Professional Documents

Culture Documents

Trabajo en Clase No 6

Trabajo en Clase No 6

Uploaded by

Maria Valentina Mendez PardoCopyright:

Available Formats

You might also like

- NPFA 15 For TransformerDocument31 pagesNPFA 15 For TransformerNinh Nguyễn100% (3)

- 1) What Are Types of Automated Storage System? and Their Applications?Document18 pages1) What Are Types of Automated Storage System? and Their Applications?Khánh Đoan Lê Đình75% (4)

- Assignment Traffic EngineeringDocument9 pagesAssignment Traffic EngineeringNadeem YousafzaiNo ratings yet

- ASRS ExercisesDocument2 pagesASRS ExercisesPhan Gia Nghi100% (1)

- Storage System ExercisesDocument3 pagesStorage System ExercisesMỹ Quyên Nguyễn HữuNo ratings yet

- Tutorial 2 Storage System PDF FreeDocument2 pagesTutorial 2 Storage System PDF Freepeter oumaNo ratings yet

- Tutorial 2 Storage SystemDocument2 pagesTutorial 2 Storage SystemSu YiNo ratings yet

- AsrsDocument58 pagesAsrsaman_88_vermaNo ratings yet

- ASRS ExercisesDocument3 pagesASRS ExercisesTôn Nữ Minh UyênNo ratings yet

- Assignment 2 - Storage SystemsDocument2 pagesAssignment 2 - Storage SystemsTrịnh Thị Khánh TrâmNo ratings yet

- Lec # 7 Storage SystemsDocument22 pagesLec # 7 Storage SystemsEman ShahidNo ratings yet

- ExercisesDocument4 pagesExercisesTôn Nữ Minh UyênNo ratings yet

- 23 15 SA V1 S1 - AsrsassDocument5 pages23 15 SA V1 S1 - AsrsassAbimaelNMNo ratings yet

- 8450 ESE DEC21 SOE 7 B.tech (ME) MEPD4014 Automation in ManufacturingDocument2 pages8450 ESE DEC21 SOE 7 B.tech (ME) MEPD4014 Automation in ManufacturingJoy SummersNo ratings yet

- ASRS SystemsDocument21 pagesASRS Systemsdiu123No ratings yet

- Automated Storage and Retrieval Systems BakiDocument4 pagesAutomated Storage and Retrieval Systems BakiArick LakhaniNo ratings yet

- Engineering Analysis of Storage SystemsDocument5 pagesEngineering Analysis of Storage SystemsIvett LunaNo ratings yet

- Auto WMDocument10 pagesAuto WMFadhil Akmal FakhriNo ratings yet

- Crane and Shuttle Optimization in Warehousing Systems: Amatol, Bade2, PasqualeDocument7 pagesCrane and Shuttle Optimization in Warehousing Systems: Amatol, Bade2, PasqualeGilmar Vieira de SouzaNo ratings yet

- Eazc 4121Document1 pageEazc 4121Priyanka MahajanNo ratings yet

- Imo PS GyrocompassDocument3 pagesImo PS Gyrocompassatinder13No ratings yet

- Our Innovative Breakthrough Vessel:: Strength and DepthDocument20 pagesOur Innovative Breakthrough Vessel:: Strength and DepthKenneth TanNo ratings yet

- Standards of Airport 1Document58 pagesStandards of Airport 1eshNo ratings yet

- ASN WX Radar FacilitiesDocument3 pagesASN WX Radar FacilitiesJamieNo ratings yet

- SHIPMA Deltares MarinDocument4 pagesSHIPMA Deltares Marinmurali.5482No ratings yet

- Mechanical Engineering 7 Sem Batch: 7C2: Name Enroll NoDocument33 pagesMechanical Engineering 7 Sem Batch: 7C2: Name Enroll NoElena JelerNo ratings yet

- Standards and Requirements: For AirportDocument51 pagesStandards and Requirements: For AirporteshNo ratings yet

- Feasibillity Study of Semi Automatic Pipe Handling - Great ArticleDocument97 pagesFeasibillity Study of Semi Automatic Pipe Handling - Great ArticleTom ZimmerNo ratings yet

- Ropeway Conveyor and Unloading System Using PLCDocument3 pagesRopeway Conveyor and Unloading System Using PLCeditor_ijcatNo ratings yet

- MCE 439 Assignment 3Document2 pagesMCE 439 Assignment 3Ammar1994No ratings yet

- Standards of Airport 01Document51 pagesStandards of Airport 01esh100% (1)

- Review MHS So N PDFDocument11 pagesReview MHS So N PDFNhan DONo ratings yet

- HondaJet SpecificationsDocument5 pagesHondaJet SpecificationsJohn Jennings100% (1)

- AsrsDocument58 pagesAsrsgarvitamiparaNo ratings yet

- Quantitative Analysis of AS/RS & Carousal SystemsDocument30 pagesQuantitative Analysis of AS/RS & Carousal Systemssireetharan99No ratings yet

- Baggage Conveyor Technology at Hamburg Airport: DrivesystemsDocument8 pagesBaggage Conveyor Technology at Hamburg Airport: Drivesystemsbiny4No ratings yet

- Runway DesignDocument7 pagesRunway DesignConsistencyNo ratings yet

- ATR 600 Series WebDocument28 pagesATR 600 Series Webbardan0178% (9)

- General Laying ProceduresDocument20 pagesGeneral Laying ProceduresLiladhar Ganesh Dhoble100% (1)

- Jack Up Drilling RigDocument2 pagesJack Up Drilling RigMaría MarquinaNo ratings yet

- Mechanised Track Construction On DFC Projects: Manjul Mathur, GGM/MA/EC, DFCCIL Atul Khare, CPM/ Tundla, DFCCILDocument9 pagesMechanised Track Construction On DFC Projects: Manjul Mathur, GGM/MA/EC, DFCCIL Atul Khare, CPM/ Tundla, DFCCILnk229330No ratings yet

- Aeb Baroda Aug 07: Time 106 MinDocument9 pagesAeb Baroda Aug 07: Time 106 MinAbhishek TewariNo ratings yet

- P-047 Full PaperDocument7 pagesP-047 Full PapervdNo ratings yet

- Case Study On Warehouse ManagementDocument2 pagesCase Study On Warehouse ManagementSafijo AlphonsNo ratings yet

- Unit 2 ExercisesDocument10 pagesUnit 2 ExercisesAlberto Rivas CidNo ratings yet

- Handbook On Standardization of Infrastructural Facilities For Maintenance of ART ARME 140T CraneDocument12 pagesHandbook On Standardization of Infrastructural Facilities For Maintenance of ART ARME 140T CraneSaptarshi PalNo ratings yet

- Z - Sari@mail - Univ-Tlemcen - DZ: E E E E V E V E L, H, D M M NDocument21 pagesZ - Sari@mail - Univ-Tlemcen - DZ: E E E E V E V E L, H, D M M NSuvin NambiarNo ratings yet

- Scarpa - LNG TErminal AssessmentDocument11 pagesScarpa - LNG TErminal Assessmentyan energia100% (1)

- Modern Logistics: Case Study On JSW Crm2 Total Automatic Yms and AsrsDocument19 pagesModern Logistics: Case Study On JSW Crm2 Total Automatic Yms and Asrsakashkr619No ratings yet

- Main Group 3 Equipment For CargoDocument13 pagesMain Group 3 Equipment For CargoVladi GasperNo ratings yet

- 80 Ton AHTS Specification Rev 0Document81 pages80 Ton AHTS Specification Rev 0Mark Samsel RohanNo ratings yet

- Expressor CompressorDocument81 pagesExpressor Compressormep.No ratings yet

- Aerodrome Data, Physical Characteristics and Obstacle RestrictionDocument19 pagesAerodrome Data, Physical Characteristics and Obstacle RestrictionElakkiya Karthic100% (1)

- Load Estimation For Airport ProjectDocument9 pagesLoad Estimation For Airport ProjectAisha GamalNo ratings yet

- Unit 4 Automated Storage/Retrieval Systems: StructureDocument11 pagesUnit 4 Automated Storage/Retrieval Systems: StructureRuby SmithNo ratings yet

- A330 Normal Law: Putting Fly-by-Wire Into PerspectiveFrom EverandA330 Normal Law: Putting Fly-by-Wire Into PerspectiveRating: 5 out of 5 stars5/5 (2)

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- EE201 Circuits N NetworksDocument2 pagesEE201 Circuits N NetworksArya ANo ratings yet

- Electrical Distribution Systems - Unit - V - Voltage ControlDocument20 pagesElectrical Distribution Systems - Unit - V - Voltage ControlSatishdhora SiddanaNo ratings yet

- Chem Lec Module 2 NotesDocument20 pagesChem Lec Module 2 NotesPinuela, Kristine AngeliqueNo ratings yet

- 464 HW 3 Due 14 FebDocument14 pages464 HW 3 Due 14 FebBook MitreevejNo ratings yet

- Final Report of AntennaDocument4 pagesFinal Report of AntennaAmir Al-ashtalNo ratings yet

- 01 Intro To HarmonyDocument16 pages01 Intro To Harmonyvikas kunduNo ratings yet

- Cutting Mechanics of The Gear Shaping Process: by Andrew KatzDocument137 pagesCutting Mechanics of The Gear Shaping Process: by Andrew KatzM MADYAN HAMDINo ratings yet

- General Organic and Biological Chemistry 7Th Edition Stoker Solutions Manual Full Chapter PDFDocument18 pagesGeneral Organic and Biological Chemistry 7Th Edition Stoker Solutions Manual Full Chapter PDFallison.young656100% (19)

- 01 CTS KIPS Schedule MDCAT, NUMS, SET (21-08-20)Document5 pages01 CTS KIPS Schedule MDCAT, NUMS, SET (21-08-20)Hanzala ShahidNo ratings yet

- PHYSICS21 Magnetic Field LinesDocument28 pagesPHYSICS21 Magnetic Field Linesapi-3805293100% (1)

- Used Water SES 5 Construction of Tunnels Ancillaries 2012Document28 pagesUsed Water SES 5 Construction of Tunnels Ancillaries 2012Mark BenjieNo ratings yet

- Ilovepdf MergedDocument69 pagesIlovepdf MergedZihad Khan HabibNo ratings yet

- Radioactivity Physics Lab AnswersDocument3 pagesRadioactivity Physics Lab AnswersAaliyah Senior100% (1)

- Hardening Soil ModelDocument4 pagesHardening Soil Modelprantik.ceNo ratings yet

- Construction and Building Materials: Bashar S. Mohammed, Musa AdamuDocument18 pagesConstruction and Building Materials: Bashar S. Mohammed, Musa AdamuMuaz Bin Ali ArafNo ratings yet

- LS1 - Analysis of Air-Conditioning Processes PDFDocument4 pagesLS1 - Analysis of Air-Conditioning Processes PDFdildin01No ratings yet

- Ficha Técnica Conectores de TornilloDocument6 pagesFicha Técnica Conectores de TornilloFernando Castillo HerreraNo ratings yet

- Scaffolding Megapal-Catalogue2021Document28 pagesScaffolding Megapal-Catalogue2021Hoang Cong DungNo ratings yet

- Alkene Structure and PreparationDocument2 pagesAlkene Structure and PreparationCarlo Jay BasulNo ratings yet

- TGADocument31 pagesTGABhuvnesh SharmaNo ratings yet

- SurgebinderDocument21 pagesSurgebinderdavid castillo riveraNo ratings yet

- Organometallic ChemistryDocument90 pagesOrganometallic Chemistrytharun thennarasuNo ratings yet

- NMRV enDocument336 pagesNMRV engbys456jqcNo ratings yet

- Bond Energy Calculations - QuestionsDocument6 pagesBond Energy Calculations - QuestionsernestasNo ratings yet

- A Technical Seminar On: Holographic Data StorageDocument12 pagesA Technical Seminar On: Holographic Data StorageNilkanta MondalNo ratings yet

- Tropismo - Psilocybe CubensisDocument6 pagesTropismo - Psilocybe CubensisLucas AntoniniNo ratings yet

- Grade 8 DLP (Science)Document6 pagesGrade 8 DLP (Science)Breeza Marie VeralloNo ratings yet

- Innstruct ManualDocument26 pagesInnstruct ManualOmer HayatNo ratings yet

- Messko Compact Temperature Measurement System For TransformersDocument6 pagesMessko Compact Temperature Measurement System For Transformersfarzad dalaviNo ratings yet

Trabajo en Clase No 6

Trabajo en Clase No 6

Uploaded by

Maria Valentina Mendez PardoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trabajo en Clase No 6

Trabajo en Clase No 6

Uploaded by

Maria Valentina Mendez PardoCopyright:

Available Formats

DISEÑO DE SISTEMAS DE PRODUCCIÓN 2021

UNIVERSIDAD MILITAR NUEVA GRANADA

FACULTAD DE INGENIERIA

SECCIONAL VILLA ACADÉMICA

PROGRAMA DE INGENIERIA INDUSTRIAL

Work in Class No 3 - Part B

12 de noviembre de 2021

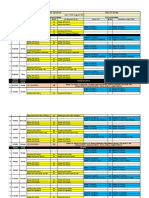

1. An AS/RS is to be designed for the storage of 60”X48” unit loads. The S/R machine will

travel horizontally at a speed of 500 fpm; simultaneously, it will travel vertically at a speed

of 80 fpm. The storage aisle will be 400’ long and 60’ tall. The pick-up and deposit station

will be located at the end of the aisle and will be elevated 20’ above floor level. Assume

randomized storage will be used and the storage region served by the S/R is a continuous,

rectangular region 400’X60’. The P/D time will be 0.30 minute.

a. Determine the single-command cycle time, including P/D times.

b. Determine the dual-command cycle time, including P/D times.

c. Suppose three classes of products are to be stored in the storage aisle. Fast movers will

be stored in a rectangular region defined by the following coordinates: (0,0), (0,40),

(125,40), and (125,0). Medium movers will be stored in an L-shaped region between the

fast and slow movers. Slow movers will be stored in a rectangular region defined by

(250,0), (250,60), (400,60), and (400,0). Fast movers represent 60% of the storage and

retrieval operations performed; medium movers account for 30% of the activity; slow

movers represent the balance. Determine the average single-command cycle time,

including P/D times.

2. In deriving the cycle time equations, the I/O point was assumed to be located at the lower

lefthand corner of the rack. Based on the particular type of hardware involved, however,

the exact location of the I/O point may not coincide with the lower lefthand corner of the

rack. In fact, suppose the I/O point is located 12’ from the lower lefthand corner of the rack,

as shown below:

Further assume that the storage rack is small-say, 150’ long and 30’ high. The S/R

machine travels at 400 fpm and 80 fpm in the horizontal and vertical directions,

OSCAR PALACIO LEÓN, PhD Página 1

DISEÑO DE SISTEMAS DE PRODUCCIÓN 2021

respectively. Calculate the expected S/R machine travel time for single- and dual-

command cycles for the above case. Note: In traveling from the I/O point to a location in

the rack (and vice versa), the S/R machine is not required to pass through the lower

lefthand corner of the rack. Compare your results with the expected travel times obtained if

the I/O point is assumed to be located at the lower lefthand corner of the rack; show the

percent difference.

3. An AS/R system is being designed for 42”X48” unit loads that are 42” high. One of the

design alternatives involves eight aisles, no transfer cars, 1,100 openings per aisle, 11

levels and 50 columns of storage on each side of the aisle, and sprinklers. The S/R will

travel horizontally at an average speed of 300 fpm; simultaneously, it will travel vertically at

an average speed of 70 fpm. The time required for the shuttle to perform either a pickup

(P) or a deposit (D) operation is 0.35 minute. Each S/R will have to store and retrieve at a

rate of 18 storages per hour and 18 retrievels per hour. Due to the uncertainty concerning

the proportion of the operations that will be single command versus dual command, you

are to determine the maximum percentage of single command operations so that utilization

of the S/R does not exceed 85%. Also, the costs of the building, rack, and S/R machines

are to be determined. Assume 2,000 lb loads, off-board computer controls (but not a

central console), and a 20 USD/ft2 building cost for a 25’-high building.

4. An AS/RS is to be designed for a 40”X48” unit load that is 48” high. There are eight aisles;

each aisle is 12 loads high and 50 loads long. There are to be sprinklers and no transfer

cars. It takes 0.30 minute to perform a P/D operation. The S/R travels horizontally at a

speed of 300 fpm and travels vertically at a speed of 60 fpm. Thirty percent of the

retrievals and 30% of the storages are single-command operations.

a. How many storages per hour and retrievals per hour can each S/R handle without being

utilized more than 90%?

b. Estimate the cost of racks, S/R machines, and the building. Assume it costs 25USD/ft2

to build a 25’-high building, loads weigh 3,000 lb, there is a central console, and the

structure is conventional (not rack supported).

5. An AS/R system is to be designed to store approximately 12,000 loads. Due to space

limitations in the existing facility, it is known that the system will have eight tiers of storage.

The choice has been reduced to having either (a) 10 aisles, 75 openings long, (b) 9 aisles,

84 openings long, or (c) 8 aisles, 94 openings long. The S/R will travel horizontally at an

average speed of 450 fpm; simultaneously, it will travel vertically at an average speed of

80 fpm. 48”X40” unit loads, 44” high and weighing 2,500 lb, are to be stored. The I/O point

is located at the end of the aisle, at floor level. The time required to pick up (P) or to

deposit (D) a load is 0.30 minute. The throughput requirement on the system is to perform

a total of 180 storages per hour and 180 retrievals per hour. Randomized storage is used.

Forty percent single-command operations are anticipated. A maximum utilization of 95%

can be planned for an individual S/R. A central computer console is to be used to control

the S/Rs. Determine the least-cost alternative that satisfies the throughput constraint.

Consider only rack cost and S/R machine cost; do not consider building cost. (Assume

sprinklers and no transfer cars are to be used.)

OSCAR PALACIO LEÓN, PhD Página 2

You might also like

- NPFA 15 For TransformerDocument31 pagesNPFA 15 For TransformerNinh Nguyễn100% (3)

- 1) What Are Types of Automated Storage System? and Their Applications?Document18 pages1) What Are Types of Automated Storage System? and Their Applications?Khánh Đoan Lê Đình75% (4)

- Assignment Traffic EngineeringDocument9 pagesAssignment Traffic EngineeringNadeem YousafzaiNo ratings yet

- ASRS ExercisesDocument2 pagesASRS ExercisesPhan Gia Nghi100% (1)

- Storage System ExercisesDocument3 pagesStorage System ExercisesMỹ Quyên Nguyễn HữuNo ratings yet

- Tutorial 2 Storage System PDF FreeDocument2 pagesTutorial 2 Storage System PDF Freepeter oumaNo ratings yet

- Tutorial 2 Storage SystemDocument2 pagesTutorial 2 Storage SystemSu YiNo ratings yet

- AsrsDocument58 pagesAsrsaman_88_vermaNo ratings yet

- ASRS ExercisesDocument3 pagesASRS ExercisesTôn Nữ Minh UyênNo ratings yet

- Assignment 2 - Storage SystemsDocument2 pagesAssignment 2 - Storage SystemsTrịnh Thị Khánh TrâmNo ratings yet

- Lec # 7 Storage SystemsDocument22 pagesLec # 7 Storage SystemsEman ShahidNo ratings yet

- ExercisesDocument4 pagesExercisesTôn Nữ Minh UyênNo ratings yet

- 23 15 SA V1 S1 - AsrsassDocument5 pages23 15 SA V1 S1 - AsrsassAbimaelNMNo ratings yet

- 8450 ESE DEC21 SOE 7 B.tech (ME) MEPD4014 Automation in ManufacturingDocument2 pages8450 ESE DEC21 SOE 7 B.tech (ME) MEPD4014 Automation in ManufacturingJoy SummersNo ratings yet

- ASRS SystemsDocument21 pagesASRS Systemsdiu123No ratings yet

- Automated Storage and Retrieval Systems BakiDocument4 pagesAutomated Storage and Retrieval Systems BakiArick LakhaniNo ratings yet

- Engineering Analysis of Storage SystemsDocument5 pagesEngineering Analysis of Storage SystemsIvett LunaNo ratings yet

- Auto WMDocument10 pagesAuto WMFadhil Akmal FakhriNo ratings yet

- Crane and Shuttle Optimization in Warehousing Systems: Amatol, Bade2, PasqualeDocument7 pagesCrane and Shuttle Optimization in Warehousing Systems: Amatol, Bade2, PasqualeGilmar Vieira de SouzaNo ratings yet

- Eazc 4121Document1 pageEazc 4121Priyanka MahajanNo ratings yet

- Imo PS GyrocompassDocument3 pagesImo PS Gyrocompassatinder13No ratings yet

- Our Innovative Breakthrough Vessel:: Strength and DepthDocument20 pagesOur Innovative Breakthrough Vessel:: Strength and DepthKenneth TanNo ratings yet

- Standards of Airport 1Document58 pagesStandards of Airport 1eshNo ratings yet

- ASN WX Radar FacilitiesDocument3 pagesASN WX Radar FacilitiesJamieNo ratings yet

- SHIPMA Deltares MarinDocument4 pagesSHIPMA Deltares Marinmurali.5482No ratings yet

- Mechanical Engineering 7 Sem Batch: 7C2: Name Enroll NoDocument33 pagesMechanical Engineering 7 Sem Batch: 7C2: Name Enroll NoElena JelerNo ratings yet

- Standards and Requirements: For AirportDocument51 pagesStandards and Requirements: For AirporteshNo ratings yet

- Feasibillity Study of Semi Automatic Pipe Handling - Great ArticleDocument97 pagesFeasibillity Study of Semi Automatic Pipe Handling - Great ArticleTom ZimmerNo ratings yet

- Ropeway Conveyor and Unloading System Using PLCDocument3 pagesRopeway Conveyor and Unloading System Using PLCeditor_ijcatNo ratings yet

- MCE 439 Assignment 3Document2 pagesMCE 439 Assignment 3Ammar1994No ratings yet

- Standards of Airport 01Document51 pagesStandards of Airport 01esh100% (1)

- Review MHS So N PDFDocument11 pagesReview MHS So N PDFNhan DONo ratings yet

- HondaJet SpecificationsDocument5 pagesHondaJet SpecificationsJohn Jennings100% (1)

- AsrsDocument58 pagesAsrsgarvitamiparaNo ratings yet

- Quantitative Analysis of AS/RS & Carousal SystemsDocument30 pagesQuantitative Analysis of AS/RS & Carousal Systemssireetharan99No ratings yet

- Baggage Conveyor Technology at Hamburg Airport: DrivesystemsDocument8 pagesBaggage Conveyor Technology at Hamburg Airport: Drivesystemsbiny4No ratings yet

- Runway DesignDocument7 pagesRunway DesignConsistencyNo ratings yet

- ATR 600 Series WebDocument28 pagesATR 600 Series Webbardan0178% (9)

- General Laying ProceduresDocument20 pagesGeneral Laying ProceduresLiladhar Ganesh Dhoble100% (1)

- Jack Up Drilling RigDocument2 pagesJack Up Drilling RigMaría MarquinaNo ratings yet

- Mechanised Track Construction On DFC Projects: Manjul Mathur, GGM/MA/EC, DFCCIL Atul Khare, CPM/ Tundla, DFCCILDocument9 pagesMechanised Track Construction On DFC Projects: Manjul Mathur, GGM/MA/EC, DFCCIL Atul Khare, CPM/ Tundla, DFCCILnk229330No ratings yet

- Aeb Baroda Aug 07: Time 106 MinDocument9 pagesAeb Baroda Aug 07: Time 106 MinAbhishek TewariNo ratings yet

- P-047 Full PaperDocument7 pagesP-047 Full PapervdNo ratings yet

- Case Study On Warehouse ManagementDocument2 pagesCase Study On Warehouse ManagementSafijo AlphonsNo ratings yet

- Unit 2 ExercisesDocument10 pagesUnit 2 ExercisesAlberto Rivas CidNo ratings yet

- Handbook On Standardization of Infrastructural Facilities For Maintenance of ART ARME 140T CraneDocument12 pagesHandbook On Standardization of Infrastructural Facilities For Maintenance of ART ARME 140T CraneSaptarshi PalNo ratings yet

- Z - Sari@mail - Univ-Tlemcen - DZ: E E E E V E V E L, H, D M M NDocument21 pagesZ - Sari@mail - Univ-Tlemcen - DZ: E E E E V E V E L, H, D M M NSuvin NambiarNo ratings yet

- Scarpa - LNG TErminal AssessmentDocument11 pagesScarpa - LNG TErminal Assessmentyan energia100% (1)

- Modern Logistics: Case Study On JSW Crm2 Total Automatic Yms and AsrsDocument19 pagesModern Logistics: Case Study On JSW Crm2 Total Automatic Yms and Asrsakashkr619No ratings yet

- Main Group 3 Equipment For CargoDocument13 pagesMain Group 3 Equipment For CargoVladi GasperNo ratings yet

- 80 Ton AHTS Specification Rev 0Document81 pages80 Ton AHTS Specification Rev 0Mark Samsel RohanNo ratings yet

- Expressor CompressorDocument81 pagesExpressor Compressormep.No ratings yet

- Aerodrome Data, Physical Characteristics and Obstacle RestrictionDocument19 pagesAerodrome Data, Physical Characteristics and Obstacle RestrictionElakkiya Karthic100% (1)

- Load Estimation For Airport ProjectDocument9 pagesLoad Estimation For Airport ProjectAisha GamalNo ratings yet

- Unit 4 Automated Storage/Retrieval Systems: StructureDocument11 pagesUnit 4 Automated Storage/Retrieval Systems: StructureRuby SmithNo ratings yet

- A330 Normal Law: Putting Fly-by-Wire Into PerspectiveFrom EverandA330 Normal Law: Putting Fly-by-Wire Into PerspectiveRating: 5 out of 5 stars5/5 (2)

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- EE201 Circuits N NetworksDocument2 pagesEE201 Circuits N NetworksArya ANo ratings yet

- Electrical Distribution Systems - Unit - V - Voltage ControlDocument20 pagesElectrical Distribution Systems - Unit - V - Voltage ControlSatishdhora SiddanaNo ratings yet

- Chem Lec Module 2 NotesDocument20 pagesChem Lec Module 2 NotesPinuela, Kristine AngeliqueNo ratings yet

- 464 HW 3 Due 14 FebDocument14 pages464 HW 3 Due 14 FebBook MitreevejNo ratings yet

- Final Report of AntennaDocument4 pagesFinal Report of AntennaAmir Al-ashtalNo ratings yet

- 01 Intro To HarmonyDocument16 pages01 Intro To Harmonyvikas kunduNo ratings yet

- Cutting Mechanics of The Gear Shaping Process: by Andrew KatzDocument137 pagesCutting Mechanics of The Gear Shaping Process: by Andrew KatzM MADYAN HAMDINo ratings yet

- General Organic and Biological Chemistry 7Th Edition Stoker Solutions Manual Full Chapter PDFDocument18 pagesGeneral Organic and Biological Chemistry 7Th Edition Stoker Solutions Manual Full Chapter PDFallison.young656100% (19)

- 01 CTS KIPS Schedule MDCAT, NUMS, SET (21-08-20)Document5 pages01 CTS KIPS Schedule MDCAT, NUMS, SET (21-08-20)Hanzala ShahidNo ratings yet

- PHYSICS21 Magnetic Field LinesDocument28 pagesPHYSICS21 Magnetic Field Linesapi-3805293100% (1)

- Used Water SES 5 Construction of Tunnels Ancillaries 2012Document28 pagesUsed Water SES 5 Construction of Tunnels Ancillaries 2012Mark BenjieNo ratings yet

- Ilovepdf MergedDocument69 pagesIlovepdf MergedZihad Khan HabibNo ratings yet

- Radioactivity Physics Lab AnswersDocument3 pagesRadioactivity Physics Lab AnswersAaliyah Senior100% (1)

- Hardening Soil ModelDocument4 pagesHardening Soil Modelprantik.ceNo ratings yet

- Construction and Building Materials: Bashar S. Mohammed, Musa AdamuDocument18 pagesConstruction and Building Materials: Bashar S. Mohammed, Musa AdamuMuaz Bin Ali ArafNo ratings yet

- LS1 - Analysis of Air-Conditioning Processes PDFDocument4 pagesLS1 - Analysis of Air-Conditioning Processes PDFdildin01No ratings yet

- Ficha Técnica Conectores de TornilloDocument6 pagesFicha Técnica Conectores de TornilloFernando Castillo HerreraNo ratings yet

- Scaffolding Megapal-Catalogue2021Document28 pagesScaffolding Megapal-Catalogue2021Hoang Cong DungNo ratings yet

- Alkene Structure and PreparationDocument2 pagesAlkene Structure and PreparationCarlo Jay BasulNo ratings yet

- TGADocument31 pagesTGABhuvnesh SharmaNo ratings yet

- SurgebinderDocument21 pagesSurgebinderdavid castillo riveraNo ratings yet

- Organometallic ChemistryDocument90 pagesOrganometallic Chemistrytharun thennarasuNo ratings yet

- NMRV enDocument336 pagesNMRV engbys456jqcNo ratings yet

- Bond Energy Calculations - QuestionsDocument6 pagesBond Energy Calculations - QuestionsernestasNo ratings yet

- A Technical Seminar On: Holographic Data StorageDocument12 pagesA Technical Seminar On: Holographic Data StorageNilkanta MondalNo ratings yet

- Tropismo - Psilocybe CubensisDocument6 pagesTropismo - Psilocybe CubensisLucas AntoniniNo ratings yet

- Grade 8 DLP (Science)Document6 pagesGrade 8 DLP (Science)Breeza Marie VeralloNo ratings yet

- Innstruct ManualDocument26 pagesInnstruct ManualOmer HayatNo ratings yet

- Messko Compact Temperature Measurement System For TransformersDocument6 pagesMessko Compact Temperature Measurement System For Transformersfarzad dalaviNo ratings yet