Professional Documents

Culture Documents

MM-1 31

MM-1 31

Uploaded by

Jesús Vázquez HerreroOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MM-1 31

MM-1 31

Uploaded by

Jesús Vázquez HerreroCopyright:

Available Formats

TM 55-2840-241-23

LIST OF ILLUSTRATIONS

Number Title Page Number Title Page

1-1. Right Side View of Engine (Typical) . . . . . . . . . . . 1-21 5-6.2 Start-Derich and Start-Accel

1-2. Engine Airflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3 (Tweaker) Adjustments . . . . . . . . . . . . . . . . . . . . . 5-10.4

1-3. Fuel System Schematic . . . . . . . . . . . . . . . . . . . . . 1-5 5-7. Fuel Control Max Flow Stop Adjustment . . . . . . . 5-11

1-4. Fuel Control System Schematic. . . . . . . . . . . . . . . 1-7 5-8. Fuel Control Fuel Filter . . . . . . . . . . . . . . . . . . . . . 5-12

1-5. Fuel Pump and Filter Assembly . . . . . . . . . . . . . . . 1-9 5-9. Carbon Buildup on Fuel Nozzle . . . . . . . . . . . . . . . 5-14

1-6. Engine Lubrication System Schematic . . . . . . . . . 1-11 5-9.1. Removal of Accumulator and Union . . . . . . . . . . . 5-15

1-7. Oil Pump Schematic . . . . . . . . . . . . . . . . . . . . . . . . 1-12 5-9.2 Installation of P/N MS 9015-04 Plug. . . . . . . . . . . 5-15

1-8. Compressor Bleed Control Valve . . . . . . . . . . . . . . 1-13 5-10. Particlle Accumulation on Magnetic

1-9. Compressor Bleed Control Valve Operation . . . . . 1-13 Chip Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

2-1. Engine Turning Adapter 6799790 . . . . . . . . . . . . . 2-2 5-10.1 Pressure Oil Tube and

2-2. Compressor Vibration Pickup Pressure Oil Filtering Screen . . . . . . . . . . . . . . . . 5-18.1

Mounting Bracket 6872539 . . . . . . . . . . . . . . . . . . 2-2 5-11. Oil Falter, Housing, Check Valve, and

2-3. Loop Clamps 6799952 and 6799953 . . . . . . . . . . . 2-2 Regulator Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

2-4. Compressor Protector Kit 6886204 . . . . . . . . . . . . 2-2 5-12. External Oil Check Valve . . . . . . . . . . . . . . . . . . . . 5-20.1

2-5. Engine Assembly Lift 6796963 . . . . . . . . . . . . . . . 2-2 5-13. Engine Air Systems (Anti-icing and Bleed Air) . . 5-23

2-6. Mechanical Puller Kit 6796941 . . . . . . . . . . . . . . . 2-2 5-14. Anti-icing Valve Poppet Seat Replacement . . . . . . 5-24

2-7. Modular Engine Test Stand LTCT10465-22 . . . . 2-3 5-15. Anti-icing Valve Lever Repair . . . . . . . . . . . . . . . . 5-25

2-8. Engine Assembly Turnover Stand 6795579 . . . . . . 2-3 5-16. Ignition System . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

2-9. Ground Idle Wrench 6798292 . . . . . . . . . . . . . . . . 2-3 5-17. Spark Igniter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

3-1. Engine Shipping Container . . . . . . . . . . . . . . . . . . 3-3 6-1. Compressor Case Assembly . . . . . . . . . . . . . . . . . . 6-2

3-2. Engine Shipping Parts . . . . . . . . . . . . . . . . . . . . . . 3-4 7-1. Bleed Valve Jet and Nozzle Removal . . . . . . . . . . 7-3

3-3. Engine Shipping Container Stenciling 7-2 Compressor Blade Damage Caused By Rub . . . . . 7-5

and Labeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9 7-3. Compressor Vane Erosion . . . . . . . . . . . . . . . . . . . 7-6

3-4. Accessories Shipping Container . . . . . . . . . . . . . . 3-10 7-4. Gearbox Accessory Pad Locations . . . . . . . . . . . . 7-7

3-5. Accessories Shipping Container Stenciling . . . . . . 3-11 7-5. Outer Combustion Case Inspection . . . . . . . . . . . . 7-8

3-6. Gas Producer Fuel Control Ports Identification . . . 3-12 7-6. Dent Limits-Top of Outer Combustion Case . . . . . 7-9

3-7. Engine Assembly Turnover Stand 6795579 . . . . . . 3-13 7-7. Outer Combustion Case Air Tube Boss. . . . . . . . . 7-9

3-8. Combustion Section Removal . . . . . . . . . . . . . . . . 3-15 7-8. Combustion Liner Inspection. . . . . . . . . . . . . . . . . 7-13

4-1. OH58C HIT T0T Worksheet . . . . . . . . . . . . . . . . 4-14.2 7-9. Inspection of Combustion Liner

4-2. OH58C HIT TOT Log . . . . . . . . . . . . . . . . . . . . . . 4-15 Dome Louvers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

4-3. Bendix Governor . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16 7-10. Compressor Rotor Blade Leading

4-4. Bendix Fuel Control . . . . . . . . . . . . . . . . . . . . . . . . 4-16 and Trailing Edge Blend Limits. . . . . . . . . . . . . . . 7-15

4-5. P. C. Gage Test Kit . . . . . . . . . . . . . . . . . . . . . . . . . 4-16.3 7-11. Compressor Rotor Blade Tip Blend Limits . . . . . . 7-15

4-6. Set-Up of P.C. Gage . . . . . . . . . . . . . . . . . . . . . . . . 4-163 7-12. Compressor Blade Surface Blending Limits . . . . . 7-16

5-1. Universal Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 7-13. Compressor Stator Vane Blend Limits. . . . . . . . . . 7-17

5-2. Fuel, Oil, and Air Tubing . . . . . . . . . . . . . . 5-5 7-14. Seal Puller Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

5-3. Fuel System Components . . . . . . . . . . . . . . . . . . . . 5-6 7-15. Gearbox External Seals . . . . . . . . . . . . . . . . . . . . . 7-19

5-4. Fuel Filter Replacement . . . . . . . . . . . . . . . . . . . . . 5-8 7-16. Gearbox External Stud Data . . . . . . . . . . . . . . . . . 7-20

5-5. Fuel Control Quadrant and Pointer . . . . . . . . . . . . 5-10 10-1. Idle Flight Automtation GPTOT Limits . . . . . . . . 10-3

5-6. Gas Producer Fuel Control Adjustmemts . . . . . . . . 5-10.1 10-2. Diffuser Vent Orifice Installation . . . . . . . . . . . . . . 10-7

5-6.1 Start Acceleration and Start 11-1. Typical Locknut Installation . . . . . . . . . . . . . . . . . 11-4

Derichment Adjustments. . . . . . . . . . . . . . . . . . . . 5-10.2 12-1. Typical First-Stage Turbine Nozzle . . . . . . . . . . . . 12-2

LIST OF TABLES

Number Title Page Number Title Page

1-1. Leading Particulars . . . . . . . . . . . . . . . . . . . . . . . . 1-14 7-1. Combustion Liner Inspection . . . . . . . . . . . . . . . . . 7-10

1-2. Performance Ratings (Standard Sea 10-1. Operating Limits. . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Level Static Conditions) . . . . . . . . . . . . . . . . . . . . . 1-14 10-2. Test Requirements . . . . . . . . . . . . . . . . . . . . . . . . 10-6

2-1. Special Tools and Test Equipment . . . . . . . . . . . . . 2-1 10-3. Functional Test Schedule . . . . . . . . . . . . . . . . . . . . 10-8

2-2. Consumable Materials . . . . . . . . . . . . . . . . . . . . . . 2-4 11-1. Torwue Values . . . . . . . . . . . . . . . . . . . 11-1

3-1. Container Air Pressure vs. Ambient Temperature . 3-8 11-1.1 Minimum Prevailing Torque for Used Locknuts 11-4

4-1. Troubleshooting. . . . . . . . . . . . . . . . . . 4-1 11-2. Dimensional Limits . . . . . . . . . . . . . . . . . . . . . . . . 11-5

5-1. Recommended Torque for Airframe 12-1. Overtemperature During Start . . . . . . . . . . . . . . . . 12-1

Engine Interface Connections . . . . . . . . . . . . . . . . 5-2.1 12-2. Overtemperature During Power Transients . . . . . . 12-1

5-1.1 Adjustments to Improve Starting . . . . . . . . . . . . . . 5-10.3 12-3. First-stage Turbine Nozzle and Shield Inspection . 12-2

5-1.2 Torque Limits for Steel Couplings on Steel 13-1. Overhaul and Retirement Intend . . . . . . . . . . . . . 13-1

Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15 Maintenance Allocation Chart . . . . . . . . . . . . . . . . B-1

5-2. Anti-icing Air Valve Inspection and Repair . . . . . . 5-24

ii Change 18

You might also like

- The One Manual TokheimDocument74 pagesThe One Manual TokheimJuan Carlos Barreto100% (1)

- Kioti Daedong Series 3C, A, B Engines Service Manual 4A220LWSDocument19 pagesKioti Daedong Series 3C, A, B Engines Service Manual 4A220LWSLisakoly0% (1)

- Hustler Shibaura S773L N843 N843L Service Manual 109823 0209Document75 pagesHustler Shibaura S773L N843 N843L Service Manual 109823 0209Maurice 'Bud' Muser III83% (29)

- 2003 Yamaha RX-1 Service ManualDocument683 pages2003 Yamaha RX-1 Service ManualShane78% (9)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- Mercruiser Service Manual - 25 GM V6 1998 - 2001Document225 pagesMercruiser Service Manual - 25 GM V6 1998 - 2001an82mustang100% (3)

- Construction For Landscape Architecture Portfolio Skills - Robert Holden, Jamie Liversedge PDFDocument572 pagesConstruction For Landscape Architecture Portfolio Skills - Robert Holden, Jamie Liversedge PDFsebastian castro100% (3)

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Traffic Plan Coachella 03-22-22 V5 - RevisedDocument112 pagesTraffic Plan Coachella 03-22-22 V5 - RevisedTaiggNo ratings yet

- The Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreFrom EverandThe Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreRating: 3 out of 5 stars3/5 (2)

- T4F Workshop Service ManualDocument165 pagesT4F Workshop Service ManualDanilo Garcia67% (3)

- 320C Excavator PartsDocument571 pages320C Excavator PartsRay100% (8)

- 1971 C.C.W Model 340, 400, and 440 Engine Technical Service ManualDocument68 pages1971 C.C.W Model 340, 400, and 440 Engine Technical Service ManualGus McGrathNo ratings yet

- Technical FTPDocument200 pagesTechnical FTPJosé Da Silva Mata100% (1)

- Operation and Installation ManualDocument105 pagesOperation and Installation ManualNAVEDTRA12204No ratings yet

- TM9-2815-200-35 AVDS-1790-2A M60 EngineDocument780 pagesTM9-2815-200-35 AVDS-1790-2A M60 EngineTom TechoueyresNo ratings yet

- BMW F30 Coding CheatSheetDocument2 pagesBMW F30 Coding CheatSheetАрсений Старк100% (1)

- PSST (T-2) RefresherDocument115 pagesPSST (T-2) Refresherjake100% (1)

- Jungheinrich DFG 660 Service ManualDocument194 pagesJungheinrich DFG 660 Service ManualNhàn Nguyễn ThanhNo ratings yet

- T-300 Paymover PartsDocument224 pagesT-300 Paymover PartsGregory NavaNo ratings yet

- EVO-NK Manual 2018 09 10 ENDocument65 pagesEVO-NK Manual 2018 09 10 ENgerman100% (1)

- Engine and Accessory: Section 5Document236 pagesEngine and Accessory: Section 5សុខ ប៊ុនណារ៉ង់No ratings yet

- SM301-05 Diagnostico K21Document17 pagesSM301-05 Diagnostico K21juan antonio hdezNo ratings yet

- 245 324 326 331 335 A 339 352 356 Supplement TitleDocument172 pages245 324 326 331 335 A 339 352 356 Supplement TitleDmitryNo ratings yet

- Manual de Partes JLG 450AJDocument212 pagesManual de Partes JLG 450AJfernando100% (1)

- Ih Engine List 1975 1993 1995 1997Document100 pagesIh Engine List 1975 1993 1995 1997Eduardo Sainz100% (1)

- Yanmar Marine Diesel Engine 2QM20H 3QM30H Service ManualDocument349 pagesYanmar Marine Diesel Engine 2QM20H 3QM30H Service ManualPer ForsbergNo ratings yet

- Pièces 1250AJPDocument282 pagesPièces 1250AJPClémentNo ratings yet

- Parts 3120750english PDFDocument266 pagesParts 3120750english PDFJuniaman SinagaNo ratings yet

- Manual de Partes 120 HXDocument208 pagesManual de Partes 120 HXLuciano Ernesto Martel VillanuevaNo ratings yet

- Sr-70!80!00 Complete Service Manual 2006-07Document144 pagesSr-70!80!00 Complete Service Manual 2006-07brunosamaeian100% (1)

- Manual 05k en InglesDocument22 pagesManual 05k en InglesCocom Ivan100% (2)

- Cummins Engine Service Manual Cum S H NHDocument11 pagesCummins Engine Service Manual Cum S H NHWalter Lazo50% (2)

- Compressor: Model 05G and 05G BusDocument23 pagesCompressor: Model 05G and 05G BusJOSE GUTIERREZNo ratings yet

- Parts - 3120687 - 8-31-11 - ANSI - English - 2022-04-11T144845.985 - PTA 120 HXDocument210 pagesParts - 3120687 - 8-31-11 - ANSI - English - 2022-04-11T144845.985 - PTA 120 HXFabricio MendonçaNo ratings yet

- 33Document150 pages33mandy johnNo ratings yet

- Chapter 0 Engine Outline and Equipment: Part ListDocument4 pagesChapter 0 Engine Outline and Equipment: Part ListİsmailKılıçNo ratings yet

- 740AJ Parts ManualDocument216 pages740AJ Parts Manualy.inafuku0209yNo ratings yet

- Toro Snow Blower s620 S-620Document62 pagesToro Snow Blower s620 S-620Mauricio Daniel PaniaguaNo ratings yet

- Yanmar Models YSM8-R YSM8-Y YSM12-R YSM12-Y Marine Diesel EnginesDocument197 pagesYanmar Models YSM8-R YSM8-Y YSM12-R YSM12-Y Marine Diesel EnginesHal PalmerNo ratings yet

- DrillingDocument64 pagesDrillingDomi Mora100% (2)

- Parts 3121811 1-2-12 CE EnglishDocument224 pagesParts 3121811 1-2-12 CE EnglishFrancisco barba lópezNo ratings yet

- JGL 45Document160 pagesJGL 45Ulises QuezadaNo ratings yet

- 1500 PartsDocument296 pages1500 PartsfernandoNo ratings yet

- Manual de Partes E600jDocument212 pagesManual de Partes E600jhectorNo ratings yet

- Toro CCR Powerlite Service ManualDocument124 pagesToro CCR Powerlite Service ManualBrian Crown100% (3)

- PDSR30Document172 pagesPDSR30kirk sutherlandNo ratings yet

- 53 WK 57Document44 pages53 WK 57Navid EbrahimniaNo ratings yet

- PDR Series: Power Drive Reach Lift Truck Serial Number 333423 and HigherDocument186 pagesPDR Series: Power Drive Reach Lift Truck Serial Number 333423 and HigherDmitryNo ratings yet

- JLG E45 MENLİFTDocument196 pagesJLG E45 MENLİFTHasan Hamit AydınNo ratings yet

- MDKAU Service Manual PDFDocument66 pagesMDKAU Service Manual PDFrepelind100% (1)

- Operating Instructions and PARTS LIST For: Rix Industries Gas CompressorDocument65 pagesOperating Instructions and PARTS LIST For: Rix Industries Gas CompressorDomingoscarlos RubbenNo ratings yet

- Parts 3121106 1-2-12 ANSI EnglishDocument246 pagesParts 3121106 1-2-12 ANSI EnglishAndres JimenezNo ratings yet

- STS12 Parts Manual 2015 PDFDocument138 pagesSTS12 Parts Manual 2015 PDFMiguel Gonzalez CondeNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- The Boatbuilder's Apprentice: The Ins and Outs of Building Lapstrake, Carvel, Stitch-and-Glue, Strip-Planked, and Other Wooden BoaFrom EverandThe Boatbuilder's Apprentice: The Ins and Outs of Building Lapstrake, Carvel, Stitch-and-Glue, Strip-Planked, and Other Wooden BoaRating: 4 out of 5 stars4/5 (2)

- MM-1 44Document1 pageMM-1 44Jesús Vázquez HerreroNo ratings yet

- MM-1 43Document1 pageMM-1 43Jesús Vázquez HerreroNo ratings yet

- MM-1 39Document1 pageMM-1 39Jesús Vázquez HerreroNo ratings yet

- MM-1 36Document1 pageMM-1 36Jesús Vázquez HerreroNo ratings yet

- MM-1 37Document1 pageMM-1 37Jesús Vázquez HerreroNo ratings yet

- MM-1 34Document1 pageMM-1 34Jesús Vázquez HerreroNo ratings yet

- MM-1 26Document1 pageMM-1 26Jesús Vázquez HerreroNo ratings yet

- MM-1 16Document1 pageMM-1 16Jesús Vázquez HerreroNo ratings yet

- MM-1 32Document1 pageMM-1 32Jesús Vázquez HerreroNo ratings yet

- MM-1 20Document1 pageMM-1 20Jesús Vázquez HerreroNo ratings yet

- MM-1 23Document1 pageMM-1 23Jesús Vázquez HerreroNo ratings yet

- MM-1 30Document1 pageMM-1 30Jesús Vázquez HerreroNo ratings yet

- MM-1 27Document1 pageMM-1 27Jesús Vázquez HerreroNo ratings yet

- MM-1 13Document1 pageMM-1 13Jesús Vázquez HerreroNo ratings yet

- MM-1 18Document1 pageMM-1 18Jesús Vázquez HerreroNo ratings yet

- MM-1 12Document1 pageMM-1 12Jesús Vázquez HerreroNo ratings yet

- MM-1 5Document1 pageMM-1 5Jesús Vázquez HerreroNo ratings yet

- Grade 11 ICT Week 1Document13 pagesGrade 11 ICT Week 1Baki100% (4)

- Boiler Mountings and AccessoriesDocument14 pagesBoiler Mountings and AccessoriesAnil DamaheNo ratings yet

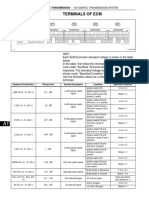

- A750F Automatic Transmission SystemDocument3 pagesA750F Automatic Transmission SystemĐạt NguyễnNo ratings yet

- Mr. Krunal Patel PNR: G8H6Jf/ SG: Ahmedabad (T1) SG 4491 BagdograDocument3 pagesMr. Krunal Patel PNR: G8H6Jf/ SG: Ahmedabad (T1) SG 4491 BagdograKrunal PatelNo ratings yet

- Finnish Winter Navigation 18-19 PDFDocument30 pagesFinnish Winter Navigation 18-19 PDFАндрей КирилловNo ratings yet

- A. Des ResearchDocument39 pagesA. Des ResearchJesus RodriguezNo ratings yet

- Article Revision Report (AGD)Document18 pagesArticle Revision Report (AGD)FikeduNo ratings yet

- European Road Mobility During The Marshall Plan YearsDocument19 pagesEuropean Road Mobility During The Marshall Plan YearsMd. Abu TaherNo ratings yet

- Banzai Гайковерты.Document24 pagesBanzai Гайковерты.MasterrNo ratings yet

- Warehouse 1 of 9: List of Pre-Owned Vehicles For SaleDocument11 pagesWarehouse 1 of 9: List of Pre-Owned Vehicles For SaleJeremiah GatchalianNo ratings yet

- Liye - Info Manual Motro Cat 3406 Volumen 01pdf PRDocument634 pagesLiye - Info Manual Motro Cat 3406 Volumen 01pdf PRM/V C-Ambassador100% (1)

- Catalog Tu ZG3.2 Gian 35kV H'MunDocument40 pagesCatalog Tu ZG3.2 Gian 35kV H'MunHà Văn TiếnNo ratings yet

- Unit ReconstitutionDocument87 pagesUnit ReconstitutionMichael CessnaNo ratings yet

- Latihan Toefl - ReadingDocument3 pagesLatihan Toefl - ReadingSyifa RizkyaNo ratings yet

- B Tech ThesisDocument69 pagesB Tech ThesisvivekNo ratings yet

- Motion Graphs Part 2 Notes and IdeasDocument5 pagesMotion Graphs Part 2 Notes and IdeasKo KoNo ratings yet

- Vertical Neighbourhood at Mumbai by Shivam SinghDocument86 pagesVertical Neighbourhood at Mumbai by Shivam SinghJashin BansalNo ratings yet

- SMK - Fuel SystemDocument19 pagesSMK - Fuel SystemDeo Agung Prananta GintingNo ratings yet

- General English Model Paper 2 - 2020Document14 pagesGeneral English Model Paper 2 - 2020SL VimuthNo ratings yet

- 3000J Tamper 0718Document2 pages3000J Tamper 0718balaji817150No ratings yet

- Goodness of Fit AssignmentDocument3 pagesGoodness of Fit Assignmentfatima zaheerNo ratings yet

- Daihatsu Charade 2003 Workshop ManualDocument3 pagesDaihatsu Charade 2003 Workshop ManualSidali KilardjNo ratings yet

- Grove Model Hl150T - 150 Ton Capacity: Transportation Specs - Conventional Truck CranesDocument6 pagesGrove Model Hl150T - 150 Ton Capacity: Transportation Specs - Conventional Truck Cranesgiledu6122No ratings yet

- Post-Test Answer Key: D. EmployeesDocument2 pagesPost-Test Answer Key: D. EmployeesSiThu KhineNo ratings yet