Professional Documents

Culture Documents

3 Bill of Material

3 Bill of Material

Uploaded by

Dirar AribkusumaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 Bill of Material

3 Bill of Material

Uploaded by

Dirar AribkusumaCopyright:

Available Formats

3

Module

BILL OF MATERIAL (BOM)

I. Objectives

The objectives of the practicum are:

1. To make an Assembly Chart (AC)

2. To make a product structure

3. Explain step by step of Bill of Material (BOM) making process.

II. Literature Review

A. Assembly Chart

An assembly chart, which is sometimes called a gozinto chart, maps

how a product’s parts go together and the order in which they are

assembled. Detailed instructions for all major parts of the product and all

assembly and subassembly operations and inspections are included on the

chart (Venkataraman & Pinto, 2017).

6 mm

8 mm

9 mm

Komponen 1 10 mm

A

SSSA

-1 12 mm

Komponen 2

B

SSA-

1

Komponen 3

C

SA-1

Komponen 4

D

A-1

Komponen 5

E

Komponen 6

F

SSSA

Komponen 7 -2

G SSA-

SSA-

22

Komponen 8

H SA-2 A-2

Komponen 9

I

Komponen 10

J

Komponen 11

SA-3 A-3

K

Source: (Apple, 1977)

Figure 3.1 Assembly Chart Example

Drawing rules:

a. Diameter of the components is 6 mm,

b. Diameter of the sub-assembly is 7 to 11 mm, and

c. Diameter of the assembly is 12 mm.

Industrial Engineering Laboratory

BINUS University 43 Revision:

Practicum module

ISYE6101011 – Production & operation analysis

B. The Product Structure and Bill of Materials (BOM)

A Bill of Materials (BOM) contains a listing of all of the assemblies,

subassemblies, parts, and raw materials that are needed to produce one unit

of a finished product (Stevenson & Chuong, 2014). Heizer and Reinder

(2013) stated that one way a bill of material defines a product is by

providing a product structure. A product structure tree is useful in

illustrating how the bill of materials is used to determine the quantities of

each of the ingredients (requirements) needed to obtain a desired number

of end items (Stevenson & Chuong, 2014). Specifically, the Bill of

Materials structure contains not only the composition of the components,

but also the completion of the finished product. Bill of material function is

as a network or network that describes the relationship of parent (parent

product) to the component. Here is the use of Bill of Materials (Arif, 2016):

1. Needed as input in planning and control of production activity.

2. Without Bill of Materials it is impossible to implement MRP.

III. Tables

PRODUCT STRUCTURE

OBJECT NAME :

MAPPED BY : Now

MAPPED DATE : Proposed

THE WAY OF MAPPING :

Level

FINISHED

0

PRODUCT

W M

W M

A2 C4 1

W M W M

A1 C3 2

W M W M

C1 C2 3

Figure 3.2 Example of The Product Structures

Where:

W = Numbering

M = Required number

Table 3.1 Example of Bill of Material

Component

Level Description Code Quantity Units

No.

1 .1.. Assembly 2 A2 1 piece

2 ..2. Assembly 1 A1 1 piece

Industrial Engineering Laboratory

BINUS University 44 Revision:

Practicum module

ISYE6101011 – Production & operation analysis

IV. Procedures

The following is a picture of the components of a train toy, the picture

will be used to make assemble charts and product structures with the Bill of

Material table. Following are the steps to make an assembly chart, product

structure, and Bill of Material (BOM)

Figure 3.3 Toy Train View Drawing

Figure 3.4 Toy Train Exploded View

Industrial Engineering Laboratory

BINUS University 45 Revision:

Practicum module

ISYE6101011 – Production & operation analysis

Assembly Chart

1. The following is information about the code and number of components and

list of an assembly of a toy train. Use this information to make assembly

charts, product structure, and bill of materials.

Table 3.2 Component’s Code and Quantity

Index Code Components Quantity (unit)

1 TB Train Body 1

2 S Stack 1

3 W Wheel 4

4 LA Linkage Arm 2

5 WP Wheel Peg 4

6 CC Cow Catcher 1

7 LP Linkage Peg 4

8 HP Hitch Peg 1

9 HM Hitch Magnet 1

Tabel 3.3 List of Assembly

Name Assembly

A5 S + A4

A4 CC + A3

A3 SA2 + A2

A2 WP + A1

A1 TB + SA1

SA2 HM + HP

SA1 LP + SSA1

SSA1 LA + W

2. The first step in making a train toy assembly chart is to write sequentially

from the first component assembled into the last component assembled. Code

and component names are written in circles with a diameter of 6 mm.

Wheel

W

Linkage Arm

LA

Linkage Peg

LP

Train Body

TB

Wheel Peg

WP

Hitch Peg

HP

Hitch Magnet

HM

Cow Catcher

CC

Stack

S

Industrial Engineering Laboratory

BINUS University 46 Revision:

Practicum module

ISYE6101011 – Production & operation analysis

3. The first component assembled on the train toy is the Wheel (W) and Linkage

Arm (LA) components, the two components are connected by a line to a circle

with a diameter of 9 forming Sub-Sub-Assembly 1 (SSA-1).

Wheel

W

SSA

-1

Linkage Arm

LA

Linkage Peg

LP

Train Body

TB

Wheel Peg

WP

Hitch Peg

HP

Hitch Magnet

HM

Cow Catcher

CC

Stack

S

4. Next, the components Sub-sub-Assembly 1 (SSA-1) are assembled with the

Linkage Peg (LP) component. Both components are connected by a line to a

circle with a diameter of 10 mm and form Sub-Assembly 1 (SA-1).

Wheel

W

SSA

-1

Linkage Arm

LA

SA-1

Linkage Peg

LP

Train Body

TB

Wheel Peg

WP

Hitch Peg

HP

Hitch Magnet

HM

Cow Catcher

CC

Stack

S

Industrial Engineering Laboratory

BINUS University 47 Revision:

Practicum module

ISYE6101011 – Production & operation analysis

5. After that, the components Sub-Assembly1 (SA-1) are assembled with the

Train Body (TB) component. Both components are connected by a line to a

circle with diameter of 12 mm and form Assembly 1 (A-1).

Wheel

W

SSA

-1

Linkage Arm

LA

SA-1

Linkage Peg

LP

A-1

Train Body

TB

Wheel Peg

WP

Hitch Peg

HP

Hitch Magnet

HM

Cow Catcher

CC

Stack

S

6. The next stage is the components Assembly1 (A-1) are assembled with the

Wheel Peg (WP) component. Both components are connected by a line to a

circle with diameter of 12 mm and form Assembly 2 (A-2).

Wheel

W

SSA

-1

Linkage Arm

LA

SA-1

Linkage Peg

LP

A-1

Train Body

TB

Wheel Peg

WP A-2

Hitch Peg

HP

Hitch Magnet

HM

Cow Catcher

CC

Stack

S

Industrial Engineering Laboratory

BINUS University 48 Revision:

Practicum module

ISYE6101011 – Production & operation analysis

7. After that, the Hitch Peg (HP) and Hitch Magnet (HM) components are

assembled. Both components are connected by a line to a circle with diameter

of 10 mm and form Sub-Assembly 2.

Wheel

W

SSA

-1

Linkage Arm

LA

SA-1

Linkage Peg

LP

A-1

Train Body

TB

Wheel Peg

WP A-2

Hitch Peg

HP

SA-2

Hitch Magnet

HM

Cow Catcher

CC

Stack

S

8. The next step in assembling train toys is assembling Sub-Assembly 2 (SA-2)

components with Cow Catcher component, both components are connected

by a line to a circle with diameter of 12 mm and form Assembly 3 (A-3).

Wheel

W

SSA

-1

Linkage Arm

LA

SA-1

Linkage Peg

LP

A-1

Train Body

TB

Wheel Peg

WP A-2

Hitch Peg

HP

SA-2 A-3

Hitch Magnet

HM

Cow Catcher

CC

Stack

S

Industrial Engineering Laboratory

BINUS University 49 Revision:

Practicum module

ISYE6101011 – Production & operation analysis

9. After Assembly 3 (A-3) is formed, the next step is to assemble the Cow

Catcher (CC) component with Assembly 3 (A-3). The combination of the two

components forms Assembly 4 (A-4).

W Wheel

SSA

-1

LA Linkage Arm

SA-1

LP Linkage Peg

A-1

TB Train Body

WP Wheel Peg A-2

HP Hitch Peg

SA-2 A-3

HM Hitch Magnet

CC Cow Catcher A-4

S Stack

10. The final step in assembling train toy is by assembling the Stack (S)

component with a combination of Assembly 4 (A-4) components. The two

are connected by a line leading to a circle with a diameter of 12 mm and

forming Assembly 5 (A-5), namely finished goods toys.

W Wheel

SSA

-1

LA Linkage Arm

SA-1

LP Linkage Peg

A-1

TB Train Body

WP Wheel Peg A-2

HP Hitch Peg

SA-2 A-3

HM Hitch Magnet

CC Cow Catcher A-4

S Stack A-5

Industrial Engineering Laboratory

BINUS University 50 Revision:

Practicum module

ISYE6101011 – Production & operation analysis

Product Structure

After making the assembly chart, the next step is to make the product

structure of the train toy. Following are the steps in making product's structure:

1. The following is the product structure of a train toy, the value of w means

numbering and the value of m means the number of requirements for the

component. Component numbering begins with components located on the

right side of the structure

Product Structure

OBJECT NAME : TOY TRAIN

MAPPED BY : POA ## Now

MAPPED DATE : MM - DD - YYYY Proposed

THE WAY OF MAPPING :1

Level

W : Numbering

M : Req. Numbering Finished

0

Goods

1 1 16 1

Assembly 4 Stack 1

2 1 15 1

Cow

Assembly 3 2

Catcher

3 4 1214 1

Sub-

Assembly 2 3

Assembly 2

4 1 11 4 12

13 1 1413 1

Hitch

Assembly 1 Wheel Peg Hitch Peg 4

Magnet

5 4 10 1

Sub-

Train Body 5

Assembly 1

6 2 9 4

Sub-sub Linkage

6

Assembly 1 Peg

7 4 8 2

Linkage 7

Wheel

Arm

2. First, In product's structure, there is a level of assembly arranged sequentially

starting from level 0, namely finished goods in the form of a train toy.

Product Structure

OBJECT NAME : TOY TRAIN

MAPPED BY : POA ## Now

MAPPED DATE : MM - DD - YYYY Proposed

THE WAY OF MAPPING :1

Level

Finished

0

Goods

3. Next, level 1 in the product structure contains components that form finished

goods at level 0. The two components are Stack and Assembly 4.

Industrial Engineering Laboratory

BINUS University 51 Revision:

Practicum module

ISYE6101011 – Production & operation analysis

Product Structure

OBJECT NAME : TOY TRAIN

MAPPED BY : POA ## Now

MAPPED DATE : MM - DD - YYYY Proposed

THE WAY OF MAPPING :1

Level

Finished

0

Goods

1 1 16 1

Assembly 4 Stack 1

4. The next step is to arrange level 2 which contains the components that form

Assembly 4 at level 1. The components that make up Assembly 4 are Cow

Catcher and assembly 3.

Product Structure

OBJECT NAME : TOY TRAIN

MAPPED BY : POA ## Now

MAPPED DATE : MM - DD - YYYY Proposed

THE WAY OF MAPPING :1

Level

Finished

0

Goods

1 1 16 1

Assembly 4 Stack 1

2 1 15 1

Cow

Assembly 3 2

Catcher

5. Then level 3 is arranged based on the components that form Assembly 3 on

level 2. The two components that form Assembly 3 are Sub-Assembly 2 and

Assembly 2.

Product Structure

OBJECT NAME : TOY TRAIN

MAPPED BY : POA ## Now

MAPPED DATE : MM - DD - YYYY Proposed

THE WAY OF MAPPING :1

Level

Finished

0

Goods

1 1 16 1

Assembly 4 Stack 1

2 1 15 1

Cow

Assembly 3 2

Catcher

3 4 14 1

Sub-

Assembly 2 3

Assembly 2

12

6. The next step is to arrange level 4 based on the components that form

Assembly 2 and Sub-Assembly 2 on level 3, the two components that form

Assembly 2 are Wheel Peg and Assembly 1 while the Sub-Assembly is

formed by components of Hitch Peg and Hitch Magnet

Industrial Engineering Laboratory

BINUS University 52 Revision:

Practicum module

ISYE6101011 – Production & operation analysis

Product Structure

OBJECT NAME : TOY TRAIN

MAPPED BY : POA ## Now

MAPPED DATE : MM - DD - YYYY Proposed

THE WAY OF MAPPING :1

Level

Finished

0

Goods

1 1 16 1

Assembly 4 Stack 1

2 1 15 1

Cow

Assembly 3 2

Catcher

3 4 14

12 1

Sub-

Assembly 2 3

Assembly 2

4 1 11 4 12

13 1 13

14 1

Hitch

Assembly 1 Wheel Peg Hitch Peg 4

Magnet

7. After that level 5 is arranged based on the components that form Assembly 1

at the previous level. Assembly 1 is formed by the components of Train Body

and Sub-Assembly 1.

Product Structure

OBJECT NAME : TOY TRAIN

MAPPED BY : POA ## Now

MAPPED DATE : MM - DD - YYYY Proposed

THE WAY OF MAPPING :1

Level

Finished

0

Goods

1 1 16 1

Assembly 4 Stack 1

2 1 15 1

Cow

Assembly 3 2

Catcher

3 4 14

12 1

Sub-

Assembly 2 3

Assembly 2

4 1 11 4 12

13 1 13

14 1

Hitch

Assembly 1 Wheel Peg Hitch Peg 4

Magnet

5 4 10 1

Sub-

Train Body 5

Assembly 1

8. Next, at level 6 there are components that form Sub-Assembly 1 at the

previous level, the components that form Sub-Assembly 1 are Sub-sub

Assembly 1 and train body.

Industrial Engineering Laboratory

BINUS University 53 Revision:

Practicum module

ISYE6101011 – Production & operation analysis

Product Structure

OBJECT NAME : TOY TRAIN

MAPPED BY : POA ## Now

MAPPED DATE : MM - DD - YYYY Proposed

THE WAY OF MAPPING :1

Level

Finished

0

Goods

1 1 16 1

Assembly 4 Stack 1

2 1 15 1

Cow

Assembly 3 2

Catcher

3 4 14

12 1

Sub-

Assembly 2 3

Assembly 2

4 1 11 4 12

13 1 14

13 1

Hitch

Assembly 1 Wheel Peg Hitch Peg 4

Magnet

5 4 10 1

Sub-

Train Body 5

Assembly 1

6 2 9 4

Sub-sub Linkage

6

Assembly 1 Peg

9. Level 7 is the last level of train toy product's structure, at level 7 there are

components that form Sub-sub Assembly 1. Both components are Wheel and

Linkage Arm. Components contained in level 7 are the first components

assembled in the train toy assembly.

Product Structure

OBJECT NAME : TOY TRAIN

MAPPED BY : POA ## Now

MAPPED DATE : MM - DD - YYYY Proposed

THE WAY OF MAPPING :1

Level

Finished

0

Goods

1 1 16 1

Assembly 4 Stack 1

2 1 15 1

Cow

Assembly 3 2

Catcher

3 4 12

14 1

Sub-

Assembly 2 3

Assembly 2

4 1 11 4 13

12 1 14

13 1

Hitch

Assembly 1 Wheel Peg Hitch Peg 4

Magnet

5 4 10 1

Sub-

Train Body 5

Assembly 1

6 2 9 4

Sub-sub Linkage

6

Assembly 1 Peg

7 4 8 2

Linkage 7

Wheel

Arm

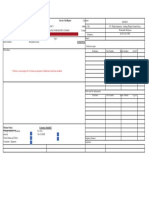

Bill Of Material (BOM)

The Following are the steps in making a Bill of Material (BOM):

1. Bill of material can be made based on product's structure that has been made

in the previous stage. The following is a table of Bill of Materials (BOM).

Industrial Engineering Laboratory

BINUS University 54 Revision:

Practicum module

ISYE6101011 – Production & operation analysis

Component No. Level Description Code Quantity Units

2. Enter the components of the assembly in accordance with the numbering

given on product's structure. Like the example below, the first component is

Assembly 4 which is at level 1 with the required number 1.

Component No. Level Description Code Quantity Units

1 .1…… Assembly 4 A-4 1 Piece

3. After that enter the second component on product's structure, the second

component is assembly 3 which is at level 2 with the required number 1.

Component No. Level Description Code Quantity Units

1 .1…… Assembly 4 A-4 1 Piece

2 ..2….. Assembly 3 A-3 1 Piece

4. After that, continue to input all existing components in sequence according to

numbering on product's structure, level, description, and quantity.

Component code information can be seen in the Table 3.2.

Component

Level Description Code Quantity Units

No.

1 .1…… Assembly 4 A-4 1 Piece

2 ..2….. Assembly 3 A-3 1 Piece

3 ..3…. Assembly 2 A-2 4 Pieces

4 …4… Assembly 1 A-1 1 Piece

5 ….5.. Sub Assembly 1 SA-1 4 Pieces

6 …..6. Sub-sub Assembly 1 SSA-1 1 Piece

7 ……7 Wheel W 4 Pieces

8 ……7 Linkage Arm LA 2 Pieces

9 …..6. Linkage Peg LP 4 Pieces

10 ….5.. Train Body TB 1 Piece

11 …4… Wheel Peg WP 4 Pieces

12 ..3…. Sub Assembly 2 SA-2 1 Piece

13 …4… Hitch Peg HP 1 Piece

14 …4… Hitch Magnet HM 1 Piece

15 ..2….. Cow Catcher CC 1 Piece

16 .1…… Stack S 1 Piece

Industrial Engineering Laboratory

BINUS University 55 Revision:

You might also like

- Subaru Legacy MY05-09 Service Manual CompleteDocument4,537 pagesSubaru Legacy MY05-09 Service Manual Completemvillalonm88% (17)

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- Subaru Forester 2005 Service ManualDocument20 pagesSubaru Forester 2005 Service Manualbessie100% (53)

- LECTURE 14 - Implementing The Designed Curriculum As A Change ProcessDocument4 pagesLECTURE 14 - Implementing The Designed Curriculum As A Change ProcessAeleu JoverzNo ratings yet

- Poa26 - Modul 3 - Bill of Material (Bom)Document7 pagesPoa26 - Modul 3 - Bill of Material (Bom)rizki septiaNo ratings yet

- Subaru-Impreza 2003 en UNK Manual de Taller D12ab41c6bDocument3,604 pagesSubaru-Impreza 2003 en UNK Manual de Taller D12ab41c6bMatias GallardoNo ratings yet

- AutoCAD Exercises For TutorialsDocument23 pagesAutoCAD Exercises For TutorialsIbrahimElKelanyNo ratings yet

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- BOWIN SERVICE MANUAL (Ceiling LED) PDFDocument28 pagesBOWIN SERVICE MANUAL (Ceiling LED) PDFCarolina Diaz MurillasNo ratings yet

- Exploratory Course - Computer Hardware Servicing For G 7and 8 - Answer Key PDFDocument9 pagesExploratory Course - Computer Hardware Servicing For G 7and 8 - Answer Key PDFSirossi Ven67% (12)

- BJC6200 PCDocument20 pagesBJC6200 PCMaciel-copymac CopymacNo ratings yet

- 125256-22072 LCG3015AJM2 (PL940) (AMNC3i - FS31i-LB) (EXP) Ver1.1Document1,944 pages125256-22072 LCG3015AJM2 (PL940) (AMNC3i - FS31i-LB) (EXP) Ver1.1jturnerNo ratings yet

- QY8-31BA-000: Revision 0Document19 pagesQY8-31BA-000: Revision 0Nebi aktaşNo ratings yet

- QY8-31BB-000: Revision 0Document19 pagesQY8-31BB-000: Revision 0Nebi aktaşNo ratings yet

- Lista de Peças RessonadorDocument191 pagesLista de Peças RessonadorDavid Manrique ZanchettaNo ratings yet

- ProjectDocument1 pageProjectAmy Wong Ho Yin (Student - Dewey THT)No ratings yet

- Canon SmartBase Mpc400, 600 Parts ManualDocument76 pagesCanon SmartBase Mpc400, 600 Parts ManualokeinfoNo ratings yet

- Engineering Drawing Ii (Mec 223)Document86 pagesEngineering Drawing Ii (Mec 223)Ibraheem Abdulrasheed Ayomide100% (1)

- Main Board: Optical Engine UnitDocument2 pagesMain Board: Optical Engine Unitwilliam lozadaNo ratings yet

- 126155-22147 Ensis3015ajm2zoom (Exp)Document2,272 pages126155-22147 Ensis3015ajm2zoom (Exp)AlexNo ratings yet

- TM-V71A/V71E: Service Man UalDocument4 pagesTM-V71A/V71E: Service Man Ualjoaquin ferNo ratings yet

- Exploded Views and Parts List (ML-1520) : Part Number & Description FormatDocument11 pagesExploded Views and Parts List (ML-1520) : Part Number & Description FormatAAAMARONo ratings yet

- 124770-12966 ENSIS3015AJ (EXP) (Ver.1.0)Document1,167 pages124770-12966 ENSIS3015AJ (EXP) (Ver.1.0)AlexNo ratings yet

- AAV8790601-00 MergedDocument7 pagesAAV8790601-00 Mergedengineeringcem99No ratings yet

- QY8-31BC-000: Revision 0Document19 pagesQY8-31BC-000: Revision 0Nebi aktaşNo ratings yet

- Push Over Analysis PDFDocument28 pagesPush Over Analysis PDFSardimalAmirNo ratings yet

- 2018 BRZ WiringDocument422 pages2018 BRZ WiringDaniel Dario Greig SalazarNo ratings yet

- 1.3 Sustructure Assembly DrawingsDocument31 pages1.3 Sustructure Assembly Drawingsdanielra85No ratings yet

- Canon bjc-50 bjc-50v Parts CatalogDocument40 pagesCanon bjc-50 bjc-50v Parts CatalogPeter AndrassyNo ratings yet

- I3040170817 (Grid Plate MHP66 Hammer Mill)Document1 pageI3040170817 (Grid Plate MHP66 Hammer Mill)bblacksmith29100% (1)

- AnsambluDocument1 pageAnsambluFlorin BuruNo ratings yet

- Spare Parts Catalogue: Aluminium Slide ValveDocument6 pagesSpare Parts Catalogue: Aluminium Slide Valvegracy2288No ratings yet

- A B C D E F: Q1: The Parts of A Machine As Shown in Fig. 1 Are Given in AdjoiningDocument12 pagesA B C D E F: Q1: The Parts of A Machine As Shown in Fig. 1 Are Given in AdjoiningMohit GargNo ratings yet

- Topic 2 Manufacturing EngineeringDocument26 pagesTopic 2 Manufacturing EngineeringCyclops JiNo ratings yet

- Exploded Views and Parts List (ML-2010 /) : R SEEDocument11 pagesExploded Views and Parts List (ML-2010 /) : R SEEGoran Ristic-RileNo ratings yet

- !!! Leg3 - Gen - Splošno - Vzdrževalni NačrtDocument104 pages!!! Leg3 - Gen - Splošno - Vzdrževalni NačrtMarko GergičNo ratings yet

- 29EDRA Exercises-AY2023 r5Document29 pages29EDRA Exercises-AY2023 r5Zion LauNo ratings yet

- ABS Series: 1 Point Relay Terminal Block (5A)Document1 pageABS Series: 1 Point Relay Terminal Block (5A)Fuck youNo ratings yet

- Methode Supplier PPAP Requirements March 2018 1Document12 pagesMethode Supplier PPAP Requirements March 2018 1harishg 213No ratings yet

- ET Series Pro2.0 GB V1.0Document23 pagesET Series Pro2.0 GB V1.0Victor PATIÑONo ratings yet

- PalaDocument2 pagesPalaAdrian Röman MayrNo ratings yet

- Assembly Drawing (Amplifier PCB Assembly, 055-227-10)Document1 pageAssembly Drawing (Amplifier PCB Assembly, 055-227-10)thiep tranNo ratings yet

- DSCH 50Document155 pagesDSCH 50裴兆奇No ratings yet

- PPMP20010 Assessment 1 - Project Status and Control Reports - TemplateDocument8 pagesPPMP20010 Assessment 1 - Project Status and Control Reports - TemplateTeja CNo ratings yet

- Mezclado RaDocument1 pageMezclado RaMarcel PiersonNo ratings yet

- BaldeDocument2 pagesBaldeAdrian Röman MayrNo ratings yet

- For3 GenerDocument96 pagesFor3 GenerTheVojislavbbNo ratings yet

- Dell Inspiron 1545 Wistron Dr1 Roberts Uma 48 4aq01 031 08212 3 PDFDocument59 pagesDell Inspiron 1545 Wistron Dr1 Roberts Uma 48 4aq01 031 08212 3 PDFrafael vidalNo ratings yet

- DAV02PI16E0Document9 pagesDAV02PI16E0Chami NdaNo ratings yet

- HDR-HC1 Hc1e HC1K Hc1ek Ver.1.3 2006.07 Service Manual Suplemento 1Document8 pagesHDR-HC1 Hc1e HC1K Hc1ek Ver.1.3 2006.07 Service Manual Suplemento 1Javier GutiérrezNo ratings yet

- Revision 0Document19 pagesRevision 0Nebi aktaşNo ratings yet

- Micom P741: Numerical Busbar ProtectionDocument32 pagesMicom P741: Numerical Busbar ProtectionDũng Đinh TiếnNo ratings yet

- Zero Set Patent - ReviewDocument12 pagesZero Set Patent - ReviewMike TernoeyNo ratings yet

- Micom P741: Numerical Busbar ProtectionDocument36 pagesMicom P741: Numerical Busbar ProtectionDũng Đinh TiếnNo ratings yet

- Weld Power SupplyDocument1 pageWeld Power SupplyK PNo ratings yet

- Exploded Views and Parts List (SCX-4200/X)Document15 pagesExploded Views and Parts List (SCX-4200/X)Carlos Roberto PereiraNo ratings yet

- CDH l32fd10 Service ManualDocument42 pagesCDH l32fd10 Service Manualtravieso112No ratings yet

- Shed ST11Document1 pageShed ST11abuNo ratings yet

- ML 2010Document11 pagesML 2010christophemajcherekNo ratings yet

- User 14/11/2022: Designed by Checked by Approved by Date DateDocument1 pageUser 14/11/2022: Designed by Checked by Approved by Date DateDaha Fire Team OfficialNo ratings yet

- MAC120 PartsDocument23 pagesMAC120 PartspRAMOD g pATOLENo ratings yet

- WA22A3354GVDocument14 pagesWA22A3354GVHolman CastiblancoNo ratings yet

- Formal-Relational Query Languages: Practice ExercisesDocument4 pagesFormal-Relational Query Languages: Practice ExercisesDivyanshu BoseNo ratings yet

- Transmitters To Detect Carbon Dioxide (Co)Document6 pagesTransmitters To Detect Carbon Dioxide (Co)Petar RudešNo ratings yet

- Accounting ProblemsDocument31 pagesAccounting ProblemsJanna Gunio100% (1)

- The Beginnings of IndustrializationDocument3 pagesThe Beginnings of Industrializationyochoa1No ratings yet

- 800-04194 EQUIPSeries ACUIX IP-Install-Config PDFDocument148 pages800-04194 EQUIPSeries ACUIX IP-Install-Config PDFVictor AponteNo ratings yet

- Msc-mepc.6-Circ.14 - Annex 2 - Sopep - 31 March 2016Document55 pagesMsc-mepc.6-Circ.14 - Annex 2 - Sopep - 31 March 2016captaksah100% (1)

- Legal Provisions Relating To Managing Director / Whole-Time DirectorDocument10 pagesLegal Provisions Relating To Managing Director / Whole-Time DirectorSoumitra ChawatheNo ratings yet

- I.T Unit 1Document9 pagesI.T Unit 1Gowtham R GowthamNo ratings yet

- Permit-To-Work - General Electrical (Under 1000 Volts) : ANNEX 16.1.6Document3 pagesPermit-To-Work - General Electrical (Under 1000 Volts) : ANNEX 16.1.6RihardsNo ratings yet

- N - M G E: Eher C Rath QuationDocument15 pagesN - M G E: Eher C Rath Quationgerrzen64No ratings yet

- Listado JM Motors Jun-2020Document291 pagesListado JM Motors Jun-2020OliverNo ratings yet

- Winsem2020-21 Ece1007 TH Vl2020210507666 Reference Material I 05-Apr-2021 Hetero Junction LedDocument17 pagesWinsem2020-21 Ece1007 TH Vl2020210507666 Reference Material I 05-Apr-2021 Hetero Junction LednikithaNo ratings yet

- Compromise Agreement For CollectionDocument2 pagesCompromise Agreement For CollectionIke CimafrancaNo ratings yet

- Ranjit's ResumeDocument1 pageRanjit's ResumeRanjit KaranNo ratings yet

- CS0005873Document1 pageCS0005873heryantoNo ratings yet

- Ix Astronic BlockdiagramDocument34 pagesIx Astronic BlockdiagramЕвгений АксёновNo ratings yet

- NEW - Brochure Villas DAOS ENG LowDocument30 pagesNEW - Brochure Villas DAOS ENG Lowsean golarNo ratings yet

- Handbook TNSTC CbeDocument25 pagesHandbook TNSTC CbeAnonymous SEDun6PWNo ratings yet

- TOG 2022 Volume 24 Issue 4Document80 pagesTOG 2022 Volume 24 Issue 4saeed hasan saeedNo ratings yet

- Globe Valves: Standard SpecificationDocument26 pagesGlobe Valves: Standard SpecificationHammad AshrafNo ratings yet

- Kalinga University at A Glance 1Document40 pagesKalinga University at A Glance 1Pranav Shukla PNo ratings yet

- Recent Legislations - CabarlesDocument11 pagesRecent Legislations - CabarlesKarl CabarlesNo ratings yet

- SAFe Agilist 6.0 Real DumpsDocument11 pagesSAFe Agilist 6.0 Real DumpsRomromNo ratings yet

- Chapter No 03 Class 6th Notes For Computer Science English MediumDocument5 pagesChapter No 03 Class 6th Notes For Computer Science English MediumAbid HussainNo ratings yet

- Passive Active Ve Reactive. Flow ControlpdfDocument441 pagesPassive Active Ve Reactive. Flow Controlpdfayabozgoren100% (1)

- ForestDocument30 pagesForestZarjaan ShahidNo ratings yet

- Queens University Belfast PHD Thesis GuidelinesDocument7 pagesQueens University Belfast PHD Thesis GuidelinesCheapCustomWrittenPapersUK100% (2)