Professional Documents

Culture Documents

Corrosoin Resistance TMT Rebar Diff. Types

Corrosoin Resistance TMT Rebar Diff. Types

Uploaded by

Sasanka SekharOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Corrosoin Resistance TMT Rebar Diff. Types

Corrosoin Resistance TMT Rebar Diff. Types

Uploaded by

Sasanka SekharCopyright:

Available Formats

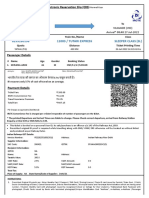

Fusion bonded epoxy Cement-polymer composite

SL NO Parameter Corrosion resistant steel (CRS) rebar

coated rebar coated (CPCC) rebar

Corrosion For protection of

For protection of reinforcing

Resistance reinforcing bars against

bars against corrosion, coating

Tech corrosion, epoxy coating is For protection of reinforcing bars against corr

of rapid setting primer

Corrosion done on these bars by chemical composition of rebar is made such as to

1 followed by a coat of cement

Resistance electrostatic spraying of inherent corrosion resisting property.

polymer sealing product is

Technology fusion bonded epoxy

done.

powder.

No BIS code available. Developed by

CECRI, Karaikudi. They have the

No BIS code available for CRS yet. Complying to BIS1786-20

2 BIS code BIS13620-1993 detailed specification of chemicals

and quality control with them.

Difficult, as it needs to pass Difficult, as it involves various steps

Manufacturing

3 some critical procedures as per like surface preparation, coating Easier to control, as it is dependent on mother billet com

process control

BIS. application on rebar.

A coating of 0.1-0.3mm on

external surface of rebar and

It can be brush applied or sprayed

Damage liable to damage. Performance Inherent property of rebar itself. No chance of damage/c

4 and hence defects in the coating can

possibility of the system depends upon property.

be patch repaired.

least defect in the coating.

About 20% less strength than Has good bond strength and hence

Bond strength of

5 conventional reinforcing bars, bond between coated rod and No effect on bond strength.

rebar

due to the coating. concrete unaffected, as per CECRI.

Special procedure is there for

handling such rebar, otherwise

Care to be taken while handling such

the coating may get damaged.

6 Handing rebar, otherwise the coating may get No restriction in handling procedure.

Even dropping or dragging such

damaged.

rebar is prohibited.

Chance of damage in coating

Chance of damage in coating during

Fabrication during fabrication. Exposed

fabrication. Exposed edge of rebar

7 (Cutting) edge of rebar will be affected by Normal practice like conventional rebar.

will be affected by corrosion.

corrosion.

Chance of dis bonding in coating

Chance of dis bonding in

8 Bending during bending. Bending of rebar to Normal practice like conventional rebar.

coating during bending.

be completed prior to coating.

Not advisable as coating get Not advisable as coating get

9 Welding No special care is required.

damaged during welding. damaged during welding.

Threaded portion of rebar Threaded portion of rebar without

Usage of Threading and coupler usage is not an issue due to inherent

10 without coating for fixing coating for fixing couplers leads to

couplers rebar.

couplers leads to corrosion. corrosion.

No measurement of extent of

protection to rebar due to the

coating, as per BIS. Smallest This system is newly developed by

Extent of

11 damage in coating can initiate CECRI and the long term results are About 25% lower rate of corrosion compared to conventio

protection

corrosion under severe not known.

environment.

Cost higher compared to

conventional rebar typically by

Rs 6000-13000/MT, due to the Cost higher compared to

coating. Moreover, due to less conventional rebar typically by Rs

bond strength, more 5000-8000/MT, due to the coating.

12 Cost saving development length required, Cost higher compared to conventional rebar by Rs 2500-3

leading to more cost.

You might also like

- Service-Manual 4000-9000 Eng 06 05 08Document327 pagesService-Manual 4000-9000 Eng 06 05 08Edgar Ebar67% (3)

- GMW 3359 Non Electrolytically Applied Zinc Rich Coating 2 1 14 PDFDocument9 pagesGMW 3359 Non Electrolytically Applied Zinc Rich Coating 2 1 14 PDFjoaopedrosousaNo ratings yet

- Remcor Folder GB WebDocument12 pagesRemcor Folder GB WebDinh TuNo ratings yet

- Astm F-1136Document2 pagesAstm F-1136tai100% (3)

- 12 LS 430 (Cont. Next Page) : Power Source Electronic Modulated Air SuspensionDocument2 pages12 LS 430 (Cont. Next Page) : Power Source Electronic Modulated Air Suspensionbob loblaw100% (1)

- Business Strategy For The Digital WorldDocument25 pagesBusiness Strategy For The Digital Worldhardseba100% (1)

- Comparison of Epoxy Coated Rebar Vs CPCC Rebar Vs CRS RebarDocument2 pagesComparison of Epoxy Coated Rebar Vs CPCC Rebar Vs CRS RebarAravindanNo ratings yet

- Comparison of Epoxy Coated Rebar Vs CPCC Rebar Vs CRS RebarDocument5 pagesComparison of Epoxy Coated Rebar Vs CPCC Rebar Vs CRS RebarDEBOPRASAD BISWASNo ratings yet

- How To Control Corrosion of Reinforcement in ConcreteDocument5 pagesHow To Control Corrosion of Reinforcement in ConcreteSRPC CIVILNo ratings yet

- Corrosion Control of Reinforcement Bars (Rebars)Document7 pagesCorrosion Control of Reinforcement Bars (Rebars)Lan LavistoNo ratings yet

- Application Notes Zinc PDFDocument6 pagesApplication Notes Zinc PDFTNNo ratings yet

- Hot-Dip Galvanized Rebar Performance & Condition Epoxy-Coated RebarDocument4 pagesHot-Dip Galvanized Rebar Performance & Condition Epoxy-Coated RebarJoaquin RiccitelliNo ratings yet

- Corrosive Protective CoatingsDocument6 pagesCorrosive Protective CoatingsMarcelo MinaNo ratings yet

- Metallographic Preparation of Zinc Coatings: Notes ApplicationDocument6 pagesMetallographic Preparation of Zinc Coatings: Notes ApplicationkhurshedlakhoNo ratings yet

- Comparison Between CPCC FBEC Amp CRSDDocument6 pagesComparison Between CPCC FBEC Amp CRSDSrikanth SrikantiNo ratings yet

- Corrosion Control of Reinforcement BarsDocument6 pagesCorrosion Control of Reinforcement BarsBhaskar ReddyNo ratings yet

- Bolting-Galvanized-Steel GAA ch4Document16 pagesBolting-Galvanized-Steel GAA ch4dfdfdNo ratings yet

- Galvanising InspectionDocument3 pagesGalvanising InspectionannamachaaryaNo ratings yet

- Paint Systems For Steel StructuresDocument7 pagesPaint Systems For Steel StructuresHermann Lowe100% (1)

- Integraheader: The Long-Term Chlorine Header SolutionDocument8 pagesIntegraheader: The Long-Term Chlorine Header Solutionmanuel.ape6263No ratings yet

- Comparison Between CPCC FBEC CRSDDocument5 pagesComparison Between CPCC FBEC CRSDAravindanNo ratings yet

- Concrete Construction Article PDF - Choices in Corrosion-Resistant RebarDocument4 pagesConcrete Construction Article PDF - Choices in Corrosion-Resistant RebarAnkur SinghNo ratings yet

- 11138.0997 Cathodic Protection of Surface Storage Tank BottomsDocument7 pages11138.0997 Cathodic Protection of Surface Storage Tank Bottomsoussama somraniNo ratings yet

- Article Zinc Flake CoatingDocument3 pagesArticle Zinc Flake CoatingStefano ZontaNo ratings yet

- Zinc Coatings PDFDocument12 pagesZinc Coatings PDFMuhammadImaduddienSalamNo ratings yet

- Giúdice, 2004, Combinational Use of Extenders With Lamellar ZincDocument14 pagesGiúdice, 2004, Combinational Use of Extenders With Lamellar Zinccyclo DreamNo ratings yet

- Corrosion Resistant Coated Dowel Bars: Standard Specification ForDocument2 pagesCorrosion Resistant Coated Dowel Bars: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Vci MBDocument23 pagesVci MBAyeshaNo ratings yet

- Galvashield CCDocument4 pagesGalvashield CCm.elsanee.cubicNo ratings yet

- CFW 59 W 54 PDFDocument2 pagesCFW 59 W 54 PDFLeonardo LuizNo ratings yet

- ExperimentalDocument18 pagesExperimentalhari haranNo ratings yet

- Surface & Coatings Technology: A. Azimi, F. Ashra Fizadeh, M.R. Toroghinejad, F. ShahriariDocument8 pagesSurface & Coatings Technology: A. Azimi, F. Ashra Fizadeh, M.R. Toroghinejad, F. ShahriarikhurshedlakhoNo ratings yet

- A Review of Shop Coating FailuresDocument5 pagesA Review of Shop Coating FailuresHugo F Barrera AlvaradoNo ratings yet

- Corrosion On Solar StructuresDocument2 pagesCorrosion On Solar StructuresyounNo ratings yet

- Hilti - PostInstalled Vs CastIn RebarDocument82 pagesHilti - PostInstalled Vs CastIn RebarSantosoNo ratings yet

- F13 - Carboguard 893-Zn PDS 10-09Document2 pagesF13 - Carboguard 893-Zn PDS 10-09naveenbaskaran1989No ratings yet

- 1 PCRDocument78 pages1 PCRTressa SoNo ratings yet

- Deterioration of Concrete - 105202Document22 pagesDeterioration of Concrete - 105202Hacking SoftwareNo ratings yet

- RESPONSIBILITY: G - Galvanized D - Designer B - Builder/Fabricator S - Steel Type/SurfaceDocument11 pagesRESPONSIBILITY: G - Galvanized D - Designer B - Builder/Fabricator S - Steel Type/SurfaceLaxit100% (1)

- Field Guide For Rust On Reinforcing BarsDocument4 pagesField Guide For Rust On Reinforcing Barsragunas tatyaNo ratings yet

- Corrosion Performance of Metallic Coated SteelsDocument4 pagesCorrosion Performance of Metallic Coated SteelsLian HoaNo ratings yet

- DIN en 4042 - A3C BicromatizadoDocument10 pagesDIN en 4042 - A3C BicromatizadoBruno FaveroNo ratings yet

- Introduction, Types and Causes of Distress in RCCDocument21 pagesIntroduction, Types and Causes of Distress in RCCRamNo ratings yet

- HDG Datasheet 8 - Welding Before and After Hot Dip GalvanizingDocument2 pagesHDG Datasheet 8 - Welding Before and After Hot Dip GalvanizingCheah Hon KeongNo ratings yet

- 129 - Download - Application of Corrosion Protection TechniqueDocument4 pages129 - Download - Application of Corrosion Protection TechniqueAli BahraniNo ratings yet

- Crsi Technical Rebar GuideDocument4 pagesCrsi Technical Rebar Guideحسن كاظم ريسان B-4No ratings yet

- Rust Mill Scale and Other Surface Contaminants - ETN-M-5-14Document8 pagesRust Mill Scale and Other Surface Contaminants - ETN-M-5-14ali tahaNo ratings yet

- Work Stage and Code Potential Defects How Determined Likely Cause Suggestions For ActionDocument9 pagesWork Stage and Code Potential Defects How Determined Likely Cause Suggestions For ActionIniyavanHajiMohamedNo ratings yet

- Zinc Flake CoatingsDocument1 pageZinc Flake CoatingsDinh TuNo ratings yet

- Carboguard 703Document2 pagesCarboguard 703Achraf BoudayaNo ratings yet

- Zinc 300 GCC: Art - No. 0892 2001Document1 pageZinc 300 GCC: Art - No. 0892 2001Dhanush santhoshNo ratings yet

- CM June 2011 Next Gen Metal Coatings Tech NoteDocument2 pagesCM June 2011 Next Gen Metal Coatings Tech NoteYusuf KhoirNo ratings yet

- CCS Brosur BrochureDocument3 pagesCCS Brosur Brochurerobby armandoNo ratings yet

- Carboguard 893 PDSDocument2 pagesCarboguard 893 PDSNguyễn Thị Châu TâyNo ratings yet

- 26 Core SolutionsDocument32 pages26 Core SolutionsSunil SinghNo ratings yet

- Gavalnise Vs PaintsDocument35 pagesGavalnise Vs Paintsian1000100% (2)

- Ref07 The Use of Predictive Models in Specifying Selective Use of Stainless Steel ReinforcementDocument80 pagesRef07 The Use of Predictive Models in Specifying Selective Use of Stainless Steel ReinforcementgbsimpsaNo ratings yet

- Tis 0003 Webbing Straps and Ratchets Issue 1 British SteelDocument2 pagesTis 0003 Webbing Straps and Ratchets Issue 1 British SteelJuan AlfaroNo ratings yet

- Om Prakash - PaperDocument7 pagesOm Prakash - PaperShivam SinghalNo ratings yet

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- Aluminum Structures: A Guide to Their Specifications and DesignFrom EverandAluminum Structures: A Guide to Their Specifications and DesignRating: 5 out of 5 stars5/5 (2)

- Carpentry and Framing Inspection Notes: Up to CodeFrom EverandCarpentry and Framing Inspection Notes: Up to CodeRating: 5 out of 5 stars5/5 (1)

- Rate CardsDocument32 pagesRate CardsSasanka SekharNo ratings yet

- Approximate BOQ For Limestone Crusher & Load CentreDocument8 pagesApproximate BOQ For Limestone Crusher & Load CentreSasanka SekharNo ratings yet

- BBS of Material GateDocument2 pagesBBS of Material GateSasanka SekharNo ratings yet

- Work Schedule BANJARI DEVELOPMENT JOBDocument4 pagesWork Schedule BANJARI DEVELOPMENT JOBSasanka SekharNo ratings yet

- Work Schedule Banjari Development JobDocument7 pagesWork Schedule Banjari Development JobSasanka SekharNo ratings yet

- Highway Rating CircularDocument18 pagesHighway Rating CircularSasanka SekharNo ratings yet

- BBS For Kerb Wall Material GateDocument9 pagesBBS For Kerb Wall Material GateSasanka SekharNo ratings yet

- AnalysisOfDesignOfAFlexiblePavementWithCementedBaseAndGranularSubbase (187 192)Document6 pagesAnalysisOfDesignOfAFlexiblePavementWithCementedBaseAndGranularSubbase (187 192)Sasanka SekharNo ratings yet

- BBS of Foundation (Material Gate)Document2 pagesBBS of Foundation (Material Gate)Sasanka SekharNo ratings yet

- NDT PPT ShubhamDocument34 pagesNDT PPT ShubhamSasanka SekharNo ratings yet

- BBS of Kerb WallDocument3 pagesBBS of Kerb WallSasanka SekharNo ratings yet

- Amc QapDocument8 pagesAmc QapSasanka SekharNo ratings yet

- Nov 18Document1 pageNov 18Sasanka SekharNo ratings yet

- Quality Assurance PlanDocument4 pagesQuality Assurance PlanSasanka SekharNo ratings yet

- Mix Design For PQCDocument20 pagesMix Design For PQCSasanka SekharNo ratings yet

- Mix Design of CTB As Per MORT&HDocument21 pagesMix Design of CTB As Per MORT&HSasanka SekharNo ratings yet

- Coal Truck Parking Exit Road Bbs2Document7 pagesCoal Truck Parking Exit Road Bbs2Sasanka SekharNo ratings yet

- Mix Design of DLCDocument8 pagesMix Design of DLCSasanka SekharNo ratings yet

- Moisture Correction SheetDocument4 pagesMoisture Correction SheetSasanka SekharNo ratings yet

- California Bearing Ratio Test Data Sheets & GraphsDocument4 pagesCalifornia Bearing Ratio Test Data Sheets & GraphsSaad JuventinoNo ratings yet

- Sale Deed of Dipannita Construction Legal (Dilip Show)Document20 pagesSale Deed of Dipannita Construction Legal (Dilip Show)Sasanka SekharNo ratings yet

- Amc Rates 2018Document23 pagesAmc Rates 2018Sasanka SekharNo ratings yet

- Weight Bridge ENTRY RampDocument12 pagesWeight Bridge ENTRY RampSasanka SekharNo ratings yet

- Coal Entry Road Bbs1Document9 pagesCoal Entry Road Bbs1Sasanka SekharNo ratings yet

- 10C... For PF WithdrwalDocument2 pages10C... For PF WithdrwalSasanka SekharNo ratings yet

- B.B.S (300 Dia Hume Pipe)Document2 pagesB.B.S (300 Dia Hume Pipe)Sasanka SekharNo ratings yet

- Weight Bridge Exit RampDocument12 pagesWeight Bridge Exit RampSasanka SekharNo ratings yet

- Specification Tender No 1920000627Document201 pagesSpecification Tender No 1920000627Sasanka SekharNo ratings yet

- Tendernotice 1Document9 pagesTendernotice 1Sasanka SekharNo ratings yet

- RMC Rate AnalysisDocument100 pagesRMC Rate AnalysisSasanka SekharNo ratings yet

- ECG Abstract PDFDocument2 pagesECG Abstract PDFgangadhara0% (1)

- Chapter 1Document21 pagesChapter 1iris33% (3)

- Literature ReviewDocument11 pagesLiterature ReviewAsif RahmanNo ratings yet

- RFP - Honorarium For NSM SpeakershipDocument3 pagesRFP - Honorarium For NSM SpeakershipRodcyn YumangNo ratings yet

- Opnet CsmacdDocument10 pagesOpnet Csmacddineshs519No ratings yet

- Tutari Express Sleeper Class (SL)Document1 pageTutari Express Sleeper Class (SL)vaibhavNo ratings yet

- Hazard Mapping Checklist-1Document1 pageHazard Mapping Checklist-1John Matthew CerenoNo ratings yet

- Report On SMW WeekDocument1 pageReport On SMW WeekJoan RosanwoNo ratings yet

- Describing GraphDocument20 pagesDescribing GraphGita RahMaNo ratings yet

- SAP GUI Family: Guided TourDocument98 pagesSAP GUI Family: Guided Tourmca1954No ratings yet

- 2014 Survey of Living Conditions QuestionnaireDocument59 pages2014 Survey of Living Conditions QuestionnaireabguyNo ratings yet

- CA ch2Document14 pagesCA ch2Llazi LegjendaNo ratings yet

- Khubaib Akhtar: Career ObjectiveDocument3 pagesKhubaib Akhtar: Career Objectivekhubaib akhtarNo ratings yet

- DD Security Configuration GuideDocument50 pagesDD Security Configuration GuideRatataNo ratings yet

- Automatic Timetable GeneratorDocument4 pagesAutomatic Timetable GeneratorArohi LigdeNo ratings yet

- OptiFDTD Tutorials PDFDocument36 pagesOptiFDTD Tutorials PDFKhải NguyễnNo ratings yet

- Utm Locartic Slides 17 Dec 2016Document19 pagesUtm Locartic Slides 17 Dec 2016Nordin SuhadatNo ratings yet

- Standards Development Centre (SDC), IT & ICT Division: Technical Committee Membership FormDocument1 pageStandards Development Centre (SDC), IT & ICT Division: Technical Committee Membership FormEngr Ishfaque TunioNo ratings yet

- 15HP 4P XP Us MotorsDocument10 pages15HP 4P XP Us MotorsAndres SanchezNo ratings yet

- Pcie Intel SpecificationDocument9 pagesPcie Intel Specificationdipin555No ratings yet

- Higher Education Graduates by Discipline PDFDocument1 pageHigher Education Graduates by Discipline PDFRap SamsonNo ratings yet

- Technical Data Sheet For Ep 7-12 (12V 7ah) Vrla BatteryDocument3 pagesTechnical Data Sheet For Ep 7-12 (12V 7ah) Vrla BatteryJegadeshwaran RNo ratings yet

- Material Selection GuideDocument72 pagesMaterial Selection Guideeitan-dalia4971No ratings yet

- MuleitorDocument282 pagesMuleitorFrancisco MontecinosNo ratings yet

- $SysAdm Made Easy 46cd (Entire Book-2002)Document781 pages$SysAdm Made Easy 46cd (Entire Book-2002)Avijit RoyNo ratings yet

- Prepare A Report On Any Four Electrical Application in Smart CitiesDocument16 pagesPrepare A Report On Any Four Electrical Application in Smart CitiesSahil MeshramNo ratings yet

- Coprative BankDocument4 pagesCoprative BankJasmandeep brarNo ratings yet