Professional Documents

Culture Documents

LAMP. 4. 4. Draft Lifting Plan Procedure

LAMP. 4. 4. Draft Lifting Plan Procedure

Uploaded by

KONSULTAN RELOKASI RTGOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LAMP. 4. 4. Draft Lifting Plan Procedure

LAMP. 4. 4. Draft Lifting Plan Procedure

Uploaded by

KONSULTAN RELOKASI RTGCopyright:

Available Formats

KOP SURAT

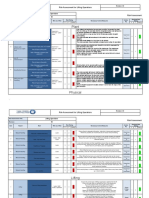

ATTACHMENT 2 : CHECKLISTS

CRANE /MOTOR VEHICLE INSPECTION CHECKLIST

CONTRCATOR/SUBCONTRACTOR

VEHICLE NO: ______________________________ PMA NO:

______________________

TYPR: ______________________________ EXPIRES NO:

______________________

MODEL: ______________________________ ROAD TAX EXPIRES NO:

____________

CAPACITY: OTHERS:

NIRC NO: _________________________ DATE OF INSPECTION: ___________

LICENSE NO: _________________________

SIGNAL MAN NAEM: -------------- ----------------

_________________________ SIGN HSE STAMP

BADGE NO:

CONTRACTORINSPECTORNAME: REINSPECTION ON:

_____________________ ____________

DATE OF INSPECTION: _____________________ INSPECTION CERT. NO:

____________

NEXT INSPECTION ON: _____________________ REINSPECTED ON:

____________

INSPECTION CERT. NO: INSPECTION CERT. NO:

ALL CRANE, EXCAVATORS, FORKLIFTS SHALL BE REINSPECTED FOLLOWING AN

ENTRY WHENEVER IT IS TAKEN OFFSITE AFTER EACH WORK DAY.

Y= YES N= NO NA= NOT APPICAABLE

LOAD RATING SHART ________________ ________________________________

SAFE LOAD INDICATOR ________________________________

OUTRIGGERS ________________________________

LEAKING HYDROAULICS ________________________________

BOOM BREAK ________________________________

BOOM HANDLING DEVICE ________________________________

HOOK OVER HEIGHT LIMIT SWICH ALARM ________________________________

HOOK CATCH/MOUSED/”C” ________________________________

BOOM TELESCOPIC MECHANISM HOLDING ________________________________

DEVICE

SLEWING BREAK ________________________________

SLEWING HOLDING DEVICE ________________________________

SLEWING LOCK ________________________________

FLY JIB ________________________________

VISIBLE DAMAGE ________________________________

VISIBLE CORROSION ________________________________

VISIBLE CRACKS ________________________________

SHACKLES WITH S.W.L ________________________________

September 2012- LIFTING,RIGGING AND HEAVY LIFTING Page 70

KOP SURAT

SLINGS WITH S.W.L ________________________________

LOCATION FOR CRANE POSITION ________________________________

GROUN CONDITION CHECKED ________________________________

OUTREIGGING WITH STEEL PLATE ________________________________

CRANE BOOM SLING WIRE ROPE CHECKED ________________________________

HOIST BLOCK CHECKED ________________________________

WORKING RADIOUS LOAD CAPACITY ________________________________

CONFIRMED

REMARKS

٭description,e.g,little,etc .

٭٭comments, e.g.descriptionof a rope deformation .

September 2012- LIFTING,RIGGING AND HEAVY LIFTING Page 71

KOP SURAT

WIRE ROPE INSPECTION CHECKLISTS

Wire rope inspection

Check List

Machine: application:

Type of rope: left hand lay right hand lay

Nominal diameter [ mm]: regular lay langs lay

Tensile strength [N/mm2]: ungalvanized galvanized

Rope length [m]: type of end fitting :

Date of installation: working hours to date:

no. of broken

Diameter/

wires abrasion corrosion other

-reduction mm/%

Location on10xd

measured Allowed no.:

٭ ٭ eff. of new rope ٭٭

Final evaluation : Date /signature:

September 2012- LIFTING,RIGGING AND HEAVY LIFTING Page 72

KOP SURAT

CHECK LIST (A)

BELOW ARE SOME ITEMS WHICH SHOULD BE CHECKED WHEN CONSIDERING

LIFTING GEAR / MATERIAL HANDLING .

No Description yes no n/a Comments

1 Is the correct color code clearly displayed on

prominent signs around the site?

2 Are suitable quarantine arrangements made for out of

spec. / out of test lifting gear?

3 Is a list of lifting gear & examination results

available?

4 Are correct slinging arrangements being used?

5 Do all crane hooks have safety latches?

6 Are slings marked with a SWL, ID number and color

coded?

7 Are personnel aware of the maximum internal angle

between each leg of a sling and that special

precautions should be taken when lifting with an angle

> 90o.

8 Is the weight of the object satisfactorily known?

9 Are all shackles and eye bolts marked with the SWL,

ID number and color coded?

9 Are all chains and plate clamps marked with the SWL,

ID number and color coded?

10 Are plates being handled correctly?

11 Has the correct examinations / tests been carried out

on the crane?

12 Before a new crane works on site has the certification

of the crane & the driver been checked?

September 2012- LIFTING,RIGGING AND HEAVY LIFTING Page 73

KOP SURAT

CHECK LIST (B) :

BELOW ARE SOME ITEMS WHICH SHOULD BE CHECKED WHEN CONSIDERING

CRANE OPERATIONS

No. Description yes no n/a Comments

1 Does the crane have the correct certification?

2 Does the crane operator have the correct

certification? Is he competent? Has he been

tested by Authorities?

3 Are the appropriate weekly checks made and

records kept?

4 Has the crane been load tested and examined

in accordance with the inspection procedures?

Are records OK?

5 Is the lifting tackle properly marked? Are the

records OK?

6 Has the lifting gear been examined in

accordance with the inspection procedures?

Are records OK?

7 Is all lifting tackles correctly color coded?

8 Is the radius/load indicator working correctly?

9 Are there audible signals both inside & outside

the cabin at predetermined radius/load values?

10 Is there a fire extinguisher in the cabin?

11 Is the crane operator aware of any restricted

area i.e. lifting over live process plant or

pipelines?

September 2012- LIFTING,RIGGING AND HEAVY LIFTING Page 74

KOP SURAT

MANBASKET Checklist

Item Y N n/a

The basket has been designed with a 5:1 safety factor by a qualified engineer and

welded by a qualified welder.

The suspension rigging system has been designed in such a way as to minimize

tipping of the manbasket

The maximum rated load and maximum capacity is posted on a permanently

affixed plate on the manbasket.

The guardrail designed to enclose the platform is provided and is enclosed from the

toeboard to the mid-rail.

Body harness anchorage provided

The access gate has been designed to open in and is positively prevented from

swinging outward while the manbasket is in use.

The access gate must have a positive locking system to prevent accidental opening

during operation.

The design allows enough headroom for employees to stand upright

There are no rough edges on any manbasket surface.

In addition to hard hats, overhead protection is provided when employees are

exposed to falling objects.

A trial-lift meeting has been attended by the crane or derrick operator, signal

person(s) (if necessary for the lift), employee(s) to be lifted, and the employee

responsible for the task to be performed

Precautions have been taken to protect employees from any special hazards in the

area where the crane and manbasket will be operating; for example, power lines or

areas where the manbasket will be out of the operator’s view.

Special precautions have been taken to protect personnel from electrical hazards.

When the crane with a manbasket is working near electrical lines or devices, the

minimum working clearances shall be at least twice those for material handling

operations.

A manbasket use authorization has been issued dated and properly signed for the

task at hand.

The manbasket and rigging has been proof-tested to 125 percent of the platform

rated capacity.

An unoccupied trial lift loaded to at least the anticipated lift weight has been

performed and hoisted to each location where work is to be performed, or to any

point where employees are expected to enter or exit the platform. NOTE: The trial

lift must be performed each time the crane is moved.

A post trial-lift inspection of the crane has been carried out by a designated

employee.

September 2012- LIFTING,RIGGING AND HEAVY LIFTING Page 75

KOP SURAT

The loading is less than 50 percent of the crane-rating chart for all work locations.

The operator has determined that all systems, controls, and safety devices are

activated and functioning properly and that no interferences exist.

The manbasket has been hoisted a few inches and has been re-inspected after the

trial lift for any deficiencies.

Prior to hoisting personnel, the manbasket has been hoisted a few inches to verify

its hang level.

All hoist ropes are free of kinks.

MANBASKET Checklist

Item Y N n/a

Multipart lines are not twisted around each other.

The hook is centered over the load.

The hoist lines are laying properly on hoist drums and in the sheaves.

All post trial lift defects have been corrected.

The crane-bearing surface has been rechecked and crane re-leveled as required.

Have the crane safety components, dogs, pawls, brakes, etc., have been re-

inspected after the trial lift.

Travel with the crane is not permitted except where all requirements are satisfied

and where not to do so would endanger life

The operator has been advised that the load and boom hoist drum brakes, swing

brakes, and locking devices such as pawls or dogs must be engaged when the

occupied personnel platform is in a stationary working position.

The operator has been advised that the platform must be hoisted in a slow,

controlled, cautious manner with no sudden movement of the crane, derrick or

platform.

The operator has been advised that the platform must be hoisted in a slow,

controlled, cautious manner with no sudden movement of the crane, derrick or

platform.

Employees have been advised to perform tasks specified in the manbasket

authorized only. NOTE: Only the number of employees needed for the task at

hand is allowed to be hoisted.

Prior to hoisting personnel, the manbasket has been hoisted a few inches to verify

its hang level.

All hoist ropes are free of kinks.

All employees have been advised to keep all body parts inside the platform during

raising. NOTE: This provision does not apply to an occupant of the platform

performing the duties of a signal person.

All employees have been advised that they are not allowed to enter or exit the

September 2012- LIFTING,RIGGING AND HEAVY LIFTING Page 76

KOP SURAT

platform when it is secured to the structure where the work is to be performed

unless securing to the structure creates an unsafe situation.

All employees have been advised that they are not allowed to exit the platform

before landing.

All employees have been advised that taglines must be used unless their use would

create an unsafe condition.

The operator has been advised to remain at the controls at all times while the crane

engine is running and the platform is occupied.

All employees have been advised that platform use must be promptly discontinued

if there is any indication of dangerous weather conditions or other impending

danger.

The operator is in constant contact by standard hand signals or voice

communications during operation of crane and manbasket.

All employees have been advised to remain in continuous sight of or in direct

communication with the operator or signal person.

All employees have been advised that the use of a radio is permissible when direct

visual contact is not possible, or where the use of a signal person could create a

greater hazard.

MANBASKET Checklist

Item Y N n/a

All employees occupying the platform have been advised to wear a body belt or

harness system, with the lanyard appropriately attached to the lower load block,

overhaul ball, or structural member within the personnel platform capable of

supporting the fall impact for employees using the anchorage.

All employees have been advised to wear a life vest when working over water.

Employees have been advised to secure materials and tools to prevent

displacement during the lift.

All employees have been advised to load the manbasket evenly and to only carry

tools and materials needed for the task at hand.

The operator, and all employees that will be using the platform, have been advised

that no other object may be lifted on any of the crane load lines while the platform

is suspended.

An audible and visual device has been provided to the personnel in the platform so

that they can signal for assistance in the event of an emergency.

Personnel have been advised to stand firmly on the floor of the platform and to not

sit or climb on the edge of the platform or use planks, ladders, or other devices for

attaining a work position.

If welding is to be performed by employees occupying the platform, the electrode

must be protected from touching the metal components of the platform.

September 2012- LIFTING,RIGGING AND HEAVY LIFTING Page 77

KOP SURAT

Any needed repairs to the crane or manbasket used only original manufacturer

parts to ensure that the new components are compatible with their original

counterparts.

Care taken to prevent ropes, electrical chords, and hoses from becoming entangled

in the platform when the platform is being moved.

Operator aids or interlocks have not been altered, modified, or disabled in any

way.

The crane operator responsible for operating the cranes used for personnel

handling is a thoroughly trained operator and has related experience operating the

subject crane.

All manuals, operating instructions, and load charts provided have been read and

understood by the operating personnel prior to starting the operation.

The operator has ensured that the area surrounding the platform is clear of

personnel and equipment before moving the platform.

Prior to the trial lift at each new location, a pre-lift meeting has been held, and is

also held for any new employee assigned to the manbasket.

All deficiencies discovered in post trial-lift inspection have been corrected.

All employees attending the pre-lift meeting signed the roster for the meeting.

The trial-lift calculation sheet has been completed, signed and dated.

All employees have been advised to keep all body parts inside the platform during

raising. NOTE: This provision does not apply to an occupant of the platform

performing the duties of a signal person.

All employees have been advised that they are not allowed to enter or exit the

platform when it is secured to the structure where the work is to be performed

unless securing to the structure creates an unsafe situation.

All employees have been advised that they are not allowed to exit the platform

before landing.

All employees have been advised that taglines must be used unless their use would

create an unsafe condition.

MANBASKET Checklist

Item Y N n/a

The operator has been advised to remain at the controls at all times while the crane

engine is running and the platform is occupied.

All employees have been advised that platform use must be promptly discontinued

if there is any indication of dangerous weather conditions or other impending

danger.

The operator is in constant contact by standard hand signals or voice

communications during operation of crane and manbasket.

All employees have been advised to remain in continuous sight of or in direct

communication with the operator or signal person.

September 2012- LIFTING,RIGGING AND HEAVY LIFTING Page 78

KOP SURAT

All employees have been advised that the use of a radio is permissible when direct

visual contact is not possible, or where the use of a signal person could create a

greater hazard.

All employees occupying the platform have been advised to wear a body belt or

harness system, with the lanyard appropriately attached to the lower load block,

overhaul ball, or structural member within the personnel platform capable of

supporting the fall impact for employees using the anchorage.

All employees have been advised to wear a life vest when working over water.

Employees have been advised to secure materials and tools to prevent

displacement during the lift.

All employees have been advised to load the manbasket evenly and to only carry

tools and materials needed for the task at hand.

The operator, and all employees that will be using the platform, have been advised

that no other object may be lifted on any of the crane load lines while the platform

is suspended.

An audible and visual device has been provided to the personnel in the platform so

that they can signal for assistance in the event of an emergency.

Personnel have been advised to stand firmly on the floor of the platform and to not

sit or climb on the edge of the platform or use planks, ladders, or other devices for

attaining a work position.

September 2012- LIFTING,RIGGING AND HEAVY LIFTING Page 79

KOP SURAT

Attachment 3: Lifting equipment register form

Lifting Equipment Register Form

N I O C

Equipment Name (Description):........................................................................................

Serial Number:.................................................................................................................

Name of manufacturer:.....................................................................................................

Subcontractor:.................................................................................................................

Working area:..............................................................................................................................................

Date of first Used: SWL:

Test Date : Test Load:

Defects:

Comments:

Results:

Defective ( Unusable) Repairable Safe

Retest date:

Operator: tester: HSE Supervisor:

Signature: Signature: Signature:

Date: Date: Date:

September 2012- LIFTING,RIGGING AND HEAVY LIFTING Page 80

KOP SURAT

SUGGESTIONS FOR THE POGC

LIFTING, RIGGING & HEAVY LIFTING OPERATIONS SAFETY PROCEDURE

MANAGER, HSE Department

Pars Oil & Gas Company

Tehran I.R. Iran

Please consider the following suggestion(s) relative to the POGC Lifting, rigging & heavy lifting operations

safety procedure:

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_________________________________________________________________________________________

_______________________________________

(Signature)

________________________________________

(Date)

________________________________________

(Address)

________________________________________

Contact Telephone Number

________________________________________

Contact FAX Number

September 2012- LIFTING,RIGGING AND HEAVY LIFTING Page 81

You might also like

- Wheelie Trainer First Manual PDFDocument28 pagesWheelie Trainer First Manual PDFGerardo Espinola Cardozo58% (31)

- Lifting PermitDocument1 pageLifting PermitFrank Abuda60% (5)

- 10795750-DKP8P8EM-Download Komatsu Pc138us-8 Pc138uslc-8 Excavator ManualDocument946 pages10795750-DKP8P8EM-Download Komatsu Pc138us-8 Pc138uslc-8 Excavator ManualEdison Correa92% (39)

- Rigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Document3 pagesRigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Cleiciane FrancoNo ratings yet

- Man Riding Checklist: HSE - 7474.0 - Rev 0 - (16-Dec-2020)Document1 pageMan Riding Checklist: HSE - 7474.0 - Rev 0 - (16-Dec-2020)MARIO LEALNo ratings yet

- Form-067-Weekly Crane Inspection ChecklistDocument2 pagesForm-067-Weekly Crane Inspection Checklistshamroz khanNo ratings yet

- Rigging Plan FormatDocument3 pagesRigging Plan FormatuzairmetallurgistNo ratings yet

- Planned Critical Lift Crane PermitDocument5 pagesPlanned Critical Lift Crane PermitsurnaikNo ratings yet

- Physics Acceleration WorksheetDocument2 pagesPhysics Acceleration WorksheetNapoleon Addison0% (1)

- TE90 Service ManualDocument0 pagesTE90 Service ManualJeferson SilvaNo ratings yet

- FC 4.1.8 - Critical Lift PlanDocument1 pageFC 4.1.8 - Critical Lift PlanJosef Demner Tiu PaspeNo ratings yet

- Monorail Overhead Travelling CraneDocument9 pagesMonorail Overhead Travelling CraneAbakar MahamatNo ratings yet

- Crane LiftsDocument1 pageCrane LiftsJasonNo ratings yet

- 3 Green Lift Checklist FormDocument2 pages3 Green Lift Checklist FormHưng Hoàng DuyNo ratings yet

- Anthony James CV Feb 24 - 2023 PDFDocument3 pagesAnthony James CV Feb 24 - 2023 PDFanthony jamesNo ratings yet

- Site:FSW - Major Overhaul GTG#1: Alstom Zero Deviation Plan Audit ReportDocument26 pagesSite:FSW - Major Overhaul GTG#1: Alstom Zero Deviation Plan Audit ReportRoy MangaraNo ratings yet

- Tools & Tackles Tpi DetailsDocument4 pagesTools & Tackles Tpi DetailsJ FREDERICKNo ratings yet

- 012 Piling WorkDocument17 pages012 Piling WorkSarah HaiderNo ratings yet

- Crane Inspection Checklist RevDocument1 pageCrane Inspection Checklist RevMuhammadHaziqHaiqalNo ratings yet

- Hot Work PermitDocument2 pagesHot Work Permitimranul haqNo ratings yet

- Webbing SligDocument8 pagesWebbing SligAJITH VSNo ratings yet

- EHSDP0120.9 Crane Operation Pre-Lift ChecklistDocument1 pageEHSDP0120.9 Crane Operation Pre-Lift Checklistshravani mangalpalliNo ratings yet

- Inspection Checklist NGS12 - GCN02Document5 pagesInspection Checklist NGS12 - GCN02El D GraciaNo ratings yet

- 8 - Lifting Plan For Transfering Engine (z1) Landing Area Then Loading From Ground To Truck and Vice VersaDocument24 pages8 - Lifting Plan For Transfering Engine (z1) Landing Area Then Loading From Ground To Truck and Vice VersaMo'tasem SerdanehNo ratings yet

- Onshore Critical Lift Plan FormDocument2 pagesOnshore Critical Lift Plan FormSyaiful Akhmad100% (1)

- Lifting Plan FormDocument2 pagesLifting Plan FormezuanNo ratings yet

- Bar Cutting Machine Safety Inspection ChecklistDocument1 pageBar Cutting Machine Safety Inspection ChecklistsanjeetNo ratings yet

- UFP - Pre-Lift Safety Checklist - CFN-1092Document2 pagesUFP - Pre-Lift Safety Checklist - CFN-1092BhaiJan59No ratings yet

- EOHSMS-02-C22 LOA Lifting SupervisorDocument3 pagesEOHSMS-02-C22 LOA Lifting SupervisorHassan Abdullah100% (1)

- Captain Francesco Suma CV: Work ExperienceDocument4 pagesCaptain Francesco Suma CV: Work Experiencemister greenNo ratings yet

- Inspection Checklist Overhead CraneDocument2 pagesInspection Checklist Overhead CraneMohammad Safdar SadatNo ratings yet

- LP 1T Pipes Critical Crane Lift Plan 25T Crane CPFDocument1 pageLP 1T Pipes Critical Crane Lift Plan 25T Crane CPFMPS PSKNo ratings yet

- Plant 6 3: Risk Assessment For Lifting OperationsDocument4 pagesPlant 6 3: Risk Assessment For Lifting OperationsIdris AdeniranNo ratings yet

- Minutes of Drill - s9.17f PDFDocument2 pagesMinutes of Drill - s9.17f PDFNaNNo ratings yet

- Tower Crane Check ListDocument1 pageTower Crane Check ListRashidi RahmanNo ratings yet

- Rigging Equipment Inspection FormDocument4 pagesRigging Equipment Inspection FormWaqar AhmedNo ratings yet

- SWP-SF010A - 11 Daily Boom - Scissor Insp Rev ADocument2 pagesSWP-SF010A - 11 Daily Boom - Scissor Insp Rev ACliffordNo ratings yet

- Inspection Report Conditional Survey Inspection Checklist: Report No: Date: 9-Mar-21Document1 pageInspection Report Conditional Survey Inspection Checklist: Report No: Date: 9-Mar-21ResearcherNo ratings yet

- Maj Concslb 043 0Document3 pagesMaj Concslb 043 0Mohammed JassimNo ratings yet

- Lifting Plan Registration PDFDocument1 pageLifting Plan Registration PDFScribdTranslationsNo ratings yet

- GMSB - Level 3 - SWI - 006 - Crane and Lifting WorkDocument16 pagesGMSB - Level 3 - SWI - 006 - Crane and Lifting WorkZulhaidy Salim100% (1)

- Appendix A1 Mobile Cranes Lift Plans Addendum Standard Lift Plan FormDocument1 pageAppendix A1 Mobile Cranes Lift Plans Addendum Standard Lift Plan FormharryNo ratings yet

- LEEA-030.2c2 Certificate of Thorough Examination (Multiple Items) (Overseas) (Dev)Document1 pageLEEA-030.2c2 Certificate of Thorough Examination (Multiple Items) (Overseas) (Dev)GaniyuNo ratings yet

- 16 Hoist ChecklistDocument1 page16 Hoist ChecklistNavdeep Singh GrewalNo ratings yet

- Official Confined Space Entry ChecklistDocument2 pagesOfficial Confined Space Entry ChecklistSaim AliNo ratings yet

- Lift Plan-Wilco Extenral StairsDocument25 pagesLift Plan-Wilco Extenral StairsEdgar ChecaNo ratings yet

- Crane Lift Work PlatformDocument13 pagesCrane Lift Work PlatformsheqarayzanNo ratings yet

- Strong Dual Hawk Tandem Rev H 2008Document70 pagesStrong Dual Hawk Tandem Rev H 2008FaderNo ratings yet

- Lifting Plan 50ton Tadano 13.8.20Document17 pagesLifting Plan 50ton Tadano 13.8.20Surin KumarNo ratings yet

- LiftingDocument5 pagesLiftingBoma IpaliboNo ratings yet

- Heavy Vehicle Monthly Inspection TagDocument3 pagesHeavy Vehicle Monthly Inspection TagCharantej TejaNo ratings yet

- Statement For Routine Lifting: (XXX Room For Your Own Numbering System)Document3 pagesStatement For Routine Lifting: (XXX Room For Your Own Numbering System)Mark Julius CabasanNo ratings yet

- Upper Mast Section Lifting PlanDocument7 pagesUpper Mast Section Lifting PlanDurgham Adel EscanderNo ratings yet

- Monthly Crane Inspection ChecklistDocument2 pagesMonthly Crane Inspection Checklistslamet4riadiNo ratings yet

- Health and Safety Policies and Procedures Manual HQS-HSE-PP-01Document12 pagesHealth and Safety Policies and Procedures Manual HQS-HSE-PP-01Ayman64No ratings yet

- LEEA-030.2c2 Certificate of Thorough Examination (Multiple Items) (Overseas) (Dev)Document1 pageLEEA-030.2c2 Certificate of Thorough Examination (Multiple Items) (Overseas) (Dev)nisarNo ratings yet

- HoistingRiggingPlan PDFDocument5 pagesHoistingRiggingPlan PDFRaja GuruNo ratings yet

- Conbextra EP120 TDS PDFDocument3 pagesConbextra EP120 TDS PDFzulfikarNo ratings yet

- 27k Crane Lifting PermitDocument1 page27k Crane Lifting Permitsafety86No ratings yet

- Ind Swift Limited (Gbu) : Manpower Summary of (Company Name) As On 31.05.2010 (Permanent)Document14 pagesInd Swift Limited (Gbu) : Manpower Summary of (Company Name) As On 31.05.2010 (Permanent)tarique1189040No ratings yet

- Appointed Person (Lifting Operations)Document2 pagesAppointed Person (Lifting Operations)reda mesbah100% (1)

- Oversized & Project CargoDocument2 pagesOversized & Project CargoEric PanNo ratings yet

- Test Certificate NDT / Inspection: - YOKRIDocument9 pagesTest Certificate NDT / Inspection: - YOKRIikponmwonsaNo ratings yet

- Simedarby Monthly ReportDocument16 pagesSimedarby Monthly ReportSumithra PushpanathanNo ratings yet

- Rencana Penugasan PersonilDocument1 pageRencana Penugasan PersonilKONSULTAN RELOKASI RTGNo ratings yet

- Daftar PersonilDocument1 pageDaftar PersonilKONSULTAN RELOKASI RTGNo ratings yet

- Lampiran 2. Survey Kondisi Dan Local Part IdentificationDocument8 pagesLampiran 2. Survey Kondisi Dan Local Part IdentificationKONSULTAN RELOKASI RTGNo ratings yet

- Time Line ScheduleDocument1 pageTime Line ScheduleKONSULTAN RELOKASI RTGNo ratings yet

- D. Bolt & Nut IdetificationDocument3 pagesD. Bolt & Nut IdetificationKONSULTAN RELOKASI RTGNo ratings yet

- Jsa SIMPLEDocument42 pagesJsa SIMPLEKONSULTAN RELOKASI RTGNo ratings yet

- Form Survey Kondisi Fisik & Draft Rencana BongkarDocument25 pagesForm Survey Kondisi Fisik & Draft Rencana BongkarKONSULTAN RELOKASI RTGNo ratings yet

- Material Take Off (MTO) Hull Construction & Outfittings Kapal Patroli ImigrasiDocument2 pagesMaterial Take Off (MTO) Hull Construction & Outfittings Kapal Patroli ImigrasiKONSULTAN RELOKASI RTGNo ratings yet

- Bibliography: and Supply Chain Management, 12Document2 pagesBibliography: and Supply Chain Management, 12KONSULTAN RELOKASI RTGNo ratings yet

- Gate and Hoist DesignDocument15 pagesGate and Hoist DesignRajivNo ratings yet

- PROBLEM 4.19: SolutionDocument10 pagesPROBLEM 4.19: SolutionGelvânio VieiraNo ratings yet

- PDF Valve ManuDocument28 pagesPDF Valve ManuSumit JadhavNo ratings yet

- Asphalt Binder MSCR UpdatedDocument12 pagesAsphalt Binder MSCR Updatedjulio sierra0% (1)

- En NEX LRDocument332 pagesEn NEX LRsandeepbhallaNo ratings yet

- Math Investigatory ProjectDocument9 pagesMath Investigatory ProjectKavinn100% (1)

- Actuador Abb Up D-AAP-UP - EDocument36 pagesActuador Abb Up D-AAP-UP - EHumberto SerratoNo ratings yet

- Part Book d10t Vol 2Document729 pagesPart Book d10t Vol 2rayendraprasyadi100% (1)

- 4T Owner Manual ENGDocument104 pages4T Owner Manual ENGruiznelsonNo ratings yet

- ETABS Shear Wall DesignDocument2 pagesETABS Shear Wall DesignMihai CalinNo ratings yet

- Physical Science Worksheet Conservation of Energy #2: KE MV GPE MGH Me Ke + GpeDocument4 pagesPhysical Science Worksheet Conservation of Energy #2: KE MV GPE MGH Me Ke + GpeJudy MelegritoNo ratings yet

- Physics Midterm Practice TestDocument4 pagesPhysics Midterm Practice TestSebastianPosadaNo ratings yet

- Effect of J-Groove On The Suppression of Swirl Flow in A Conical DiffuserDocument8 pagesEffect of J-Groove On The Suppression of Swirl Flow in A Conical DiffuserYoung Do ChoiNo ratings yet

- Dynamic Analysis of Intake Towerr PDFDocument5 pagesDynamic Analysis of Intake Towerr PDFchutton681No ratings yet

- BME18R311: Biofluids and DynamicsDocument32 pagesBME18R311: Biofluids and DynamicsEbe Nezer GNo ratings yet

- Call Us First!: Electric Generator - Groupe Electrogene - Generador ElectricoDocument36 pagesCall Us First!: Electric Generator - Groupe Electrogene - Generador ElectricojbgrayNo ratings yet

- Catalog: Flanged Safety Relief Valves Series 526 CCDocument12 pagesCatalog: Flanged Safety Relief Valves Series 526 CCSuelen SobrinhoNo ratings yet

- DV8R G3 G4flexisparepartmanualDocument107 pagesDV8R G3 G4flexisparepartmanualVlad PopescuNo ratings yet

- Lecture#1 12092022Document12 pagesLecture#1 12092022CHS WORLDNo ratings yet

- Compendiu Aer Comprimat PDFDocument230 pagesCompendiu Aer Comprimat PDFVisan GheorgheNo ratings yet

- Special Features of The MEGANE Sports TourerDocument102 pagesSpecial Features of The MEGANE Sports Tourerhrc555No ratings yet

- Service Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional InformationDocument11 pagesService Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional Informationa_sharafiehNo ratings yet

- ValveDocument30 pagesValveFrendy RianNo ratings yet

- Ujian Bulanan 1 Fizik Tingkatan 4 2013Document5 pagesUjian Bulanan 1 Fizik Tingkatan 4 2013Siti Aminah Alwi100% (1)

- Adhitya Wikan Tyoso-17031010156-Paralel D HAZARD AND OPERABILITY STUDYDocument4 pagesAdhitya Wikan Tyoso-17031010156-Paralel D HAZARD AND OPERABILITY STUDYsofi bachtiarNo ratings yet