Professional Documents

Culture Documents

PDF Niticu

PDF Niticu

Uploaded by

Santu BhattacharyaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PDF Niticu

PDF Niticu

Uploaded by

Santu BhattacharyaCopyright:

Available Formats

NiTiCu Property Study And Its Advantages Over NiTi Alloy

Difficulties :Incorporation of NiTi thin films could not be incorporated in microelectrochemical systems because they have large deformation and recovery forces. Since they are shape memory alloys they show cute compositional sensitivity that means that a small in compositional shift causes a large transformation temperature change. The above problem can be solved by substituting copper (<25 at%) for nickel in NiTi significantly which reduces compositional sensitivity.

Comparitive study of crystallisation tempature:For comparison NiTi samples with same amount of Ti(50.4%) since copper substitutes for Ni. With 1m deposited on silicon wafers both NiTiCu and NiTi films were tested to 550c at the rates of 50,20and 10 c/min using differential scanning calorimetry. The following graph is obtained:

The schematic drawn graph shows crystallisation temperatures and overall activation energy of NiTi and NiTiCu thin films under different heating rates with pek crystallisation temperature indicated.

Pictures obtained from TEM :

However results obtained from TEM are markedly different and contradicting for that obtained from DSC technique.This is because of the fact shown at various stages of crystallisation (1,30,100%) for isothermal anneals at 480,500,520 degree celcius.

Study of the nucleation rate:

1) NiTi crystallised polymorphically with nucleation occuring rapidly and continuously. ( 0.8 1.6 micro meters) 2) NiTiCu thin film crystallize with fewer nuclei that produce a small number of crystals ( 5- 8 micro meters).

Time Duration:NiTi 475O C 495O C 515O C NiTiCu 480OC 500OC 520OC

210SECS 107SECS 11SECS

800SECS 280SECS 31SECS

Activation energy measurement by lissinger method :-

=heating rate C = constant TP= crystallization peak temperature

Hot tensile properties of as cast NiTi and NiTiCu shape memory alloys were investigated by hot tensile test at temperature range of 700-1100 C using the strain rate of 0.1 s1. The NiTi alloy exhibited a maximum hot ductility at temperature range of 750-1000C, while the NiTiCu alloy showed it at temperature range of 800-10000C. It was found that at temperatures less than 750C, diffusion-assisted deformation mechanism was inactive leading to semi-brittle type of failure and limited ductility in both alloys. Also it was found that at temperature range of 800-1000C, dynamic

recrystallization is dominant leading to high ductility. Likewise, the fracture surface of the specimens presenting the maximum hot ductility showed an ideal type of ductile rupture in which they gradually pulled out to a fine point. On the other hand, the decline in ductility occurred at the temperatures above 1000 C was attributed to the liquid phase formation leading to inter-dendritic and inter-granular type of fracture

Thermal efficiencies of NiTiCu shape memory alloys:Thermal efficiencies were calculated based on an ideal shape-memory-effect heat-engine cycle. It was found that the addition of copper in the NiTi shapememory alloy provides an important increase of the thermal efficiency with the highest temperature transformation range. Thermal efficiency values obtained range from 4.7 to 5.3% and Carnot efficiencies were around 25%. These efficiencies have been evaluated by means of calorimetric techniques and mechanical tests for five NiTiCu shape-memory alloys.

Materials used and experimental data:

Five polycrystalline NiTiCu alloys were investigated with chemical compositions shown in Table 1. Table 1. Chemical compositions in weight percentage for the different alloys studied

For the calorimetric studies, cylindrical test samples 5 mm in diameter, 2 mm high and weighing 400 mg. were submitted to heat treatment (850C for 10 min and, subsequently, quenched in water at room temperature). The calorimetric measurements were performed twenty-four hours after the heat treatment. The flow calorimeter used is a highly sensitive model with differential signal detectors made up of 32 thermocouples, the working range of which is from 150 to 100C. The temperature was measured by the standard Pt-100 probe. All signals were digitised by a multichannel analyser and treated by a computer. The heating and cooling rates were 1C/min. The uncertainty of the

enthalpy and entropy variations is 5% and 0.5K in temperature values. The transformation temperatures are taken to be the moment at which a sudden rise in the calorimetric curve takes place and when the signal returns to the base line. The heat absorbed or expelled in the transformation is determined by calculating the area within the curve. The mechanical tests were carried out 24h after the heat treatment using an MTSAdamel machine at different temperatures (10, 20, 30, 40, 50 and 70C). The cross-head speed was 1mm/s. A submersible extensometer was used in the tensile tests.

Experimental values and discusiions on it:-

Table 3. Transformation temperatures determined by calorimetry and by extrapolating the linear equation to the origin, in K

Table 4. Equilibrium temperatures and enthapies associated with SIM transformation

The addition of Cu (56% in weight percentage) in NiTi produced an increase in

the thermal and the Carnot efficiencies. Small changes of the chemical composition of NiTiCu alloys did not affect their martensitic tranformation characteristics in comparison with other shape-memory alloys. This stability produces an increase in the stability and reproducibility of the properties of these alloys producing an important improvement to design new shape-memory effect heat engines.

Conclusions:Higher growth rate for NiTiCu with low crystallization rate due to high interfacial energy between the amorphous and crystalline phases. The interfacial energy play a dominant role in the crystallisation of copper containing NiTi thin films This study helps us in understanding of SMA as tailoring materialsfor use in MEMs

You might also like

- 16MnCr5 PropertyDocument7 pages16MnCr5 PropertyGuru SamyNo ratings yet

- Thermo Cycles 2Document16 pagesThermo Cycles 2cobalt boronNo ratings yet

- Capdevila 2006 - Influence of Processing Parameters On The RX Microstructure of Extra-LC SteelsDocument10 pagesCapdevila 2006 - Influence of Processing Parameters On The RX Microstructure of Extra-LC SteelsElliot AmadiNo ratings yet

- Title: Effects of Thermo-Mechanical Processing On The Microstructure and Mechanical Properties of NB Micro-Alloyed SteelDocument15 pagesTitle: Effects of Thermo-Mechanical Processing On The Microstructure and Mechanical Properties of NB Micro-Alloyed SteelAshutosh GautamNo ratings yet

- Two Step SinteringDocument4 pagesTwo Step Sinteringrajadasari5682No ratings yet

- Ni Ti - Precipitation During Aging of Niti Shape Memory Alloys and Its Influence On Martensitic Phase TransformationsDocument20 pagesNi Ti - Precipitation During Aging of Niti Shape Memory Alloys and Its Influence On Martensitic Phase Transformationsali mirzaeiNo ratings yet

- Sintering of Silica-Nickel NanocompositesDocument5 pagesSintering of Silica-Nickel NanocompositesInternational Journal of Research in Engineering and ScienceNo ratings yet

- 1 s2.0 S0921452699001866 MainDocument9 pages1 s2.0 S0921452699001866 MainJajsjshshhsNo ratings yet

- MTIPROFEDocument9 pagesMTIPROFEMar Cerda SilvaNo ratings yet

- Evaluation of The Austenite Recrystallization by Multideformation and DoubleDocument10 pagesEvaluation of The Austenite Recrystallization by Multideformation and DoubleJoselo HRNo ratings yet

- 1 s2.0 S2238785421006712 MainDocument8 pages1 s2.0 S2238785421006712 MainSwaminathan GNo ratings yet

- BaTiO3 Ceramica ArtigoDocument7 pagesBaTiO3 Ceramica ArtigoLays de AraújoNo ratings yet

- DR Paper 1Document15 pagesDR Paper 1Malik Al TurkiNo ratings yet

- The Effect of Microstructure On Tensile Behaviour of X80 Microalloyed SteelDocument7 pagesThe Effect of Microstructure On Tensile Behaviour of X80 Microalloyed SteelMarcelo Varejão CasarinNo ratings yet

- 1 s2.0 S0025540820315373 MainDocument11 pages1 s2.0 S0025540820315373 Mainswaminathan G.No ratings yet

- Grain Size Effect On Structural, Electrical and Mechanical Properties of NiTi Thin FilmsDocument8 pagesGrain Size Effect On Structural, Electrical and Mechanical Properties of NiTi Thin Filmsehagar60No ratings yet

- Detremination of CCT Diagrams by Thermal Anal of HSLA Bainitic Submitet To Thermomech TreatDocument5 pagesDetremination of CCT Diagrams by Thermal Anal of HSLA Bainitic Submitet To Thermomech TreatLjubica MilovicNo ratings yet

- Unit IIIDocument8 pagesUnit IIIPrashant NandanNo ratings yet

- Differential Scanning Calorimetry Response of Aged NiTiHfPd Shape Memory Alloysapplied Physics A Materials Science and ProcessingDocument6 pagesDifferential Scanning Calorimetry Response of Aged NiTiHfPd Shape Memory Alloysapplied Physics A Materials Science and Processingswaminathan G.No ratings yet

- 2 - Fabrication and Photocatalytic Activity of TiO2 Nano Ber Membrane 2009Document3 pages2 - Fabrication and Photocatalytic Activity of TiO2 Nano Ber Membrane 2009Yavuz GençNo ratings yet

- Nanotechnology Materials For Heat Sink: Nathan Otundo OnsareDocument12 pagesNanotechnology Materials For Heat Sink: Nathan Otundo OnsareOtundo OnsareNo ratings yet

- Reformer Furnaces - Material, Damage Mechanism and AssessmentDocument21 pagesReformer Furnaces - Material, Damage Mechanism and AssessmentMuhammad Noor FadhliNo ratings yet

- 1 s2.0 S0925838817338227 MainDocument11 pages1 s2.0 S0925838817338227 MainAli UzunNo ratings yet

- Nanoscale, Phonon-Coupled Calorimetry With Sub-Attojoule/Kelvin ResolutionDocument4 pagesNanoscale, Phonon-Coupled Calorimetry With Sub-Attojoule/Kelvin ResolutionemediageNo ratings yet

- Effect of The Fe Substitution in Ti-Ni Shape Memory AlloysDocument14 pagesEffect of The Fe Substitution in Ti-Ni Shape Memory AlloysSreekumar RajendrababuNo ratings yet

- Iron Ore Characterisation During High Temperature Thermal ProcessingDocument14 pagesIron Ore Characterisation During High Temperature Thermal ProcessingKrol PrietoNo ratings yet

- Ramesh Singh - NACE MP - December 2009 - MP - Hydrocarbon Reformer TubesDocument5 pagesRamesh Singh - NACE MP - December 2009 - MP - Hydrocarbon Reformer TubesAntonio PerezNo ratings yet

- Exp 1 Fourier's LawDocument11 pagesExp 1 Fourier's LawLukman Benzo100% (1)

- Paper JMRT 2015 - Rev01Document8 pagesPaper JMRT 2015 - Rev01jose laraNo ratings yet

- Materials 13 04256Document13 pagesMaterials 13 04256İlknur KaraNo ratings yet

- ManuscriptDocument17 pagesManuscriptEidelsayedNo ratings yet

- PhysicsDocument5 pagesPhysicsAditya Budi FauziNo ratings yet

- Applied Thermal Engineering: C.J. Ho, L.C. Wei, Z.W. LiDocument8 pagesApplied Thermal Engineering: C.J. Ho, L.C. Wei, Z.W. LireasercherNo ratings yet

- JP 54 3 1087Document4 pagesJP 54 3 1087Fabian MelinaoNo ratings yet

- Heat Setting of Oriented Poly (Ethylene Terephthalate) Effects of Deformation Mode, Strain Level, and Heating MediumDocument15 pagesHeat Setting of Oriented Poly (Ethylene Terephthalate) Effects of Deformation Mode, Strain Level, and Heating Mediumapi-3733260No ratings yet

- Combustion of Spanish Coals Under Simulated Pressurized - Uidized-Bed-Combustion ConditionsDocument6 pagesCombustion of Spanish Coals Under Simulated Pressurized - Uidized-Bed-Combustion Conditionsphemt84No ratings yet

- Multiple Cycle MartensiteDocument8 pagesMultiple Cycle MartensitePracheeGuptaNo ratings yet

- 1 s2.0 S0924013607005341 MainDocument6 pages1 s2.0 S0924013607005341 Mainswaminathan G.No ratings yet

- Siemens 1 GTX 100 TurbineDocument16 pagesSiemens 1 GTX 100 Turbinejparmar100% (1)

- Effect of Co Laser On Some Properties of Ni TI CU Shape Memory AlloyDocument11 pagesEffect of Co Laser On Some Properties of Ni TI CU Shape Memory AlloyTJPRC PublicationsNo ratings yet

- Calibration of Radiation Thermometry FixDocument11 pagesCalibration of Radiation Thermometry FixAufaGuenevereNo ratings yet

- Journal of Alloys and Compounds: Rapolu Sridhar, D. Ravinder, K. Vijaya KumarDocument7 pagesJournal of Alloys and Compounds: Rapolu Sridhar, D. Ravinder, K. Vijaya KumarHuckkey HuNo ratings yet

- Thermal ExpansionDocument16 pagesThermal ExpansionParlin Febrianto SianiparNo ratings yet

- v1 StampedDocument23 pagesv1 StampedChiheb BaNo ratings yet

- Lagging Temperature Problem in DTADSC MeasurementDocument9 pagesLagging Temperature Problem in DTADSC Measurementswaminathan G.No ratings yet

- Internal Stress in A Cured Epoxy Resin System: C. Brahatheeswaran and V. B. GuptaDocument6 pagesInternal Stress in A Cured Epoxy Resin System: C. Brahatheeswaran and V. B. GuptasasidharkanthetiNo ratings yet

- Thin Film Resistance Thermometers On Silicon WafersDocument18 pagesThin Film Resistance Thermometers On Silicon WafersGuiyi YangNo ratings yet

- Re CrystallizationDocument5 pagesRe CrystallizationZubair AhmadNo ratings yet

- Chapter 2 TemperatureDocument22 pagesChapter 2 Temperaturetanzil10No ratings yet

- Influence of Warm-Working On Quality of AISI 1015 Carbon SteelDocument7 pagesInfluence of Warm-Working On Quality of AISI 1015 Carbon SteelRicho Firdaus TumanggorNo ratings yet

- Thermo-Mechanical Treatment of The C-MN Steel With NB, Ti, V and B MicroadditionsDocument4 pagesThermo-Mechanical Treatment of The C-MN Steel With NB, Ti, V and B MicroadditionsGaurav TripathiNo ratings yet

- Adhikary2021 Article DevelopmentOfNi44Ti35Zr15Cu6QuDocument8 pagesAdhikary2021 Article DevelopmentOfNi44Ti35Zr15Cu6QuSantosh SNo ratings yet

- Karakteristik Tembaga TemperaturDocument12 pagesKarakteristik Tembaga TemperaturdharmantoNo ratings yet

- Adiabatic and Semi-Adiabatic Calorimetry ToDocument14 pagesAdiabatic and Semi-Adiabatic Calorimetry TopedroNo ratings yet

- Transfer Hasan 2011 PDFDocument14 pagesTransfer Hasan 2011 PDFmalikaNo ratings yet

- A Microreactor For In-Situ Hydrogen Production by Catalytic Methanol ReformingDocument11 pagesA Microreactor For In-Situ Hydrogen Production by Catalytic Methanol ReformingramahtamahNo ratings yet

- Effect of Deformation On The Continuous Cooling Transformation (CCT) Diagram of Steel 32Crb4Document4 pagesEffect of Deformation On The Continuous Cooling Transformation (CCT) Diagram of Steel 32Crb4Najib RahmanNo ratings yet

- Thermal Conductivity and Stability of Paraffin Wax With Various Nanoparticles Without RevisionDocument30 pagesThermal Conductivity and Stability of Paraffin Wax With Various Nanoparticles Without Revisionvahit06No ratings yet

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Clean Energy Cost Savings STUDY OF CFEDocument27 pagesClean Energy Cost Savings STUDY OF CFEFrancisco EspañaNo ratings yet

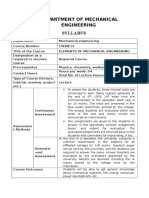

- SYLLABUSDocument6 pagesSYLLABUSSyedZameerNo ratings yet

- Vapour Power Cycles - 275Document53 pagesVapour Power Cycles - 275aditya yadavNo ratings yet

- Im 240 PEDocument62 pagesIm 240 PEHimanshu SharmaNo ratings yet

- EET 222 Exam Questions, Sem 2, 2017-18 Session (Final)Document3 pagesEET 222 Exam Questions, Sem 2, 2017-18 Session (Final)Dominic JosephNo ratings yet

- Farm Power and Energy QuestionsDocument6 pagesFarm Power and Energy QuestionsAlejandrino PascuaNo ratings yet

- VHP Phase 2Document167 pagesVHP Phase 2nathaniel villanuevaNo ratings yet

- ME6404 Thermal EngineeringDocument21 pagesME6404 Thermal EngineeringAnonymous mRBbdopMKfNo ratings yet

- Chapter 10 Vapor and Combined Power CyclesDocument29 pagesChapter 10 Vapor and Combined Power Cyclesnamsun100% (1)

- Cat 2Document67 pagesCat 2ChinmayNo ratings yet

- Sheet 1: Review On Thermodynamics: A Energy, Energy Transfer, and General Energy AnalysisDocument8 pagesSheet 1: Review On Thermodynamics: A Energy, Energy Transfer, and General Energy AnalysisAbdelaziz TamimNo ratings yet

- Chapter 2 - Basics of ThermodynamicsDocument52 pagesChapter 2 - Basics of ThermodynamicsQuốc Huy HoàngNo ratings yet

- A Fall 2018 Pet & Agric Eng Thermodynamics Exam I I Che 304 Che 212 Fall SolutionDocument3 pagesA Fall 2018 Pet & Agric Eng Thermodynamics Exam I I Che 304 Che 212 Fall SolutionfalmubaddelNo ratings yet

- 3.internal Combustion Engine-1-10Document10 pages3.internal Combustion Engine-1-10Aqsa KanwalNo ratings yet

- Supplementary ProblemsDocument18 pagesSupplementary ProblemsVon A. DamirezNo ratings yet

- Thermodynamics of Fuel Cells: 2.2.1 Electrochemical AspectsDocument13 pagesThermodynamics of Fuel Cells: 2.2.1 Electrochemical AspectsKemas FarosiNo ratings yet

- Gas Turbines Worked Out ExamplesDocument33 pagesGas Turbines Worked Out ExamplesShankarMukherjee100% (1)

- Pipe CNS 03Document59 pagesPipe CNS 03maria katherine pantojaNo ratings yet

- ME Lab Experiment ReportDocument7 pagesME Lab Experiment ReportHowon LeeNo ratings yet

- Design and Rating of Fired HeatersDocument33 pagesDesign and Rating of Fired HeatersRishabh Jain100% (1)

- CimacDocument78 pagesCimactieideNo ratings yet

- ProblemsDocument13 pagesProblemsArgielJohn LlagasNo ratings yet

- WBT Data-Calculation Sheet 4.2.2Document54 pagesWBT Data-Calculation Sheet 4.2.2Tatiana Torrico CaprilesNo ratings yet

- Organic Rankine Cycle System For Waste Heat Recovery From Twin Cylinder Diesel Engine ExhaustDocument7 pagesOrganic Rankine Cycle System For Waste Heat Recovery From Twin Cylinder Diesel Engine ExhaustSabi SanthoshNo ratings yet

- Assignment 2 Second Law 2016Document7 pagesAssignment 2 Second Law 2016Mohit SInhaNo ratings yet

- Lesson 6 Slides - The Rankine Power Cycle PDFDocument18 pagesLesson 6 Slides - The Rankine Power Cycle PDFPheza AndrewNo ratings yet

- Chapter 5 (2nd Law of ... )Document64 pagesChapter 5 (2nd Law of ... )yohannes lemiNo ratings yet

- Answer Problem Sheet-05 Me201 2nd LawDocument9 pagesAnswer Problem Sheet-05 Me201 2nd LawshantanuNo ratings yet

- First Law of Thermodynamics For A Control MassDocument51 pagesFirst Law of Thermodynamics For A Control MassTushyNo ratings yet