Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

9 viewsSubpart F - Records and Reports

Subpart F - Records and Reports

Uploaded by

Christian Perez DelgadilloThis document summarizes regulations for records and reports required for thermally processed low-acid foods packaged in hermetically sealed containers. It details what must be included in processing and production records, such as product information and temperature readings. It also requires maintenance of records for accuracy testing of temperature devices and container closure inspections. Records must be kept for at least 3 years under specified conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Method Statement For Instrument CalibrationDocument19 pagesMethod Statement For Instrument Calibrationwasilmd75% (16)

- Batch Manufacturing RecordDocument3 pagesBatch Manufacturing RecordPrince Moni75% (4)

- HVAC Master Validation PlanDocument51 pagesHVAC Master Validation Plannavas197293% (30)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- GMP of Packaging OperationsDocument19 pagesGMP of Packaging OperationsgeethavinodNo ratings yet

- 06a Itp730 Iftps 2 Temperature Distribution Protocol For Processing in Steam Still RetortDocument7 pages06a Itp730 Iftps 2 Temperature Distribution Protocol For Processing in Steam Still RetortAndre MarthayudhaNo ratings yet

- PerformanceTest Updated9octDocument38 pagesPerformanceTest Updated9octHossein100% (1)

- Cosmetic GMP Implementation Part 6Document23 pagesCosmetic GMP Implementation Part 6Anonymous yBhOAi5UH100% (1)

- Subpart E - Production and Process ControlsDocument4 pagesSubpart E - Production and Process ControlsChristian Perez DelgadilloNo ratings yet

- Guide Mqa 011 007 PDFDocument13 pagesGuide Mqa 011 007 PDFAnonymous RuVgQLNo ratings yet

- Moist Heat SterilizatiojnDocument16 pagesMoist Heat Sterilizatiojnajitjoshi950No ratings yet

- Guide Mqa 011 007Document13 pagesGuide Mqa 011 007Ian G. Walker100% (2)

- Procedure: Pressure Equipment Safety: PurposeDocument9 pagesProcedure: Pressure Equipment Safety: PurposeChegwe CorneliusNo ratings yet

- Protocolo Mango - JapónDocument7 pagesProtocolo Mango - JapónPaul Zevallos HuertoNo ratings yet

- Validation of Sterilization of AutoclavesDocument15 pagesValidation of Sterilization of AutoclavesErich Hermann Günther Molina100% (3)

- Process Validation - Moist Heat Sterilization For PharmaceuticalsDocument15 pagesProcess Validation - Moist Heat Sterilization For PharmaceuticalsPalash DasNo ratings yet

- Format PQ WHODocument6 pagesFormat PQ WHODono WayNo ratings yet

- Commercial Sterilization of Low-Acid Food in Hermetically Sealed Containers - Retort Systems - Canadian Food Inspection AgencyDocument26 pagesCommercial Sterilization of Low-Acid Food in Hermetically Sealed Containers - Retort Systems - Canadian Food Inspection AgencyRobert HeSNo ratings yet

- Calibration, Validation and Verification of Equipment, Instruments and Other DevicesDocument2 pagesCalibration, Validation and Verification of Equipment, Instruments and Other DevicesTinnysumardiNo ratings yet

- Finished ProductDocument4 pagesFinished ProductDilip Chaudhary100% (1)

- Commissioning PlanDocument25 pagesCommissioning Plananjum128100% (2)

- EU - Quality ControlDocument3 pagesEU - Quality Controlapi-3859063No ratings yet

- Guideline For Sterilization Process ValidationDocument21 pagesGuideline For Sterilization Process Validationboddarambabu100% (1)

- 21 CFR 211Document2 pages21 CFR 211Golda Meir MassalangNo ratings yet

- Last Page PG TestDocument31 pagesLast Page PG Testarmanshaikh.engNo ratings yet

- Heater Tube InspectionDocument129 pagesHeater Tube Inspectionuniquepp100% (2)

- Q.A of Packaging MaterialsDocument10 pagesQ.A of Packaging MaterialsDeepak BhanjiNo ratings yet

- General Chapters - 1079 - Good Storage and Shipping PracticesDocument8 pagesGeneral Chapters - 1079 - Good Storage and Shipping PracticescamilaNo ratings yet

- Appendix - I (See Rule 4 (2) )Document4 pagesAppendix - I (See Rule 4 (2) )uknandiNo ratings yet

- Validation: Presented To: Prof. H.S. Keerthy Department of Pharmaceutics Mallige College of PharmacyDocument26 pagesValidation: Presented To: Prof. H.S. Keerthy Department of Pharmaceutics Mallige College of PharmacyAfdal Naim100% (1)

- The Good Manufacturing Practice For Pharmaceutical Products in Korea (KGMP)Document29 pagesThe Good Manufacturing Practice For Pharmaceutical Products in Korea (KGMP)Rodrigo CenturionNo ratings yet

- Subpart A - General ProvisionsDocument3 pagesSubpart A - General ProvisionsChristian Perez DelgadilloNo ratings yet

- CIP and SIPDocument5 pagesCIP and SIPwondwosseng100% (1)

- Measuring Equipment in A LaboratoryDocument8 pagesMeasuring Equipment in A Laboratorypulas6289No ratings yet

- NRMCA Plant Certification: Items The Company Should Have Ready Prior To Requesting An InspectionDocument2 pagesNRMCA Plant Certification: Items The Company Should Have Ready Prior To Requesting An Inspectioncah_mbuhNo ratings yet

- Lab Policies Temperature Recording and Maintenance of Temperature Dependent Equipment Lab 0265Document3 pagesLab Policies Temperature Recording and Maintenance of Temperature Dependent Equipment Lab 0265Helen grace NidoyNo ratings yet

- AHRI 740 1998 Corrected TablesDocument21 pagesAHRI 740 1998 Corrected TablesBernardo LeorNo ratings yet

- Code of Federal RegulationsDocument5 pagesCode of Federal RegulationsQuality Assurance EuroTecNo ratings yet

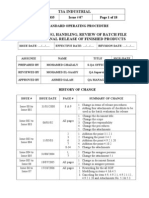

- Issuing, Handling, Revision of Batch File and Final Release of Finished Products For Sale and Distribution 07Document18 pagesIssuing, Handling, Revision of Batch File and Final Release of Finished Products For Sale and Distribution 07ibrahimgomaaNo ratings yet

- Sow TCP DST SWT 2023 - 2025 R0Document45 pagesSow TCP DST SWT 2023 - 2025 R0Marc LefrancqNo ratings yet

- PG Test Procedure Modified DT 14 11 2018Document24 pagesPG Test Procedure Modified DT 14 11 2018Bhupender BishtNo ratings yet

- Manufacturing Operations and Controls: Charge-In of ComponentsDocument19 pagesManufacturing Operations and Controls: Charge-In of Componentsmunni sundaraneedi07No ratings yet

- Ao 43 S 1999Document92 pagesAo 43 S 1999Ella RivaNo ratings yet

- DocumenttionDocument6 pagesDocumenttionTejNo ratings yet

- NR 13 - Comentada - InglêsDocument65 pagesNR 13 - Comentada - InglêsFilipe NicácioNo ratings yet

- DocumentationDocument46 pagesDocumentationajak16406No ratings yet

- Instrumentation Construction ActivityDocument22 pagesInstrumentation Construction ActivityMohamed Amin67% (3)

- Data Item Description System Problem Report FAA-TE-002Document2 pagesData Item Description System Problem Report FAA-TE-002Bre TroNo ratings yet

- Temp MappingDocument13 pagesTemp MappingJoshua JumaNo ratings yet

- STR Item Specific Guidelines For GRSP Document No - TDG 0008 Rev 4Document13 pagesSTR Item Specific Guidelines For GRSP Document No - TDG 0008 Rev 4Preeti goswamiNo ratings yet

- Termometer and Hygrometer Calibration LiteratureDocument2 pagesTermometer and Hygrometer Calibration LiteratureHarryNo ratings yet

- QC& QaDocument48 pagesQC& QaManohar KasdekarNo ratings yet

- Quality Control Manual: Company Name Address City, State, ZipDocument10 pagesQuality Control Manual: Company Name Address City, State, ZipMarco CandoNo ratings yet

- Mechanical Running Test Procedure For Air CompressorDocument7 pagesMechanical Running Test Procedure For Air CompressorkhozaqiNo ratings yet

- DHR NotesDocument4 pagesDHR Notesisrael afolayan mayomiNo ratings yet

- DHS ValidationDocument7 pagesDHS Validationmuna82dasNo ratings yet

- Guideline For Sterilization Process Validation: (Date:1995-11-01)Document17 pagesGuideline For Sterilization Process Validation: (Date:1995-11-01)Antonius MikaelNo ratings yet

- Pharma Cold Chain ProcessDocument3 pagesPharma Cold Chain ProcessakaiunepNo ratings yet

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsFrom EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsNo ratings yet

- Ubpart D - Control of Components, Food Product Containers, Closures, and In-Process MaterialsDocument4 pagesUbpart D - Control of Components, Food Product Containers, Closures, and In-Process MaterialsChristian Perez DelgadilloNo ratings yet

- Subpart C - EquipmentDocument30 pagesSubpart C - EquipmentChristian Perez DelgadilloNo ratings yet

- Subpart E - Production and Process ControlsDocument4 pagesSubpart E - Production and Process ControlsChristian Perez DelgadilloNo ratings yet

- Nutrientes Proteinas Calcio Ensilado 78.6 6.5 0.02 Forrjero 80.1 8.8 0.03 Algodón 70.6 32.8 0.2 Gluten 76.3 21.3 0.48 Garbanzo 67.2 13.7 0.14 Req Min 96.8981914 19.9 0.21 74.2 19.9 0.21 Total KGDocument2 pagesNutrientes Proteinas Calcio Ensilado 78.6 6.5 0.02 Forrjero 80.1 8.8 0.03 Algodón 70.6 32.8 0.2 Gluten 76.3 21.3 0.48 Garbanzo 67.2 13.7 0.14 Req Min 96.8981914 19.9 0.21 74.2 19.9 0.21 Total KGChristian Perez DelgadilloNo ratings yet

- Subpart A - General ProvisionsDocument3 pagesSubpart A - General ProvisionsChristian Perez DelgadilloNo ratings yet

- "Determination of Parameters in The Universal Induction Motor Model" Anand KumarDocument19 pages"Determination of Parameters in The Universal Induction Motor Model" Anand KumarAmit VermaNo ratings yet

- Clause 7.2.8. Enclosure Tightness Test at Ambient TemperatureDocument1 pageClause 7.2.8. Enclosure Tightness Test at Ambient Temperaturelnhoang.fgroupNo ratings yet

- Test On Projectile MotionDocument7 pagesTest On Projectile Motionsananjay BiswasNo ratings yet

- Pi Problem SetDocument4 pagesPi Problem Setdummy emailNo ratings yet

- Determining The Damping Coefficient of A Simple Pendulum Oscillating in AirDocument6 pagesDetermining The Damping Coefficient of A Simple Pendulum Oscillating in Airdavid paezNo ratings yet

- Gyroscope MC Graw HillDocument9 pagesGyroscope MC Graw HillTom TambeNo ratings yet

- SensitometriDocument33 pagesSensitometriDewi RetnoNo ratings yet

- 4 Hydrostatic Forces On Curved SurfacesDocument12 pages4 Hydrostatic Forces On Curved SurfacesBillie Ian. Salamante Jr100% (2)

- Experiment No. 3 Transfer Function of Two Phase A. C. Servo MotorDocument3 pagesExperiment No. 3 Transfer Function of Two Phase A. C. Servo MotorSHIVAM KUMAR SINGHWALNo ratings yet

- 312 Inter Physics Vol 1 EMDocument361 pages312 Inter Physics Vol 1 EMvishwadeepreddy42No ratings yet

- NMB 2410ML 05W B79 E50 Datasheet - 031901Document2 pagesNMB 2410ML 05W B79 E50 Datasheet - 031901MAS MUHNo ratings yet

- Temperature Calibrator - GuidelinessDocument2 pagesTemperature Calibrator - GuidelinessShanmugamoorthyNo ratings yet

- Elevator Scale Problem: Return To Table ofDocument12 pagesElevator Scale Problem: Return To Table ofElizabeth RankinNo ratings yet

- Air Resistance On Falling Balls and BalloonsDocument4 pagesAir Resistance On Falling Balls and Balloonsapostolos efstathiouNo ratings yet

- 3 - Thermal Energy Storage in District Heating and Cooling Systems A ReviewDocument22 pages3 - Thermal Energy Storage in District Heating and Cooling Systems A ReviewRicardo ToledoNo ratings yet

- Astm D7042-2021Document14 pagesAstm D7042-2021jose reyNo ratings yet

- Roundness Measuring MachineDocument19 pagesRoundness Measuring MachineArif SanjidNo ratings yet

- Power System Operation & Control - Lab ManualDocument33 pagesPower System Operation & Control - Lab Manualrakesh shuklaNo ratings yet

- "Kit For Over Voltagre Under Voltage Protection": A Micro Project Report ONDocument12 pages"Kit For Over Voltagre Under Voltage Protection": A Micro Project Report ONAjinkya PethkarNo ratings yet

- Ruide RT-2 User Manual 1908 (A5)Document14 pagesRuide RT-2 User Manual 1908 (A5)Karya Perdana MandiriNo ratings yet

- Xii Physics Lab Manual Sec BDocument29 pagesXii Physics Lab Manual Sec BB. AsmaNo ratings yet

- ME302 - LAB 1 - Öğretim Elemanı Ödev DosyasıDocument4 pagesME302 - LAB 1 - Öğretim Elemanı Ödev DosyasıYusuf Ersin ÇALIŞKANNo ratings yet

- ESP REPORT-finalDocument17 pagesESP REPORT-final1322 - Prasad KumbharNo ratings yet

- Formula CheatsheetDocument1 pageFormula CheatsheetGABRIEL LOUIS GUANONo ratings yet

- SIEMENS Squirrel Cage Induction Standard Three-Phase MotorsDocument19 pagesSIEMENS Squirrel Cage Induction Standard Three-Phase MotorsGraphios UtaNo ratings yet

- Distance and DisplacementDocument31 pagesDistance and DisplacementChristine D. BaliloNo ratings yet

- Chapter 7 - ExerciseDocument2 pagesChapter 7 - ExerciseTien ThanhNo ratings yet

- MTPPT3 Motion in 1 DimensionDocument37 pagesMTPPT3 Motion in 1 DimensionMarvin CincoNo ratings yet

- Ee 404 Laboratory Experiment 2Document6 pagesEe 404 Laboratory Experiment 2andrei saad100% (1)

- Em 2Document89 pagesEm 2Wallace JnrNo ratings yet

Subpart F - Records and Reports

Subpart F - Records and Reports

Uploaded by

Christian Perez Delgadillo0 ratings0% found this document useful (0 votes)

9 views3 pagesThis document summarizes regulations for records and reports required for thermally processed low-acid foods packaged in hermetically sealed containers. It details what must be included in processing and production records, such as product information and temperature readings. It also requires maintenance of records for accuracy testing of temperature devices and container closure inspections. Records must be kept for at least 3 years under specified conditions.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes regulations for records and reports required for thermally processed low-acid foods packaged in hermetically sealed containers. It details what must be included in processing and production records, such as product information and temperature readings. It also requires maintenance of records for accuracy testing of temperature devices and container closure inspections. Records must be kept for at least 3 years under specified conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

9 views3 pagesSubpart F - Records and Reports

Subpart F - Records and Reports

Uploaded by

Christian Perez DelgadilloThis document summarizes regulations for records and reports required for thermally processed low-acid foods packaged in hermetically sealed containers. It details what must be included in processing and production records, such as product information and temperature readings. It also requires maintenance of records for accuracy testing of temperature devices and container closure inspections. Records must be kept for at least 3 years under specified conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

[Code of Federal Regulations]

[Title 21, Volume 2]

[Revised as of April 1, 2020]

[CITE: 21CFR113]

TITLE 21--FOOD AND DRUGS

CHAPTER I--FOOD AND DRUG ADMINISTRATION

DEPARTMENT OF HEALTH AND HUMAN SERVICES

SUBCHAPTER B - FOOD FOR HUMAN CONSUMPTION

PART 113 THERMALLY PROCESSED LOW-ACID FOODS

PACKAGED IN HERMETICALLY SEALED

CONTAINERS

Subpart F - Records and Reports

Sec. 113.100 Processing and production records.

(a) Processing and production information shall be entered at the time it

is observed by the retort or processing system operator, or other

designated person, on forms that include the product, the code number, the

date, the retort or processing system number, the size of container, the

approximate number of containers per coding interval, the initial

temperature, the actual processing time, the temperature-indicating device

and temperature-recording device readings, and other appropriate processing

data. Closing machine vacuum in vacuum-packed products, maximum fill-in or

drained weight, or other critical factors specified in the scheduled

process shall also be recorded. In addition, the following records shall be

maintained:

(1) Still retorts. Time steam on; time temperature up to processing

temperature; time steam off; venting time and temperature to which vented.

(2) Agitating retorts. Functioning of condensate bleeder; retort speed;

and, when specified in the scheduled process, headspace, consistency,

maximum drained weight, minimum net weight, and percent solids.

(3) Hydrostatic retorts. The temperature in the steam chamber between the

steam-water interface and the lowest container position; speed of the

container conveyor chain; and, when the scheduled process specifies

maintenance of particular temperatures in the hydrostatic water legs, the

temperatures near the top and the bottom of each hydrostatic water leg.

(4) Aseptic processing and packaging systems. Product temperature in the

holding tube outlet as indicated by the temperature-indicating device and

the temperature-recording device; differential pressure as indicated by the

differential pressure recorder-controller, if a product-to-product

regenerator is used; product flow rate, as determined by the flow

controlling device or by filling and closing rates; sterilization media

flow rate or temperature or both; retention time of containers, and

closures when applicable, in the sterilizing environment; and, when a batch

system is used for container and/or closure sterilization, sterilization

cycle times and temperatures.

(5) Flame sterilizers. Container conveyor speed; surface temperature at the

beginning and at the end of the holding period; nature of container.

(6) Food preservation methods wherein critical factors such as water

activity are used in conjunction with thermal processing. Product

formulation and scheduled processes used, including the thermal process,

its associated critical factors, as well as other critical factors, and

results of aw determinations.

(7) Other systems. Critical factors specified in the formulation of the

product or in the scheduled process.

(b) Temperature-recording device records shall be identified by date,

retort number, and other data as necessary, so they can be correlated with

the record of lots processed. Each entry on the processing and production

records shall be made by the retort or processing system operator, or other

designated person, at the time the specific retort or processing system

condition or operation occurs, and this retort or processing system

operator or other designated person shall sign or initial each record form.

Not later than 1 working day after the actual process, and before shipment

or release for distribution, a representative of plant management who is

qualified by suitable training or experience shall review all processing

and production records for completeness and to ensure that the product

received the scheduled process. The records, including temperature-

recording device records, shall be signed or initialed and dated by the

reviewer.

(c) Records of the accuracy of a temperature-indicating device shall

include:

(1) A reference to the tag, seal, or other means of identity used by the

processor to identify the temperature-indicating device;

(2) The name of the manufacturer of the temperature-indicating device;

(3) The identity of the reference device, equipment, and procedures used

for the accuracy test and to adjust the temperature-indicating device or,

if an outside facility is used to conduct the accuracy test for the

temperature-indicating device, a guarantee, certificate of accuracy,

certificate of calibration, or other document from the facility that

includes a statement or other documentation regarding the traceability of

the accuracy to a National Institute of Standards and Technology (NIST) or

other national metrology institute standard;

(4) The identity of the person or facility that performed the accuracy test

and adjusted or calibrated the temperature-indicating device;

(5) The date and results of each accuracy test, including the amount of

calibration adjustment; and

(6) The date on or before which the next accuracy test must be performed.

(d) Records of the accuracy of a reference device maintained by the

processor shall include:

(1) A reference to the tag, seal, or other means of identity used by the

processor to identify the reference device;

(2) The name of the manufacturer of the reference device;

(3) The identity of the equipment and reference to procedures used for the

accuracy test and to adjust or calibrate the reference device or, if an

outside facility is used to conduct the accuracy test for the reference

device, a guarantee, certificate of accuracy, certificate of calibration,

or other document from the facility that includes a statement or other

documentation regarding the traceability of the accuracy to a NIST or other

national metrology institute standard;

(4) The identity of the person or facility that performed the accuracy test

and adjusted or calibrated the reference device;

(5) The date and results of each accuracy test, including the amount of

calibration adjustment; and

(6) The date on or before which the next accuracy test must be performed.

(e) Records of all container closure examinations shall specify the product

code, the date and time of container closure inspections, the measurements

obtained, and all corrective actions taken. Records shall be signed or

initialed by the container closure inspector and reviewed by management

with sufficient frequency to ensure that the containers are hermetically

sealed. The records shall be signed or initialed and dated by the reviewer.

(f) Records shall be maintained to identify the initial distribution of the

finished product to facilitate, when necessary, the segregation of specific

food lots that may have become contaminated or otherwise rendered unfit for

their intended use.

(g) Copies of all records provided for in this part, except those required

under § 113.83 establishing scheduled processes, shall be retained at the

processing plant for a period of not less than 1 year from the date of

manufacture, and at the processing plant or other reasonably accessible

location for an additional 2 years. If, during the first year of the 3-year

record-retention period, the processing plant is closed for a prolonged

period between seasonal packs, the records may be transferred to some other

reasonably accessible location at the end of the seasonal pack.

(h) Records of this part may be maintained electronically, provided they

are in compliance with part 11 of this chapter.

[44 FR 16215, Mar. 16, 1979, as amended at 76 FR 11923, Mar. 3, 2011]

Authority: 21 U.S.C. 342, 371, 374; 42 U.S.C. 264.

Source: 44 FR 16215, Mar. 16, 1979, unless otherwise noted.

You might also like

- Method Statement For Instrument CalibrationDocument19 pagesMethod Statement For Instrument Calibrationwasilmd75% (16)

- Batch Manufacturing RecordDocument3 pagesBatch Manufacturing RecordPrince Moni75% (4)

- HVAC Master Validation PlanDocument51 pagesHVAC Master Validation Plannavas197293% (30)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- GMP of Packaging OperationsDocument19 pagesGMP of Packaging OperationsgeethavinodNo ratings yet

- 06a Itp730 Iftps 2 Temperature Distribution Protocol For Processing in Steam Still RetortDocument7 pages06a Itp730 Iftps 2 Temperature Distribution Protocol For Processing in Steam Still RetortAndre MarthayudhaNo ratings yet

- PerformanceTest Updated9octDocument38 pagesPerformanceTest Updated9octHossein100% (1)

- Cosmetic GMP Implementation Part 6Document23 pagesCosmetic GMP Implementation Part 6Anonymous yBhOAi5UH100% (1)

- Subpart E - Production and Process ControlsDocument4 pagesSubpart E - Production and Process ControlsChristian Perez DelgadilloNo ratings yet

- Guide Mqa 011 007 PDFDocument13 pagesGuide Mqa 011 007 PDFAnonymous RuVgQLNo ratings yet

- Moist Heat SterilizatiojnDocument16 pagesMoist Heat Sterilizatiojnajitjoshi950No ratings yet

- Guide Mqa 011 007Document13 pagesGuide Mqa 011 007Ian G. Walker100% (2)

- Procedure: Pressure Equipment Safety: PurposeDocument9 pagesProcedure: Pressure Equipment Safety: PurposeChegwe CorneliusNo ratings yet

- Protocolo Mango - JapónDocument7 pagesProtocolo Mango - JapónPaul Zevallos HuertoNo ratings yet

- Validation of Sterilization of AutoclavesDocument15 pagesValidation of Sterilization of AutoclavesErich Hermann Günther Molina100% (3)

- Process Validation - Moist Heat Sterilization For PharmaceuticalsDocument15 pagesProcess Validation - Moist Heat Sterilization For PharmaceuticalsPalash DasNo ratings yet

- Format PQ WHODocument6 pagesFormat PQ WHODono WayNo ratings yet

- Commercial Sterilization of Low-Acid Food in Hermetically Sealed Containers - Retort Systems - Canadian Food Inspection AgencyDocument26 pagesCommercial Sterilization of Low-Acid Food in Hermetically Sealed Containers - Retort Systems - Canadian Food Inspection AgencyRobert HeSNo ratings yet

- Calibration, Validation and Verification of Equipment, Instruments and Other DevicesDocument2 pagesCalibration, Validation and Verification of Equipment, Instruments and Other DevicesTinnysumardiNo ratings yet

- Finished ProductDocument4 pagesFinished ProductDilip Chaudhary100% (1)

- Commissioning PlanDocument25 pagesCommissioning Plananjum128100% (2)

- EU - Quality ControlDocument3 pagesEU - Quality Controlapi-3859063No ratings yet

- Guideline For Sterilization Process ValidationDocument21 pagesGuideline For Sterilization Process Validationboddarambabu100% (1)

- 21 CFR 211Document2 pages21 CFR 211Golda Meir MassalangNo ratings yet

- Last Page PG TestDocument31 pagesLast Page PG Testarmanshaikh.engNo ratings yet

- Heater Tube InspectionDocument129 pagesHeater Tube Inspectionuniquepp100% (2)

- Q.A of Packaging MaterialsDocument10 pagesQ.A of Packaging MaterialsDeepak BhanjiNo ratings yet

- General Chapters - 1079 - Good Storage and Shipping PracticesDocument8 pagesGeneral Chapters - 1079 - Good Storage and Shipping PracticescamilaNo ratings yet

- Appendix - I (See Rule 4 (2) )Document4 pagesAppendix - I (See Rule 4 (2) )uknandiNo ratings yet

- Validation: Presented To: Prof. H.S. Keerthy Department of Pharmaceutics Mallige College of PharmacyDocument26 pagesValidation: Presented To: Prof. H.S. Keerthy Department of Pharmaceutics Mallige College of PharmacyAfdal Naim100% (1)

- The Good Manufacturing Practice For Pharmaceutical Products in Korea (KGMP)Document29 pagesThe Good Manufacturing Practice For Pharmaceutical Products in Korea (KGMP)Rodrigo CenturionNo ratings yet

- Subpart A - General ProvisionsDocument3 pagesSubpart A - General ProvisionsChristian Perez DelgadilloNo ratings yet

- CIP and SIPDocument5 pagesCIP and SIPwondwosseng100% (1)

- Measuring Equipment in A LaboratoryDocument8 pagesMeasuring Equipment in A Laboratorypulas6289No ratings yet

- NRMCA Plant Certification: Items The Company Should Have Ready Prior To Requesting An InspectionDocument2 pagesNRMCA Plant Certification: Items The Company Should Have Ready Prior To Requesting An Inspectioncah_mbuhNo ratings yet

- Lab Policies Temperature Recording and Maintenance of Temperature Dependent Equipment Lab 0265Document3 pagesLab Policies Temperature Recording and Maintenance of Temperature Dependent Equipment Lab 0265Helen grace NidoyNo ratings yet

- AHRI 740 1998 Corrected TablesDocument21 pagesAHRI 740 1998 Corrected TablesBernardo LeorNo ratings yet

- Code of Federal RegulationsDocument5 pagesCode of Federal RegulationsQuality Assurance EuroTecNo ratings yet

- Issuing, Handling, Revision of Batch File and Final Release of Finished Products For Sale and Distribution 07Document18 pagesIssuing, Handling, Revision of Batch File and Final Release of Finished Products For Sale and Distribution 07ibrahimgomaaNo ratings yet

- Sow TCP DST SWT 2023 - 2025 R0Document45 pagesSow TCP DST SWT 2023 - 2025 R0Marc LefrancqNo ratings yet

- PG Test Procedure Modified DT 14 11 2018Document24 pagesPG Test Procedure Modified DT 14 11 2018Bhupender BishtNo ratings yet

- Manufacturing Operations and Controls: Charge-In of ComponentsDocument19 pagesManufacturing Operations and Controls: Charge-In of Componentsmunni sundaraneedi07No ratings yet

- Ao 43 S 1999Document92 pagesAo 43 S 1999Ella RivaNo ratings yet

- DocumenttionDocument6 pagesDocumenttionTejNo ratings yet

- NR 13 - Comentada - InglêsDocument65 pagesNR 13 - Comentada - InglêsFilipe NicácioNo ratings yet

- DocumentationDocument46 pagesDocumentationajak16406No ratings yet

- Instrumentation Construction ActivityDocument22 pagesInstrumentation Construction ActivityMohamed Amin67% (3)

- Data Item Description System Problem Report FAA-TE-002Document2 pagesData Item Description System Problem Report FAA-TE-002Bre TroNo ratings yet

- Temp MappingDocument13 pagesTemp MappingJoshua JumaNo ratings yet

- STR Item Specific Guidelines For GRSP Document No - TDG 0008 Rev 4Document13 pagesSTR Item Specific Guidelines For GRSP Document No - TDG 0008 Rev 4Preeti goswamiNo ratings yet

- Termometer and Hygrometer Calibration LiteratureDocument2 pagesTermometer and Hygrometer Calibration LiteratureHarryNo ratings yet

- QC& QaDocument48 pagesQC& QaManohar KasdekarNo ratings yet

- Quality Control Manual: Company Name Address City, State, ZipDocument10 pagesQuality Control Manual: Company Name Address City, State, ZipMarco CandoNo ratings yet

- Mechanical Running Test Procedure For Air CompressorDocument7 pagesMechanical Running Test Procedure For Air CompressorkhozaqiNo ratings yet

- DHR NotesDocument4 pagesDHR Notesisrael afolayan mayomiNo ratings yet

- DHS ValidationDocument7 pagesDHS Validationmuna82dasNo ratings yet

- Guideline For Sterilization Process Validation: (Date:1995-11-01)Document17 pagesGuideline For Sterilization Process Validation: (Date:1995-11-01)Antonius MikaelNo ratings yet

- Pharma Cold Chain ProcessDocument3 pagesPharma Cold Chain ProcessakaiunepNo ratings yet

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsFrom EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsNo ratings yet

- Ubpart D - Control of Components, Food Product Containers, Closures, and In-Process MaterialsDocument4 pagesUbpart D - Control of Components, Food Product Containers, Closures, and In-Process MaterialsChristian Perez DelgadilloNo ratings yet

- Subpart C - EquipmentDocument30 pagesSubpart C - EquipmentChristian Perez DelgadilloNo ratings yet

- Subpart E - Production and Process ControlsDocument4 pagesSubpart E - Production and Process ControlsChristian Perez DelgadilloNo ratings yet

- Nutrientes Proteinas Calcio Ensilado 78.6 6.5 0.02 Forrjero 80.1 8.8 0.03 Algodón 70.6 32.8 0.2 Gluten 76.3 21.3 0.48 Garbanzo 67.2 13.7 0.14 Req Min 96.8981914 19.9 0.21 74.2 19.9 0.21 Total KGDocument2 pagesNutrientes Proteinas Calcio Ensilado 78.6 6.5 0.02 Forrjero 80.1 8.8 0.03 Algodón 70.6 32.8 0.2 Gluten 76.3 21.3 0.48 Garbanzo 67.2 13.7 0.14 Req Min 96.8981914 19.9 0.21 74.2 19.9 0.21 Total KGChristian Perez DelgadilloNo ratings yet

- Subpart A - General ProvisionsDocument3 pagesSubpart A - General ProvisionsChristian Perez DelgadilloNo ratings yet

- "Determination of Parameters in The Universal Induction Motor Model" Anand KumarDocument19 pages"Determination of Parameters in The Universal Induction Motor Model" Anand KumarAmit VermaNo ratings yet

- Clause 7.2.8. Enclosure Tightness Test at Ambient TemperatureDocument1 pageClause 7.2.8. Enclosure Tightness Test at Ambient Temperaturelnhoang.fgroupNo ratings yet

- Test On Projectile MotionDocument7 pagesTest On Projectile Motionsananjay BiswasNo ratings yet

- Pi Problem SetDocument4 pagesPi Problem Setdummy emailNo ratings yet

- Determining The Damping Coefficient of A Simple Pendulum Oscillating in AirDocument6 pagesDetermining The Damping Coefficient of A Simple Pendulum Oscillating in Airdavid paezNo ratings yet

- Gyroscope MC Graw HillDocument9 pagesGyroscope MC Graw HillTom TambeNo ratings yet

- SensitometriDocument33 pagesSensitometriDewi RetnoNo ratings yet

- 4 Hydrostatic Forces On Curved SurfacesDocument12 pages4 Hydrostatic Forces On Curved SurfacesBillie Ian. Salamante Jr100% (2)

- Experiment No. 3 Transfer Function of Two Phase A. C. Servo MotorDocument3 pagesExperiment No. 3 Transfer Function of Two Phase A. C. Servo MotorSHIVAM KUMAR SINGHWALNo ratings yet

- 312 Inter Physics Vol 1 EMDocument361 pages312 Inter Physics Vol 1 EMvishwadeepreddy42No ratings yet

- NMB 2410ML 05W B79 E50 Datasheet - 031901Document2 pagesNMB 2410ML 05W B79 E50 Datasheet - 031901MAS MUHNo ratings yet

- Temperature Calibrator - GuidelinessDocument2 pagesTemperature Calibrator - GuidelinessShanmugamoorthyNo ratings yet

- Elevator Scale Problem: Return To Table ofDocument12 pagesElevator Scale Problem: Return To Table ofElizabeth RankinNo ratings yet

- Air Resistance On Falling Balls and BalloonsDocument4 pagesAir Resistance On Falling Balls and Balloonsapostolos efstathiouNo ratings yet

- 3 - Thermal Energy Storage in District Heating and Cooling Systems A ReviewDocument22 pages3 - Thermal Energy Storage in District Heating and Cooling Systems A ReviewRicardo ToledoNo ratings yet

- Astm D7042-2021Document14 pagesAstm D7042-2021jose reyNo ratings yet

- Roundness Measuring MachineDocument19 pagesRoundness Measuring MachineArif SanjidNo ratings yet

- Power System Operation & Control - Lab ManualDocument33 pagesPower System Operation & Control - Lab Manualrakesh shuklaNo ratings yet

- "Kit For Over Voltagre Under Voltage Protection": A Micro Project Report ONDocument12 pages"Kit For Over Voltagre Under Voltage Protection": A Micro Project Report ONAjinkya PethkarNo ratings yet

- Ruide RT-2 User Manual 1908 (A5)Document14 pagesRuide RT-2 User Manual 1908 (A5)Karya Perdana MandiriNo ratings yet

- Xii Physics Lab Manual Sec BDocument29 pagesXii Physics Lab Manual Sec BB. AsmaNo ratings yet

- ME302 - LAB 1 - Öğretim Elemanı Ödev DosyasıDocument4 pagesME302 - LAB 1 - Öğretim Elemanı Ödev DosyasıYusuf Ersin ÇALIŞKANNo ratings yet

- ESP REPORT-finalDocument17 pagesESP REPORT-final1322 - Prasad KumbharNo ratings yet

- Formula CheatsheetDocument1 pageFormula CheatsheetGABRIEL LOUIS GUANONo ratings yet

- SIEMENS Squirrel Cage Induction Standard Three-Phase MotorsDocument19 pagesSIEMENS Squirrel Cage Induction Standard Three-Phase MotorsGraphios UtaNo ratings yet

- Distance and DisplacementDocument31 pagesDistance and DisplacementChristine D. BaliloNo ratings yet

- Chapter 7 - ExerciseDocument2 pagesChapter 7 - ExerciseTien ThanhNo ratings yet

- MTPPT3 Motion in 1 DimensionDocument37 pagesMTPPT3 Motion in 1 DimensionMarvin CincoNo ratings yet

- Ee 404 Laboratory Experiment 2Document6 pagesEe 404 Laboratory Experiment 2andrei saad100% (1)

- Em 2Document89 pagesEm 2Wallace JnrNo ratings yet