Professional Documents

Culture Documents

The Prosecc LTD

The Prosecc LTD

Uploaded by

UV patelCopyright:

Available Formats

You might also like

- ASTM-D3230-19 Salinidad en CrudoDocument7 pagesASTM-D3230-19 Salinidad en CrudoAngel MurilloNo ratings yet

- Astm D 3230 - 08 PDFDocument6 pagesAstm D 3230 - 08 PDFJulian Felipe Noguera Cruz100% (2)

- Microsoft Word - Iit Assignments - KRR - PDFDocument60 pagesMicrosoft Word - Iit Assignments - KRR - PDFggk201350% (2)

- ZLD Evaparation Crystallization Plant in The Hydrometallurgical IndustryDocument6 pagesZLD Evaparation Crystallization Plant in The Hydrometallurgical Industrykosmc123No ratings yet

- A New Approach For Particle Size ReductionDocument7 pagesA New Approach For Particle Size Reductioncsyena28225No ratings yet

- HomeworkDocument3 pagesHomeworkJudluzNo ratings yet

- Recovery of Molybdenum From Spent Acid by Ammonia Gas NeutralizationDocument6 pagesRecovery of Molybdenum From Spent Acid by Ammonia Gas NeutralizationМладен БугарчићNo ratings yet

- Technical Paper PresentationDocument27 pagesTechnical Paper PresentationBhagyashree BachhavNo ratings yet

- Acid Soluble Magnesia Cement: New Applications in Completion and Workover OperationsDocument7 pagesAcid Soluble Magnesia Cement: New Applications in Completion and Workover OperationsCoolProphetNo ratings yet

- Preparation of Silica Gel From Rice Husk Ash Using Microwave HeatingDocument6 pagesPreparation of Silica Gel From Rice Husk Ash Using Microwave HeatingArauAnaNo ratings yet

- In Situ Hypochlorous Acid Generation For The Treatment of Distillery SpentwashDocument4 pagesIn Situ Hypochlorous Acid Generation For The Treatment of Distillery SpentwashGregorio ValeroNo ratings yet

- Problem Set - Particle Fluid Separation2012Document3 pagesProblem Set - Particle Fluid Separation2012John Kevin San Jose50% (2)

- Micro-Structured Reactor To Generate Hydrogen From MethylcyclohexaneDocument4 pagesMicro-Structured Reactor To Generate Hydrogen From MethylcyclohexaneMujahid Al HinaiNo ratings yet

- Preparation of Silica Gel From Rice Husk Ash UsingDocument7 pagesPreparation of Silica Gel From Rice Husk Ash UsingCaro DominguezNo ratings yet

- Admixtures 2Document18 pagesAdmixtures 2stephanyNo ratings yet

- Fluorite - Saving EnergyDocument9 pagesFluorite - Saving EnergyrecaiNo ratings yet

- Exergy Analysis of A 10,000 M /day Tajoura SWRO Desalination PlantDocument7 pagesExergy Analysis of A 10,000 M /day Tajoura SWRO Desalination Plantchengawy7No ratings yet

- Catalytic Reforming Improved by Moisture MeteringDocument4 pagesCatalytic Reforming Improved by Moisture MeteringIrfan QadirNo ratings yet

- Precipitation of Magnesium Hydroxide From Brine PDFDocument7 pagesPrecipitation of Magnesium Hydroxide From Brine PDFHandoko AhmadNo ratings yet

- Flocculation of Kaolinite Suspensions in Water by Coconut Cream CaseinDocument7 pagesFlocculation of Kaolinite Suspensions in Water by Coconut Cream CaseinNadia MandasariNo ratings yet

- Power Plant Water ManagementDocument8 pagesPower Plant Water ManagementSarah FrazierNo ratings yet

- US3983180Document7 pagesUS3983180Agustina TriyaniNo ratings yet

- s11814 017 0002 8Document10 pagess11814 017 0002 8Augusto Antonio MenzelNo ratings yet

- 1) Introduction To VCM Process: 1.1vinyl Chloride From AcetyleneDocument12 pages1) Introduction To VCM Process: 1.1vinyl Chloride From AcetyleneSaleamlak ZerihunNo ratings yet

- United States Patent Office: Patented Oct. 7, 1958Document4 pagesUnited States Patent Office: Patented Oct. 7, 1958udinPet0tNo ratings yet

- Morales 2015Document11 pagesMorales 2015Beatriz Emanuella de Andrade BressanNo ratings yet

- Cobalt precipitation with MgODocument32 pagesCobalt precipitation with MgOjoseph kafumbilaNo ratings yet

- US2687435Document2 pagesUS2687435Ipalma 3No ratings yet

- Peroxido de Hidrogeno-ChitinDocument12 pagesPeroxido de Hidrogeno-ChitinRodrigo EspinozaNo ratings yet

- Pelagia Research Library: Precipitation of Nano-Magnesium Hydroxide From Bittern Using Ultrasound IrradiationDocument13 pagesPelagia Research Library: Precipitation of Nano-Magnesium Hydroxide From Bittern Using Ultrasound IrradiationChemical Ferdi IzzecsonNo ratings yet

- Manufacture of Sulfuric Acid: S.R.M. Engineering CollegeDocument76 pagesManufacture of Sulfuric Acid: S.R.M. Engineering CollegeCharles RiosNo ratings yet

- Process For Recovering Lithium From Brine by Salting Out Lithium Sulfate MonohydrateDocument8 pagesProcess For Recovering Lithium From Brine by Salting Out Lithium Sulfate MonohydrateGabriel ChurioNo ratings yet

- 43 Optimization Lime KilnDocument10 pages43 Optimization Lime KilnAris parkerNo ratings yet

- Maillard Reaction in Molasses Storage Tank PDFDocument4 pagesMaillard Reaction in Molasses Storage Tank PDFArthur Yanez100% (2)

- Heat Evolution in Alkali Activated Synthetic Slag-Metakaolin MixturesDocument5 pagesHeat Evolution in Alkali Activated Synthetic Slag-Metakaolin MixturesSereenen OtgonjargalNo ratings yet

- Hydrogenation of Maltose in Catalytic Membrane ReaDocument4 pagesHydrogenation of Maltose in Catalytic Membrane Reakhaled kaidNo ratings yet

- Thermodynamic Analysis and Optimization of Adsorption-Based Atmospheric Water HarvestingDocument10 pagesThermodynamic Analysis and Optimization of Adsorption-Based Atmospheric Water Harvestingmm tNo ratings yet

- PROBLEM SET March 4.2021Document4 pagesPROBLEM SET March 4.2021Thalia RodriguezNo ratings yet

- Us 5282882Document5 pagesUs 5282882DhrupadSoniRaviNo ratings yet

- Regeneration of The Waste Selective Catalytic Reduction Denitrification Catalyst by Nitric Acid WashingDocument9 pagesRegeneration of The Waste Selective Catalytic Reduction Denitrification Catalyst by Nitric Acid WashingJoyce WongNo ratings yet

- Problem As Cat Al Is Is 2018Document10 pagesProblem As Cat Al Is Is 2018Victor Daniel Martínez CarreteroNo ratings yet

- Test Prep Rep Sanitary SolutionsDocument31 pagesTest Prep Rep Sanitary SolutionsVincent SantamariaNo ratings yet

- Name Matric Id Group Course Code ExperimentDocument7 pagesName Matric Id Group Course Code ExperimentadillaaazmiNo ratings yet

- Us 4370422Document5 pagesUs 4370422praptining pangertiNo ratings yet

- Capitulo FarinhaDocument128 pagesCapitulo Farinhaoliveira.patricia008No ratings yet

- Reactor Exercises - 2013 PDFDocument19 pagesReactor Exercises - 2013 PDFtehbear0% (1)

- ppmp44 257-272Document16 pagesppmp44 257-272Chemical Ferdi IzzecsonNo ratings yet

- Dehydration of 2 3-Butanediol To Mek.2Document9 pagesDehydration of 2 3-Butanediol To Mek.2hidayahNo ratings yet

- Cat. Reforming - Part 2Document68 pagesCat. Reforming - Part 2LoneHighland100% (4)

- 9ICAAR SorrentinoD 1Document8 pages9ICAAR SorrentinoD 1apiece1983No ratings yet

- US2019618 Sodium Aluminate FirebrickDocument6 pagesUS2019618 Sodium Aluminate FirebrickonixexenNo ratings yet

- Day 2Document2 pagesDay 2Kuo Garol SarongNo ratings yet

- Actual Process Report For Purification of ChlorosilanesDocument10 pagesActual Process Report For Purification of Chlorosilanesdileepkumarsaidu1985No ratings yet

- Colorimetric Determination of Common Industrial FrothersDocument4 pagesColorimetric Determination of Common Industrial FrothersJaime Omar Godinez RevelesNo ratings yet

- Improvement of Product Quality in Circulating Fluidized Bed CalcinationDocument6 pagesImprovement of Product Quality in Circulating Fluidized Bed CalcinationmorongobillNo ratings yet

- 1978 - Rouillard - The Crystallization of HighDocument7 pages1978 - Rouillard - The Crystallization of Higheal3019No ratings yet

- D7206D7206M-06 (2013) E1 Standard Guide For Cyclic DeactivationDocument5 pagesD7206D7206M-06 (2013) E1 Standard Guide For Cyclic Deactivationastewayb_964354182No ratings yet

- The Roles of Fine Silica and Reactive Alumina and Their Interactions With Calcium Aluminates in Refractory CastablesDocument9 pagesThe Roles of Fine Silica and Reactive Alumina and Their Interactions With Calcium Aluminates in Refractory CastablesDick ManNo ratings yet

- Pozzolanic Properties of Flash-Calcined Kaolinite A Comparative Study With Soak-Calcined ProductsDocument11 pagesPozzolanic Properties of Flash-Calcined Kaolinite A Comparative Study With Soak-Calcined ProductsDIAZCORDOBANo ratings yet

- Coker HT - 1000153Document7 pagesCoker HT - 1000153Garry DavidNo ratings yet

- Pervaporation 1Document5 pagesPervaporation 1Yadav VirendraNo ratings yet

- United States Patent Office: Patented Apr. 7, 1953Document3 pagesUnited States Patent Office: Patented Apr. 7, 1953Syahrul SandreaNo ratings yet

- Nanoporous Catalysts for Biomass ConversionFrom EverandNanoporous Catalysts for Biomass ConversionFeng-Shou XiaoNo ratings yet

- Mineral Water Calculator v5Document7 pagesMineral Water Calculator v5mauricio0327No ratings yet

- LAB #3 Trends in Group IIDocument3 pagesLAB #3 Trends in Group IIAmelia LlewellynNo ratings yet

- Calculating Reacting MassesDocument16 pagesCalculating Reacting MassesMarcus WrightNo ratings yet

- Astm - D3230.39961-2019Document7 pagesAstm - D3230.39961-2019CarlosJayaNo ratings yet

- Basic Principle of Extraction of IronDocument35 pagesBasic Principle of Extraction of IronHimanshuNo ratings yet

- Engineeing Solutions: Rev 01 - Nov 2014Document22 pagesEngineeing Solutions: Rev 01 - Nov 2014aliNo ratings yet

- Acceleration of CO2 Mineralisation of Alkaline Brines With Nickel Nanoparticles Catalysts in Continuous Tubular ReactorDocument11 pagesAcceleration of CO2 Mineralisation of Alkaline Brines With Nickel Nanoparticles Catalysts in Continuous Tubular ReactorASinopoliNo ratings yet

- ASTM E534-08.33273 Chemical Analysis of Sodium ChlorideDocument7 pagesASTM E534-08.33273 Chemical Analysis of Sodium ChlorideMario Rodrigo Ramirez MesaNo ratings yet

- SEAFDEC Practicum ReportDocument23 pagesSEAFDEC Practicum ReportSam BrilloNo ratings yet

- General Chemistry 10th Edition by Ebbing Gammon ISBN Test BankDocument63 pagesGeneral Chemistry 10th Edition by Ebbing Gammon ISBN Test Bankmichael97% (36)

- Writing and Balancing Chemical EquationsDocument31 pagesWriting and Balancing Chemical EquationsEthan-Dale BrownNo ratings yet

- University of Cambridge International Examinations General Certificate of Education Ordinary LevelDocument20 pagesUniversity of Cambridge International Examinations General Certificate of Education Ordinary LevelChido NcubeNo ratings yet

- 2025 Specimen Paper 1Document16 pages2025 Specimen Paper 1suganpradesNo ratings yet

- TRITON Retail Pack 24-04-19Document19 pagesTRITON Retail Pack 24-04-19Utkarsh PokhriyalNo ratings yet

- W4 G Butler Electrolysis Worksheet Solutions 2kuxr8jDocument4 pagesW4 G Butler Electrolysis Worksheet Solutions 2kuxr8jhelenaNo ratings yet

- S Block PDFDocument22 pagesS Block PDFRoshita G PillaiNo ratings yet

- Boiler Troubles Lecture 6 (Water) PDFDocument11 pagesBoiler Troubles Lecture 6 (Water) PDFSlok GinodiaNo ratings yet

- ASTM D3230-13 (Reaprobada 2018) Salinidad en CrudoDocument7 pagesASTM D3230-13 (Reaprobada 2018) Salinidad en CrudoAngel MurilloNo ratings yet

- Factors Affecting Formation of Chemical By-Products During Ballast Water Treatment Based On An Advanced Oxidation ProcessDocument7 pagesFactors Affecting Formation of Chemical By-Products During Ballast Water Treatment Based On An Advanced Oxidation ProcessNgurah BuanaNo ratings yet

- Chemical Equations & ReactionsDocument76 pagesChemical Equations & ReactionsTalitha AslamiyahNo ratings yet

- c3 Quantitative ChemistryDocument105 pagesc3 Quantitative Chemistryraja balaNo ratings yet

- Chemistry Project MGDocument4 pagesChemistry Project MGPirvu ValentinaNo ratings yet

- Physical Sciences P2 QP Sept 2020 EngDocument17 pagesPhysical Sciences P2 QP Sept 2020 EngOnalenna LegodiNo ratings yet

- MT 18 Standard Waters: Miscellaneous Techniques and ImpuritiesDocument16 pagesMT 18 Standard Waters: Miscellaneous Techniques and ImpuritiesFelipe NavarreteNo ratings yet

- 17BEM0049DA1Document12 pages17BEM0049DA1Vedant KarnatakNo ratings yet

- Nigari (Deep Seawater Concentrate) Enhances The Treadmill Exercise Performance of GerbilsDocument4 pagesNigari (Deep Seawater Concentrate) Enhances The Treadmill Exercise Performance of GerbilsSukmaNo ratings yet

- Astm e 449 Cloruro de CalcioDocument5 pagesAstm e 449 Cloruro de Calcioandrea sanchezNo ratings yet

The Prosecc LTD

The Prosecc LTD

Uploaded by

UV patelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Prosecc LTD

The Prosecc LTD

Uploaded by

UV patelCopyright:

Available Formats

2,892,683

United States Patent Office 1.

Patented June 30, 1959

2

The amount of the polymer to be added depends upon

2,892,683 the specific activity of the polymer itself and upon the

PROCESS OF PRECIPITATING AND FILTERING time required for the reaction between the magnesium

MAGNESUM HYDROXDE salt and the precipitating reactant. Generally, if it is

Giacinto Veronica, Milan, Italy, assignor to Montecatini desired to filter and wash the precipitate completely free

Societa Generale per Industria Mineraria e Chimica, of calcium within a reasonably short time, amounts cor

a corporation of Italy responding to from 0.2 to 1% of the resulting dry

Mg(OH) are needed. If only a shortening of the

No Drawing. Application July 1, 1954 settling time is desired, it suffices to add amounts from

Seria No. 440,849 0 0.2 to a maximum of 0.5% based on dry Mg(OH)2.

Claims priority, application Italy July 8, 1953 In the following examples, a comparison is made be

tween the rates of filtration and decantation of Mg(OH)2

7 Claims. (C. 23-201) precipitates obtained either in the presence or in the

absence of polyelectrolytes after various reaction times

The present invention relates to a new process of 5 between the magnesium salt and the precipitating agent.

precipitating and filtering magnesium hydroxide, resulting Example I

in an increased operation speed and in a product of

greater purity. While stirring vigorously, 50 ml. of a 280 gram per

Ordinarily, the filtration and washing of Mg(OH)2 liter (g./I.) MgCl2 solution are rapidly added, at room

precipitates is difficult because of the particular jellylike 20 temperature, to 24.5 g. of a 40% Ca(OH)2 suspension,

structure of these precipitates. A review of the pertinent passed through a 270 mesh screen. The molar ratio

literature shows that numerous processes have been Sug MgCl2: CaO is 1:0.9.

gested in order to overcome these difficulties; for in After stirring for 3 minutes, the precipitate is filtered

stance, the addition to the precipitant (generally in form 25

under vacuum upon a Buchner filter (9 cm. diameter)

of a lime slurry) of alkaline-earth nitrates, alkaline and the filter cake is washed with 150 ml. of cold dis

chlorates or calcium chloride; employment of various tilled water divided in three portions of 50 ml. each.

flocculating agents, almost all derived from plant sources; The filtration periods are:

or the use of precipitation reactants in the form of grains Seconds

of definite particle size. Solution ------------------------------------ 40

While the overall operation time may be reduced by 30 Ist Washing ---------------------------------- 75

these expedients, substantial periods of time are still re 2nd Washing --------------------------------- 120

quired for the filtration which, in addition, generally 3rd Washing -------------------------------- 250

requires the application of heat. According to recent Example 2

findings, the precipitation reaction occurs in two steps

according to the following scheme: 35 0.05 g. of polyacrylate obtained by saponification of

polyacrylonitrile is added to the reactants of Example 1.

Seconds

Solution ------------------------------------- 25

By employing a molar ratio MgCl2: CaO equal to 40

1st Washing ---------------------------------- 40

1:0.75 and by restricting the time of the reaction between 2nd Washing --------------------------------- 60

lime and magnesium chloride to a period from 3 to 5 3rd Washing ---------------------------------- 75

minutes, the product obtained consists chiefly of the un In both examples the process is too rapid to allow

stable oxychloride which, owing to its granular structure, the reaction to go to completion. In fact, in both in

may be readily filtered. 45 stances the dry filter cakes still contain 3.1% Ca.

The reaction goes to completion on the filter within Instead of increasing the number of washings, it is more

about half an hour and the resulting CaCl2 can be re convenient to wait for the completion of the reaction

Imoved by continuous washing with water. However, as by employing longer contact times. Moreover, dilution

the magnesium salt slowly goes into Mg(OH)2 the filtra of the produced CaCl2 in a large volume of washing

tion difficulties peculiar of this product increase. The 50 liquid is thereby avoided. This offers the possibility of

washing operation becomes progressively slower and the recovering the CaCl2 in form of a solution having a

complete removal of the Ca ion from the filter cake be concentration substantially identical with that of the

comes practically impossible within a reasonable time. magnesium salt solution at the start.

The average composition of the product obtained ac Example 3

cording to this process is as follows: 55

(Moist): HO-76.8%; Cl-0.9%; Ca-0.1%; Mg The reactants used in Example 1, in the same molar

(OH)-21.6% ratio, are kept in contact for 21 minutes while rapidly

(Dry): Cl-3.9%; Ca-0.4%; Mg(OH)2-93% stirring. The precipitate is washed with 20 mi. of warm

It is an object of the invention to greatly increase the H2O and then with 30 ml. of cold H2O. In this case the

60 filtration rates are:

filtration rate of the above-mentioned Mg(OH)2 precipi Seconds

tates.

Solution ----------------------------------- 330

To this end, and in accordance with a feature of the 1st Washing -------------------------------- 680

invention the precipitation from a soluble Mig salt, 2nd Washing -------------------------------- 1200

effected with the aid of an alkaline solution or suspen 65

sion, is carried out in the presence of an appropriate The washed product contains 70% moisture. The

amount of a synthetic polyelectrolyte. More specifically, analysis of the dried product indicates 3% Ca and

the polyelectrolyte is a synthetic organic polymer which, 2% C.

when dissolved in a solvent of a high dielectric constant, Example 4

produces polyvalent ions of positive or negative char 70 To the reactants of Example 3, used at the same molar

acter. Such a polyelectrolyte may have a molecular ratio and permitted to react for the same period of time,

weight from 5,000 to 300,000. 0.1 g of the polyacrylate of Example 2 are added,

2,892,688 t

3 4.

Washing with the same amounts of water, the filtra magnesium hydroxide from a magnesium salt Solution

tion rates are: with an alkaline-earth base at a molar ratio of about

Seconds 45 to 60 in the presence of a water-soluble Saponification

Solution ------------------------------------ 30 product of a maleic anhydride-vinyl acetate copolymer.

1st Washing --------------------------------- 20 3. A process for accelerating the precipitation of mag

2nd washing -------------------------------- 600 nesium hydroxide and for obtaining a readily filterable

The filter cake has a 52% moisture content and, after product of high purity, which comprises precipitating

drying, contains: C-3%; Ca-unmeasurable traces. magnesium hydroxide from a magnesium Salt Solution

If magnesium hydroxide is precipitated from very with an alkaline-earth base at a molar ratio of about

diluted solutions such as when for instance sea-water is 0. 45 to 60 in the presence of a polyacrylate obtained

employed, the suspension is advantageously first decanted, through the saponification of polyacrylonitrile.

whereupon the thickened portion is filtered. In the fol 4. A process for accelerating the precipitation of mag

lowing example, a comparison is made between settling nesium hydroxide and for obtaining a readily filterable

and filtration rate of Mg(OH)2 obtained from sea-water product of high purity, which comprises precipitating mag

and lime, with and without the addition of polyelec 5 nesium hydroxide from a magnesium salt solution with an

trolytes. alkaline-earth base at a molar ratio of about 45 to 60

Example 5 in the presence of a polyacrylate obtained through the

saponification of polyacrylonitrile and continuing the

500 ml. of sea-water (containing 4.1 g/l. of MgCl2) reaction between magnesium salt and alkaline-earth base.

are reacted, after the elimination of the bicarbonates, 20 until the magnesium salt is substantially fully converted

for 15 minutes with 10 ml. of a lime suspension (7.4 to Mg(OH)2 before filtering and washing.

g/l. Ca) while rapidly stirring. 5. A process for accelerating the precipitation of mag

The suspension obtained in this matter is poured in nesium hydroxide and for obtaining a readily filterable

a cylinder of 60 mm. diameter, and the settling rate is product of high purity, which comprises precipitating

observed. The same experiment is repeated after adding 25 magnesium hydroxide from a magnesium salt solution

the polyacrylate of Example 2 and the saponification with an alkaline-earth base at a molar ratio of about 5

product of a maleic anhydride-vinyl acetate copolymer, to 60 in the presence of a water soluble saponification

in amounts of 0.2 and 0.5%, for the first respectively product of a maleic anhydride-vinyl acetate copolymer

0.4% for the second calculated on the theoretical amount. and continuing the reaction between magnesium salt

of Mg(OH)2. 30 and alkaline-earth base until the magnesium salt is sub

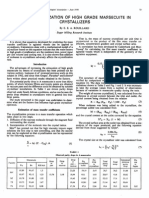

The following table demostrates the time within which stantially fully converted to Mg(OH)2 before filtering

100 mm. of clear liquid are obtained. and washing.

6. The process of claim 3 in which the magnesium

Polyelectrolyte

100 Inn, of

clear liquid

salt is magnesium chloride and the alkaline-earth base is

obtained

35 calcium hydroxide.

after 7. The process of claim 4 in which the magnesium salt

is magnesium chloride and the alkaline-earth base is

None.----------------------------- 140 minutes. calcium hydroxide.

Polyacrylate, 0.2%----------------- ---- 106 minutes.

Polyacrylate, 0.5%----------------- ---- 48 minutes. 40 References Cited in the file of this patent

Saponification product of maleic anhydride-vinyl 97 minutes.

acetate copolymer, 0.4%. UNITED STATES PATENTS

I claim: 2,255,422 Heath et al. ------------ Sept. 9, 1941

1. A process for accelerating the precipitation of mag 2,625,529 Heddricket al. ---------- Jan. 13, 1953.

nesium hydroxide and for obtaining a readily filterable 45 2,652,380 Heddricket al. ---------- Sept. 15, 1953.

product of high purity, which comprises precipitating FOREIGN PATENTS

magnesium hydroxide from a magnesium salt solution 547,526 Great Britain ------------ Sept. 1, 1942

with an alkaline-earth base at a molar ratio of about As 558,882 Great Britain ----------- Jan. 26, 1944

to 40 in the presence of a water-soluble, macromolecular 154,799 Australia -------------- Jan. 19, 1954

synthetic polyelectrolyte taken from the group consisting 50

OTHER REFERENCES

of a polyacrylic polyelectrolyte obtained from the saponi

fication of polyacrylonitrile and a water-soluble saponi Gardner et al.: “Factors Influencing the Flocculating

fication product of a maleic anhydride-vinyl acetate Capacity of Polyacrylates' (summary of thesis), Mass.

copolymer. 55

Inst. of Technology (1953).

2. A process for accelerating the precipitation of mag Michaels et al.: "Soil Flocculants and Stabilizers,'

nesium hydroxide and for obtaining a readily filterable Agricultural and Food Chemistry, vol. 1, No. 13, Sept.

product of high purity, which comprises precipitating 16, 1953, pages 835 to 843,

You might also like

- ASTM-D3230-19 Salinidad en CrudoDocument7 pagesASTM-D3230-19 Salinidad en CrudoAngel MurilloNo ratings yet

- Astm D 3230 - 08 PDFDocument6 pagesAstm D 3230 - 08 PDFJulian Felipe Noguera Cruz100% (2)

- Microsoft Word - Iit Assignments - KRR - PDFDocument60 pagesMicrosoft Word - Iit Assignments - KRR - PDFggk201350% (2)

- ZLD Evaparation Crystallization Plant in The Hydrometallurgical IndustryDocument6 pagesZLD Evaparation Crystallization Plant in The Hydrometallurgical Industrykosmc123No ratings yet

- A New Approach For Particle Size ReductionDocument7 pagesA New Approach For Particle Size Reductioncsyena28225No ratings yet

- HomeworkDocument3 pagesHomeworkJudluzNo ratings yet

- Recovery of Molybdenum From Spent Acid by Ammonia Gas NeutralizationDocument6 pagesRecovery of Molybdenum From Spent Acid by Ammonia Gas NeutralizationМладен БугарчићNo ratings yet

- Technical Paper PresentationDocument27 pagesTechnical Paper PresentationBhagyashree BachhavNo ratings yet

- Acid Soluble Magnesia Cement: New Applications in Completion and Workover OperationsDocument7 pagesAcid Soluble Magnesia Cement: New Applications in Completion and Workover OperationsCoolProphetNo ratings yet

- Preparation of Silica Gel From Rice Husk Ash Using Microwave HeatingDocument6 pagesPreparation of Silica Gel From Rice Husk Ash Using Microwave HeatingArauAnaNo ratings yet

- In Situ Hypochlorous Acid Generation For The Treatment of Distillery SpentwashDocument4 pagesIn Situ Hypochlorous Acid Generation For The Treatment of Distillery SpentwashGregorio ValeroNo ratings yet

- Problem Set - Particle Fluid Separation2012Document3 pagesProblem Set - Particle Fluid Separation2012John Kevin San Jose50% (2)

- Micro-Structured Reactor To Generate Hydrogen From MethylcyclohexaneDocument4 pagesMicro-Structured Reactor To Generate Hydrogen From MethylcyclohexaneMujahid Al HinaiNo ratings yet

- Preparation of Silica Gel From Rice Husk Ash UsingDocument7 pagesPreparation of Silica Gel From Rice Husk Ash UsingCaro DominguezNo ratings yet

- Admixtures 2Document18 pagesAdmixtures 2stephanyNo ratings yet

- Fluorite - Saving EnergyDocument9 pagesFluorite - Saving EnergyrecaiNo ratings yet

- Exergy Analysis of A 10,000 M /day Tajoura SWRO Desalination PlantDocument7 pagesExergy Analysis of A 10,000 M /day Tajoura SWRO Desalination Plantchengawy7No ratings yet

- Catalytic Reforming Improved by Moisture MeteringDocument4 pagesCatalytic Reforming Improved by Moisture MeteringIrfan QadirNo ratings yet

- Precipitation of Magnesium Hydroxide From Brine PDFDocument7 pagesPrecipitation of Magnesium Hydroxide From Brine PDFHandoko AhmadNo ratings yet

- Flocculation of Kaolinite Suspensions in Water by Coconut Cream CaseinDocument7 pagesFlocculation of Kaolinite Suspensions in Water by Coconut Cream CaseinNadia MandasariNo ratings yet

- Power Plant Water ManagementDocument8 pagesPower Plant Water ManagementSarah FrazierNo ratings yet

- US3983180Document7 pagesUS3983180Agustina TriyaniNo ratings yet

- s11814 017 0002 8Document10 pagess11814 017 0002 8Augusto Antonio MenzelNo ratings yet

- 1) Introduction To VCM Process: 1.1vinyl Chloride From AcetyleneDocument12 pages1) Introduction To VCM Process: 1.1vinyl Chloride From AcetyleneSaleamlak ZerihunNo ratings yet

- United States Patent Office: Patented Oct. 7, 1958Document4 pagesUnited States Patent Office: Patented Oct. 7, 1958udinPet0tNo ratings yet

- Morales 2015Document11 pagesMorales 2015Beatriz Emanuella de Andrade BressanNo ratings yet

- Cobalt precipitation with MgODocument32 pagesCobalt precipitation with MgOjoseph kafumbilaNo ratings yet

- US2687435Document2 pagesUS2687435Ipalma 3No ratings yet

- Peroxido de Hidrogeno-ChitinDocument12 pagesPeroxido de Hidrogeno-ChitinRodrigo EspinozaNo ratings yet

- Pelagia Research Library: Precipitation of Nano-Magnesium Hydroxide From Bittern Using Ultrasound IrradiationDocument13 pagesPelagia Research Library: Precipitation of Nano-Magnesium Hydroxide From Bittern Using Ultrasound IrradiationChemical Ferdi IzzecsonNo ratings yet

- Manufacture of Sulfuric Acid: S.R.M. Engineering CollegeDocument76 pagesManufacture of Sulfuric Acid: S.R.M. Engineering CollegeCharles RiosNo ratings yet

- Process For Recovering Lithium From Brine by Salting Out Lithium Sulfate MonohydrateDocument8 pagesProcess For Recovering Lithium From Brine by Salting Out Lithium Sulfate MonohydrateGabriel ChurioNo ratings yet

- 43 Optimization Lime KilnDocument10 pages43 Optimization Lime KilnAris parkerNo ratings yet

- Maillard Reaction in Molasses Storage Tank PDFDocument4 pagesMaillard Reaction in Molasses Storage Tank PDFArthur Yanez100% (2)

- Heat Evolution in Alkali Activated Synthetic Slag-Metakaolin MixturesDocument5 pagesHeat Evolution in Alkali Activated Synthetic Slag-Metakaolin MixturesSereenen OtgonjargalNo ratings yet

- Hydrogenation of Maltose in Catalytic Membrane ReaDocument4 pagesHydrogenation of Maltose in Catalytic Membrane Reakhaled kaidNo ratings yet

- Thermodynamic Analysis and Optimization of Adsorption-Based Atmospheric Water HarvestingDocument10 pagesThermodynamic Analysis and Optimization of Adsorption-Based Atmospheric Water Harvestingmm tNo ratings yet

- PROBLEM SET March 4.2021Document4 pagesPROBLEM SET March 4.2021Thalia RodriguezNo ratings yet

- Us 5282882Document5 pagesUs 5282882DhrupadSoniRaviNo ratings yet

- Regeneration of The Waste Selective Catalytic Reduction Denitrification Catalyst by Nitric Acid WashingDocument9 pagesRegeneration of The Waste Selective Catalytic Reduction Denitrification Catalyst by Nitric Acid WashingJoyce WongNo ratings yet

- Problem As Cat Al Is Is 2018Document10 pagesProblem As Cat Al Is Is 2018Victor Daniel Martínez CarreteroNo ratings yet

- Test Prep Rep Sanitary SolutionsDocument31 pagesTest Prep Rep Sanitary SolutionsVincent SantamariaNo ratings yet

- Name Matric Id Group Course Code ExperimentDocument7 pagesName Matric Id Group Course Code ExperimentadillaaazmiNo ratings yet

- Us 4370422Document5 pagesUs 4370422praptining pangertiNo ratings yet

- Capitulo FarinhaDocument128 pagesCapitulo Farinhaoliveira.patricia008No ratings yet

- Reactor Exercises - 2013 PDFDocument19 pagesReactor Exercises - 2013 PDFtehbear0% (1)

- ppmp44 257-272Document16 pagesppmp44 257-272Chemical Ferdi IzzecsonNo ratings yet

- Dehydration of 2 3-Butanediol To Mek.2Document9 pagesDehydration of 2 3-Butanediol To Mek.2hidayahNo ratings yet

- Cat. Reforming - Part 2Document68 pagesCat. Reforming - Part 2LoneHighland100% (4)

- 9ICAAR SorrentinoD 1Document8 pages9ICAAR SorrentinoD 1apiece1983No ratings yet

- US2019618 Sodium Aluminate FirebrickDocument6 pagesUS2019618 Sodium Aluminate FirebrickonixexenNo ratings yet

- Day 2Document2 pagesDay 2Kuo Garol SarongNo ratings yet

- Actual Process Report For Purification of ChlorosilanesDocument10 pagesActual Process Report For Purification of Chlorosilanesdileepkumarsaidu1985No ratings yet

- Colorimetric Determination of Common Industrial FrothersDocument4 pagesColorimetric Determination of Common Industrial FrothersJaime Omar Godinez RevelesNo ratings yet

- Improvement of Product Quality in Circulating Fluidized Bed CalcinationDocument6 pagesImprovement of Product Quality in Circulating Fluidized Bed CalcinationmorongobillNo ratings yet

- 1978 - Rouillard - The Crystallization of HighDocument7 pages1978 - Rouillard - The Crystallization of Higheal3019No ratings yet

- D7206D7206M-06 (2013) E1 Standard Guide For Cyclic DeactivationDocument5 pagesD7206D7206M-06 (2013) E1 Standard Guide For Cyclic Deactivationastewayb_964354182No ratings yet

- The Roles of Fine Silica and Reactive Alumina and Their Interactions With Calcium Aluminates in Refractory CastablesDocument9 pagesThe Roles of Fine Silica and Reactive Alumina and Their Interactions With Calcium Aluminates in Refractory CastablesDick ManNo ratings yet

- Pozzolanic Properties of Flash-Calcined Kaolinite A Comparative Study With Soak-Calcined ProductsDocument11 pagesPozzolanic Properties of Flash-Calcined Kaolinite A Comparative Study With Soak-Calcined ProductsDIAZCORDOBANo ratings yet

- Coker HT - 1000153Document7 pagesCoker HT - 1000153Garry DavidNo ratings yet

- Pervaporation 1Document5 pagesPervaporation 1Yadav VirendraNo ratings yet

- United States Patent Office: Patented Apr. 7, 1953Document3 pagesUnited States Patent Office: Patented Apr. 7, 1953Syahrul SandreaNo ratings yet

- Nanoporous Catalysts for Biomass ConversionFrom EverandNanoporous Catalysts for Biomass ConversionFeng-Shou XiaoNo ratings yet

- Mineral Water Calculator v5Document7 pagesMineral Water Calculator v5mauricio0327No ratings yet

- LAB #3 Trends in Group IIDocument3 pagesLAB #3 Trends in Group IIAmelia LlewellynNo ratings yet

- Calculating Reacting MassesDocument16 pagesCalculating Reacting MassesMarcus WrightNo ratings yet

- Astm - D3230.39961-2019Document7 pagesAstm - D3230.39961-2019CarlosJayaNo ratings yet

- Basic Principle of Extraction of IronDocument35 pagesBasic Principle of Extraction of IronHimanshuNo ratings yet

- Engineeing Solutions: Rev 01 - Nov 2014Document22 pagesEngineeing Solutions: Rev 01 - Nov 2014aliNo ratings yet

- Acceleration of CO2 Mineralisation of Alkaline Brines With Nickel Nanoparticles Catalysts in Continuous Tubular ReactorDocument11 pagesAcceleration of CO2 Mineralisation of Alkaline Brines With Nickel Nanoparticles Catalysts in Continuous Tubular ReactorASinopoliNo ratings yet

- ASTM E534-08.33273 Chemical Analysis of Sodium ChlorideDocument7 pagesASTM E534-08.33273 Chemical Analysis of Sodium ChlorideMario Rodrigo Ramirez MesaNo ratings yet

- SEAFDEC Practicum ReportDocument23 pagesSEAFDEC Practicum ReportSam BrilloNo ratings yet

- General Chemistry 10th Edition by Ebbing Gammon ISBN Test BankDocument63 pagesGeneral Chemistry 10th Edition by Ebbing Gammon ISBN Test Bankmichael97% (36)

- Writing and Balancing Chemical EquationsDocument31 pagesWriting and Balancing Chemical EquationsEthan-Dale BrownNo ratings yet

- University of Cambridge International Examinations General Certificate of Education Ordinary LevelDocument20 pagesUniversity of Cambridge International Examinations General Certificate of Education Ordinary LevelChido NcubeNo ratings yet

- 2025 Specimen Paper 1Document16 pages2025 Specimen Paper 1suganpradesNo ratings yet

- TRITON Retail Pack 24-04-19Document19 pagesTRITON Retail Pack 24-04-19Utkarsh PokhriyalNo ratings yet

- W4 G Butler Electrolysis Worksheet Solutions 2kuxr8jDocument4 pagesW4 G Butler Electrolysis Worksheet Solutions 2kuxr8jhelenaNo ratings yet

- S Block PDFDocument22 pagesS Block PDFRoshita G PillaiNo ratings yet

- Boiler Troubles Lecture 6 (Water) PDFDocument11 pagesBoiler Troubles Lecture 6 (Water) PDFSlok GinodiaNo ratings yet

- ASTM D3230-13 (Reaprobada 2018) Salinidad en CrudoDocument7 pagesASTM D3230-13 (Reaprobada 2018) Salinidad en CrudoAngel MurilloNo ratings yet

- Factors Affecting Formation of Chemical By-Products During Ballast Water Treatment Based On An Advanced Oxidation ProcessDocument7 pagesFactors Affecting Formation of Chemical By-Products During Ballast Water Treatment Based On An Advanced Oxidation ProcessNgurah BuanaNo ratings yet

- Chemical Equations & ReactionsDocument76 pagesChemical Equations & ReactionsTalitha AslamiyahNo ratings yet

- c3 Quantitative ChemistryDocument105 pagesc3 Quantitative Chemistryraja balaNo ratings yet

- Chemistry Project MGDocument4 pagesChemistry Project MGPirvu ValentinaNo ratings yet

- Physical Sciences P2 QP Sept 2020 EngDocument17 pagesPhysical Sciences P2 QP Sept 2020 EngOnalenna LegodiNo ratings yet

- MT 18 Standard Waters: Miscellaneous Techniques and ImpuritiesDocument16 pagesMT 18 Standard Waters: Miscellaneous Techniques and ImpuritiesFelipe NavarreteNo ratings yet

- 17BEM0049DA1Document12 pages17BEM0049DA1Vedant KarnatakNo ratings yet

- Nigari (Deep Seawater Concentrate) Enhances The Treadmill Exercise Performance of GerbilsDocument4 pagesNigari (Deep Seawater Concentrate) Enhances The Treadmill Exercise Performance of GerbilsSukmaNo ratings yet

- Astm e 449 Cloruro de CalcioDocument5 pagesAstm e 449 Cloruro de Calcioandrea sanchezNo ratings yet