel

Water-bearing parts:

Pressed brass DN 15 CW617N,

DN 20 - 50 CW602N (DZR), bronze,

EPDM seal, stainless steel,

EN-JM1130 fitting as per EN1562

LCD Backlit liquid crystal display, 2x16

characters

Ambient conditions

Admissible ambient temperature 10...45 °C

Admissible storage temperature -20...50 °C

Admissible ambient humidity Max. 90% rh, no condensation

Standards and directives

Type of protection5) IP54 (EN 60529), horizontal

CE conformity according to EMC Directive 2014/30/EU EN 61000-6-3 (2007)

EN 61000-3-2 (2006)

EN 61000-3-3 (1995) + am1 (2001)

EN 61000-6-1 (2005)

PED 2014/68/EU Fluid group II, no CE label

Overview of types

Type Description Weight

UVC102MF015 2-way ultrasonic energy regulating valve DN 3.5 kg

15

UVC102MF020 2-way ultrasonic energy regulating valve DN 5.1 kg

20

UVC102MF025 2-way ultrasonic energy regulating valve DN 5.2 kg

25

UVC102MF032 2-way ultrasonic energy regulating valve DN 5.5 kg

32

UVC102MF040 2-way ultrasonic energy regulating valve DN 6.8 kg

40

UVC102MF050 2-way ultrasonic energy regulating valve DN 7.5 kg

50

UVC103MF015 3-way ultrasonic energy regulating valve DN 3.6 kg

15

UVC103MF020 3-way ultrasonic energy regulating valve DN 5.1 kg

20

UVC103MF025 3-way ultrasonic energy regulating valve DN 5.4 kg

25

UVC103MF032 3-way ultrasonic energy regulating valve DN 5.7 kg

32

UVC103MF040 3-way ultrasonic energy regulating valve DN 7.1 kg

40

UVC103MF050 3-way ultrasonic energy regulating valve DN 8 kg

50

Additional technical data

Parameters, fitting notes, control, general informa- Applicable EN, DIN, AD, TRD and accident prevention regu-

tion lations

Description of operation

The UVC 102 / UVC 103 combines three functions in one system: a pressure-independent flow regu-

lating valve, a shut-off valve and energy monitoring. It is used in variable-flow HVAC heating and cool-

ing systems. With this combined function, the UVC102/103 system replaces both a balancing valve

and a regulating valve.

5) See fitting instructions P100017043

2/11 Right of amendment reserved © 2019 Fr. Sauter AG

Product data sheet 2.1 57.011

UVC 102 UVC 103

(1) (2) (3)

(7) (6) (5) (4)

(1) Flow controller with Modbus interface

(2) LCD

(3) Rotary actuator for ball valve

(4) Ball valve

(5) Supply temperature sensor

(6) Ultrasonic flow sensor

(7) Return temperature sensor

The UVC 102/103 series is designed for automatic hydronic balancing and simultaneous real-time

flow control. This means no additional balancing valves are required and the hydronic system is con-

trolled independently of pressure fluctuations during full-load and partial-load operation without any

additional devices.

)p

mam = ms, Y1 m actual flow

Note

) Correct flow control is only possible if there is sufficient system pressure.

To prevent cavitation, the static system pressure must be at least 1 bar. At static pressures below 1 bar,

air bubbles can form in the system and accumulate in the measuring chamber. If this happens, the meas-

urement is stopped and the actual value output is set to 0 m3/h.

The UVC 102 / UVC 103 receives a setpoint, e.g. from an external controller or optionally via Mod-

bus. The setpoint is internally converted into a flow rate setpoint. The target flow is achieved by ad-

justing the valve opening based on the comparison of the actual and target value. The actual flow is

continuously monitored by the built-in ultrasonic flow sensor.

The UVC102/103 series is available as a 2-way or 3-way ball valve with various flow ranges.

Flow rates

Type Ball valve Flow controller

DN Δp6) Kvs7) Min.8) Max.9)

UVC102MF015 15 mm 240 kPa 4.0 m3/h 0.017 m3/h 3.3 m3/h

UVC102MF020 20 mm 240 kPa 6.3 m3/h 0.024 m3/h 5.7 m3/h

UVC102MF025 25 mm 240 kPa 10.0 m3/h 0.024 m3/h 7.0 m3/h

6) Maximum closing pressure

7) Actual flow rate of the valve at nominal stroke

8) The minimum controllable flow is the minimum flow rate (other than zero) that can still be set and regulated.

9) The maximum flow is reached at a differential pressure of 1 bar (100 kPa). The target flow can be set to a value

that is equal to or less than the maximum flow.

Right of amendment reserved © 2019 Fr. Sauter AG 3/11

Product data sheet 2.1 57.011

Type Ball valve Flow controller

DN Δp6) Kvs7) Min.8) Max.9)

UVC102MF032 32 mm 240 kPa 16.0 m3/h 0.042 m3/h 10.5 m3/h

UVC102MF040 40 mm 240 kPa 25.0 m3/h 0.07 m3/h 15.0 m3/h

UVC102MF050 50 mm 240 kPa 40.0 m3/h 0.07 m3/h 20.0 m3/h

UVC103MF015 15 mm 240 kPa 4.0 m3/h 0.017 m3/h 3.3 m3/h

UVC103MF020 20 mm 240 kPa 6.3 m3/h 0.024 m3/h 5.7 m3/h

UVC103MF025 25 mm 240 kPa 10.0 m3/h 0.024 m3/h 7.0 m3/h

UVC103MF032 32 mm 240 kPa 16.0 m3/h 0.042 m3/h 10.5 m3/h

UVC103MF040 40 mm 240 kPa 25.0 m3/h 0.07 m3/h 15.0 m3/h

UVC103MF050 50 mm 240 kPa 40.0 m3/h 0.07 m3/h 20.0 m3/h

Intended use

This product is only suitable for the purpose intended by the manufacturer, as described in the “De-

scription of operation” section.

All related product regulations must also be adhered to. Changing or converting the product is not ad-

missible.

Improper use

The eValveco flow control system does not meet the conformity requirements of the Measuring Instru-

ments Directive 2014/32/EU. The eValveco system cannot be used instead of a calibrated heat meter

for the purposes of energy billing.

The system is not suitable for use in drinking water systems according to the directives 98/83/EC and

2015/1787/EU.

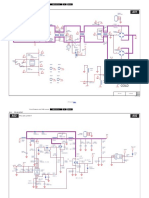

Application example

Power regulation of supply air heat exchangers

The power to be delivered to the heat exchanger is specified by the external control system using the

flow rate setpoint m (sh = heating / sc = cooling) for the required volume flow in relation to the temper-

ature difference between the supply and return temperatures. The SAUTER eValveco system deter-

mines the current power across the heat exchangers and returns the value as an output signal (ana-

logue or Modbus) to the higher-level control system. This adjusts the volume flow m until the setpoint

for the heating or cooling power has been reached.

OA SA

UVC102

T

~

AB

B

A UVC103

~ T

T y

Temperature Controller

6) Maximum closing pressure

7) Actual flow rate of the valve at nominal stroke

8) The minimum controllable flow is the minimum flow rate (other than zero) that can still be set and regulated.

9) The maximum flow is reached at a differential pressure of 1 bar (100 kPa). The target flow can be set to a value

that is equal to or less than the maximum flow.

4/11 Right of amendment reserved © 2019 Fr. Sauter AG

Product data sheet 2.1 57.011

Operation

The UVC 102 / UVC 103 adjusts the flow to the required rate, independently of the system pressure.

With analogue activation, the required flow setpoint is specified by a 0 ... 10 V signal from an external

controller. Alternatively, the setpoint can be specified using the operator panel or a Modbus com-

mand.

The LCD and simple menu structure allow quick start-up and display of the flow rate and other impor-

tant system parameters such as:

• m smaxd: Maximum controlled flow setting

• m smind: Minimum controlled flow setting

• m am: Current flow rate of the medium

• Sam: Current flow velocity of the medium

mnom mmax

msmaxd mDesign (1)

ms, Y1 mSetpoint

mam mactual flow

msmind mmin

(1) Design volume flow

Volume flow limitation

The system provides parameters for minimum and maximum volume flow limits. The limitation en-

sures that the flow does go over or under these values in any operating case. The system completely

opens or closes the ball valve as long as the minimum or maximum value is not reached. This means

the position of the ball valve always depends on the prevailing system pressure.

ON/OFF control with volume flow limitation

In addition to the variable flow control, the device can be activated via a potential-free contact (switch

or relay). This allows the system to either be completely closed or operated at the parameterised

maximum volume flow. In this case, the parameters must be set as follows:

• Y 1minh and Y 1minc to 1 V

• Y 1maxh and Y 1maxc to 1.5 V

UVC102MF0xx

UVC103MF0xx

AI AO RS485 RS485

24V

in out

LS MM Xs Xi D- D+ D- D+ C

WH

WH

GR

GR

BN

BN

YE

YE

BK

potentialfreier Kontakt

potential-free contact

contact sans potentiel

24 V~

EN 61558-2-6

Right of amendment reserved © 2019 Fr. Sauter AG 5/11

Product data sheet 2.1 57.011

Flush mode

When commissioned for the first time, the UVC 102 / UVC 103 is in flush mode, with the ball valve

fully opened. It exits flush mode as soon as the setpoint is above 8 V or when this mode is deactiva-

ted using a Modbus command or the control panel.

If a fault occurs in the power supply before flush mode is deactivated, flush mode remains active also

after the power returns.

If there is a power failure after flush mode has been completed, flush mode is deactivated after the

power returns.

Temperature measurement

The UVC 102 and UVC 103 contain one Pt500 temperature sensor in the supply line and one in the

return line. The measured temperatures can be read via Modbus or the LCD.

The temperature sensor T1 is integrated in the flow meter in the UVC 102 and UVC 103. The temper-

ature sensor T2 must be mounted on site.

The temperature sensor is supplied with a free cable length of 2.0 m.

Note

) In order to properly calculate the energy consumption, the temperature sensors must be correctly as-

signed to the supply and return lines using the variable Treturn.

Energy monitoring

The UVC 102 / UVC 103 calculates the current thermal energy consumption and accumulates the to-

tal energy consumption during operation. The current thermal energy consumption is stored in the

variable PWR (in watts).

To measure the total energy consumption, the current consumptions are integrated over time. The en-

ergy consumption10) is saved in a read-only variable every two hours:

• EnerHeat (SysType = heating)

• EnerCool (SysType = cooling)

It is not possible to reset the accumulated value.

The values are stored in a non-volatile memory. If there is a power failure in the installation, the val-

ues for the last two hours at most can be lost. The data memory is designed for a storage period of at

least 5 years. When the memory is full, the value is reset to zero. With typical usage, the value is read

out yearly. A difference calculation is used to determine the energy consumption for the last time peri-

od.

Note

) The system always saves the energy consumption in the “EnerHeat” or “EnerCool” variable based on the

“ClimStatus” value.

Energy calculation

The thermal energy consumption is provided by the read-only variable PWR. PWR is proportional to

the flow mam and the difference between inflow and outflow temperatures │Tam2 − Tam1│. The thermal

output is calculated internally using the following formula:

= = 2 1│

3600 3600

3

[ ], , [ ]

"

= 977.8 3

( @ 70 ° )

= 4191 ( @ 70 ° )

10) Possible units: watt hour (Wh) or British thermal units (BTU)

6/11 Right of amendment reserved © 2019 Fr. Sauter AG

Product data sheet 2.1 57.011

Note

) In the PWR variable, the value 0xFFF may be displayed under the following conditions:

• Energy consumption outside the measured value

• Tam1 > 95 °C or Tam2 > 95 °C (range exceeded)

• Tam2 is not connected and Text = 0

Error handling

Self-test

When it is switched on, the device performs a self-test and checks the program and data memory. If

one of these checks fails, an error bit is set depending on the type of error. This can be read via Mod-

bus.

Warning

If the system is operated outside the valid temperature range, it cannot achieve its guaranteed accu-

racy. This may result in irreparable damage to the product. For this reason, if the water temperature is

outside the permissible range, the warning bit “b0” is set to 1 and “Err” appears on the display. It is

deleted as soon as the temperature is back in the specified range.

Note

) If the required setpoint is between the closed ball valve position and the smallest possible opening, the

controller alternately opens and closes the ball valve. In this case, the mean volume flow corresponds to

the setpoint.

Error

In the event of a system error, the following information is provided:

• b0: Error in CRC check during boot process.

• b1: EEPROM area error while booting.

• b2: Invalid variable: This bit is set when a variable outside the valid range is entered. It is reset as

soon as the variable is entered in the correct range.

• b3: Conflict on changeover switching: This bit is set if Y1h and Y1c are both higher than their respec-

tive minimum values Y1minh and Y1minc.

• b4 and b5: unused, reserved for future use

Modbus

The system is equipped with an RS-485 Modbus interface. All the Modbus parameters are listed in

the manual P100017780.

RS-485 bus connection

UVC102MF0xx UVC102MF0xx

Modbus Master UVC103MF0xx UVC103MF0xx

RS485 AI AO RS485 RS485 AI AO RS485 RS485

24V 24V

in out in out

D- D+ C LS MM Xs Xi D- D+ D- D+ C LS MM Xs Xi D- D+ D- D+ C

WH

WH

WH

WH

GR

GR

GR

GR

BN

BN

BN

BN

YE

YE

BK

YE

YE

BK

0,25 W 0,25 W

The max. admissible bus length depends on the cable type used and the correct termination with ter-

minating resistors. In general, a 4-wire shielded cable with twisted wire pairs must be used.

Use of one of the following cable types is recommended:

• Lapp cable UNITRONIC® BUS LD 2170204

• Lapp cable UNITRONIC® BUS LD FD P 2170214

• Belden 9842

• Belden 3106A

Right of amendment reserved © 2019 Fr. Sauter AG 7/11

Product data sheet 2.1 57.011

• Belden 3107A

Observe the correct polarity of all signals. The cable shield of the entire bus line must be connected

continuously, and connected to protective earth as directly as possible at one location. The shielding

is to be earthed in the plant as follows:

• Shielding earthed at one end is suitable for protection from electrical interference (from overhead

power lines, static charges etc.)

• Shielding earthed at both ends is suitable for protection from electromagnetic interference (from fre-

quency converters, electric motors, coils etc.)

Note

) Faulty wiring can result in damage to the device.

All the devices in a network must be connected to the same power supply.

For Ethernet CAT-5 cables and J-Y(ST)Y cables, a bus length of up to 500 m is possible. The length

of the bus line is limited by the following parameters:

• Number of connected devices

• Cross-section of cable used

In the case of RS-485 interfaces, the bus wiring must follow line topology. Star, tree or branch topolo-

gies are not recommended. The devices do not have internal terminating resistors. Therefore, a ter-

minating resistor of 120 Ω (0.25 W) must be connected at the start and end of the bus line, parallel to

the D+/D- data lines.

Connection diagram

Cable Type Function Colour

1 LS 24 V~ Brown

1 MM Power supply ground White

1 Xi (actual value) AI 0...10 V Green

1 Xs (setpoint) AO 0...10 V Yellow

2 Modbus RS-485 IN D- White

2 Modbus RS-485 IN D+ Brown

2 Modbus RS-485 OUT D- Yellow

2 Modbus RS-485 OUT D+ Green

2 Modbus Power supply ground Shielding

UVC102MF0xx

UVC103MF0xx

AI AO RS485 RS485

24V

in out

LS MM Xs Xi D- D+ D- D+ C

WH

WH

GR

GR

BN

BN

YE

YE

BK

24 V~

EN 61558-2-6

8/11 Right of amendment reserved © 2019 Fr. Sauter AG

Product data sheet 2.1 57.011

Connection diagram: Application with analogue actual value and setpoint

UVC102MF0xx

UVC103MF0xx

EY-AS52x

EY-RC500 / EY-RC502

AI AO RS485 RS485 EY-EM5xx

24V

in out

AI AO

LS MM Xs Xi D- D+ D- D+ C

WH

WH

GR

GR

BN

BN

YE

YE

BK

LS

24 V~ MM 230 V~

EN 61558-2-6

(1) (2)

(1) Components with distance to power source

(2) Power source close to the controller

Right of amendment reserved © 2019 Fr. Sauter AG 9/11

Product data sheet 2.1 57.011

Dimensional drawings and table of dimensions

All dimensions in millimetres.

UVC 102

Type DN ISO 228-1 ISO 7/1 L1 L2 H H1 H2 H3 B B1

[mm] C C1 C2 [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

UVC102MF015 15 G1" Rp½" Rp½" 328 304 173 153 131 107 86 70

UVC102MF020 20 Rp¾" 397 369 178 158 131 151 89 70

UVC102MF025 25 G1¼" Rp¾" Rp1" 404 376 181 161 134 151 90 70

UVC102MF032 32 Rp1¼" 406 379 183 163 137 149 90 70

UVC102MF040 40 Rp1½" 457 424 203 183 143 163 90 70

G2" Rp1¼"

UVC102MF050 50 Rp2" 475 442 216 196 156 163 90 70

10/11 Right of amendment reserved © 2019 Fr. Sauter AG

Product data sheet 2.1 57.011

UVC 103

Type DN ISO 228-1 ISO 7/1 L1 L2 L3 H H1 H2 H3 B B1 B2

[mm] C C1 C2 C3 [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

UVC103MF015 15 G1" Rp½" Rp½" Rp½" 333 309 34 173 153 131 107 86 70 34

UVC103MF020 20 Rp¾" Rp¾" 399 372 37 178 158 131 151 89 70 37

UVC103MF025 25 G1¼" Rp¾" Rp1" Rp1" 412 385 45 181 161 134 151 93 70 45

UVC103MF032 32 Rp1¼" Rp1¼" 419 393 53 183 163 137 149 101 70 53

UVC103MF040 40 Rp1½" Rp1½" 465 432 57 202.7 183 143 163 105 70 57

G2" Rp1¼"

UVC103MF050 50 Rp2" Rp2" 490 457 69 216 196 156 163 117 70 69

Fr. Sauter AG

Im Surinam 55

CH-4058 Basel

Tel. +41 61 - 695 55 55

www.sauter-controls.com

Right of amendment reserved © 2019 Fr. Sauter AG 11/11

You might also like

- Garmin Connect OAuth SpecificationDocument8 pagesGarmin Connect OAuth SpecificationDANIEL MARQUEZNo ratings yet

- A Single SignOn Guide For SAP S4HANA Cloud, Private EditionDocument15 pagesA Single SignOn Guide For SAP S4HANA Cloud, Private EditionmutyalapatiNo ratings yet

- The HY6801M Electric Leakage Relay Using Introduction: Edition v1.0Document10 pagesThe HY6801M Electric Leakage Relay Using Introduction: Edition v1.0Jon Chen0% (2)

- Maine Exporter's Guide To The European Union's: CE Marking RequirementsDocument35 pagesMaine Exporter's Guide To The European Union's: CE Marking Requirementssopuser100% (1)

- EP..F+MP Datasheet en-APDocument10 pagesEP..F+MP Datasheet en-APLandz GanzonNo ratings yet

- E3ZM20 Timers - MultifunctionDocument3 pagesE3ZM20 Timers - MultifunctionNhung NguyenNo ratings yet

- MTE - CheckMeter 2.3 Genx English - R06 (06.2016)Document2 pagesMTE - CheckMeter 2.3 Genx English - R06 (06.2016)Genci GjergjaniNo ratings yet

- Pantron Amplifier ISG-N138 DatasheetDocument7 pagesPantron Amplifier ISG-N138 DatasheetlutfirozaqiNo ratings yet

- Description Key Features: Clamp On Current TransducerDocument2 pagesDescription Key Features: Clamp On Current TransducerNebojsaNo ratings yet

- InteliPro-Datasheet 1Document4 pagesInteliPro-Datasheet 1Jan Antonius DjunaediNo ratings yet

- Inteligennt GC DatasheetDocument4 pagesInteligennt GC DatasheetٍJordan SportNo ratings yet

- InteliPro DatasheetDocument4 pagesInteliPro Datasheethapem4No ratings yet

- Ifm S2 CatalogDocument2 pagesIfm S2 CatalogInbanesan AkNo ratings yet

- Datasheet BES05RM 272792 enDocument2 pagesDatasheet BES05RM 272792 enAleksandar MarkovićNo ratings yet

- RunnTech RT01 Cobra-Head Shaped Joystick ControllerDocument9 pagesRunnTech RT01 Cobra-Head Shaped Joystick ControllerRunnTechNo ratings yet

- Tele E3ZM20 0900766b80dc73a2Document3 pagesTele E3ZM20 0900766b80dc73a2TaQuangDucNo ratings yet

- Z170REG DatasheetDocument1 pageZ170REG DatasheetAutomation WorksNo ratings yet

- IG-NTC DatasheetDocument4 pagesIG-NTC DatasheetsNo ratings yet

- 3-Phase Power Network Analyzer Recorder nd40 1158757-2815139 PDFDocument5 pages3-Phase Power Network Analyzer Recorder nd40 1158757-2815139 PDFqwertyui123321No ratings yet

- RunnTech RT02 Series Robust Industrial JoystickDocument10 pagesRunnTech RT02 Series Robust Industrial JoystickRunnTechNo ratings yet

- RunnTech RT02 Series Robust Industrial JoystickDocument9 pagesRunnTech RT02 Series Robust Industrial JoystickRahmatArifinNo ratings yet

- InteliDrive Lite FPC Datasheet - 4Document4 pagesInteliDrive Lite FPC Datasheet - 4widiNo ratings yet

- TimerDocument2 pagesTimerivaNo ratings yet

- IG NTC BB Datasheet - 1Document4 pagesIG NTC BB Datasheet - 1Tiên Lê Trần MỹNo ratings yet

- InteliSys NTC Hybrid DatasheetDocument4 pagesInteliSys NTC Hybrid DatasheetfernandoNo ratings yet

- Multifunction Power Meter: DescriptionDocument3 pagesMultifunction Power Meter: DescriptionKatherine SmithNo ratings yet

- SM6100 03 - en GBDocument6 pagesSM6100 03 - en GBphalkejituNo ratings yet

- InteliCompact NT MINT Datasheet PDFDocument4 pagesInteliCompact NT MINT Datasheet PDFAung MhNo ratings yet

- InteliCompact NT SPTM DatasheetDocument4 pagesInteliCompact NT SPTM DatasheetKingsley MichaelNo ratings yet

- Datasheet: Inteligen NTC BaseboxDocument4 pagesDatasheet: Inteligen NTC BaseboxsantoNo ratings yet

- Nxt4 Dab e 1.23 WebDocument2 pagesNxt4 Dab e 1.23 WebFelipe AchurraNo ratings yet

- Sitrans F M Magflo: Electromagnetic Flowmeters Transmitter Types MAG 5000, MAG 6000Document16 pagesSitrans F M Magflo: Electromagnetic Flowmeters Transmitter Types MAG 5000, MAG 6000Daniela KroetzNo ratings yet

- Datasheet BES05M9 266163 enDocument2 pagesDatasheet BES05M9 266163 endhananjay_hawaldarNo ratings yet

- IFM Speed Relay DD0203 Data SheetDocument2 pagesIFM Speed Relay DD0203 Data SheetRaymund GatocNo ratings yet

- IG NT BB DatasheetDocument4 pagesIG NT BB DatasheetWilliam Will Controle WoodwardNo ratings yet

- AMF9Document5 pagesAMF9Ayadi39No ratings yet

- RT-100 Industrial JoystickDocument11 pagesRT-100 Industrial JoystickRunnTechNo ratings yet

- Datasheet: Intelilite Amf 20Document4 pagesDatasheet: Intelilite Amf 20Suwara EngineNo ratings yet

- ms1022 gp22 EquivalentDocument60 pagesms1022 gp22 Equivalentdbm100% (1)

- Ig-Ntc-Bb 400 HZ DatasheetDocument4 pagesIg-Ntc-Bb 400 HZ DatasheetManivannan ManikamNo ratings yet

- 1598 FichaDocument7 pages1598 FichabrandoninduNo ratings yet

- Ba dr4310Document2 pagesBa dr4310BaoLCNo ratings yet

- En E1zm, E1z1Document3 pagesEn E1zm, E1z1retrueke1170No ratings yet

- Digital Temperature Transmitter For Resistance Sensors, Head-And Rail-Mounted Version Models T15.H, T15.RDocument11 pagesDigital Temperature Transmitter For Resistance Sensors, Head-And Rail-Mounted Version Models T15.H, T15.RGerardo SánchezNo ratings yet

- General Specifications: YokogawaDocument16 pagesGeneral Specifications: YokogawaapisituNo ratings yet

- Spesifikasi Loop Calibrator VC05sDocument4 pagesSpesifikasi Loop Calibrator VC05sDaniel SilitongaNo ratings yet

- Meg 40+Document44 pagesMeg 40+Laurentiu CatalinNo ratings yet

- Magnetic Inductive FlowmeterDocument5 pagesMagnetic Inductive Flowmeterarif kurniawanNo ratings yet

- Electrical Energy Meter With Integrated Serial Modbus Interface EEM230-D-MODocument6 pagesElectrical Energy Meter With Integrated Serial Modbus Interface EEM230-D-MOVadres GeMnNo ratings yet

- Test Labs TL401 TL402: Test Lab Consisting of Oscilloscope, Function Generator, Frequency Counter and Power SupplyDocument2 pagesTest Labs TL401 TL402: Test Lab Consisting of Oscilloscope, Function Generator, Frequency Counter and Power SupplyAngappa MegatechNo ratings yet

- Intelimains NTC Basebox DatasheetDocument4 pagesIntelimains NTC Basebox DatasheetEnny ClocielNo ratings yet

- Intelidrive Lite FPC DatasheetDocument4 pagesIntelidrive Lite FPC DatasheetEduardo A PaduanNo ratings yet

- Belimo NV24-MFT - T Datasheet En-GbDocument5 pagesBelimo NV24-MFT - T Datasheet En-GbAndrzej KrzyżanowskiNo ratings yet

- MRS11 DatasheetDocument4 pagesMRS11 DatasheetMaylen RivasNo ratings yet

- PSR SXP 230uc, Esam4,3x1,1x2, BDocument8 pagesPSR SXP 230uc, Esam4,3x1,1x2, BConstantin MoldoNo ratings yet

- BS5Document2 pagesBS5Min ZayarNo ratings yet

- SM7100 03 - en Us PDFDocument5 pagesSM7100 03 - en Us PDFIzidor JuniorNo ratings yet

- v604s DatasheetDocument9 pagesv604s DatasheetzefisefNo ratings yet

- InteliLite AMF20 DatasheetDocument4 pagesInteliLite AMF20 DatasheetMaylen Rivas100% (1)

- Working Standard: Electricity Meters Test EquipmentDocument2 pagesWorking Standard: Electricity Meters Test EquipmentLOUKILkarimNo ratings yet

- Sm-I552 Sin-Db 02-001203Document5 pagesSm-I552 Sin-Db 02-001203ari___wicaksonoNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Z-ABS Technical Data Sheet Eng-1Document2 pagesZ-ABS Technical Data Sheet Eng-1PeroNo ratings yet

- X-Mini II User Manual EnglishDocument7 pagesX-Mini II User Manual EnglishstephenrleeNo ratings yet

- Ads Remove - Regex CodeDocument3 pagesAds Remove - Regex Code2023.myspyNo ratings yet

- Internet of Things in Industries: A Survey: Li Da Xu (Senior Member, IEEE), Wu He, Shancang LiDocument11 pagesInternet of Things in Industries: A Survey: Li Da Xu (Senior Member, IEEE), Wu He, Shancang LiSachin PatilNo ratings yet

- Full Download Modern Systems Analysis and Design 7th Edition Hoffer Test BankDocument13 pagesFull Download Modern Systems Analysis and Design 7th Edition Hoffer Test Bankkunzlidinoopq100% (39)

- Joint Measurement Sheet: Name of CollegeDocument1 pageJoint Measurement Sheet: Name of CollegeVenu GopalNo ratings yet

- Flight Data Monitoring (FDM) Unknown Hazards Detection During Approach Phase Using Clustering Techniques and AutoEncodersDocument9 pagesFlight Data Monitoring (FDM) Unknown Hazards Detection During Approach Phase Using Clustering Techniques and AutoEncodersPedro Rossel AlarcónNo ratings yet

- Isuzu 4fb1 Engine ManualDocument3 pagesIsuzu 4fb1 Engine ManualOrlando Zaldivar33% (3)

- Example de Datasheet Complet D'un SoC - TI DM814x - sprs647cDocument375 pagesExample de Datasheet Complet D'un SoC - TI DM814x - sprs647cJean-Philippe УдеNo ratings yet

- Master Thesis - Andre ConceicaoDocument109 pagesMaster Thesis - Andre ConceicaothendyNo ratings yet

- 715g7312 p01 000 0020 - Philips - PsuDocument6 pages715g7312 p01 000 0020 - Philips - PsuAlberto CamarenaNo ratings yet

- Electric PC LS160 LS170 6 EUDocument62 pagesElectric PC LS160 LS170 6 EUsassine khouryNo ratings yet

- PM Parts List CS10GC - T8FDocument1 pagePM Parts List CS10GC - T8FKristomiDerMarine-IngenieurNo ratings yet

- Motores Marathon Electric ULDocument1 pageMotores Marathon Electric ULMilton TapiaNo ratings yet

- Melissa Esenam Klu CVDocument1 pageMelissa Esenam Klu CVmelissa.esenamNo ratings yet

- Citel Portico Compatible HandsetDocument2 pagesCitel Portico Compatible HandsetcpeanoNo ratings yet

- TSE Jan 22 - WebDocument44 pagesTSE Jan 22 - WebBharath Kumar SudarsanNo ratings yet

- Fortigate System Admin 40 Mr3Document331 pagesFortigate System Admin 40 Mr3ROMAN FORTISNo ratings yet

- Preserving Privacy: Efficient and Provably Secure Two-Factor Authentication (2FA) Scheme of AmazonDocument4 pagesPreserving Privacy: Efficient and Provably Secure Two-Factor Authentication (2FA) Scheme of AmazonDandanNo ratings yet

- Rosenberger Site Solutions Installer CatalogDocument32 pagesRosenberger Site Solutions Installer Catalogyou are awesomeNo ratings yet

- Tpmc-8X: Isysâ 8.4" Wifi TouchpanelDocument7 pagesTpmc-8X: Isysâ 8.4" Wifi TouchpanelHira SinghNo ratings yet

- Bill of QuantityDocument7 pagesBill of QuantityAnonymous YHVmpLoNo ratings yet

- Ux09 400 PDFDocument58 pagesUx09 400 PDFjashkishoreNo ratings yet

- Artificial Intelligence and Expert Systems: ITEC 1010 Information and OrganizationsDocument23 pagesArtificial Intelligence and Expert Systems: ITEC 1010 Information and OrganizationsParth MehtaNo ratings yet

- For Today's Emergency DepartmentsDocument4 pagesFor Today's Emergency DepartmentsdesbestNo ratings yet

- Wordpress The Right WayDocument62 pagesWordpress The Right WayAdela CCNo ratings yet

- WP1 ImplementingPull PDFDocument4 pagesWP1 ImplementingPull PDFN Pe CervNo ratings yet