Professional Documents

Culture Documents

13L00501A - 7P-A: General Notes

13L00501A - 7P-A: General Notes

Uploaded by

CLS AKOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

13L00501A - 7P-A: General Notes

13L00501A - 7P-A: General Notes

Uploaded by

CLS AKCopyright:

Available Formats

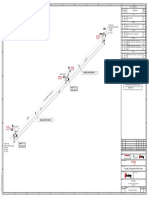

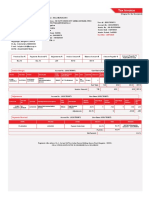

FABRICATION MATERIALS

PT COMPONENT DESCRIPTION N.B. ITEM CODE QTY

NO (INS) (mm/no.)

9a PIPE

E 161975

- P- 0

7P N 7740 7P

- 14 1 PIPE, SEAMLESS ASTM A106 GR B, ASME B36.10, BEVEL END, 12 A2/PAC11ABEG12ST 2610MM

EL +49734 0b CS01, STD

35

0

35

20 FITTINGS

2 ELBOW 90, SEAMLESS ASTM A234 GR WPB-S, ASME B16.9, 12 A2/E9C41EBWG12ST 1

2

R=1.5D, BUTT WELD, CS01, STD

EL +49734

FLANGES

3 FLANGE WN, ASTM A105N, ASME B16.5, FLANGED RAISED 12 A2/FWC31ARFAAG12ST 2

FACE, ASME CLASS 150, CS01, STD

SUPPORTS

4 STANDARD WELDED SHOE WITH REINF. PAD ; S3-12-300-CS ; 12 7PPS7936.1 1

0 RP1-1-12-340-CS-10 ; BP2-12-152x180-P

96 5 STANDARD WELDED SHOE WITH REINF. PAD ; S3-12-350-CS ; 12 7PPS7044.1 1

RP1-1-12-390-CS-10 ; BP2-12-152.4x180-P

80 ERECTION MATERIALS

6 14

TAIL NORTH

A2/F8C22AFFAAG12:SPB,300 PT COMPONENT DESCRIPTION N.B. ITEM CODE QTY

<1> 1

NO (INS) (mm/no.)

S4

7PPS7936 FITTINGS

ORI = D

6 FIG 8 FLANGE, ASTM A516 GR 70N, ASME B16.48, ASME B16.5, 12 A2/F8C22AFFAAG12 1

FLANGED FLAT FACE, ASME CLASS 150, CS01

S12

GASKETS

7PPS7936

S11 ORI = D

7 GASKET, 316L SS (ALL RINGS) WITH NON-ASBESTOS FILLER 12 A2/GAS71PAA12 3

1 (E.G. GRAPHITE), SPIRAL WOUND ASME B16.20, 4.5 MM THK

< 2>

(3.175 MM THK SOLID RINGS), FLEXITALLIC TYPE "CGI", ASME

CLASS 150

22 0 PENETRATION AT EL+48820 BOLTS

61

8 150 MM LONG, STUDBOLT, WITH 2 HEX HEAVY NUTS, ASME 7/8 BOLT-A2/150-0.875_CB 12

B18.31.2/B18.2.2, ZN-NI PLATED + WHITFORD XYLAN 1014-DEEP

F3 G7 B9 MED BLUE COLOR ASTM A320 GR L7 / ASTM A194 GR 7

1560

9 125 MM LONG, STUDBOLT, WITH 2 HEX HEAVY NUTS, ASME 7/8 BOLT-A2/150-0.875_CB 12

G7 B18.31.2/B18.2.2, ZN-NI PLATED + WHITFORD XYLAN 1014-DEEP

0

41 MED BLUE COLOR ASTM A320 GR L7 / ASTM A194 GR 7

S5 F3 G7 B8

7PPS7044 13XSV0326 INSTRUMENTS

10 PROCESS SHUTDOWN VALVE 150# 13XSV0326 13XSV0326 12 1

10

FC SUPPORTS

B S14

1 2" N FB

11 SPECIAL SUPPORT 12 7PPS7936/SREF.1 1

SID-INST-150#/13XSV0326

S15 12 HOLD DOWN GUIDE FOR PIPE SHOE ; G12B-12-112-36 12 7PPS7936.2 1

1 13 HOLD DOWN GUIDE FOR PIPE SHOE ; G12B-12-115-33 12 7PPS7044.2 1

7PPS7044

14 SPECIAL SUPPORT 12 7PPS7044/SREF.1 1

S13 ORI = D

15 LINE STOP ON PIPE SHOE ; LS2B-12 12 7PPS7044.3 1

7PPS7044 Stop Clearance = 0

CONT. ON ORI = D

646

2

CUT PIPE LENGTH

E 159138

N 7740 PIECE CUT N.B. REMARKS PIECE CUT N.B. REMARKS

EL +49734 NO LENGTH (INS) NO LENGTH (INS)

<1> 1103 12 <2> 908 12

12"NB

CONT. ON

13L00487A_7P-A

E 161975

N 7740

EL +48174

13L00501A_7P-A

GENERAL NOTES:

1. ALL DIMENSIONS AND CO-ORDINATES ARE IN MM.

2. ALL ELEVATIONS ARE WITH REFERENCE TO ABSOLUTE BASELINE ELEVATION OF SHIP.

3. FFWs - 150mm EXTRA SPOOL TO BE INCLUDED IN PIPE CUT LENGTH (NOT INCLUDED IN DIMENSION/MTO).

4. PIPE SUPPORT STANDARD AND SUPPORT DESIGN CRITERIA REFER 4014-MI20-00S1-1502-001 AND 4014-MI20-92S1-1503-001.

5. PAINTING AND CORROSION PROTECTION PAINTING AND COATING REFER 2500-M380-00S1-0030-001 & 4014-MI20-00S1-0030/0031-001.

6. THERMAL INSULATION SPECIFICATION REFER 4014-MI20-00S1-0010-001.

7. FABRICATION OF PIPING SPECIFICATION AND NDT, PWHT REFER 2500-M380-00S1-0070-001 & 4014-MI20-00S1-0070-001.

8. PRESSURE TESTING AND FLUSHING REFER 4014-MI20-00S1-0070-001.

9. ALL LOW POINT DRAIN AND HIGH POINT VENTS HAVE BEEN CONSIDERED IN PIPE ROUTING. HOWEVER SOME EXTRA HYDRO TEST DRAIN/VENT

(NON-VALVED) MAY BE REQUIRED AS PER HYDRO TEST PACKAGE, THOSE SHALL BE PROVIDED AND MTO SHALL ALSO BE ARRANGED BY

FABRICATOR AS PER PIPING STANDARD 4014-MI20-92S1-1500-001 AND RESPECTIVE PMS.

10.STRESS ANALYSIS REPORT REFER STRESS CRITICAL LINE LIST NO. 2500-M380-00S1-1500-001 AND 4014-SID20-9202-0002-001.

11.MTO FOR HYDROSTATIC DRAIN/VENT (NON VALVED) SHALL BE AS PER PIPING STANDARD 2500-M380-00S1-1500-001 &

4014-MI20-92S1-1500-001 AND RESPECTIVE PMS.

12.HYDROSTATIC DRAIN/VENT (NON VALVED) SHALL BE SEAL WELDED AFTER HYDRO-TEST.

13.REFER RESPECTIVE PIPE SUPPORT DRAWING FOR SPECIAL/SECONDARY SUPPORT. 1 OF 7

bala.murugan DATE: 29 Aug 2022 TIME: 16:19

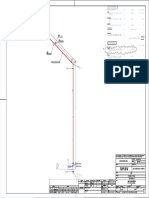

FABRICATION MATERIALS

PT COMPONENT DESCRIPTION N.B. ITEM CODE QTY

NO (INS) (mm/no.)

PIPE

1 PIPE, SEAMLESS ASTM A106 GR B, ASME B36.10, BEVEL END, 12 A2/PAC11ABEG12ST 201MM

CS01, STD

FITTINGS

2 FLANGOLET, ASTM A105N, MSS SP-97, ASME B16.5, FLANGED 12 x 2 A2/OFC31BRFAAG12ST0 1

RAISED FACE, ASME CLASS 150, CS01, STD x XS 2

SUPPORTS

3 GUSSET FOR TWO DIRECTIONAL BRACING ; GT1-2"-CS 2 7PPS2894.1 1

ERECTION MATERIALS

ORIA:180degree

Y IS W AND Z IS N 45 D PT COMPONENT DESCRIPTION N.B. ITEM CODE QTY

CONT. FROM NO (INS) (mm/no.)

2

5 1

12"x2"NB 71 FITTINGS

INSUL 312

B E 159138 4 SIMPLE BASKET STRAINER BUTT WELD END SI-5006/13CB502 12 SID-SPITEMS/13CB502 1

6H1 "N

178 12 N 7740

INSUL EL +49734 GASKETS

6Y1

S3 5 GASKET, 316L SS (ALL RINGS) WITH NON-ASBESTOS FILLER 2 A2/GAS71PAA02 3

7PPS2894 (E.G. GRAPHITE), SPIRAL WOUND ASME B16.20, 4.5 MM THK

G5 B7 (3.175 MM THK SOLID RINGS), FLEXITALLIC TYPE "CGI", ASME

10 CLASS 150

SID-INST-150#/FLUSH-50 VB13-0362

13PDT0341 35

BOLTS

378

TP1

E 159138 G5 B6 6 130 MM LONG, STUDBOLT, WITH 2 HEX HEAVY NUTS, ASME 5/8 BOLT-A2/150-0.625_ZB 4

N 8118 B18.31.2/B18.2.2, DEGREASED + WHITFORD XYLAN 1014-GRAY

11 EL +49356 COLOR ASTM A1082 UNS S32760, MDS DS06

SID-INST-150#/PDT-50 7 85 MM LONG, STUDBOLT, WITH 2 HEX HEAVY NUTS, ASME 5/8 BOLT-A2/150-0.625_CB 8

37 9 B18.31.2/B18.2.2, ZN-NI PLATED + WHITFORD XYLAN 1014-DEEP

8

VALVE LEVER/HW ORI. N 45 D MED BLUE COLOR ASTM A320 GR L7 / ASTM A194 GR 7

8 65 MM LONG, STUDBOLT, WITH 2 HEX HEAVY NUTS, ASME 1/2 BOLT-A2/150-0.5_CBJ6 4

G5 B18.31.2/B18.2.2, ZN-NI PLATED + WHITFORD XYLAN 1014-DEEP

MED BLUE COLOR ASTM A320 GR L7 / ASTM A194 GR 7

VALVES / IN-LINE ITEMS

2 00 9 V-TAG:A2-2RNC BALL VALVE ASME CLASS 150 REDUCED PORT 2 A2/2"-A2-2RNC 1

RF FLGD LOP, 0200-A2-2RNC

INSTRUMENTS

10 FLUSHING RING 150# RF 2 SID-INST-150#/FLUSH- 1

11 PRESSURE DIFF. TRANSMITTER DIA SEAL 150# RF 13PDT0341 2 1

TP1

CUT PIPE LENGTH

TAPPING COORDINATES

E 158488 >1 PIECE CUT N.B. REMARKS PIECE CUT N.B. REMARKS

<3

N 7590 B NO LENGTH (INS) NO LENGTH (INS)

EL +50376 1 2" N <3> 800 12

CONT. ON

3

INSUL

INSUL 6H1 900

6Y1

B8 E 158488

E 158038 N 7590

N 7740 EL +50379

EL +49734 CONT. ON B7

5

E 158105

CONT. ON N 7740

4 EL +48984

TAPPING COORDINATES

E 158108 4

N 7740 SI-5006/13CB502

EL +48984 SID-SPITEMS/13CB502

13L00501A_7P-A

GENERAL NOTES:

1. ALL DIMENSIONS AND CO-ORDINATES ARE IN MM.

2. ALL ELEVATIONS ARE WITH REFERENCE TO ABSOLUTE BASELINE ELEVATION OF SHIP.

3. FFWs - 150mm EXTRA SPOOL TO BE INCLUDED IN PIPE CUT LENGTH (NOT INCLUDED IN DIMENSION/MTO).

4. PIPE SUPPORT STANDARD AND SUPPORT DESIGN CRITERIA REFER 4014-MI20-00S1-1502-001 AND 4014-MI20-92S1-1503-001.

5. PAINTING AND CORROSION PROTECTION PAINTING AND COATING REFER 2500-M380-00S1-0030-001 & 4014-MI20-00S1-0030/0031-001.

6. THERMAL INSULATION SPECIFICATION REFER 4014-MI20-00S1-0010-001.

7. FABRICATION OF PIPING SPECIFICATION AND NDT, PWHT REFER 2500-M380-00S1-0070-001 & 4014-MI20-00S1-0070-001.

8. PRESSURE TESTING AND FLUSHING REFER 4014-MI20-00S1-0070-001.

9. ALL LOW POINT DRAIN AND HIGH POINT VENTS HAVE BEEN CONSIDERED IN PIPE ROUTING. HOWEVER SOME EXTRA HYDRO TEST DRAIN/VENT

(NON-VALVED) MAY BE REQUIRED AS PER HYDRO TEST PACKAGE, THOSE SHALL BE PROVIDED AND MTO SHALL ALSO BE ARRANGED BY

FABRICATOR AS PER PIPING STANDARD 4014-MI20-92S1-1500-001 AND RESPECTIVE PMS.

10.STRESS ANALYSIS REPORT REFER STRESS CRITICAL LINE LIST NO. 2500-M380-00S1-1500-001 AND 4014-SID20-9202-0002-001.

11.MTO FOR HYDROSTATIC DRAIN/VENT (NON VALVED) SHALL BE AS PER PIPING STANDARD 2500-M380-00S1-1500-001 &

4014-MI20-92S1-1500-001 AND RESPECTIVE PMS.

12.HYDROSTATIC DRAIN/VENT (NON VALVED) SHALL BE SEAL WELDED AFTER HYDRO-TEST.

13.REFER RESPECTIVE PIPE SUPPORT DRAWING FOR SPECIAL/SECONDARY SUPPORT. 2 OF 7

bala.murugan DATE: 29 Aug 2022 TIME: 16:19

ERECTION MATERIALS

PT COMPONENT DESCRIPTION N.B. ITEM CODE QTY

NO (INS) (mm/no.)

FLANGES

1 FLANGE BLIND, ASTM A105N, ASME B16.5, FLANGED RAISED 1 A2/FBC31ARFAAG0D 1

FACE, ASME CLASS 150, CS01

GASKETS

2 GASKET, 316L SS (ALL RINGS) WITH NON-ASBESTOS FILLER 1 A2/GAS71PAA0D 2

(E.G. GRAPHITE), SPIRAL WOUND ASME B16.20, 4.5 MM THK

(3.175 MM THK SOLID RINGS), FLEXITALLIC TYPE "CGI", ASME

CLASS 150

BOLTS

3 65 MM LONG, STUDBOLT, WITH 2 HEX HEAVY NUTS, ASME 1/2 BOLT-A2/150-0.5_CBJ6 4

B18.31.2/B18.2.2, ZN-NI PLATED + WHITFORD XYLAN 1014-DEEP

MED BLUE COLOR ASTM A320 GR L7 / ASTM A194 GR 7

VALVES / IN-LINE ITEMS

4 V-TAG:A2-2RBC BALL VALVE ASME CLASS 150 FULL PORT RF 1 A2/1"-A2-2RBC 1

FLGD LOP, 0100-A2-2RBC

E 158488

N 7590

G2 B3 EL +50524

4

VALVE LEVER/HW ORI. U 1 127

VB13-0364

NC G2

E 158488

N 7590

CONT. FROM

EL +50376

2

13L00501A_7P-A

GENERAL NOTES:

1. ALL DIMENSIONS AND CO-ORDINATES ARE IN MM.

2. ALL ELEVATIONS ARE WITH REFERENCE TO ABSOLUTE BASELINE ELEVATION OF SHIP.

3. FFWs - 150mm EXTRA SPOOL TO BE INCLUDED IN PIPE CUT LENGTH (NOT INCLUDED IN DIMENSION/MTO).

4. PIPE SUPPORT STANDARD AND SUPPORT DESIGN CRITERIA REFER 4014-MI20-00S1-1502-001 AND 4014-MI20-92S1-1503-001.

5. PAINTING AND CORROSION PROTECTION PAINTING AND COATING REFER 2500-M380-00S1-0030-001 & 4014-MI20-00S1-0030/0031-001.

6. THERMAL INSULATION SPECIFICATION REFER 4014-MI20-00S1-0010-001.

7. FABRICATION OF PIPING SPECIFICATION AND NDT, PWHT REFER 2500-M380-00S1-0070-001 & 4014-MI20-00S1-0070-001.

8. PRESSURE TESTING AND FLUSHING REFER 4014-MI20-00S1-0070-001.

9. ALL LOW POINT DRAIN AND HIGH POINT VENTS HAVE BEEN CONSIDERED IN PIPE ROUTING. HOWEVER SOME EXTRA HYDRO TEST DRAIN/VENT

(NON-VALVED) MAY BE REQUIRED AS PER HYDRO TEST PACKAGE, THOSE SHALL BE PROVIDED AND MTO SHALL ALSO BE ARRANGED BY

FABRICATOR AS PER PIPING STANDARD 4014-MI20-92S1-1500-001 AND RESPECTIVE PMS.

10.STRESS ANALYSIS REPORT REFER STRESS CRITICAL LINE LIST NO. 2500-M380-00S1-1500-001 AND 4014-SID20-9202-0002-001.

11.MTO FOR HYDROSTATIC DRAIN/VENT (NON VALVED) SHALL BE AS PER PIPING STANDARD 2500-M380-00S1-1500-001 &

4014-MI20-92S1-1500-001 AND RESPECTIVE PMS.

12.HYDROSTATIC DRAIN/VENT (NON VALVED) SHALL BE SEAL WELDED AFTER HYDRO-TEST.

13.REFER RESPECTIVE PIPE SUPPORT DRAWING FOR SPECIAL/SECONDARY SUPPORT. 3 OF 7

bala.murugan DATE: 29 Aug 2022 TIME: 16:19

ERECTION MATERIALS

PT COMPONENT DESCRIPTION N.B. ITEM CODE QTY

NO (INS) (mm/no.)

FITTINGS

1 FIG 8 FLANGE, ASTM A516 GR 70N, ASME B16.48, ASME B16.5, 2 A2/F8C22AFFAAG02 1

FLANGED FLAT FACE, ASME CLASS 150, CS01

GASKETS

2 GASKET, 316L SS (ALL RINGS) WITH NON-ASBESTOS FILLER 2 A2/GAS71PAA02 3

(E.G. GRAPHITE), SPIRAL WOUND ASME B16.20, 4.5 MM THK

(3.175 MM THK SOLID RINGS), FLEXITALLIC TYPE "CGI", ASME

CLASS 150

BOLTS

3 100 MM LONG, STUDBOLT, WITH 2 HEX HEAVY NUTS, ASME 5/8 BOLT-A2/150-0.625_CB 4

B18.31.2/B18.2.2, ZN-NI PLATED + WHITFORD XYLAN 1014-DEEP

MED BLUE COLOR ASTM A320 GR L7 / ASTM A194 GR 7

VALVES / IN-LINE ITEMS

4 V-TAG:A2-2RNC BALL VALVE ASME CLASS 150 REDUCED PORT 2 A2/2"-A2-2RNC 1

RF FLGD LOP, 0200-A2-2RNC

VB13-0363 E 158105

NC N 7740

8 EL +48984

9 17

CONT. ON

CONT. FROM

13L00505A_7P-A

2

E 157912

N 7740 G2

EL +48984 G2 B3

1 2"NB

TAIL SOUTH

A2/F8C22AFFAAG02:SPB,50 G2

4

VALVE LEVER/HW ORI. W

13L00501A_7P-A

GENERAL NOTES:

1. ALL DIMENSIONS AND CO-ORDINATES ARE IN MM.

2. ALL ELEVATIONS ARE WITH REFERENCE TO ABSOLUTE BASELINE ELEVATION OF SHIP.

3. FFWs - 150mm EXTRA SPOOL TO BE INCLUDED IN PIPE CUT LENGTH (NOT INCLUDED IN DIMENSION/MTO).

4. PIPE SUPPORT STANDARD AND SUPPORT DESIGN CRITERIA REFER 4014-MI20-00S1-1502-001 AND 4014-MI20-92S1-1503-001.

5. PAINTING AND CORROSION PROTECTION PAINTING AND COATING REFER 2500-M380-00S1-0030-001 & 4014-MI20-00S1-0030/0031-001.

6. THERMAL INSULATION SPECIFICATION REFER 4014-MI20-00S1-0010-001.

7. FABRICATION OF PIPING SPECIFICATION AND NDT, PWHT REFER 2500-M380-00S1-0070-001 & 4014-MI20-00S1-0070-001.

8. PRESSURE TESTING AND FLUSHING REFER 4014-MI20-00S1-0070-001.

9. ALL LOW POINT DRAIN AND HIGH POINT VENTS HAVE BEEN CONSIDERED IN PIPE ROUTING. HOWEVER SOME EXTRA HYDRO TEST DRAIN/VENT

(NON-VALVED) MAY BE REQUIRED AS PER HYDRO TEST PACKAGE, THOSE SHALL BE PROVIDED AND MTO SHALL ALSO BE ARRANGED BY

FABRICATOR AS PER PIPING STANDARD 4014-MI20-92S1-1500-001 AND RESPECTIVE PMS.

10.STRESS ANALYSIS REPORT REFER STRESS CRITICAL LINE LIST NO. 2500-M380-00S1-1500-001 AND 4014-SID20-9202-0002-001.

11.MTO FOR HYDROSTATIC DRAIN/VENT (NON VALVED) SHALL BE AS PER PIPING STANDARD 2500-M380-00S1-1500-001 &

4014-MI20-92S1-1500-001 AND RESPECTIVE PMS.

12.HYDROSTATIC DRAIN/VENT (NON VALVED) SHALL BE SEAL WELDED AFTER HYDRO-TEST.

13.REFER RESPECTIVE PIPE SUPPORT DRAWING FOR SPECIAL/SECONDARY SUPPORT. 4 OF 7

bala.murugan DATE: 29 Aug 2022 TIME: 16:19

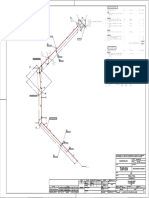

FABRICATION MATERIALS

PT COMPONENT DESCRIPTION N.B. ITEM CODE QTY

NO (INS) (mm/no.)

PIPE

1 PIPE, SEAMLESS ASTM A106 GR B, ASME B36.10, BEVEL END, 12 A2/PAC11ABEG12ST 1553MM

CS01, STD

FITTINGS

FAIL

ANCILLARY /7PPS7937.2 is not positioned on the leave tube centre line

E 158038

N 7740

EL +49734 CONT. FROM

2

4

TEE RED, SEAMLESS ASTM A234 GR WPB-S, ASME B16.9, BUTT

WELD, CS01, STD x STD

FLANGOLET, ASTM A105N, MSS SP-97, ASME B16.5, FLANGED

RAISED FACE, ASME CLASS 150, CS01, STD x XS

ELBOW 90, SEAMLESS ASTM A234 GR WPB-S, ASME B16.9,

12 x 6

12 x 2

12

A2/TRC41DBWG12ST06S 1

T

A2/OFC31BRFAAG12ST0 2

2

A2/E9C41EBWG12ST 1

2 R=1.5D, BUTT WELD, CS01, STD

ORIA:180degree B FLANGES

Y IS W AND Z IS N 45 D "N

23

6 12

5 FLANGE WN, ASTM A105N, ASME B16.5, FLANGED RAISED 12 A2/FWC31ARFAAG12ST 2

INSUL FACE, ASME CLASS 150, CS01, STD

6H1 G11 B14

SUPPORTS

INSUL 312

6Y1 6 STANDARD WELDED SHOE WITH REINF. PAD ; S3-12-300-CS ; 12 7PPS7102.1 1

RP1-1-12-340-CS-10 ; BP2-12-101.6x180-P

17 3 7 STANDARD WELDED SHOE WITH REINF. PAD ; S3-12-300-CS ; 12 7PPS7937.1 1

SID-INST-150#/FLUSH-50 12"x2"NB RP1-1-12-340-CS-10 ; BP2-12-102x180-P

0

30 8 GUSSET FOR TWO DIRECTIONAL BRACING ; GT1-2"-CS 2 7PPS2895.1 1

178 S8 9 GUSSET FOR TWO DIRECTIONAL BRACING ; GT1-2"-CS 2 7PPS2896.1 1

7PPS2895

ERECTION MATERIALS

5

71

378

S21 35

7PPS7102 PT COMPONENT DESCRIPTION N.B. ITEM CODE QTY

E 157802 VB13-0365

ORI = D G11 B13 NO (INS) (mm/no.)

N 8118

S22 EL +49356 GASKETS

G11

>1 37 10 GASKET, 316L SS (ALL RINGS) WITH NON-ASBESTOS FILLER 12 A2/GAS71PAA12 2

<4 8

S6 16 (E.G. GRAPHITE), SPIRAL WOUND ASME B16.20, 4.5 MM THK

15 VALVE LEVER/HW ORI. N 45 D (3.175 MM THK SOLID RINGS), FLEXITALLIC TYPE "CGI", ASME

0 7PPS7102

VALVE LEVER/HW ORI. N 61 CLASS 150

ORIA:180degree ORI = D

11 GASKET, 316L SS (ALL RINGS) WITH NON-ASBESTOS FILLER 2 A2/GAS71PAA02 6

Y IS W AND Z IS N 45 D

(E.G. GRAPHITE), SPIRAL WOUND ASME B16.20, 4.5 MM THK

178 (3.175 MM THK SOLID RINGS), FLEXITALLIC TYPE "CGI", ASME

5

INSUL 26 F5 G10 B12 13PDT0341 CLASS 150

6H1 G11 B14 TP2

VB13-0366 BOLTS

INSUL 312

6S1 F5 G10 B12 18 12 125 MM LONG, STUDBOLT, WITH 2 HEX HEAVY NUTS, ASME 7/8 BOLT-A2/150-0.875_CB 24

SID-INST-150#/PDT-50 B18.31.2/B18.2.2, ZN-NI PLATED + WHITFORD XYLAN 1014-DEEP

3 MED BLUE COLOR ASTM A320 GR L7 / ASTM A194 GR 7

19 12"x2"NB 13 130 MM LONG, STUDBOLT, WITH 2 HEX HEAVY NUTS, ASME 5/8 BOLT-A2/150-0.625_ZB 8

35 70

SID-INST-150#/DS-50 2 B18.31.2/B18.2.2, DEGREASED + WHITFORD XYLAN 1014-GRAY

G11 COLOR ASTM A1082 UNS S32760, MDS DS06

S7

14 85 MM LONG, STUDBOLT, WITH 2 HEX HEAVY NUTS, ASME 5/8 BOLT-A2/150-0.625_CB 8

7PPS7937 S9 B18.31.2/B18.2.2, ZN-NI PLATED + WHITFORD XYLAN 1014-DEEP

ORI = D 0 7PPS2896

82 378 MED BLUE COLOR ASTM A320 GR L7 / ASTM A194 GR 7

VB13-0454

G11 B13 VALVES / IN-LINE ITEMS

S23

CONT. ON

13L00524A_7P-A 15 V-TAG:A2-2RBC BALL VALVE ASME CLASS 150 FULL PORT RF 12 A2/12"-A2-2RBC 1

E 156206 FLGD GOP, 1200-A2-2RBC

E 155385 N 8118 37 16

N 7740 >1 8 16 V-TAG:A2-2RNC BALL VALVE ASME CLASS 150 REDUCED PORT 2 A2/2"-A2-2RNC 2

<5 EL +49356 VALVE LEVER/HW ORI. N 45 D RF FLGD LOP, 0200-A2-2RNC

EL +49953

711 INSTRUMENTS

S24

17 FLUSHING RING 150# RF 2 SID-INST-150#/FLUSH- 1

219 7PPS7937

18 PRESSURE DIFF. TRANSMITTER DIA SEAL 150# RF 13PDT0341 2 1

ORI = D 13PST0342

4 TP2

2 Clearance (Hor) = 0 TP

E 154674 19 FLUSHING RING 150# RF 2 SID-INST-150#/DS-50 1

N 7740 12"x6"NB 20 PRESSURE DIFF. TRANSMITTER DIA SEAL 150# RF 13PST0342 2 1

EL +49734 12"NB TP

457 20

E 154674

SID-INST-150#/PDT-50 SUPPORTS

N 7740

EL +49277 21 HOLD DOWN GUIDE FOR PIPE SHOE ; G12B-12-112-36 12 7PPS7102.2 1

22 SPECIAL SUPPORT 12 7PPS7102/SREF.1 1

CONT. ON 23 SPECIAL SUPPORT 12 7PPS7937/SREF.1 1

6 24 GUIDE FOR PIPE SHOE ; G11B-12-115-53 12 7PPS7937.2 1

CUT PIPE LENGTH

PIECE CUT N.B. REMARKS PIECE CUT N.B. REMARKS

NO LENGTH (INS) NO LENGTH (INS)

<4> 836 12 <5> 717 12

13L00501A_7P-A

GENERAL NOTES:

1. ALL DIMENSIONS AND CO-ORDINATES ARE IN MM.

2. ALL ELEVATIONS ARE WITH REFERENCE TO ABSOLUTE BASELINE ELEVATION OF SHIP.

3. FFWs - 150mm EXTRA SPOOL TO BE INCLUDED IN PIPE CUT LENGTH (NOT INCLUDED IN DIMENSION/MTO).

4. PIPE SUPPORT STANDARD AND SUPPORT DESIGN CRITERIA REFER 4014-MI20-00S1-1502-001 AND 4014-MI20-92S1-1503-001.

5. PAINTING AND CORROSION PROTECTION PAINTING AND COATING REFER 2500-M380-00S1-0030-001 & 4014-MI20-00S1-0030/0031-001.

6. THERMAL INSULATION SPECIFICATION REFER 4014-MI20-00S1-0010-001.

7. FABRICATION OF PIPING SPECIFICATION AND NDT, PWHT REFER 2500-M380-00S1-0070-001 & 4014-MI20-00S1-0070-001.

8. PRESSURE TESTING AND FLUSHING REFER 4014-MI20-00S1-0070-001.

9. ALL LOW POINT DRAIN AND HIGH POINT VENTS HAVE BEEN CONSIDERED IN PIPE ROUTING. HOWEVER SOME EXTRA HYDRO TEST DRAIN/VENT

(NON-VALVED) MAY BE REQUIRED AS PER HYDRO TEST PACKAGE, THOSE SHALL BE PROVIDED AND MTO SHALL ALSO BE ARRANGED BY

FABRICATOR AS PER PIPING STANDARD 4014-MI20-92S1-1500-001 AND RESPECTIVE PMS.

10.STRESS ANALYSIS REPORT REFER STRESS CRITICAL LINE LIST NO. 2500-M380-00S1-1500-001 AND 4014-SID20-9202-0002-001.

11.MTO FOR HYDROSTATIC DRAIN/VENT (NON VALVED) SHALL BE AS PER PIPING STANDARD 2500-M380-00S1-1500-001 &

4014-MI20-92S1-1500-001 AND RESPECTIVE PMS.

12.HYDROSTATIC DRAIN/VENT (NON VALVED) SHALL BE SEAL WELDED AFTER HYDRO-TEST.

13.REFER RESPECTIVE PIPE SUPPORT DRAWING FOR SPECIAL/SECONDARY SUPPORT. 5 OF 7

bala.murugan DATE: 29 Aug 2022 TIME: 16:19

FABRICATION MATERIALS

E 156765

PT COMPONENT DESCRIPTION N.B. ITEM CODE QTY

N 10484 NO (INS) (mm/no.)

CONT. ON

EL +46904

7

PIPE

1 PIPE, SEAMLESS ASTM A106 GR B, ASME B36.10, BEVEL END, 12 A2/PAC11ABEG12ST 5381MM

CS01, STD

FITTINGS

2 ELBOW 90, SEAMLESS ASTM A234 GR WPB-S, ASME B16.9, 12 A2/E9C41EBWG12ST 2

>1 R=1.5D, BUTT WELD, CS01, STD

<8

B

"N

12 ERECTION MATERIALS

PT COMPONENT DESCRIPTION N.B. ITEM CODE QTY

NO (INS) (mm/no.)

SUPPORTS

3 HOLD DOWN GUIDE FOR PIPE SHOE ; G12B-12-110-36 12 7PPS7046.3 1

CONT. FROM 4 VARIABLE HEIGHT CLAMP SHOE SUPPORT ; S6-12-300-133-CS ; 12 7PPS7046.2 1

92 5 CP1-1-12-HT/CL ; BP2-12-100x180-P

20

CUT PIPE LENGTH

E 154674

N 7740 PIECE CUT N.B. REMARKS PIECE CUT N.B. REMARKS

EL +49277 NO LENGTH (INS) NO LENGTH (INS)

<6> 1916 12 <7> 1830 12

12"NB

<8> 1635 12

914

E 154674

N 10484

EL +46904 2

PENETRATION AT EL+48820

<7

>1

2373

27

44

<6> 1

S3

7PPS7046

ORI = D

Clearance (Hor) = 5

S4

7PPS7046

ORI = D

63

5

2

E 154674 EL +46904

N 7740

EL +46904

13L00501A_7P-A

GENERAL NOTES:

1. ALL DIMENSIONS AND CO-ORDINATES ARE IN MM.

2. ALL ELEVATIONS ARE WITH REFERENCE TO ABSOLUTE BASELINE ELEVATION OF SHIP.

3. FFWs - 150mm EXTRA SPOOL TO BE INCLUDED IN PIPE CUT LENGTH (NOT INCLUDED IN DIMENSION/MTO).

4. PIPE SUPPORT STANDARD AND SUPPORT DESIGN CRITERIA REFER 4014-MI20-00S1-1502-001 AND 4014-MI20-92S1-1503-001.

5. PAINTING AND CORROSION PROTECTION PAINTING AND COATING REFER 2500-M380-00S1-0030-001 & 4014-MI20-00S1-0030/0031-001.

6. THERMAL INSULATION SPECIFICATION REFER 4014-MI20-00S1-0010-001.

7. FABRICATION OF PIPING SPECIFICATION AND NDT, PWHT REFER 2500-M380-00S1-0070-001 & 4014-MI20-00S1-0070-001.

8. PRESSURE TESTING AND FLUSHING REFER 4014-MI20-00S1-0070-001.

9. ALL LOW POINT DRAIN AND HIGH POINT VENTS HAVE BEEN CONSIDERED IN PIPE ROUTING. HOWEVER SOME EXTRA HYDRO TEST DRAIN/VENT

(NON-VALVED) MAY BE REQUIRED AS PER HYDRO TEST PACKAGE, THOSE SHALL BE PROVIDED AND MTO SHALL ALSO BE ARRANGED BY

FABRICATOR AS PER PIPING STANDARD 4014-MI20-92S1-1500-001 AND RESPECTIVE PMS.

10.STRESS ANALYSIS REPORT REFER STRESS CRITICAL LINE LIST NO. 2500-M380-00S1-1500-001 AND 4014-SID20-9202-0002-001.

11.MTO FOR HYDROSTATIC DRAIN/VENT (NON VALVED) SHALL BE AS PER PIPING STANDARD 2500-M380-00S1-1500-001 &

4014-MI20-92S1-1500-001 AND RESPECTIVE PMS.

12.HYDROSTATIC DRAIN/VENT (NON VALVED) SHALL BE SEAL WELDED AFTER HYDRO-TEST.

13.REFER RESPECTIVE PIPE SUPPORT DRAWING FOR SPECIAL/SECONDARY SUPPORT. 6 OF 7

bala.murugan DATE: 29 Aug 2022 TIME: 16:19

FABRICATION MATERIALS

PT COMPONENT DESCRIPTION N.B. ITEM CODE QTY

E 157222 NO (INS) (mm/no.)

457 N 10484

EL +46904 PIPE

E 156765

N 10484

1 PIPE, SEAMLESS ASTM A106 GR B, ASME B36.10, BEVEL END, 12 A2/PAC11ABEG12ST 1769MM

EL +46904

CS01, STD

90 S10 2 PIPE, SEAMLESS ASTM A106 GR B, ASME B36.10, BEVEL END, 10 A2/PAC11ABEG10ST 4425MM

5 9 CS01, STD

CONT. FROM 7PPS0573

6 3 PIPE, SEAMLESS ASTM A106 GR B, ASME B36.10, BEVEL END, 8 A2/PAC11ABEG08ST 320MM

12"NB CS01, STD

INSUL

TAPPING COORDINATES FITTINGS

6H1

E 157222

N 9575 4 REDUCER CONC, SEAMLESS ASTM A234 GR WPB-S, ASME 12 x 10 A2/RCC41DBWG12ST10S 1

EL +46904 S16

7PPS7045 F7 F7 G12 B15 B16.9, BUTT WELD, CS01, STD x STD T

5 ELBOW 90, SEAMLESS ASTM A234 GR WPB-S, ASME B16.9, 12 A2/E9C41EBWG12ST 2

7PPS0573.1 120 R=1.5D, BUTT WELD, CS01, STD

<9> 3

6 ADJUSTABLE TRUNNION BASE ASSY. ; TBPAJ1-8-CS 8 7PPS0573/PLAT.1 1

320 8"NB

S19 6 1 FLANGES

7PPS0573 120 87

2 0> 5

<1

57 EL +46904 7 FLANGE WN, ASTM A105N, ASME B16.5, FLANGED RAISED 12 A2/FWC31ARFAAG12ST 2

2

12"NB

RS FACE, ASME CLASS 150, CS01, STD

560

8 FLANGE WN, ASTM A105N, ASME B16.5, FLANGED RING TYPE 10 A2/FWC31ARJFFG10ST 1

457

S20 JOINT, ASME CLASS 1500, CS01, STD

8"NB E 157222

E 157222 N 8375 SUPPORTS

N 9575 12"NB EL +46904

EL +46904 7PPS0573.3 9 STANDARD WELDED SHOE WITH REINF. PAD ; S3-10-300-CS ; 10 7PPS7738.1 1

RP1-2-10-340-CS-9.27 ; BP2-10-152x180-P

560

TAPPING COORDINATES 10 ADJUSTABLE TRUNNION BASE SUPPORT ; AJ1A-12-8-560-CS 8 7PPS0573/SREF.1 1

E 157222 4

12"x10"NB 203

E 157222 N 9575 MISCELLANEOUS COMPONENTS

N 9575 EL +46344

EL +46344 11 PIPE, SEAMLESS ASTM A106 GR B, ASME B36.10, BEVEL END, 10 A2/PAC11ABEG10ST 340MM

CS01, STD

62

7PPS0573.2 5 ERECTION MATERIALS

PT COMPONENT DESCRIPTION N.B. ITEM CODE QTY

NO (INS) (mm/no.)

GASKETS

12 GASKET, 316L SS (ALL RINGS) WITH NON-ASBESTOS FILLER 12 A2/GAS71PAA12 1

2113

(E.G. GRAPHITE), SPIRAL WOUND ASME B16.20, 4.5 MM THK

(3.175 MM THK SOLID RINGS), FLEXITALLIC TYPE "CGI", ASME

CLASS 150

13 GASKET, SOFT IRON (90 BHN MAX), OVAL RING TYPE "R" ASME 10 A2/GAC71TFF10 1

B16.20, ASME CLASS 1500

BOLTS

S9/11

14 350 MM LONG, STUDBOLT, WITH 2 HEX HEAVY NUTS, ASME 1.7/8 BOLT-A2/1500-1.875_C 12

7PPS7738

B18.31.2/B18.2.2, ZN-NI PLATED + WHITFORD XYLAN 1014-DEEP

ORI = E

MED BLUE COLOR ASTM A320 GR L7 / ASTM A194 GR 7

S18 15 125 MM LONG, STUDBOLT, WITH 2 HEX HEAVY NUTS, ASME 7/8 BOLT-A2/150-0.875_CB 12

S17

7PPS7738 B18.31.2/B18.2.2, ZN-NI PLATED + WHITFORD XYLAN 1014-DEEP

ORI = E MED BLUE COLOR ASTM A320 GR L7 / ASTM A194 GR 7

SUPPORTS

4690

16 SPECIAL SUPPORT 12 7PPS7045/SREF.1 1

17 HOLD DOWN GUIDE FOR PIPE SHOE ; G12B-10-112-36 10 7PPS7738.2 1

18 SPECIAL SUPPORT 10 7PPS7738/SREF.1 1

19 PTFE BEARING PAD FOR TRUNNION WITH DOUBLER PLATE ; 8 7PPS0573.2 1

BP3-12-8-250x250-P ; DP-550x550x15

20 LINE STOP AND GUIDE FOR ADJUSTABLE TRUNION BASE 8 7PPS0573.3 1

SUPPORT ; LS6C-12-8-135

CUT PIPE LENGTH

PIECE CUT N.B. REMARKS PIECE CUT N.B. REMARKS

<11> 2

10"NB

NO LENGTH (INS) NO LENGTH (INS)

<9> 452 12 <10> 320 8

<11> 560 12 <12> 757 12

<13> 4425 10

F8 G13 B14

CONN. TO

13PA101B/TP-S13130-01

E 157222

N 8375

EL +41550

13L00501A_7P-A

GENERAL NOTES:

1. ALL DIMENSIONS AND CO-ORDINATES ARE IN MM.

2. ALL ELEVATIONS ARE WITH REFERENCE TO ABSOLUTE BASELINE ELEVATION OF SHIP.

3. FFWs - 150mm EXTRA SPOOL TO BE INCLUDED IN PIPE CUT LENGTH (NOT INCLUDED IN DIMENSION/MTO).

4. PIPE SUPPORT STANDARD AND SUPPORT DESIGN CRITERIA REFER 4014-MI20-00S1-1502-001 AND 4014-MI20-92S1-1503-001.

5. PAINTING AND CORROSION PROTECTION PAINTING AND COATING REFER 2500-M380-00S1-0030-001 & 4014-MI20-00S1-0030/0031-001.

6. THERMAL INSULATION SPECIFICATION REFER 4014-MI20-00S1-0010-001.

7. FABRICATION OF PIPING SPECIFICATION AND NDT, PWHT REFER 2500-M380-00S1-0070-001 & 4014-MI20-00S1-0070-001.

8. PRESSURE TESTING AND FLUSHING REFER 4014-MI20-00S1-0070-001.

9. ALL LOW POINT DRAIN AND HIGH POINT VENTS HAVE BEEN CONSIDERED IN PIPE ROUTING. HOWEVER SOME EXTRA HYDRO TEST DRAIN/VENT

(NON-VALVED) MAY BE REQUIRED AS PER HYDRO TEST PACKAGE, THOSE SHALL BE PROVIDED AND MTO SHALL ALSO BE ARRANGED BY

FABRICATOR AS PER PIPING STANDARD 4014-MI20-92S1-1500-001 AND RESPECTIVE PMS.

10.STRESS ANALYSIS REPORT REFER STRESS CRITICAL LINE LIST NO. 2500-M380-00S1-1500-001 AND 4014-SID20-9202-0002-001.

11.MTO FOR HYDROSTATIC DRAIN/VENT (NON VALVED) SHALL BE AS PER PIPING STANDARD 2500-M380-00S1-1500-001 &

4014-MI20-92S1-1500-001 AND RESPECTIVE PMS.

12.HYDROSTATIC DRAIN/VENT (NON VALVED) SHALL BE SEAL WELDED AFTER HYDRO-TEST.

13.REFER RESPECTIVE PIPE SUPPORT DRAWING FOR SPECIAL/SECONDARY SUPPORT. 7 OF 7

bala.murugan DATE: 29 Aug 2022 TIME: 16:19

You might also like

- Dell Inspiron 15 3567 Wistron Vegas Turis SKL KBL U Rev A00 15341 1 SchematicDocument105 pagesDell Inspiron 15 3567 Wistron Vegas Turis SKL KBL U Rev A00 15341 1 Schematicredis1973100% (2)

- Topic 6 - Pile FootingDocument27 pagesTopic 6 - Pile FootingDhanmer Lopez0% (2)

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- South Refineries Company: Basrah Refinery Upgrading Project ProjectDocument5 pagesSouth Refineries Company: Basrah Refinery Upgrading Project ProjectBasem AlsaftliNo ratings yet

- E3D Isometric With GridDocument1 pageE3D Isometric With Griddesai_tejasNo ratings yet

- 25 10xaa1 H40 22RDCH 1014Document1 page25 10xaa1 H40 22RDCH 1014uma raneNo ratings yet

- Abo Cow 4 14Document1 pageAbo Cow 4 14AdewaleNo ratings yet

- 066504u58271 004 004-ADocument1 page066504u58271 004 004-ADINESH VNo ratings yet

- Isometric View (1:2.5) : Alternative Material For Material Standard X5Crni18-10 en 10088-2Document1 pageIsometric View (1:2.5) : Alternative Material For Material Standard X5Crni18-10 en 10088-2rajitkumar.3005No ratings yet

- Punj Lloyd: 4 See Iso ACC-5100-00015-01 5100PSV 2602Document1 pagePunj Lloyd: 4 See Iso ACC-5100-00015-01 5100PSV 2602Saptarshi MandalNo ratings yet

- 26-000-2-02-00001 FL 581542-4-R01-ModelDocument1 page26-000-2-02-00001 FL 581542-4-R01-ModelMartinAlexisGonzálezVidalNo ratings yet

- 26-000-2-02-00001 FL 581542-2-R01-ModelDocument1 page26-000-2-02-00001 FL 581542-2-R01-ModelMartinAlexisGonzálezVidalNo ratings yet

- 26-000-2-02-00001 FL 581574-4-R01-ModelDocument1 page26-000-2-02-00001 FL 581574-4-R01-ModelMartinAlexisGonzálezVidalNo ratings yet

- Clarifier Tank Layout - 250 CMH PDFDocument1 pageClarifier Tank Layout - 250 CMH PDFepe civil1No ratings yet

- Cross Section of Metal BuildingDocument1 pageCross Section of Metal BuildingtechnopreneurvizagNo ratings yet

- La233r1.ca100v-000 R03Document1 pageLa233r1.ca100v-000 R03Ricardo TurinNo ratings yet

- 3rd Sty Power SocketDocument1 page3rd Sty Power SocketArun FikdetcNo ratings yet

- Ball Valve 3020cf-SeriesDocument1 pageBall Valve 3020cf-SeriesIsrael Esquivel MartinezNo ratings yet

- P6022mab CG 150 12758 01 - S1 - WM - BDocument1 pageP6022mab CG 150 12758 01 - S1 - WM - BJohn SmitNo ratings yet

- Hy000-B0001 - 0 Skiving DeflectorDocument2 pagesHy000-B0001 - 0 Skiving DeflectorAnyNo ratings yet

- 4103 TOYO20 92DJ 1300 027 - Rev 1 - Sht001Document5 pages4103 TOYO20 92DJ 1300 027 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- 50 10xaa1 He40 21RDCH 1016Document1 page50 10xaa1 He40 21RDCH 1016uma raneNo ratings yet

- 3.50 M Span VRB Typical Drawing Of: Wing WallDocument1 page3.50 M Span VRB Typical Drawing Of: Wing WallUma KantNo ratings yet

- SA04C2-03-WP-D-43003-01-1: 3. FJ - Field Joint 4. SJ - Shop JointDocument1 pageSA04C2-03-WP-D-43003-01-1: 3. FJ - Field Joint 4. SJ - Shop JointABAID ULLAHNo ratings yet

- Tal Wsa PNG Iso 1P020807 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1P020807 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- Tupi BV: Cosco (Dalian)Document1 pageTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- 1/1 P055AZOR-05P00-1353-51 A A-2: 3c 248 HV 10 Shop ASME B31.3Document1 page1/1 P055AZOR-05P00-1353-51 A A-2: 3c 248 HV 10 Shop ASME B31.3Deshwa SaravananNo ratings yet

- Double Tango All in One H-07M - Orn 40CMDocument1 pageDouble Tango All in One H-07M - Orn 40CMmeyga riki bawonoNo ratings yet

- (40135 To E4042A) 36"18"-PV-Wz 40135: A2 1:25 Sabic CHE AB0337Document1 page(40135 To E4042A) 36"18"-PV-Wz 40135: A2 1:25 Sabic CHE AB0337hsp.2111992No ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- 4103 TOYO20 92DJ 1300 052 - Rev 1 - Sht001Document1 page4103 TOYO20 92DJ 1300 052 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- 26-000-2-02-00001 FL 581574-1-R01-ModelDocument1 page26-000-2-02-00001 FL 581574-1-R01-ModelMartinAlexisGonzálezVidalNo ratings yet

- 0479 Tec20 92DJ 21256 001Document3 pages0479 Tec20 92DJ 21256 001Dimmy mariano de limaNo ratings yet

- FL3B-474-P-2634 AsbuiltDocument1 pageFL3B-474-P-2634 AsbuiltAlbet MulyonoNo ratings yet

- Piping Isometric - 6Document1 pagePiping Isometric - 6CosminMarianNo ratings yet

- 50 10xaa1 He40 22RDCH 1016Document1 page50 10xaa1 He40 22RDCH 1016uma raneNo ratings yet

- Abs TDocument16 pagesAbs TAlbert BriceñoNo ratings yet

- Piping Isometric - 4Document1 pagePiping Isometric - 4CosminMarianNo ratings yet

- 8460cb20-40h Drawing 1Document1 page8460cb20-40h Drawing 1Janos HallaNo ratings yet

- KLD 65 Pdfeed MP 2343 00001 0114 01Document1 pageKLD 65 Pdfeed MP 2343 00001 0114 01chandana kumarNo ratings yet

- All Piping Drawings Spec SheetsDocument18 pagesAll Piping Drawings Spec Sheetsc.reid100% (1)

- KSKC-CWR24127 - Sample of Isometric (To Relaease HOLD and Uprev R1)Document7 pagesKSKC-CWR24127 - Sample of Isometric (To Relaease HOLD and Uprev R1)Ahmad AqilNo ratings yet

- Acc 5100 00012 01Document1 pageAcc 5100 00012 01Saptarshi MandalNo ratings yet

- Line No. Iso. Sht. Rev. Date Drawing No. Code No. S.O No Client Project SHTDocument5 pagesLine No. Iso. Sht. Rev. Date Drawing No. Code No. S.O No Client Project SHTAgus Umar FaruqNo ratings yet

- This Is New PDFDocument1 pageThis Is New PDFAnonymous BZQOJwWIh6No ratings yet

- 13.8Kv U/V Load Shedding Panel-2 +uvls.2: D HA555 P 3-1313003.03 EA-383186 4400004656Document1 page13.8Kv U/V Load Shedding Panel-2 +uvls.2: D HA555 P 3-1313003.03 EA-383186 4400004656Anonymous BZQOJwWIh6No ratings yet

- RTR Fuel Gas System P&IDDocument8 pagesRTR Fuel Gas System P&IDjeromejoeNo ratings yet

- A1-TR5M-L4-003 A1-TR5M-ISO-004 A1-TR5M-L4-003: Weld SummaryDocument1 pageA1-TR5M-L4-003 A1-TR5M-ISO-004 A1-TR5M-L4-003: Weld SummaryfaviikaujaNo ratings yet

- La213x.ca100v-111 R01-CLGDocument1 pageLa213x.ca100v-111 R01-CLGRicardo TurinNo ratings yet

- ECS CAT Product Catalogue E200 Z200 Series ENDocument1 pageECS CAT Product Catalogue E200 Z200 Series ENMr.T FYINo ratings yet

- Material List - Fabrication: - / - A1ZA-1 2 PMDocument2 pagesMaterial List - Fabrication: - / - A1ZA-1 2 PMMallela Sampath KumarNo ratings yet

- DA216ADocument4 pagesDA216AEl KacrutoNo ratings yet

- Pages From AMDP01LP2100 Rev01 CommentsDocument1 pagePages From AMDP01LP2100 Rev01 CommentsOkas PaskalNo ratings yet

- Training-1: 01 Issued For Training RK RK RKDocument4 pagesTraining-1: 01 Issued For Training RK RK RKJuan Luis FerretNo ratings yet

- 51062-ADR 70-MEC-025 - 0 - ADR - 2nd Elution - Thermal Pressure ChimneyDocument1 page51062-ADR 70-MEC-025 - 0 - ADR - 2nd Elution - Thermal Pressure ChimneyNur SugiartoNo ratings yet

- Tupi BV: Cosco (Dalian)Document2 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- Inv Ka B1 46781210 102017859871 March 2021Document2 pagesInv Ka B1 46781210 102017859871 March 2021CLS AKNo ratings yet

- Inv-Ka-B1-33590396-102017859871-1st July-2020 To 13TH July 2020Document2 pagesInv-Ka-B1-33590396-102017859871-1st July-2020 To 13TH July 2020CLS AKNo ratings yet

- Inv-Ka-B1-36680539-102017859871-14th February-2021 To 13TH September 2021Document2 pagesInv-Ka-B1-36680539-102017859871-14th February-2021 To 13TH September 2021CLS AKNo ratings yet

- Inv-Ka-B1-34841697-102017859871-14th July 2020 To 13TH February - 2021Document2 pagesInv-Ka-B1-34841697-102017859871-14th July 2020 To 13TH February - 2021CLS AKNo ratings yet

- Inv Ka B1 32251227 102017859871 June 2020Document2 pagesInv Ka B1 32251227 102017859871 June 2020CLS AKNo ratings yet

- 13l00501a - 7P A CLLDocument4 pages13l00501a - 7P A CLLCLS AKNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- 13l00501a - 7P A CPLFDocument7 pages13l00501a - 7P A CPLFCLS AKNo ratings yet

- LINENUMDocument5 pagesLINENUMCLS AKNo ratings yet

- 13l00501a - 7P A SupDocument10 pages13l00501a - 7P A SupCLS AKNo ratings yet

- 7Document71 pages7CLS AKNo ratings yet

- 4153 IFC ImportDocument5,454 pages4153 IFC ImportCLS AKNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- 5Document1 page5CLS AKNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- 3Document10 pages3CLS AKNo ratings yet

- Merged FileDocument1,714 pagesMerged FileCLS AKNo ratings yet

- 4Document5 pages4CLS AKNo ratings yet

- The Chemical Industry in México Evolution, Challenges, and PerspectivesDocument7 pagesThe Chemical Industry in México Evolution, Challenges, and PerspectivesDaniela HernándezNo ratings yet

- Glass Bubbles Condensation White Paper-V1-CelumDocument5 pagesGlass Bubbles Condensation White Paper-V1-CelumChris BothaNo ratings yet

- Rotational Flow and Thermal Behavior of Ternary Hybrid Nanomaterials at Small and High Prandtl NumbersDocument17 pagesRotational Flow and Thermal Behavior of Ternary Hybrid Nanomaterials at Small and High Prandtl NumbersprakashjayavelNo ratings yet

- Carbon Carbon Piston - NasaDocument16 pagesCarbon Carbon Piston - Nasakanta118No ratings yet

- Vantage BrochureDocument72 pagesVantage Brochure谭伟明No ratings yet

- Vikas Lakada DRS - Micro ProjectDocument15 pagesVikas Lakada DRS - Micro ProjectVikas LakadaNo ratings yet

- Ecg354-Aggregate Impact TestDocument7 pagesEcg354-Aggregate Impact TestNurin AdlinaNo ratings yet

- K CC1 102 Hse MSDS 005 - R0 EaDocument8 pagesK CC1 102 Hse MSDS 005 - R0 EaWalter Gerardo BelluzNo ratings yet

- NY SCA Specification 03542Document23 pagesNY SCA Specification 03542allysa almagroNo ratings yet

- 1 s2.0 S0272884217302869 MainDocument8 pages1 s2.0 S0272884217302869 MainArdian Kris BramantyoNo ratings yet

- Manufacturing Process IIDocument4 pagesManufacturing Process IIWeb FlowNo ratings yet

- AE04 SolDocument126 pagesAE04 Solbaig79No ratings yet

- Geotechnical Properties of Old Alluvium in Singapore, 2001Document11 pagesGeotechnical Properties of Old Alluvium in Singapore, 2001freezefreezeNo ratings yet

- Chapter 5Document82 pagesChapter 5Anonymous IF81QDRylNo ratings yet

- Pantnagar BOQ 03-02-2023 Final 28-02-2023Document93 pagesPantnagar BOQ 03-02-2023 Final 28-02-2023Sandeep RajurkarNo ratings yet

- 2 States of MatterDocument32 pages2 States of MatterB R YNo ratings yet

- ASTM B108B108M 15 Standard Specification For Aluminum Alloy Permanent Mold CastingsDocument22 pagesASTM B108B108M 15 Standard Specification For Aluminum Alloy Permanent Mold CastingsMohit pathakNo ratings yet

- Advances in Aseptic ProcessingDocument12 pagesAdvances in Aseptic ProcessingTasneem VahoraNo ratings yet

- Feasibility Study of Producing Bioplastic From Flower Stalk of Musa ParadisiacaDocument28 pagesFeasibility Study of Producing Bioplastic From Flower Stalk of Musa ParadisiacaLeah Rose Figueroa Paras100% (3)

- Computations:: Weight of Solute (G) Volume of SolutionDocument2 pagesComputations:: Weight of Solute (G) Volume of SolutionMichael Torres100% (1)

- FRP Above Ground Installation ManualDocument32 pagesFRP Above Ground Installation ManualCarlos GutierrezNo ratings yet

- Eccentric Combined FootingDocument3 pagesEccentric Combined Footingbishwaram gosainNo ratings yet

- Tugas Debi Putri Suprapto Matakuliah Perpindahan Panas 2 PDFDocument48 pagesTugas Debi Putri Suprapto Matakuliah Perpindahan Panas 2 PDFDebi Putri SupraptoNo ratings yet

- Esdep Lecture Note (Wg15)Document23 pagesEsdep Lecture Note (Wg15)mabuhamdNo ratings yet

- Heat SinkDocument8 pagesHeat SinkMurtadha AhmedNo ratings yet

- Building A Combiner BoxDocument5 pagesBuilding A Combiner BoxELECTROSTATIC SPRAYERS GREECENo ratings yet

- Kawayan Charcoal Specification: Chichacorn EffluentDocument2 pagesKawayan Charcoal Specification: Chichacorn EffluentRyan Bacarro BagayanNo ratings yet

- Physics: Senior Secondary School: ThirdDocument32 pagesPhysics: Senior Secondary School: ThirdAdio Babatunde Abiodun CabaxNo ratings yet

- Taller 1 Calor 1Document2 pagesTaller 1 Calor 1nataliaa.alvaradosNo ratings yet