Professional Documents

Culture Documents

GGB DU Metal Polymer Anti Friction Plain Bearings Datasheet

GGB DU Metal Polymer Anti Friction Plain Bearings Datasheet

Uploaded by

michael KetselaCopyright:

Available Formats

You might also like

- Case-Study 123Document4 pagesCase-Study 123Rei MarkNo ratings yet

- Tokheim V12 Cold Start ProcedureDocument1 pageTokheim V12 Cold Start Proceduremichael Ketsela67% (3)

- Tokheim V12 Cold Start ProcedureDocument1 pageTokheim V12 Cold Start Proceduremichael Ketsela67% (3)

- QuadFoam 500 - Installation Guide - June 2014Document9 pagesQuadFoam 500 - Installation Guide - June 2014Jorge CordobaNo ratings yet

- Troubleshooting Guide For The HydraulicDocument5 pagesTroubleshooting Guide For The Hydraulicweldsaidi100% (1)

- Walkersele D6 DatasheetDocument3 pagesWalkersele D6 DatasheetNabeel MohammedNo ratings yet

- Roto-Glyd-ring CatalogueDocument34 pagesRoto-Glyd-ring CatalogueMuthukumar RadhakrishnanNo ratings yet

- DANAIS MT II CL 300 ENDocument30 pagesDANAIS MT II CL 300 ENLasombra DelPatoNo ratings yet

- GB 2H Fills For Cross Flow CTDocument2 pagesGB 2H Fills For Cross Flow CTShahab Z AhmedNo ratings yet

- Shell Gadus S2 OG 85Document2 pagesShell Gadus S2 OG 85Anonymous oAbjbl4HNo ratings yet

- Gadus S2 OG 85Document2 pagesGadus S2 OG 85Rafael MonteiroNo ratings yet

- Trellebrog Roto Glyd RingDocument18 pagesTrellebrog Roto Glyd RingMohamedNo ratings yet

- PDS Shell GadusDocument2 pagesPDS Shell GadusTaufik BinasrNo ratings yet

- Cojinete Acero - GGB-SHB-Case-Hardened-Steel-Bearings-DatasheetDocument2 pagesCojinete Acero - GGB-SHB-Case-Hardened-Steel-Bearings-DatasheetneodymioNo ratings yet

- Basf-Ucrete Ud 200 - TdsDocument3 pagesBasf-Ucrete Ud 200 - TdsAbdul ZailaniNo ratings yet

- GGB BP25 Metafram Oil Impregnated Sintered Bronze Bearings DatasheetDocument2 pagesGGB BP25 Metafram Oil Impregnated Sintered Bronze Bearings DatasheetDominik WojtasNo ratings yet

- Shell Gadus S2 OG 40: Performance, Features & BenefitsDocument2 pagesShell Gadus S2 OG 40: Performance, Features & BenefitsAmanNo ratings yet

- Universal 1-Component Polyurethane Joint Sealant: DescriptionDocument2 pagesUniversal 1-Component Polyurethane Joint Sealant: DescriptionAkram ShaikhNo ratings yet

- Ramax Hh-Eng P 1604 E6Document8 pagesRamax Hh-Eng P 1604 E6venkithankamNo ratings yet

- Rotary Metallurgical MaterialsDocument4 pagesRotary Metallurgical MaterialsNabeel MohammedNo ratings yet

- Sikadur-42 MP Normal HCDocument6 pagesSikadur-42 MP Normal HCDidiet PuteraNo ratings yet

- Matrox X TDS PDFDocument1 pageMatrox X TDS PDFrajanarenderNo ratings yet

- Sikasil 728 SLDocument5 pagesSikasil 728 SLJesusFloresRodriguezNo ratings yet

- TI FURADUR DBK 323 enDocument5 pagesTI FURADUR DBK 323 endris.elmouteaNo ratings yet

- NANOVEA T100 Tribometer BrochureDocument15 pagesNANOVEA T100 Tribometer BrochurelxzjmailNo ratings yet

- IntercambiadorDocument2 pagesIntercambiadorIr Go JarNo ratings yet

- 18 Vetogrout EG340 - 180321Document2 pages18 Vetogrout EG340 - 180321Maha MuflehNo ratings yet

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- PDS - H2Ri - tcm29-17001 PDFDocument2 pagesPDS - H2Ri - tcm29-17001 PDFJean Paul Et La PetiteNo ratings yet

- Sikadur®-42 MP Slow - PDSDocument7 pagesSikadur®-42 MP Slow - PDSkamran abbasiNo ratings yet

- Flowcrete Asia Mondéco Crystal May2020 TdsDocument2 pagesFlowcrete Asia Mondéco Crystal May2020 TdsQuoc AnNo ratings yet

- Cepsa Fundicol Hfu: Lubricants For Industrial UseDocument1 pageCepsa Fundicol Hfu: Lubricants For Industrial UseVladislav TrempoletsNo ratings yet

- Tec 302 HF (UAE) : Highly Fluid Expansive Bedding GroutDocument3 pagesTec 302 HF (UAE) : Highly Fluid Expansive Bedding Groutmanikandan4strlNo ratings yet

- Hallite RDS DatasheetDocument7 pagesHallite RDS DatasheetTHAI PHINo ratings yet

- Matrox TDS PDFDocument1 pageMatrox TDS PDFrajanarenderNo ratings yet

- BreakerLub-F (EN - Nov'13)Document2 pagesBreakerLub-F (EN - Nov'13)dmb1692No ratings yet

- Molyduval Long-Life LM 2 P: Heavy Duty GreaseDocument1 pageMolyduval Long-Life LM 2 P: Heavy Duty GreaseGabriel NogueiraNo ratings yet

- Anabond 666t Max Gasket SealantDocument3 pagesAnabond 666t Max Gasket SealantDinesh SaravanaNo ratings yet

- IOCL Steel Conference 070618Document31 pagesIOCL Steel Conference 070618prasad24488No ratings yet

- Sikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemDocument5 pagesSikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemJay PadamaNo ratings yet

- FRCM-PBO Technical Dta Sheet PDFDocument20 pagesFRCM-PBO Technical Dta Sheet PDFHector RamosNo ratings yet

- DEUBLIN Multi Passage Soft SealDocument8 pagesDEUBLIN Multi Passage Soft SealLeonardo AlexNo ratings yet

- 220 MFD MFCK 00001 PDFDocument3 pages220 MFD MFCK 00001 PDFJulio Miranda AlarconNo ratings yet

- Matrox U110 TDS PDFDocument1 pageMatrox U110 TDS PDFrajanarenderNo ratings yet

- EagleBurgmann Pipeline & Process Equipment GasketDocument28 pagesEagleBurgmann Pipeline & Process Equipment GasketЮляNo ratings yet

- Technical Data Sheet: Silcoset 151 1 Part Adhesive SealantDocument2 pagesTechnical Data Sheet: Silcoset 151 1 Part Adhesive SealantArun VaideeswaranNo ratings yet

- AGEPAN OSB 4 PUR Technical Data SheetDocument2 pagesAGEPAN OSB 4 PUR Technical Data SheetDore EmilNo ratings yet

- Sika Nigeria - Sikadur 42 MP Slow v1Document7 pagesSika Nigeria - Sikadur 42 MP Slow v1willy iremNo ratings yet

- Performance Thickness Ratio at Its BestDocument2 pagesPerformance Thickness Ratio at Its BestmshNo ratings yet

- Rinol Crete Heavy DutyDocument2 pagesRinol Crete Heavy DutyIgor DzuklevskiNo ratings yet

- Poly Gear PG en PDFDocument2 pagesPoly Gear PG en PDFAlfredo CarlosNo ratings yet

- 12628108.GORE SMT EMI Gasket Supersoft Data SheetDocument2 pages12628108.GORE SMT EMI Gasket Supersoft Data SheetCADTDDNo ratings yet

- Super Udt: Specifications and ApprovalsDocument1 pageSuper Udt: Specifications and ApprovalsMichaelNo ratings yet

- EN350490 - 1810 2810 BrochureDocument8 pagesEN350490 - 1810 2810 Brochuresf wNo ratings yet

- Rubia Fleet HD 400 15W 40Document2 pagesRubia Fleet HD 400 15W 40سالم دريديNo ratings yet

- Sikadur Combiflex SG System Pds enDocument3 pagesSikadur Combiflex SG System Pds entry gdriveNo ratings yet

- Total Quartz 5000 SN 10W-40 15W-40 15W-50 20W50: Key DataDocument2 pagesTotal Quartz 5000 SN 10W-40 15W-40 15W-50 20W50: Key DataAwais A.No ratings yet

- TDS Total Rubia-Sx-40 G6e 202011 en CanDocument2 pagesTDS Total Rubia-Sx-40 G6e 202011 en CanRobert Isac0% (1)

- Gear Compound Plus Iso - 68 - enDocument1 pageGear Compound Plus Iso - 68 - enSedin MurtićNo ratings yet

- Gear Compound Plus Iso - 68 - enDocument1 pageGear Compound Plus Iso - 68 - enSedin MurtićNo ratings yet

- Datasheet SaphirAF 2016 EN v1Document2 pagesDatasheet SaphirAF 2016 EN v1André CardosoNo ratings yet

- Total Quartz 7000 10W 40 PDFDocument2 pagesTotal Quartz 7000 10W 40 PDFdnoaisapsNo ratings yet

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldFrom EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldRating: 3 out of 5 stars3/5 (2)

- 058 0030Document2 pages058 0030michael KetselaNo ratings yet

- 017 0294Document1 page017 0294michael KetselaNo ratings yet

- Harmony XVB - XVBC2B3Document4 pagesHarmony XVB - XVBC2B3michael KetselaNo ratings yet

- 020 0083Document1 page020 0083michael KetselaNo ratings yet

- Trelleborg MH TechnicalManual enDocument64 pagesTrelleborg MH TechnicalManual enmichael KetselaNo ratings yet

- 015 0059Document1 page015 0059michael KetselaNo ratings yet

- Master Thesis S BuysseDocument141 pagesMaster Thesis S Buyssemichael KetselaNo ratings yet

- XP1000 en LR 22Document12 pagesXP1000 en LR 22michael KetselaNo ratings yet

- TIAVS RA MountingDocument3 pagesTIAVS RA Mountingmichael Ketsela100% (1)

- Product Datasheet: LUMILUX T8 - Tubular Fluorescent Lamps 26 MM, With G13 BasesDocument8 pagesProduct Datasheet: LUMILUX T8 - Tubular Fluorescent Lamps 26 MM, With G13 Basesmichael KetselaNo ratings yet

- Numerical IntegrationDocument28 pagesNumerical Integrationmichael KetselaNo ratings yet

- Fem FormulationDocument14 pagesFem Formulationmichael KetselaNo ratings yet

- 1 Mathematical Modeling of Physical SystemsDocument18 pages1 Mathematical Modeling of Physical Systemsmichael KetselaNo ratings yet

- On 1D Heat TransferDocument22 pagesOn 1D Heat Transfermichael KetselaNo ratings yet

- MA26 Meter & MP-T1 Pulser: Document Ref 903158-001 Rev - 1 10/2001Document28 pagesMA26 Meter & MP-T1 Pulser: Document Ref 903158-001 Rev - 1 10/2001michael KetselaNo ratings yet

- Fire Suppression: Afrox FS125 - The Fi Re Suppression SolutionDocument4 pagesFire Suppression: Afrox FS125 - The Fi Re Suppression Solutionmichael KetselaNo ratings yet

- Worked Examples Ec2 Def080723Document120 pagesWorked Examples Ec2 Def080723dan_ospir67% (3)

- DEP 00 00 10 05 GenDocument198 pagesDEP 00 00 10 05 GenTochukwu Onuoha100% (1)

- Composite BeamsDocument16 pagesComposite BeamsNoureddine SemaraNo ratings yet

- Mineral Wool Pipe Insulation DatasheetDocument2 pagesMineral Wool Pipe Insulation DatasheetDenny Akbar Nur Hadyansyah100% (1)

- 221 ElectricalDocument1 page221 ElectricalAbhishek ChappaNo ratings yet

- Manual For Design & Construction Monitoring of Soil Nail WallsDocument45 pagesManual For Design & Construction Monitoring of Soil Nail Wallsmohmisa100% (1)

- Door Schedule Format - Corporate Interior Fitout WorksDocument1 pageDoor Schedule Format - Corporate Interior Fitout WorksDeepa Junnarkar DegwekarNo ratings yet

- The Canadian LRFD Standard For Cold Formed Steel DesignDocument27 pagesThe Canadian LRFD Standard For Cold Formed Steel DesignHadeer MohamedNo ratings yet

- Iare DSSD Lecture Notes-ModifiedDocument124 pagesIare DSSD Lecture Notes-ModifiedDPJAIN INFRASTRUCTURENo ratings yet

- Seismic Load: Prepared By: Placio, Princess AngelDocument21 pagesSeismic Load: Prepared By: Placio, Princess AngelRuf FethNo ratings yet

- Cut and Fill MethodDocument26 pagesCut and Fill MethodANSHUL YADAVNo ratings yet

- Mastclimber Brochure - London - 2014Document28 pagesMastclimber Brochure - London - 2014Abdelrahman ElkhollyNo ratings yet

- Prediction of Fatigue Failure in A Camshaft Using The Crack MethodDocument9 pagesPrediction of Fatigue Failure in A Camshaft Using The Crack MethodDiego PovedaNo ratings yet

- Welcome: Highway Engineering Code No. (CM 304)Document16 pagesWelcome: Highway Engineering Code No. (CM 304)narasimhanNo ratings yet

- Daikin BQSG 71 DDocument1 pageDaikin BQSG 71 DmiroNo ratings yet

- Heat Shrinkable Closures System, Jointing Kits and Cable Repair Sleeves From China Manufacturer and SupplierDocument16 pagesHeat Shrinkable Closures System, Jointing Kits and Cable Repair Sleeves From China Manufacturer and SupplierAlanNo ratings yet

- Pipe Schedule ChartDocument1 pagePipe Schedule ChartrohimNo ratings yet

- Settlement of FoundationsDocument18 pagesSettlement of FoundationsIan Seguritan100% (1)

- Introduction To The New Rule of Measurement1Document23 pagesIntroduction To The New Rule of Measurement1LiewKianHongNo ratings yet

- Check Valve CV04-20Document2 pagesCheck Valve CV04-20tungNo ratings yet

- Tabla de Equivalencias Pulgadas DiametralesDocument7 pagesTabla de Equivalencias Pulgadas DiametralesGabriela Zarraga AguileraNo ratings yet

- ST 18Document40 pagesST 18peter wongNo ratings yet

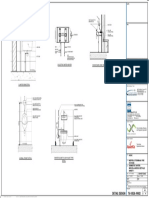

- W002 76-10526-Detail Design: 2-Electric Water Heater 3-Wash Basin (Side) DetailDocument1 pageW002 76-10526-Detail Design: 2-Electric Water Heater 3-Wash Basin (Side) DetailMazen IsmailNo ratings yet

- RE Wall For Tara Tarini Temple in Ganjam DistrictDocument58 pagesRE Wall For Tara Tarini Temple in Ganjam Districtpratima padhy100% (1)

- Industrial ApplicationsDocument7 pagesIndustrial ApplicationsAnonymous M0tjyWNo ratings yet

- Assignment-Research 2-MJD-MALLARIDocument9 pagesAssignment-Research 2-MJD-MALLARIMark MallariNo ratings yet

- Raj RewalDocument24 pagesRaj RewalRadhika VijayNo ratings yet

GGB DU Metal Polymer Anti Friction Plain Bearings Datasheet

GGB DU Metal Polymer Anti Friction Plain Bearings Datasheet

Uploaded by

michael KetselaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GGB DU Metal Polymer Anti Friction Plain Bearings Datasheet

GGB DU Metal Polymer Anti Friction Plain Bearings Datasheet

Uploaded by

michael KetselaCopyright:

Available Formats

DU

® APPLICATIONS

Industrial – Aerospace, agricultural equipment,

construction equipment, food and beverage, material

handling equipment, forming machines: metal, plastic

and rubber; office equipment, medical and scientific

METAL-POLYMER ANTI-FRICTION equipment, packaging equipment, pneumatic and

PLAIN BEARINGS hydraulic cylinders, pumps and motors, railroad and

tramways, textile machinery, valves, etc.

CHARACTERISTICS

— DU self-lubricating bushings offer very good wear

and low friction performance over a wide range of

loads, speeds and temperatures in dry running

conditions

— Bushing material suitable for lubricated applications

— Anti-friction bearing suitable for linear, oscillating

and rotating movements

— Approved to standard FAR 25.853 and FAR 25.855 -

Federal Aviation Regulations – making it suitable for

interior aircraft applications

— Tested acc. to ASTM E595/ECSS-Q-ST-70-02C -

Outgassing properties of materials used in

Spacecraft equipment

— Approved to standard DIN EN 1797 and ISO 21010

(Cryogenic Vessels – Gas/Material Compatibility)

for piping, valves, fittings and other components in

both gaseous and liquid oxygen for up to maximum

temperature of 60°C and oxygen pressure of 25

bars - contact GGB for further details

AVAILABILITY

Bearing forms available in standard dimensions:

Cylindrical bushes, flanged bushes, thrust washers,

flanged washers, sliding plates

Metric bearings and imperial bushings made to

order: Standard bushing forms in special

dimensions, half-bushings, special shapes obtained

by stamping or deep drawing, customized bushing

designs

For questions and assistance, contact a GGB

engineer at: https://www.ggbearings.com/en/contact

DU® Data Sheet

REVISION: 002 - August, 2021 1

DU® DATASHEET

BEARING PROPERTIES UNITS VALUE

GENERAL

Static N/mm2 250

Maximum load, p

Dynamic N/mm2 140

Min °C - 200

Operating temperature

Max °C 280

Coefficient of linear Parallel to the surface 10-6/K 11

thermal expansion Normal to the surface 10-6/K 30

D RY

Maximum sliding speed, U m/s 2.5

Maximum pU factor N/mm 2 x m/s 1.8

Coefficient of friction, f 0.02 - 0.25*

O I L L U B R I C AT E D

Maximum sliding speed, U m/s 5.0

Maximum pU factor N/mm 2 x m/s 5.0

Coefficient of friction, f 0.02 - 0.12*

R E C O M M E N DAT I O N S

Dry μm 0.3 - 0.5

Shaft surface roughness, Ra

Lubricated μm ≤ 0.05 - 0.40*

Unhardened acceptable,

Shaft surface hardness HB > 200

improved bearing life

* Depending on operating conditions

OPERATING PERFORMANCE MICROSECTION

Dry Very Good

Sliding Layer

Oil lubricated Very Good

+ PTFE + Fillers

Grease lubricated Fair

Porous Bronze

Sinter

Water lubricated Fair

Process fluid lubricated Fair

Steel Backing

FOR SUPERIOR / LEAD-FREE PERFORMANCE

Dry DP4 / DP11

Oil lubricated DP4 / DP31

Grease lubricated DP4 / DX

Water lubricated DP4-B

Process fluid lubricated DP4 / DP31

GGB, an Enpro company

For additional product offerings visit:

https://www.ggbearings.com/en/our-products/metal-polymer-bearings/du

DU® Data Sheet

REVISION: 002 - August, 2021 2

You might also like

- Case-Study 123Document4 pagesCase-Study 123Rei MarkNo ratings yet

- Tokheim V12 Cold Start ProcedureDocument1 pageTokheim V12 Cold Start Proceduremichael Ketsela67% (3)

- Tokheim V12 Cold Start ProcedureDocument1 pageTokheim V12 Cold Start Proceduremichael Ketsela67% (3)

- QuadFoam 500 - Installation Guide - June 2014Document9 pagesQuadFoam 500 - Installation Guide - June 2014Jorge CordobaNo ratings yet

- Troubleshooting Guide For The HydraulicDocument5 pagesTroubleshooting Guide For The Hydraulicweldsaidi100% (1)

- Walkersele D6 DatasheetDocument3 pagesWalkersele D6 DatasheetNabeel MohammedNo ratings yet

- Roto-Glyd-ring CatalogueDocument34 pagesRoto-Glyd-ring CatalogueMuthukumar RadhakrishnanNo ratings yet

- DANAIS MT II CL 300 ENDocument30 pagesDANAIS MT II CL 300 ENLasombra DelPatoNo ratings yet

- GB 2H Fills For Cross Flow CTDocument2 pagesGB 2H Fills For Cross Flow CTShahab Z AhmedNo ratings yet

- Shell Gadus S2 OG 85Document2 pagesShell Gadus S2 OG 85Anonymous oAbjbl4HNo ratings yet

- Gadus S2 OG 85Document2 pagesGadus S2 OG 85Rafael MonteiroNo ratings yet

- Trellebrog Roto Glyd RingDocument18 pagesTrellebrog Roto Glyd RingMohamedNo ratings yet

- PDS Shell GadusDocument2 pagesPDS Shell GadusTaufik BinasrNo ratings yet

- Cojinete Acero - GGB-SHB-Case-Hardened-Steel-Bearings-DatasheetDocument2 pagesCojinete Acero - GGB-SHB-Case-Hardened-Steel-Bearings-DatasheetneodymioNo ratings yet

- Basf-Ucrete Ud 200 - TdsDocument3 pagesBasf-Ucrete Ud 200 - TdsAbdul ZailaniNo ratings yet

- GGB BP25 Metafram Oil Impregnated Sintered Bronze Bearings DatasheetDocument2 pagesGGB BP25 Metafram Oil Impregnated Sintered Bronze Bearings DatasheetDominik WojtasNo ratings yet

- Shell Gadus S2 OG 40: Performance, Features & BenefitsDocument2 pagesShell Gadus S2 OG 40: Performance, Features & BenefitsAmanNo ratings yet

- Universal 1-Component Polyurethane Joint Sealant: DescriptionDocument2 pagesUniversal 1-Component Polyurethane Joint Sealant: DescriptionAkram ShaikhNo ratings yet

- Ramax Hh-Eng P 1604 E6Document8 pagesRamax Hh-Eng P 1604 E6venkithankamNo ratings yet

- Rotary Metallurgical MaterialsDocument4 pagesRotary Metallurgical MaterialsNabeel MohammedNo ratings yet

- Sikadur-42 MP Normal HCDocument6 pagesSikadur-42 MP Normal HCDidiet PuteraNo ratings yet

- Matrox X TDS PDFDocument1 pageMatrox X TDS PDFrajanarenderNo ratings yet

- Sikasil 728 SLDocument5 pagesSikasil 728 SLJesusFloresRodriguezNo ratings yet

- TI FURADUR DBK 323 enDocument5 pagesTI FURADUR DBK 323 endris.elmouteaNo ratings yet

- NANOVEA T100 Tribometer BrochureDocument15 pagesNANOVEA T100 Tribometer BrochurelxzjmailNo ratings yet

- IntercambiadorDocument2 pagesIntercambiadorIr Go JarNo ratings yet

- 18 Vetogrout EG340 - 180321Document2 pages18 Vetogrout EG340 - 180321Maha MuflehNo ratings yet

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- PDS - H2Ri - tcm29-17001 PDFDocument2 pagesPDS - H2Ri - tcm29-17001 PDFJean Paul Et La PetiteNo ratings yet

- Sikadur®-42 MP Slow - PDSDocument7 pagesSikadur®-42 MP Slow - PDSkamran abbasiNo ratings yet

- Flowcrete Asia Mondéco Crystal May2020 TdsDocument2 pagesFlowcrete Asia Mondéco Crystal May2020 TdsQuoc AnNo ratings yet

- Cepsa Fundicol Hfu: Lubricants For Industrial UseDocument1 pageCepsa Fundicol Hfu: Lubricants For Industrial UseVladislav TrempoletsNo ratings yet

- Tec 302 HF (UAE) : Highly Fluid Expansive Bedding GroutDocument3 pagesTec 302 HF (UAE) : Highly Fluid Expansive Bedding Groutmanikandan4strlNo ratings yet

- Hallite RDS DatasheetDocument7 pagesHallite RDS DatasheetTHAI PHINo ratings yet

- Matrox TDS PDFDocument1 pageMatrox TDS PDFrajanarenderNo ratings yet

- BreakerLub-F (EN - Nov'13)Document2 pagesBreakerLub-F (EN - Nov'13)dmb1692No ratings yet

- Molyduval Long-Life LM 2 P: Heavy Duty GreaseDocument1 pageMolyduval Long-Life LM 2 P: Heavy Duty GreaseGabriel NogueiraNo ratings yet

- Anabond 666t Max Gasket SealantDocument3 pagesAnabond 666t Max Gasket SealantDinesh SaravanaNo ratings yet

- IOCL Steel Conference 070618Document31 pagesIOCL Steel Conference 070618prasad24488No ratings yet

- Sikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemDocument5 pagesSikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemJay PadamaNo ratings yet

- FRCM-PBO Technical Dta Sheet PDFDocument20 pagesFRCM-PBO Technical Dta Sheet PDFHector RamosNo ratings yet

- DEUBLIN Multi Passage Soft SealDocument8 pagesDEUBLIN Multi Passage Soft SealLeonardo AlexNo ratings yet

- 220 MFD MFCK 00001 PDFDocument3 pages220 MFD MFCK 00001 PDFJulio Miranda AlarconNo ratings yet

- Matrox U110 TDS PDFDocument1 pageMatrox U110 TDS PDFrajanarenderNo ratings yet

- EagleBurgmann Pipeline & Process Equipment GasketDocument28 pagesEagleBurgmann Pipeline & Process Equipment GasketЮляNo ratings yet

- Technical Data Sheet: Silcoset 151 1 Part Adhesive SealantDocument2 pagesTechnical Data Sheet: Silcoset 151 1 Part Adhesive SealantArun VaideeswaranNo ratings yet

- AGEPAN OSB 4 PUR Technical Data SheetDocument2 pagesAGEPAN OSB 4 PUR Technical Data SheetDore EmilNo ratings yet

- Sika Nigeria - Sikadur 42 MP Slow v1Document7 pagesSika Nigeria - Sikadur 42 MP Slow v1willy iremNo ratings yet

- Performance Thickness Ratio at Its BestDocument2 pagesPerformance Thickness Ratio at Its BestmshNo ratings yet

- Rinol Crete Heavy DutyDocument2 pagesRinol Crete Heavy DutyIgor DzuklevskiNo ratings yet

- Poly Gear PG en PDFDocument2 pagesPoly Gear PG en PDFAlfredo CarlosNo ratings yet

- 12628108.GORE SMT EMI Gasket Supersoft Data SheetDocument2 pages12628108.GORE SMT EMI Gasket Supersoft Data SheetCADTDDNo ratings yet

- Super Udt: Specifications and ApprovalsDocument1 pageSuper Udt: Specifications and ApprovalsMichaelNo ratings yet

- EN350490 - 1810 2810 BrochureDocument8 pagesEN350490 - 1810 2810 Brochuresf wNo ratings yet

- Rubia Fleet HD 400 15W 40Document2 pagesRubia Fleet HD 400 15W 40سالم دريديNo ratings yet

- Sikadur Combiflex SG System Pds enDocument3 pagesSikadur Combiflex SG System Pds entry gdriveNo ratings yet

- Total Quartz 5000 SN 10W-40 15W-40 15W-50 20W50: Key DataDocument2 pagesTotal Quartz 5000 SN 10W-40 15W-40 15W-50 20W50: Key DataAwais A.No ratings yet

- TDS Total Rubia-Sx-40 G6e 202011 en CanDocument2 pagesTDS Total Rubia-Sx-40 G6e 202011 en CanRobert Isac0% (1)

- Gear Compound Plus Iso - 68 - enDocument1 pageGear Compound Plus Iso - 68 - enSedin MurtićNo ratings yet

- Gear Compound Plus Iso - 68 - enDocument1 pageGear Compound Plus Iso - 68 - enSedin MurtićNo ratings yet

- Datasheet SaphirAF 2016 EN v1Document2 pagesDatasheet SaphirAF 2016 EN v1André CardosoNo ratings yet

- Total Quartz 7000 10W 40 PDFDocument2 pagesTotal Quartz 7000 10W 40 PDFdnoaisapsNo ratings yet

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldFrom EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldRating: 3 out of 5 stars3/5 (2)

- 058 0030Document2 pages058 0030michael KetselaNo ratings yet

- 017 0294Document1 page017 0294michael KetselaNo ratings yet

- Harmony XVB - XVBC2B3Document4 pagesHarmony XVB - XVBC2B3michael KetselaNo ratings yet

- 020 0083Document1 page020 0083michael KetselaNo ratings yet

- Trelleborg MH TechnicalManual enDocument64 pagesTrelleborg MH TechnicalManual enmichael KetselaNo ratings yet

- 015 0059Document1 page015 0059michael KetselaNo ratings yet

- Master Thesis S BuysseDocument141 pagesMaster Thesis S Buyssemichael KetselaNo ratings yet

- XP1000 en LR 22Document12 pagesXP1000 en LR 22michael KetselaNo ratings yet

- TIAVS RA MountingDocument3 pagesTIAVS RA Mountingmichael Ketsela100% (1)

- Product Datasheet: LUMILUX T8 - Tubular Fluorescent Lamps 26 MM, With G13 BasesDocument8 pagesProduct Datasheet: LUMILUX T8 - Tubular Fluorescent Lamps 26 MM, With G13 Basesmichael KetselaNo ratings yet

- Numerical IntegrationDocument28 pagesNumerical Integrationmichael KetselaNo ratings yet

- Fem FormulationDocument14 pagesFem Formulationmichael KetselaNo ratings yet

- 1 Mathematical Modeling of Physical SystemsDocument18 pages1 Mathematical Modeling of Physical Systemsmichael KetselaNo ratings yet

- On 1D Heat TransferDocument22 pagesOn 1D Heat Transfermichael KetselaNo ratings yet

- MA26 Meter & MP-T1 Pulser: Document Ref 903158-001 Rev - 1 10/2001Document28 pagesMA26 Meter & MP-T1 Pulser: Document Ref 903158-001 Rev - 1 10/2001michael KetselaNo ratings yet

- Fire Suppression: Afrox FS125 - The Fi Re Suppression SolutionDocument4 pagesFire Suppression: Afrox FS125 - The Fi Re Suppression Solutionmichael KetselaNo ratings yet

- Worked Examples Ec2 Def080723Document120 pagesWorked Examples Ec2 Def080723dan_ospir67% (3)

- DEP 00 00 10 05 GenDocument198 pagesDEP 00 00 10 05 GenTochukwu Onuoha100% (1)

- Composite BeamsDocument16 pagesComposite BeamsNoureddine SemaraNo ratings yet

- Mineral Wool Pipe Insulation DatasheetDocument2 pagesMineral Wool Pipe Insulation DatasheetDenny Akbar Nur Hadyansyah100% (1)

- 221 ElectricalDocument1 page221 ElectricalAbhishek ChappaNo ratings yet

- Manual For Design & Construction Monitoring of Soil Nail WallsDocument45 pagesManual For Design & Construction Monitoring of Soil Nail Wallsmohmisa100% (1)

- Door Schedule Format - Corporate Interior Fitout WorksDocument1 pageDoor Schedule Format - Corporate Interior Fitout WorksDeepa Junnarkar DegwekarNo ratings yet

- The Canadian LRFD Standard For Cold Formed Steel DesignDocument27 pagesThe Canadian LRFD Standard For Cold Formed Steel DesignHadeer MohamedNo ratings yet

- Iare DSSD Lecture Notes-ModifiedDocument124 pagesIare DSSD Lecture Notes-ModifiedDPJAIN INFRASTRUCTURENo ratings yet

- Seismic Load: Prepared By: Placio, Princess AngelDocument21 pagesSeismic Load: Prepared By: Placio, Princess AngelRuf FethNo ratings yet

- Cut and Fill MethodDocument26 pagesCut and Fill MethodANSHUL YADAVNo ratings yet

- Mastclimber Brochure - London - 2014Document28 pagesMastclimber Brochure - London - 2014Abdelrahman ElkhollyNo ratings yet

- Prediction of Fatigue Failure in A Camshaft Using The Crack MethodDocument9 pagesPrediction of Fatigue Failure in A Camshaft Using The Crack MethodDiego PovedaNo ratings yet

- Welcome: Highway Engineering Code No. (CM 304)Document16 pagesWelcome: Highway Engineering Code No. (CM 304)narasimhanNo ratings yet

- Daikin BQSG 71 DDocument1 pageDaikin BQSG 71 DmiroNo ratings yet

- Heat Shrinkable Closures System, Jointing Kits and Cable Repair Sleeves From China Manufacturer and SupplierDocument16 pagesHeat Shrinkable Closures System, Jointing Kits and Cable Repair Sleeves From China Manufacturer and SupplierAlanNo ratings yet

- Pipe Schedule ChartDocument1 pagePipe Schedule ChartrohimNo ratings yet

- Settlement of FoundationsDocument18 pagesSettlement of FoundationsIan Seguritan100% (1)

- Introduction To The New Rule of Measurement1Document23 pagesIntroduction To The New Rule of Measurement1LiewKianHongNo ratings yet

- Check Valve CV04-20Document2 pagesCheck Valve CV04-20tungNo ratings yet

- Tabla de Equivalencias Pulgadas DiametralesDocument7 pagesTabla de Equivalencias Pulgadas DiametralesGabriela Zarraga AguileraNo ratings yet

- ST 18Document40 pagesST 18peter wongNo ratings yet

- W002 76-10526-Detail Design: 2-Electric Water Heater 3-Wash Basin (Side) DetailDocument1 pageW002 76-10526-Detail Design: 2-Electric Water Heater 3-Wash Basin (Side) DetailMazen IsmailNo ratings yet

- RE Wall For Tara Tarini Temple in Ganjam DistrictDocument58 pagesRE Wall For Tara Tarini Temple in Ganjam Districtpratima padhy100% (1)

- Industrial ApplicationsDocument7 pagesIndustrial ApplicationsAnonymous M0tjyWNo ratings yet

- Assignment-Research 2-MJD-MALLARIDocument9 pagesAssignment-Research 2-MJD-MALLARIMark MallariNo ratings yet

- Raj RewalDocument24 pagesRaj RewalRadhika VijayNo ratings yet