Professional Documents

Culture Documents

Section 27 - Ranarex Gravitometer

Section 27 - Ranarex Gravitometer

Uploaded by

hammamiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 27 - Ranarex Gravitometer

Section 27 - Ranarex Gravitometer

Uploaded by

hammamiCopyright:

Available Formats

STE

Well Test Manual 3

Section 27

Instrumentation – Ranarex

Gravitometer

Table of Contents

Introduction and Objectives……………………………………………………27-2

Specifications……………………………………………………………………27-3

General Information……..………….…………………...………………..Section 1

Installation………………………………………………………………....Section 2

Operation…………………………………………………………………..Section 3

Maintenance and Servicing………………………………………………Section 4

Calibration...………………………………………………………………..Section 5

Issued May 2007 1 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

Introduction

The section contains information on the Ranarex Gas Gravitometer

Objectives

After completing this section, you should be able to

• Understand the Specification of the Ranarex Gas Gravitometer.

• Understand the workings of Ranarex Gas Gravitometer.

• Know how to install and maintain Ranarex Gas Gravitometer.

Issued May 2007 2 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

Ranarex Gravitometer

SPECIFICATIONS

PORTABLE TYPE GRAVITOMETER

Case :

Portable with carrying handle

Size: 13%"W x 13h"H x 10%"D, excluding handle and gas hose connections

Weight: Approximately 38 lb

Readings :

Indicating dial

Drive Motor:

115 volt, +lo% 50 or 60 Hz, single-phase

Permanent split-capacitor (no arcing during Start, Run or Stop)

Explosion-proof motor not available

Accuracy :

Within 0.5% of actual value at any reading within range

Portable Gravitometers:

Dual-range: 0.52-1.03 and 0.97-1.90

GENERAL

Materials:

Case and Chassis: Aluminum

Impellers, Impulse Wheels: Molded phenolic

Drive: Stainless steel shafts; sealed ball bearings

Pivots: Stainless steel shafts in jewels

Internal trim: Aluminum and stainless steel

Ambient Temperature Rating:

Saturated gas and air: 40 to 120°F2 (4" - 50°C).

Normal gas and dry air: 0 to 130°F2 (-18" - 54°C).

Issued May 2007 3 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

SECTION I

GENERAL INFORMATION

1.1 RANAREX GAS GRAVITOMETERS

RANAREX gravitometers measure the relative density (specific gravity) of

gases as compared to air at standard temperature and pressure (STP). For all

gases there is a definite relation between the composition of the gas mixture

and its relative density. The instrument is calibrated over two ranges to

indicate relative density.

RANAREX gravitometers excel over more complex and costly analyzers in

total performance, including simplicity, fast response, accuracy, sensitivity,

ruggedness and lowest long-term cost.

1.2 THEORY OF OPERATION

The RANAREX gravitometer uses dynamic forces to measure the relative

density of a gas. The operating principle is described below. The instrument

contains two cylindrical gas-tight measuring chambers, each having separate

inlet and outlet connections. Each chamber contains an impeller and an

impulse wheel. These wheels oppose each other on separate shafts in a way

that resembles an automotive fluid coupling or torque converter. An electric

motor and drive belt rotate both impellers at the same speed.

The impellers draw the sample gas and dry reference air into their respective

chambers. The torques created on the impulse wheels are proportional to the

densities of the gas and of the reference air. The impulse wheel shafts are

coupled using a cam and flexible tape in a way that causes the torques to

balance. The ratio of the sample impulse wheel torque to the reference

impulse wheel torque represents the relative density of the gas. A mechanism

and graduated dial are used to indicate the relative density

Issued May 2007 4 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

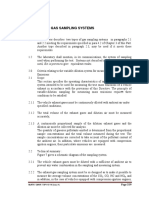

Figure 1 illustrates the measuring system for two operating conditions. The

left view shows the position of the cam and reference wheel when the

reference gas is admitted into both chambers. In this case, the impeller wheel

torques will be equal. As a result of this condition and the linear profile of the

cam, the graduated dial is calibrated to indicate 1000.

The right view of Figure 1 shows the position of the cam and reference wheel

when an unknown gas is admitted to the upper chamber and reference air is

admitted into the lower chamber. The lighter gas (in the upper chamber)

creates a smaller torque than the air in the lower chamber. As a result of this

condition, the cam will rotate until the cam radii allows the opposing torques to

balance. The cam rotation is calibrated to indicate the ratio of the torques, or

relative density.

To measure relative densities above 1.000, the unknown gas is admitted to

the lower chamber and the dry reference air is admitted to the upper chamber.

The principle of operation is the same. The graduated dial has two scales.

The inner scale is used for relative densities below 1.000. The outer scale is

used for relative densities above 1.000.

GENERAL INFORMATION

Due to the nature of the design, the pressures and temperatures of the gas

and reference air are equalized. Any changes in pressure, temperature, and

motor speed affect both torques equally. Since the torques produce opposing

forces the effects of varying pressure, temperature and motor speed are

canceled.

An air drier is built into the gravitometer to dry incoming ambient air for use as

the reference gas. The gravitometer is equipped with a selector valve that is

used to direct sample gas and dry reference air to the correct chambers. The

three positions are used for checking the instrument ZERO, for measuring gas

relative densities below 1.000, or for measuring gas relative densities above

1.000.

The motor is designed for operation on 115 VAC + l o % , 60Hz. When the

gravitometer is to be used in an area where AC power is not available, a

DCAC invertor may be used to convert the DC voltage supplied by an

automobile alternator or other DC source to the correct AC voltage.

1.3 CONDITIONING THE GAS AND AIR SAMPLES

To assure accuracy, the gas sample and the reference air must be measured

at the same temperature, atmospheric pressure and humidity content. The

sampling system must condition the gas and air to meet these requirements.

When these conditions are met, the analyzer and sampling system as a unit

will be self-compensating for all variations except the analysis and relative

density of the gas.

The RANAREX gravitometer measures relative density in accordance with the

definition:

Issued May 2007 5 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

"The ratio of the density of the gas, under the observed conditions

of pressure and temperature to the density of dry air at the same

pressure and temperature."

To provide the basis for accurate measurements a sampling system must

satisfy the following conditions:

1.3.1 Dry Reference Air

Provided by the built-in air drier. The drier uses silica gel as the desiccant and

is easily replaced when the silica gel becomes exhausted.

NOTE: The silica gel desiccant i s normally blue in color. The

desiccant must be replaced when the color has changed to pink.

1.3.2 Pressure

The gas sampling system must reduce the gas to barometric pressure to

equal the pressure of the reference air. The correct gas pressure corresponds

to a sample flow rate of 10-15 scfh for the portable RANAREX gravitometer.

The flow rate is measured by a rotameter. As an operating convenience, the

flow scale is graduated in relative density units. The operator can adjust the

needle valve so that the flow meter reads the approximate relative density of

the gas. For gas pressures above 20 psig, a suitable pressure reducing

regulator must precede the rotameter.

NOTE: The flowmeter can be used with inlet pressures up to 20 Psig.

When the sample pressure is above 20 Psig it must be reduced using an

external pressure regulator.

1.3.3 Temperature

The reference air is admitted to the gravitometer at the ambient temperature

of the instrument. For the gas and air to be measured at the same

temperature, the gas must be heated or cooled to ambient temperature. This

is important if the gas pressure has been reduced more than 100 Psig, or if

the gas flows through a temperature zone more than 10'~ (lZ°C) different from

the ambient temperature of the gravitometer. If the sample gas temperature

must be adjusted, the gas may be passed through a coiled 10 ft. (30m)

section of metal tubing before entering the gravitometer.

1.3.4 Moisture Content

Gases that are "wet" (dew point above 50°F, 10°C) must be measured against

humidified air. Gases that are "dry" (dew point below 50°F, 10°C) or gases

which would be dissolved by a humidifier, such as NH,, or gases which are

corrosive when moist, such as SO2, must be measured against dry air. Dry

instrument air may be reduced to barometric pressure and used as reference

air. If instrument air is not available, ambient air can be dried and, when

specified, the gravitometer will be equipped with an integral air drier.

Issued May 2007 6 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

1.3.5 Filtering

A commercial filter (25 micron) must be used ahead of the regulator and

flowmeter to protect the instrument. Other precautions must be used to

prevent liquids from entering the instrument. A Balston filter (or equivalent)

may be required.

NOTE: RANAREX instruments do not include the gas filter, pressure

reducing regulator or sample hose because most users have individual

preferences for these items and maintain their own stock.

1.3.6 Sampling Systems

Components for conditioning the gas and reference air may be furnished by

the purchaser. However, as a convenience and to assure correct selection, it

is recommended that they be purchased with the RANAREX gravitometer.

SECTION 2

INSTALLATION

1. Check all accessories.

A. All RANAREX gravitometers include:

1 Electric cord, 6 ft. of 18 gauge cable with male and female plugs

1 1-1/2 lb. can indicating silica gel

1 Filling funnel

1 Instruction Manual

Issued May 2007 7 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

B. When the RANAREX gravitometer is operated from a 12 volt DC battery,

the following is also furnished, unless excluded by Purchaser:

1 RANAREX Invertor

2 Battery Cables, 16 ft. of 12 gauge wire with battery clips

1 Inverter Instruction Manual (found in Reference Material section

of Gravitometer manual)

2. Select the location for the gravitometer. The instrument should not be near

hot or cold objects. Allow at least 5" clearance on the left side and 3" on the

right side for making connections and normal operating functions. If the

instrument is to be permanently mounted in one location, it should be secured

with four 1/4-20 machine screws. These screws are used with the holes in the

gravitometer base. See Figure 2 for mounting dimensions of the gravitometer

and the location of the mounting holes. See Figure 3 for location of

connections and external controls.

3. 'Install the power inverter. Read the instructions that are packed with

the inverter.

INSTALLATION

4. Fill the air drier. The air drier must be removed from the upper left side of

the instrument by loosening the two fasteners. Remove the plastic drier

assembly from the gravitometer far enough until the rubber tube can be

removed from the elbow at the rear of the drier. Remove the rubber plug on

the front of the drier by lifting the lever at the center of the plug (but do not

turn the lever).

Issued May 2007 8 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

Hold the drier horizontal with the front face up and pour silica gel using the

funnel into the spout. Tap or shake the drier vigorously and continue to fill the

drier to the base of the spout. Replace the rubber plug, attach the rubber tube

on the elbow at the rear of the drier, install the drier into the gravitometer.

NOTE: I f the drier assembly is damaged, the entire assembly must be

replaced.

The moisture capacity of the silica gel will vary according to the atmospheric

humidity and it must be inspected at regular intervals. When the upper half of

the narrow compartment shows a change from deep blue color to gray-pink

color, the silica gel must be replaced.

Active silica gel has a deep blue color and must be kept in a tightly closed

container. Expended silica gel has a light grayish-pink color. The silica gel

may be reactivated and used over and over again. To reactive, heat the silica

gel in an open container to approximately 250°F until the dark blue color

returns, then store in a tightly closed container. Additional silica gel may be

obtained from Chandler Engineering as Part

5. Attach the outlet hoses. If the gravitometer is operated in a confined space,

such as inside a vehicle, the gas sample must be discharged outside the

vehicle. This will prevent contaminating the operating space with noxious or

hazardous gas and air mixtures. If measuring only gas below 1.000 relative

density, attach a hose to the port LIGHT GAS OUTLET on upper right side of

gravitometer case. If measuring gases above 1.000 relative density, attach a

hose to the port HEAVY GAS OUTLET. These hoses must remain attached

when checking the instrument "zero point".

6 . Gas filter. If the gas contains suspended particles larger than 25 microns,

or if the gas is "wet", filtering is required. If a commercial filter is not available,

a suitable moisture trap may be made from 1" (2.54cm) pipe 15" (38cm) long

mounted vertically. Cap both ends and install a drain valve in the bottom cap.

Install an inlet connection from the gas line 2" (5cm) from the bottom and

place the outlet to the gravitometer 2" (5cm) from top. Fill the pipe loosely with

commercial No. 0 steel wool. Drain the trap frequently to keep the steel wool

free from condensate.

7. Gas temperature. If the gas sample is at a pressure above 100 Psig, or if

the sample flows through a temperature zone more than 10°F (-12°C)

different from the ambient temperature of the gravitometer, sample

temperature adjustment is required. Install a section of 3/8" (lcm) metal tube

10 ft (3m) long, and locate it near the gravitometer case. The tube may be

coiled or bent to suit the space available. The tube will serve as a heat

exchanger to heat or cool the sample gas.

8. Make the gas sample connection. Attach a pressure reducing regulator to

the sample tap and route the sample line to the gravitometer. The sample line

must be capable of delivering 12 SCFH gas, free of condensed liquids, at a

pressure not exceeding 15 Psig. It is recommended to use proper sample

probes and sampling techniques as defined in ASTM, GPA, and API

standards.

Issued May 2007 9 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

SECTION 3

OPERATION

Caution: This type WAREX Gravitometer is provided with a Pointer Lock

(Figure 4), which must be locked at all times when the RANAREX motor i

s not operating. The function of the lock is to exert tension on the

flexible tape, which connects the cam and reference wheel (Figure 1) .

This tension maintains correct "tracking" of the tape when the

RANAREX is stopped. The user is cautioned to leave the lock applied

until after the RANAREX motor has been started and to apply the lock

before shutting off the motor, to avoid operating inconvenience and

prevent damage to the RANAREX .

The "LOCK" position of the pointer is at the upper right corner of the scale,

near the 0.970-1.030 graduations. The position of the locking mechanism is

shown by the arrow of the knob and the legends on the gravitometer front

cover. To check if the pointer is locked, turn the knob to "UNLOCK" and

observe if the pointer drifts downward, then turn the knob to the "LOCK"

position and observe if the pointer snaps into original position.

3.1 PROCEDURE

The correct procedure for operating the RANAREX gravitometer is described

on the instruction plate located over the center of the indicating scale and

reproduced as Figure 5 of this section. It is recommended that the user

observe the sequence of steps as listed. In this way, maximum accuracy will

be achieved.

The following comments are also helpful :

3.1.1 Zero Adjustment:

The zero adjustment screw must be turned in the direction opposite to the

correction required in the pointer reading. For example, if the pointer must be

moved clockwise to 1.000 on the scale, the screw should be turned

counterclockwise. After making adjustments, allow the pointer to stabilize.

During normal operation, the zero adjustment screw will require less than a

1/4 turn to set pointer to 1.000. If more than 1/2 turn is ever required, stop the

motor and investigate the cause.

NOTE: Never turn the zero adjustment screw to the l i m i t of the

adjustments (clockwise or counter- clockwise) with motor operating.

3.1.2 Response Time:

When measuring gas at the normal flow rate of 12 SCFH, the response time

to reach the final reading is 40-45 seconds. This time can be reduced by

operating at a higher flow rate, obtained by adjusting the flow meter valve so

the float reads higher than the actual gas relative density.

Issued May 2007 10 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

For example, when measuring 0.6 gravity gas, a flow meter setting of about

1.2 will reduce the response time to about 30 seconds. However, the flow

must not exceed the range of the flow meter.

3.1.3 Over-Pressure Protection:

If the flowmeter valve is opened before the selector valve is turned to "LG" or

"HG" , the valve cover will lift off the body to relieve the pressure and will be

reseated by the spring.

3.1.4 Purging to 1.000 After Measuring a Gas:

The instrument must be purged to bring the pointer within the range of the

pointer lock mechanism. If the pointer starts toward 1.000 and then hesitates

and remains at an intermediate reading, turn the selector valve halfway

beyond "0" toward the next position. If the pointer then continues toward and

reaches 1.000, check for an obstruction as described in the Troubleshooting

Section.

Issued May 2007 11 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

SECTION 4

MAINTENANCE AND SERVICING

4 .1 LUBRICATION

The motor bearings, impeller bearings and idler pulley bearings have long-life

lubrication to provide long service. If the impeller bearings bind or become

extremely noisy, they may be lubricated as described in the section titled

Impeller Bearings, or the complete assembly may be replaced. The idler

pulley bearing should be inspected and re-lubricated if it does not turn freely

or becomes noisy.

4 . 2 SELECTOR VALVE

If the sample selector valve is contaminated, it will require cleaning and

lubrication. Should this become repeatedly necessary, a gas filter should be

used. To clean the selector valve, remove the screw at the center of the valve

cover and withdraw the screw, 2 washers, spring and cover. Remove all old

grease and contamination from the surfaces and channels in the cover and

valve body. Lubricate the faces of the cover and body with silicone-based

grease and replace all parts. If the valve cover or valve body become scored,

it is necessary to lap/polish the mating surfaces to eliminate the scoring.

Clean both surfaces, apply fine valve grinding compound to them and

reassemble the valve. Loosen the detent spring which engages the "O”, "LG"

and "HG" notches of the cover. Repeatedly rotate the cover on the valve body

beyond its normal operating range, continuing until the scoring is removed.

After the lapping/polishing operation, thoroughly clean, lubricate and

reassemble all parts.

4.3 POINTER LOCK

If the connecting tape leaves the cam or reference wheel while the

gravitometer is in transit, the pointer lock will require adjustment in the

following sequence:

1. Remove the front cover to check if the sides of the U-hook at end of lock

spring are parallel with inner face of the cover, and if the set screw is fully

tightened in the shaft of the lock knob. Turn the spring and tighten the screw if

necessary.

2. Remove the indicating scale, track the connecting tape on the cam and

reference wheel, then set pointer approximately at the 1.000 position. Hold

front cover by hand in correct position on gravitometer casing. Turn the knob

toward the lock position to check if the U-hook straddles the radial edge of the

cam. If necessary, bend the spring in the correct direction at the knob shaft.

3. Hold the front cover to the casing by hand, turn knob toward lock position to

check if the spring takes up the slack in the connection tape before the lower

end of the spring snaps between the detent pins of the cover. If it does not,

bend the upper section of the lock spring, at the knob, toward the cam edge.

This will be toward the left when viewed from inside the cover.

4. Finally, with the cover held to the casing, check if the lower end of the lock

spring will snap between the detent pins and will be retained. If necessary,

bend the lower end of the spring toward, or away from, the front cover, as

required.

Issued May 2007 12 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

4.4 CARE OF THE CONNECTING TAPE

4.4.1 Tracking the Tape

Release the pointer lock and remove the front cover and indicating scale. If

tape does not track on both the measuring and reference wheels, turn both

wheels clockwise. Replace the tape onto each wheel, set pointer to

approximately 1.000 and turn the reference wheel to take up slack in the tape.

If tape has fallen behind either wheel, extract it carefully by rotating the wheel

as necessary, to avoid kinking the tape.

4.4.2 Cleaning the Tape

Wipe off dust, finger marks, or oil with tissue or cloth. Do not use cleaning

fluid or solvent. At the same time clean the rims of the cam and reference

wheel.

4.4.3 Replacing the Tape

If a new tape must be installed, loosen the clip screws at the ends of the tape,

remove retaining clips from the rims of the cam and the reference wheels and

remove the old tape. Hook the new tape over the screw heads and install clips

with curved end pointing in direction of tape. Adjust tape flush with edges of

the wheels and tighten the clip screws.

If spare tape is not available, a replacement tape can be made from 3M

Company "Scotch" brand #I75 Tenzar Recording Tape, or any other 1.5 MIL

Heavy Duty Mylar Recording Tape. Cut tape to 13-9/16" long and punch 2

holes 9/64" diameter spaced 13-1/16" center to center. Check the operation of

the pointer lock and if necessary, adjust it as described in Section 4.

4.5 DRIVE BELT TENSION

The correct tension required to prevent belt slippage without overloading the

bearings is maintained by a spring loaded idler pulley. If dust or dirt

accumulates between the idler pulley arm bushing and the pivot shaft, it will

interfere with free motion and must be removed. Before disassembling,

scratch a mark on the face of the adjusting collar and end of the pivot shaft to

show the original positions. Obtain a firm grip on the collar by inserting a pin in

a hole in the rim or face and loosen set screw. Allow collar to turn clockwise

until spring tension is relieved, then draw collar and arm off shaft. After

cleaning, reassemble in original position.

The correct load of the idler pulley on the belt is 5 to 6 pounds which may be

measured with a spring scale. Remove belt and place scale hook around

pulley shaft. Pull on the scale in direction perpendicular to the normal position

of the idler pulley arm until the pulley is swung into its normal position. If

necessary to increase the load, turn the adjusting collar one quarter turn

counterclockwise to the next flat of the pivot shaft. Before loosening the set

screw, obtain a firm grip on the collar by inserting a pin in a hole in the rim of

face.

Issued May 2007 13 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

4.6 IDLER BEARING

This bearing should be inspected and replaced if it does not turn freely or

becomes noisy.

NOTE: Bearing is lubricated as shipped. It cannot be disassembled but

can be relubricated when necessary.

1. Grip round shaft where it extends from pulley.

2. Remove adapter shaft by gripping hex section and turning for right-hand

thread. Unscrew adapter shaft completely but do not lose split lock washer.

3. Insert tip of grease tube (PN 187-14010 or equivalent) into the tapped hole

in the pulley shaft. Fill the hole with grease.

4. Replace adapter shaft in pulley shaft. Be sure split lock washer is in

position in recess around base of male thread.

5. Tightening the adapter shaft into the pulley shaft will force the grease into

the bearings. Excess grease will be forced out through the seals but do not

use more grease than needed to obtain smooth rotation of shaft in the pulley.

4.7 GRAVITOMETER DISASSEMBLY PROCEDURE

If the gravitometer must be disassembled, the following sequence must be

observed.

1. Front Cover: Release pointer lock and turn fully to UNLOCK position to set

lock spring below bottom of scale plate. Loosen the 8 fasteners but hold cover

from dropping downward on scale and pointer. If cover is placed flat on

bench-top, inside face must be upward to avoid damage to locking spring.

2. Rear Cover: Loosen the 8 fasteners to remove the rear cover.

3. Indicating Scale: Set pointer to about 0.950 and loosen scale fastening

screws one turn. Lift scale up so keyholes will pass over screw heads. Then

move scale downward holding it in until right side clears pointer.

4. Front Chamber Cover: Remove 8 screws around the rim of both

chambers. Grasp assembly by scale posts and zero adjust screw and pull

forward. The assembly may be set down on a bench-top against the 4 pins

which project from the rear, or it may be placed on the right edge, steadied by

the zero adjust screw. In this position exercise care that the pointer is not

bent.

5. Rear Chamber Cover: First remove the Front Chamber cover. Then

remove the belt and unscrew both impellers from front of the chambers;

impellers have right hand threads. Remove 8 screws around rim of chambers

and 2 inner screws at lower section of casting. Grasp assembly by bearing

housing and pull outward from body. Assembly may be set on right edge,

steadied by idler pulley, or may be placed on bench with pulleys downward.

6. Operating Mechanism (Front chamber cover, chamber Body and ear

Chamber Cover) : Remove front and rear covers, as previously described,

and unscrew outlet nipples from right side of casing. Remove 2 outer screws

from base of assembly accessible through rear. Remove 2 screws with

carrying handle and internal spacer plate from upper section.

Issued May 2007 14 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

Slide assembly to rear of the instrument, supporting it by hand and guided by

pins in lower section.

4.8 IMPELLER BEARINGS

The impeller ball bearings are lubricated with sufficient grease for 2-3 years of

operation. If the bearings do not turn freely or become noisy, the bearings

should be replaced. The bearing part number is 187-17004. A design

modification has been implemented to this assembly to improve its operating

performance at low temperature as well as to simplify its service procedure.

The new design uses double seal ball bearings and additional o-rings to seal

between the bearing (Key No. 1246/PN 187-17004) and the impeller shaft

(Key No. 1247/PN 302-01889) and between the bearing and the impeller

bearing casing (Key No. 1248/PN 302-01888). Use Part Number 300-00258 if

ordering the complete bearing and shaft assembly. There is no need to fill the

void between the impeller shaft and casing with bearing grease (P/N 187-

14010).

NOTE: All portable gravitometers with serial number P-259 and later

incorporate the new design b a l l bearing assembly.

4.8.1 Impeller Disassembly

a. Remove the front chamber cover assembly, impellers and rear chamber

cover assembly from the operating mechanism per instructions 1-5 in the

section titled

Gravitometer Disassembly Procedure.

b. Temporarily reinstall front chamber cover assembly in instrument to avoid

damage while working on bearings.

c. Remove the nuts from the shaft without bending it.

d. Mark the pulleys and shafts so that they can be reinstalled in their original

positions.

e. Gently tap on the end of the shafts to push the front ball bearing out of

housing. Use small bearing puller to remove bearing from shaft.

f. Gently push or tap on threaded end of shaft to push the rear bearing out of

the housing. Use small bearing puller to remove bearing from shaft.

4.8.2 Impeller Assembly

a. Inspect and clean interior of impeller bearing casing and the shaft.

b. Insert shaft and bearing into bearing casing. Replace the nuts on the ends

of the impeller shafts. Install bearing on pulley end of shaft. Seat bearing bore

against shoulder of shaft and turn shaft by hand to check for smooth rotation.

c. Reassemble the rear chamber cover assembly, impellers, front chamber

cover assembly in reverse order of disassembly.

Issued May 2007 15 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

4.9 TROUBLESHOOTING

To be accurate the gravitometer must satisfy the following operating

conditions:

* Sufficient flow of gas sample and reference air

* Impellers rotating at correct speed

* Pointer moves without friction

Instrument free of internal leaks

* Pointer statically balanced

* Air drier filled with active silica gel

* Instrument is properly calibrated

If there is reason to believe the gravitometer is reading incorrectly, tests and

remedies should be made in the sequence described below. If necessary to

disassemble the gravitometer, refer to the Gravitometer Disassembly

Procedure found earlier in this section.

1. Check the gas and air flow. Disconnect all inlet and outlet hoses, set

selector valve to "0" and purge the gravitometer. Verify that there is flow at the

discharge ports. If there is no evidence of flow, disconnect the hose from the

rear of the air drier and retest. If flow is established, empty the air drier, clean

the outlet elbow, fill with fresh silica gel (6-16 mesh) and retest.

If there is no evidence of flow, remove the cover of the selector valve, inspect

and clean the ports and channels of the cover and valve body and retest.

Finally, if there still is no evidence of flow, it indicates the passages within the

instrument are obstructed. Remove the rear chamber cover and check the

passages which extend from impeller bearing location to the elbows near the

bottom of the chamber cover. Also check the outlet tubes and nipples from

both chambers.

2. Check the impeller speed. Correct speed is approximately 2800 RPM as

measured with a strobe tachometer. If a tachometer is not available, remove

the drive belt and verify that the motor pulley, impeller pulleys, and the idler

pulley turn freely. If the impeller pulleys do not turn freely, lubricate the

impeller bearings as described earlier in the section titled Impeller Bearings or

replace the assembly. If the idler pulley does not turn freely, the motor should

be replaced.

3. Check for frictionless indicator response. Remove front cover and connect

the instrument to a gas sample. Record the reading. Gently move the

indicator to each side of the true reading and release. Indicator should return

to the same reading from each direction, within -001 relative density within 15

seconds. If it does not, the impulse wheel shafts and bearings should be

cleaned. Remove the front chamber cover of the operating mechanism and

hold it upright by gripping firmly in a vise, or stand it securely on right side

edge. Loosen the set screws in the hub of the cam and reference wheel and

draw the impulse wheels with shafts out of the bearings. Use care that the

cam and reference wheels and the flexible tape are not damaged while

removed from the instrument. Tag the impulse wheels to indicate the chamber

from which they were removed. Polish the shafts with crocus cloth or fine

steel wool. Do not bend the shafts.

Issued May 2007 16 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

If the impulse wheel shafts show a bright polished groove where they rotate in

the jeweled bearings, or if the hubs of the cam and reference wheel show a

groove where they have been drawn against the ends of the impulse wheel

bearings, these grooves should be removed by lapping and polishing. If the

wear is excessive, the shafts must be replaced.

Gently blow out the impulse wheel bearings with clean air or gas and add a

drop of instrument oil to both ends of each bearing. Suitable oil is available

from Chandler Engineering.

Replace the shafts with wheels in their bearings in the correct chamber and

turn them slowly. If the protruding portion of the shaft wobbles or if the wheel

does not turn freely, the shaft should be replaced with a new one. A bent

impulse wheel shaft will cause the instrument to lose accuracy and sensitivity.

Attach the measuring and reference wheels to the impulse wheel shafts being

certain that the set screws bear on the flats of the shafts. A small amount of

shaft end play [.005" to 0.010" (.13-.25mm) maximum] must exist to prevent

binding. Verify that no parts of the indicating mechanism have been bent and

that there is no binding between parts.

4. Check for internal leaks. Operate the instrument connected to a gas sample

and obtain a relative density reading at the far end of the measuring range.

Shut off the gas flow by closing the flowmeter valve. The indicator should

remain steady or should not return toward 1.000 reading at a rate faster than

.007 on the inner scale in 3 minutes. If it does not meet this test, there is an

internal leak. To determine where the leak is located, stop the motor, remove

the front and rear covers and disconnect hose from the inlet port of the

selector valve. Individually pressurize (approximately 10 psig) the upper and

lower chambers with gas and use a gas leak detector to find the leak.

The leak is probably caused by loose screws or a gasket which has become

damaged. Verify that the Tygon7 tubes which join the internal connector to the

selector valve and to the elbows near bottom, of rear chamber cover are not

cracked or damaged.

5. Check the indicator balance. The measuring mechanism was statically

balanced by the manufacturer and does not change with wear or age. The

balancing weights behind the cam should not be disturbed. However, if

required, the balance can be verified and restored as described below.

Stop the motor and remove the front cover. Place the pointer consecutively at

the right side, bottom, and left side of the scale. In each position tap the front

of the gravitometer case to overcome static friction. The pointer should remain

stationary or very nearly so. If it drifts more than two small graduations on the

red scale, make compensating adjustments of the balancing weights on the

threaded rods. When loosening or re-tightening the balancing weights, use

care that the threaded rods, pointer and impulse wheel shaft are not bent or

damaged.

Balancing the cam and mechanism is a trial and error process. The pointer

may be considered balanced if it remains steady or drifts only two scale

divisions. After rebalancing, do not permit the weights to be moved. A drop of

low strength Loctite7, lacquer, or fingernail polish on the weights and threaded

rods will lock the adjustments is place.

Issued May 2007 17 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

6. Check the silica gel in the air drier. If silica gel is exhausted, remove and

empty the air drier. Refill with active silica gel.

7. The gravitometer was accurately calibrated by the manufacturer and the

calibration does not change appreciably with wear or age. The adjustments

should not be changed without first checking every other possible source of

error. Calibration should proceed if all other sources of error are eliminated.

8. Sometimes during calibration, repeatability problems occur due to static

friction

Gently tapping the side of the case will eliminate the static friction.

SECTION 5

CALIBRATION

To calibrate the instrument there are three adjustments:

1. Zero Adjust. This is the only adjustment required in normal operation. The

zero adjust screw operates the chain, sprockets and lower impulse wheel

bearing which positions the lower impulse wheel longitudinally in the lower

chamber to match the torque of the upper chamber when operating on air.

Refer to the section titled Zero Adjustment in Section 3 for instructions for use

of the zero adjust.

2. Sensitivity. The longitudinal position of the upper impulse wheel in the

upper chamber governs sensitivity of the instrument. If the pointer is too

sensitive, it may be reduced by moving the upper impulse wheel closer to the

front of the chamber, by turning the upper impulse wheel bearing

counterclockwise. If the pointer lacks sensitivity (and if there is no evidence of

mechanical binding), it may be increased by moving the upper impulse wheel

closer to the rear of the chamber, by turning the upper impulse wheel bearing

clockwise. This adjustment requires loosening the 7/8" hex lock nut behind the

measuring wheel, turning the 1/2" hex head of the bearing in correct direction,

and tightening the lock nut. Turn only one flat (1/6 turn) at a time and retest.

3. Span Adjustment. The span of the gravitometer is governed by the angular

position of the pointer on the measuring wheel. To permit adjustment, the

pointer is attached to the measuring wheel by two screws which pass through

circular slots in the pointer hub. If span adjustment is necessary, the pointer

should be moved in relation to the measuring wheel in the direction of the

desired reading. For example, if the pointer reads numerically too high on the

red scale (too low on the black scale), the pointer should be moved clockwise.

Similarly, if the pointer reads numerically too low on the red scale (too high on

the black scale), the pointer should be moved counterclockwise.

Before making an adjustment, mark the position of the pointer hub on the face

of the cam, then loosen the screws just enough that the pointer can be turned

against slight friction of the washers under the screw heads, but that it will not

slip freely. Make adjustments in small increments of 2 or 3 small graduations

on the red scale at one time and retest. When either the sensitivity or span

adjustment is changed, it is necessary to reset the zero adjust to 1.000 on air.

Issued May 2007 18 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

5.1 CALIBRATION PULLEY

A Calibration Pulley is fastened inside of every new instrument. This pulley

can be used, instead of a certified gas, to check the calibration of the

instrument. The pulley, Part No. 315-03031, is intended to make the

instrument read 0.640 theoretical relative density. Because of the tolerance on

the ,diameters of the pulleys, the following test procedure must be used to

determine the exact relative density (k.001) the pulley will produce.

1. Operate Gravitometer with new silica gel in the drier and the selector valve

on "0" . If necessary, turn ZERO ADJUST until pointer reads 1.000.

2. Turn power OFF; remove Upper Impeller Pulley and measure its maximum

diameter at the crown with a micrometer.

3. Install the Calibration Pulley on the Upper Impeller Shaft. Measure its

maximum diameter at the crown, using the micrometer.

4. Continue to operate the gravitometer without making any adjustments.

Observe and record the relative density reading.

5. Divide the diameter of the standard Upper Impeller Pulley by the diameter

of the Calibration Pulley and square the answer. This value is the correct

relative density reading.

6. If it is necessary to test the calibration at different relative density values, a

Calibration Pulley is required for each test value.

7. After completing the tests, replace the Calibration Pulley with the standard

Upper Impeller Pulley and store the Calibration Pulley for future use. The

following additional calibration pulley sizes are available:

Issued May 2007 19 Ranarex Gas Gravitometer

Revision 1

STE

Well Test Manual 3

Issued May 2007 20 Ranarex Gas Gravitometer

Revision 1

You might also like

- Calculating Settle Out PressureDocument5 pagesCalculating Settle Out PressureBehnam HosseinzadehNo ratings yet

- Calculating Settle-Out Pressure in Compressor Loops - Hydrocarbon Processing - November 2006Document3 pagesCalculating Settle-Out Pressure in Compressor Loops - Hydrocarbon Processing - November 2006bogusi100% (1)

- XCAP Quick GuideDocument56 pagesXCAP Quick GuideZaryab NisarNo ratings yet

- Oxysystems 2v3x 172 4.1 ManualDocument21 pagesOxysystems 2v3x 172 4.1 ManualDavid GarciaNo ratings yet

- Airtester HP-3-GB D3188001 03Document7 pagesAirtester HP-3-GB D3188001 03federalulNo ratings yet

- Cardless ATM Using Raspberry PiDocument4 pagesCardless ATM Using Raspberry PiSanjay ShelarNo ratings yet

- Section 27 - Ranarex GravitometerDocument48 pagesSection 27 - Ranarex GravitometeriqmpslabNo ratings yet

- Catalogo GeneralDocument21 pagesCatalogo GeneralJavierfox98No ratings yet

- Vibration Related Testing For Hermetic Compressor DevelopmentDocument6 pagesVibration Related Testing For Hermetic Compressor DevelopmentDevendra YadavNo ratings yet

- Plugin 005Document4 pagesPlugin 005csierracdtNo ratings yet

- Summary of The ReportsDocument6 pagesSummary of The ReportsStanley BoswellNo ratings yet

- Performance and Efficiency Test of A Refrigeration Plant Test ProcedurDocument4 pagesPerformance and Efficiency Test of A Refrigeration Plant Test ProcedurEJ TolentinoNo ratings yet

- HVAC T and C StandardsDocument67 pagesHVAC T and C StandardsArun kumarNo ratings yet

- RE500 Air ManifoldDocument14 pagesRE500 Air ManifoldAbhishek SrivastavaNo ratings yet

- Compressor Performance TestDocument13 pagesCompressor Performance TestAnonymous dGzE1FUSTL100% (3)

- Measurement of Atmospheric Pressure: 3.1 GeneralDocument24 pagesMeasurement of Atmospheric Pressure: 3.1 GeneralAso SerwanNo ratings yet

- An Inside Look at Gas Mixers: Product SpotlightDocument3 pagesAn Inside Look at Gas Mixers: Product SpotlightpdiconpNo ratings yet

- Part 09 Chapter06Document18 pagesPart 09 Chapter06SrewaBenshebilNo ratings yet

- Course Number: Me 433 Fluidics: Pneumatic System & CircuitDocument16 pagesCourse Number: Me 433 Fluidics: Pneumatic System & CircuitM RazzaqueNo ratings yet

- Settle OutDocument6 pagesSettle Outamitgoel1989100% (1)

- Em MissionsDocument3 pagesEm Missionsภูเก็ต เป็นเกาะNo ratings yet

- Aer 134 Unit-5Document50 pagesAer 134 Unit-5Adrian ArasuNo ratings yet

- 10.1 Ventilation Surveys - Undergound Ventilation SurveyDocument8 pages10.1 Ventilation Surveys - Undergound Ventilation SurveyDeepakKattimaniNo ratings yet

- Equipment inDocument5 pagesEquipment inAmmy kNo ratings yet

- API 20.1 Liquid Allocation Measurement 1995Document7 pagesAPI 20.1 Liquid Allocation Measurement 1995wellington88100% (1)

- Atmospheric PressureDocument30 pagesAtmospheric Pressureanon_728532472No ratings yet

- ATPL Inst 8.3 PDFDocument4 pagesATPL Inst 8.3 PDFKoustubh VadalkarNo ratings yet

- Scribd Training Report Air CompressorsDocument7 pagesScribd Training Report Air Compressorsysudharnnan100% (1)

- ASHRAE Standards For Making Solar Air HeatersDocument22 pagesASHRAE Standards For Making Solar Air HeatersAarjab GhimireNo ratings yet

- TN43183 - E 11-13C-St2-HighDocument3 pagesTN43183 - E 11-13C-St2-HighYan RiveraNo ratings yet

- T G D N 1: N G - P C P: Echnical Uidance Ocument UmberDocument20 pagesT G D N 1: N G - P C P: Echnical Uidance Ocument UmberpaulNo ratings yet

- Fundamental Principles of Gas Turbine Meters: Wayland Sligh Instromet IncDocument3 pagesFundamental Principles of Gas Turbine Meters: Wayland Sligh Instromet Incmyself_riteshNo ratings yet

- Chapter 3: Test Procedure For Measurement of Gaseous Pollutants From Diesel EnginesDocument10 pagesChapter 3: Test Procedure For Measurement of Gaseous Pollutants From Diesel EnginesApurva IndrodiaNo ratings yet

- Cable Tray Manual For Electrical Engineers and Designers 2014Document16 pagesCable Tray Manual For Electrical Engineers and Designers 2014zaffarNo ratings yet

- Application Data: Combustion Management Solutions Full-Metered, Cross-Limited ControlDocument6 pagesApplication Data: Combustion Management Solutions Full-Metered, Cross-Limited Controlsprotkar100% (1)

- Fundamentals of Gas Meter StationsDocument6 pagesFundamentals of Gas Meter StationsRachel BaileyNo ratings yet

- Is 13687 1993Document15 pagesIs 13687 1993ADIPESHNo ratings yet

- Fundamentals of Gas Pipeline Metering StationsDocument5 pagesFundamentals of Gas Pipeline Metering Stationsranjit.martisNo ratings yet

- CHAPTER 8 Natural Gas MeasurementDocument38 pagesCHAPTER 8 Natural Gas Measurementfaitholiks841No ratings yet

- Ngineering ATA: Field Testing of FansDocument5 pagesNgineering ATA: Field Testing of FansMohamed TahounNo ratings yet

- Unit 2 Part A 1. Write Short Notes On A) Deliver Ratio B) Trapping Efficiency C) Charging EfficiencyDocument22 pagesUnit 2 Part A 1. Write Short Notes On A) Deliver Ratio B) Trapping Efficiency C) Charging EfficiencyJVCNo ratings yet

- Process Compressor Gas SealsDocument3 pagesProcess Compressor Gas SealsGaurav SinghNo ratings yet

- Ac 2013 FinDocument15 pagesAc 2013 FinRay WangNo ratings yet

- Manual TLDocument59 pagesManual TLSebastian OlayaNo ratings yet

- Gauges and Ancillary EquipmentDocument26 pagesGauges and Ancillary EquipmentAlbertoNo ratings yet

- Fundamental Principles of Rotary Displacement Meters: Wayland Sligh Instromet IncDocument4 pagesFundamental Principles of Rotary Displacement Meters: Wayland Sligh Instromet Incmyself_riteshNo ratings yet

- ExamplesDocument11 pagesExamplesdong_hkNo ratings yet

- Performance and Mechanical Running Tests of Centrifugal Compressors PDFDocument9 pagesPerformance and Mechanical Running Tests of Centrifugal Compressors PDFDaniel Key Bordin100% (1)

- Fuel Gas System of Ktgtps-PresentationDocument23 pagesFuel Gas System of Ktgtps-PresentationShm BilalNo ratings yet

- Understanding Steam Sterilizer Physical Parameters: by Linda Clement and John BlileyDocument3 pagesUnderstanding Steam Sterilizer Physical Parameters: by Linda Clement and John BlileySveti Jeronim100% (1)

- Control and Condition Monitoring of Reciprocating CompressorDocument2 pagesControl and Condition Monitoring of Reciprocating CompressorPedro DiazNo ratings yet

- Air Balancing - AgDocument8 pagesAir Balancing - AgHai Le100% (2)

- 3.10 Temperature Taps 3.10.1 General: As-Lift Valve Probe TestDocument1 page3.10 Temperature Taps 3.10.1 General: As-Lift Valve Probe Testankit71989No ratings yet

- Dewpoint Compressed Air Application NoteDocument4 pagesDewpoint Compressed Air Application NoteKarthick Velayutham100% (1)

- Unaccounted For GasDocument12 pagesUnaccounted For GasShams RahmanNo ratings yet

- Guid For Air Leak in VacuumDocument4 pagesGuid For Air Leak in Vacuumscranderi100% (1)

- Modeling of Hermetic Scroll Compressors: Model Validation and ApplicationDocument24 pagesModeling of Hermetic Scroll Compressors: Model Validation and ApplicationEx LeeNo ratings yet

- Thermal Dispersion Mass FlowDocument36 pagesThermal Dispersion Mass FlowfarshidianNo ratings yet

- Handbook: Please Note Newer Operating Instructions!Document27 pagesHandbook: Please Note Newer Operating Instructions!Eslam MouhamedNo ratings yet

- Handbook: Please Note Newer Operating Instructions!Document27 pagesHandbook: Please Note Newer Operating Instructions!Ibrahim Fadhl KalajengkingNo ratings yet

- Section 28 - Deadweight TesterDocument22 pagesSection 28 - Deadweight TesterhammamiNo ratings yet

- Section 33 - Fisher 2100 and 2100EDocument14 pagesSection 33 - Fisher 2100 and 2100EhammamiNo ratings yet

- Section 32 - Hi-Lo Press PilotDocument46 pagesSection 32 - Hi-Lo Press PilothammamiNo ratings yet

- Section 30 - Relief ValvesDocument17 pagesSection 30 - Relief ValveshammamiNo ratings yet

- Section 34 - Sight GlassDocument27 pagesSection 34 - Sight GlasshammamiNo ratings yet

- Section 28 - Deadweight TesterDocument22 pagesSection 28 - Deadweight TesterhammamiNo ratings yet

- Section 23 - Floco 382 and 383 MetersDocument24 pagesSection 23 - Floco 382 and 383 MetershammamiNo ratings yet

- Section 25 - GFC 332 Gas Flow ComputerDocument30 pagesSection 25 - GFC 332 Gas Flow ComputerhammamiNo ratings yet

- Section 26 - Oilgear PV Liquid MeterDocument18 pagesSection 26 - Oilgear PV Liquid MeterhammamiNo ratings yet

- Section 2, About PetroleumDocument15 pagesSection 2, About PetroleumhammamiNo ratings yet

- Section 9, Rigging Up and DownDocument24 pagesSection 9, Rigging Up and Downhammami100% (1)

- Section 22 - MCII Flow AnalyserDocument19 pagesSection 22 - MCII Flow AnalyserhammamiNo ratings yet

- Section 24 - Floco F2500 MeterDocument28 pagesSection 24 - Floco F2500 Meterhammami100% (1)

- Section 10, Conducting The Well TestDocument24 pagesSection 10, Conducting The Well TesthammamiNo ratings yet

- Section 1 - IntroductionDocument3 pagesSection 1 - IntroductionhammamiNo ratings yet

- Section 3, Drilling and Well CompletionDocument17 pagesSection 3, Drilling and Well CompletionhammamiNo ratings yet

- Section 8 - Control Valve Flow CharacteristicsDocument6 pagesSection 8 - Control Valve Flow CharacteristicshammamiNo ratings yet

- Section 6, Well Test PlanningDocument10 pagesSection 6, Well Test PlanninghammamiNo ratings yet

- Section 4 - Gas Regulation Low PressureDocument12 pagesSection 4 - Gas Regulation Low PressurehammamiNo ratings yet

- Section 5, Introduction To Flow TestsDocument8 pagesSection 5, Introduction To Flow TestshammamiNo ratings yet

- Section 2 - Air SupplyDocument6 pagesSection 2 - Air SupplyhammamiNo ratings yet

- Section 7, Introduction To Well Testing EquipmentDocument54 pagesSection 7, Introduction To Well Testing EquipmenthammamiNo ratings yet

- Section 21 - Liquid Turbine MeterDocument9 pagesSection 21 - Liquid Turbine MeterhammamiNo ratings yet

- D300s Advanced - Shooting Custom Menu Banks 12-09-8pDocument8 pagesD300s Advanced - Shooting Custom Menu Banks 12-09-8ptelmopNo ratings yet

- SHIZUKI Capacitors and ReactorsDocument6 pagesSHIZUKI Capacitors and ReactorsUrsula JohnsonNo ratings yet

- TOPIC 1: Different Nautical ChartsDocument9 pagesTOPIC 1: Different Nautical ChartsRaymund Suaybaguio100% (2)

- Claude Shannon Masters Thesis MitDocument7 pagesClaude Shannon Masters Thesis Mitdwf6nx2z100% (2)

- At&t CL2940 Manual Del PropietarioDocument55 pagesAt&t CL2940 Manual Del PropietarioFederico Figueroa MendezNo ratings yet

- Store ConsumptionDocument11 pagesStore Consumptionwaqasasad408No ratings yet

- International Journal of ControlDocument18 pagesInternational Journal of ControlMMHFNo ratings yet

- Sample ManuscriptDocument5 pagesSample Manuscriptadi kadarsihNo ratings yet

- Catalog Naropa UniversityDocument238 pagesCatalog Naropa UniversityS4 magictechNo ratings yet

- Chapter 01 - CtsDocument56 pagesChapter 01 - CtssengthaiNo ratings yet

- Contractor's Inspection Checklist - Concrete Placement UPLOADDocument1 pageContractor's Inspection Checklist - Concrete Placement UPLOADMATE0% (1)

- I 11 Linear AnalysisDocument44 pagesI 11 Linear AnalysisTran The Khang B1806810No ratings yet

- downloadMathsA levelPapersEdexcel IALFurther PureF1QPJanuary20201520QP PDFDocument14 pagesdownloadMathsA levelPapersEdexcel IALFurther PureF1QPJanuary20201520QP PDFMaria RobellonNo ratings yet

- Social, Academic, and Business Communication in The Junctures of LifeDocument2 pagesSocial, Academic, and Business Communication in The Junctures of LifeCristina RocheNo ratings yet

- Buku UBBL 21Document232 pagesBuku UBBL 21ismail ibrahim100% (2)

- QD-BR-ST-PHI-0001 - B2 - Topside Structures Design PremiseDocument24 pagesQD-BR-ST-PHI-0001 - B2 - Topside Structures Design PremisefedemochileroNo ratings yet

- Ahmad Al Bissani I PortfolioDocument62 pagesAhmad Al Bissani I PortfolioAhmad Al BissaniNo ratings yet

- Kanishak Kataria AIR 1 Mains GS Strategy, Sources and PDF Notes222128Document6 pagesKanishak Kataria AIR 1 Mains GS Strategy, Sources and PDF Notes222128Rahul ChoudharyNo ratings yet

- British StandardsDocument26 pagesBritish StandardsHrishikesh VaspateNo ratings yet

- JF - 2 - 3 - ProjectSolution Procedures and Arguments 6pDocument6 pagesJF - 2 - 3 - ProjectSolution Procedures and Arguments 6pNikos PapadoulopoulosNo ratings yet

- Mbti Step II For PMC 04 2Document49 pagesMbti Step II For PMC 04 2TPNo ratings yet

- OAS-VD-055PPBXII-IE-LST-0001 - Fire - Gas IO Assignment List - REV 0 IFA ADocument7 pagesOAS-VD-055PPBXII-IE-LST-0001 - Fire - Gas IO Assignment List - REV 0 IFA AAhmad RezaNo ratings yet

- Expert WitnessDocument2 pagesExpert WitnessGleamy SoriaNo ratings yet

- What Is Concrete Curing Compound?Document17 pagesWhat Is Concrete Curing Compound?SHAIK ASIMUDDIN100% (2)

- ScalaDocument16 pagesScalaSamara SequeiraNo ratings yet

- Investigational Study On Strength of Fiber Concrete Using BambooDocument9 pagesInvestigational Study On Strength of Fiber Concrete Using BambooLood RafaelNo ratings yet

- Po No PO Text Doc No Vendor CodeDocument2 pagesPo No PO Text Doc No Vendor CodeAshish MishraNo ratings yet

- 19 MN VS6Document3 pages19 MN VS6Teodor EzaruNo ratings yet