Professional Documents

Culture Documents

Wire Rope Slings: End Fitting Options

Wire Rope Slings: End Fitting Options

Uploaded by

avisheklochun0 ratings0% found this document useful (0 votes)

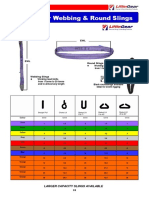

22 views1 pageThis document provides specifications for wire rope slings including rope diameters, working load limits, minimum breaking loads, and proof loads for single, two, three, and four leg slings made of galvanized wire or steel core. It also lists various end fitting options including reevable eyes, thimble eyes, solid eyes, and hook fittings. The tables are in compliance with various British standards and use a uniform load method for calculations.

Original Description:

Original Title

617

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for wire rope slings including rope diameters, working load limits, minimum breaking loads, and proof loads for single, two, three, and four leg slings made of galvanized wire or steel core. It also lists various end fitting options including reevable eyes, thimble eyes, solid eyes, and hook fittings. The tables are in compliance with various British standards and use a uniform load method for calculations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

22 views1 pageWire Rope Slings: End Fitting Options

Wire Rope Slings: End Fitting Options

Uploaded by

avisheklochunThis document provides specifications for wire rope slings including rope diameters, working load limits, minimum breaking loads, and proof loads for single, two, three, and four leg slings made of galvanized wire or steel core. It also lists various end fitting options including reevable eyes, thimble eyes, solid eyes, and hook fittings. The tables are in compliance with various British standards and use a uniform load method for calculations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

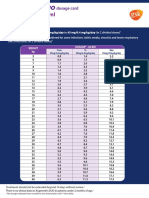

Wire Rope Slings

Made to your exact requirements Multi leg slings manufactured to

your requirements

Galvanised wire (other types available)

Rope Working Load Limit Min Proof Load

Diameter Single Leg Leg Angle Leg Angle Break Load Per Leg

0-90 0-120 @0

2 Leg 3 & 4 leg 2Leg 3 & 4 leg

mm Tonne Tonne Tonne Tonne Tonne Tonne Tonne

5 0.278 0.389 0.584 0.278 0.417 1.39 0.556

6 0.4 0.56 0.84 0.4 0.6 2 0.8

8 0.762 1 1.6 0.762 1.1 3.81 1.52

9 0.964 1.3 2 0.962 1.4 4.82 1.93

10 1.2 1.6 2.5 1.2 1.8 5.95 2.4

11 1.4 2 3 1.4 2.1 7.21 2.8

12 1.7 2.4 3.6 1.7 2.5 8.57 3.4

13 2 2.8 4.2 2 3 10.1 4

14 2.3 3.2 4.8 2.3 3.5 11.6 4.6

6 x19 6x36 FIBRE CORE

16 3 4.3 6.4 3 4.6 15.3 6

18 3.8 5.4 8.1 3.9 5.8 19.3 7.8

19 4.3 6 9 4.3 6.4 21.5 8.6

20 4.8 6.7 10 4.7 7.1 23.9 9.6

22 5.7 8 12.1 5.7 8.6 28.8 11.6

24 6.8 9.6 14.4 6.8 10.3 34.3 13.8

26 8 11.3 16.9 8 12.1 40.3 16.2

28 9.3 13 19.6 9.3 14 46.7 18.6

32 12.2 17.1 25.6 12.1 18.3 61 24.4

35 14.6 20.4 30.6 14.6 21.9 73 29.2

36 15.4 21.6 32.4 15.4 23.1 77.2 30.8

38 17.2 24 36.1 17.2 25.7 85.9 34.4

40 19 26.7 40 19 28.6 95.3 38.2

Rope Working Load Limit Min Proof Load

Diameter Single Leg Leg Angle Leg Angle Break Load Per Leg

End Fitting 0-90 0-120 @0

Options

2 Leg 3 & 4 leg 2Leg 3 & 4 leg

mm Tonne Tonne Tonne Tonne Tonne Tonne Tonne

8 0.822 1.1 1.7 0.822 1.2 4.11 1.64

9 1.0 1.4 2.1 1.0 1.5 5.20 2.0

10 1.3 1.8 2.7 1.3 1.9 6.42 2.6

11 1.5 2.2 3.2 1.5 2.3 7.77 3.2

12 1.8 2.6 3.9 1.8 2.8 9.25 3.6

13 2.1 3.0 4.5 2.1 3.2 10.8 4.4

Reevable Eye Thimble Eye 14 2.5 3.5 5.3 2.5 3.8 12.6 5.0

16 3.3 4.6 6.9 3.3 4.9 16.4 6.6

18 4.1 5.8 8.7 4.1 6.2 20.8 8.4

19 4.6 6.4 9.7 4.6 6.9 23.1 9.2

20 5.1 7.2 10.8 5.1 7.7 25.7 10.2

22 6.2 8.7 13.0 6.2 9.3 31.1 12.4

24 7.4 10.3 15.5 7.4 11.1 37.0 14.8

Solid Eye Hook Fitting 26 8.7 12.1 18.2 8.7 13.0 43.4 17.4

28 10.1 14.1 21.1 10.1 15.1 50.4 20.2

6 x19 6x36 STEEL CORE

32 13.1 18.4 27.6 13.1 19.7 65.7 26.2

35 15.7 22.0 33.0 15.7 23.6 78.7 31.4

These tables are in

36 16.6 23.3 35.0 16.6 25.0 83.3 33.4

compliance with 38 18.5 26.0 39.0 18.5 27.8 92.8 37.2

BS1290(1983) & 40 20.6 28.8 43.2 20.6 30.9 103.0 41.2

BS302 PT2 (1987) & 44 24.8 34.7 52.1 24.8 37.2 124.0 49.6

PT7(1989). 48 29.6 41.4 62.1 29.6 44.4 148.0 59.2

Uniform load method 52 34.8 48.7 73.1 34.8 52.2 174.0 69.6

calculation used 54 37.4 52.3 78.5 37.4 56.1 187.0 74.8

56 40.2 56.3 84.4 40.2 60.3 201.0 80.4

throughout WLL of

60 46.2 64.7 97.0 46.2 69.3 231.0 92.4

less than 1t are 64 54.8 76.7 115.1 54.8 82.2 274.0 109.6

normally citied in kg. 71 66.6 93.2 139.8 66.6 99.9 333.0 133.2

77 77.8 108.9 163.4 77.8 116.7 389.00 155.6

Winch ropes also made to order Wire rope crimping tools

Stainless Steel ropes supplied We can also swage using tapered ferrules

30

You might also like

- 87th (A) FSM Coursework - GRP 7Document90 pages87th (A) FSM Coursework - GRP 7Mohammad ZaidNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument27 pagesAgitator Power Requirement and Mixing Intensity Calculation@sssNo ratings yet

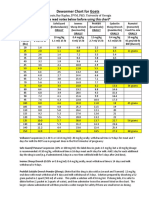

- Dewormer Chart GoatsDocument2 pagesDewormer Chart GoatsAbu Bakr AtikuNo ratings yet

- Wood Design Manual 2017 ErrataDocument20 pagesWood Design Manual 2017 ErratanoobfNo ratings yet

- BS 1290 ChartDocument1 pageBS 1290 ChartRakeshNo ratings yet

- Steel Core Rope Chart (Customer)Document1 pageSteel Core Rope Chart (Customer)chx6sprrvcNo ratings yet

- Approximate Fuel Consumption ChartDocument1 pageApproximate Fuel Consumption ChartMohammed AlkhawlaniNo ratings yet

- All Units in Metric Tons: BS 13414 Wire Rope Chart For Sling SetsDocument1 pageAll Units in Metric Tons: BS 13414 Wire Rope Chart For Sling SetsHelmiNo ratings yet

- Grade-80-WLLDocument1 pageGrade-80-WLLSajith VenkitachalamNo ratings yet

- IS 3601-2006 TablesDocument3 pagesIS 3601-2006 TablesarabsniperNo ratings yet

- HDPE Pipe Flow RatesDocument2 pagesHDPE Pipe Flow Ratesalaa sadikNo ratings yet

- Generator Fuel Consumption As Per LoadDocument1 pageGenerator Fuel Consumption As Per LoadJason SecretNo ratings yet

- Hdpe WeightDocument3 pagesHdpe Weightwebhareggebru06No ratings yet

- Friction Loss ChartDocument1 pageFriction Loss ChartNoriel LunaNo ratings yet

- Pressure Loss AwwaDocument1 pagePressure Loss AwwaSashiNo ratings yet

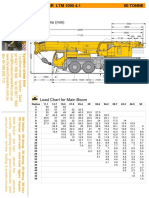

- Ltm1090-4.1 Liebherr SpecificationsDocument3 pagesLtm1090-4.1 Liebherr SpecificationsclaudobaNo ratings yet

- Pipe Friction Loss Charts Pipe and EquivDocument1 pagePipe Friction Loss Charts Pipe and EquivDoaa HassanNo ratings yet

- Fuel Consumption Chart PDFDocument1 pageFuel Consumption Chart PDFhc1210No ratings yet

- Tools TipsExtensionsDocument4 pagesTools TipsExtensionsSolina AlunorteNo ratings yet

- HDPE Pipe Dimensions and Pressure Ratings1 - P.E.S CoDocument2 pagesHDPE Pipe Dimensions and Pressure Ratings1 - P.E.S CoJGon100% (1)

- Cactus 2016Document4 pagesCactus 2016Alina AlbuNo ratings yet

- Plasco Brochure HDPEDocument2 pagesPlasco Brochure HDPEhaitham655766No ratings yet

- Carbon Steel / Alloy Steel / Seamless Pipe: Download SpecificationDocument2 pagesCarbon Steel / Alloy Steel / Seamless Pipe: Download SpecificationSreenubabu Kandru100% (1)

- Recommended Winding TensionsDocument1 pageRecommended Winding TensionsDeaferrantNo ratings yet

- U PVCDocument1 pageU PVCUsman AliNo ratings yet

- Pipes_DiameterDocument1 pagePipes_DiameterNasir AhmadNo ratings yet

- Buckling Lab ResultsDocument3 pagesBuckling Lab ResultsDanelNo ratings yet

- Butorphanol CriDocument1 pageButorphanol CriARJUN V THAMPINo ratings yet

- Poultry Disease Diagnosis - Picture Book-2Document2 pagesPoultry Disease Diagnosis - Picture Book-2बनकर परिवाराचा लाडका गोट्याNo ratings yet

- Memanjang Tipe Panjang Tinggi Luas Kusen Luas Dinding: MelintangDocument3 pagesMemanjang Tipe Panjang Tinggi Luas Kusen Luas Dinding: MelintangAfishyNellyArifiantyNo ratings yet

- 3 120 240 enDocument1,699 pages3 120 240 enRafael FroehlichNo ratings yet

- Augmentin DuoDocument2 pagesAugmentin Duojunaid hashmiNo ratings yet

- Pipe Quality Manual 1Document1 pagePipe Quality Manual 1Nasir AhmadNo ratings yet

- D 9 Cdecb 492 Ea 257 e 2 DFC 6 C 346Document7 pagesD 9 Cdecb 492 Ea 257 e 2 DFC 6 C 346Nagaradanna pavanNo ratings yet

- Technical Section: DIN 79 Square Tolerance, For Shafts and Square BoresDocument1 pageTechnical Section: DIN 79 Square Tolerance, For Shafts and Square BoresVelibor StokicNo ratings yet

- Pipe Sizes According To Schedule Input Value Unit: Pipe Table - Extracted From Asme B36.1Document6 pagesPipe Sizes According To Schedule Input Value Unit: Pipe Table - Extracted From Asme B36.1Richard ObinnaNo ratings yet

- Grade-100-WLLDocument1 pageGrade-100-WLLSajith VenkitachalamNo ratings yet

- Fuel Consumption ChartDocument1 pageFuel Consumption Chartuzair faridNo ratings yet

- Fuel Consumption ChartDocument1 pageFuel Consumption ChartMannyBaldonadoDeJesusNo ratings yet

- Job Satisfaction StatisticsDocument4 pagesJob Satisfaction StatisticsJoy GinesNo ratings yet

- Plasco - PVC U Pipes Brochure S Min PDFDocument2 pagesPlasco - PVC U Pipes Brochure S Min PDFadam rahaNo ratings yet

- PVC-U Pressure Pipes: Lifelines For The NationDocument2 pagesPVC-U Pressure Pipes: Lifelines For The NationElisha WankogereNo ratings yet

- Uniaxial Compressive Strength Versus Point Load Index Graph: LegendDocument3 pagesUniaxial Compressive Strength Versus Point Load Index Graph: LegendsyafixNo ratings yet

- Approximate Fuel Consumption ChartDocument1 pageApproximate Fuel Consumption ChartMykeNo ratings yet

- Fuel_Consumption_ChartDocument1 pageFuel_Consumption_Chartahmed elsheikhNo ratings yet

- Fuel Consumption ChartDocument1 pageFuel Consumption ChartLupul50No ratings yet

- Questra World InvestmentDocument6 pagesQuestra World InvestmentShahzaibUsmanNo ratings yet

- Musical NotesDocument4 pagesMusical Noteszalatta7No ratings yet

- Spreadsheet Conversion TableDocument82 pagesSpreadsheet Conversion TableHector GuerreroNo ratings yet

- Fuel Consumption Chart Diesel GeneratorsDocument1 pageFuel Consumption Chart Diesel GeneratorsYasir MehmoodNo ratings yet

- B-Class Medium Pipe - Is.1239.1.b.2004Document1 pageB-Class Medium Pipe - Is.1239.1.b.2004Anwar khanNo ratings yet

- Interplast Iso-161 SpecificationDocument1 pageInterplast Iso-161 SpecificationDaniel MarteyNo ratings yet

- 004 VSL Datasheets US-ADocument22 pages004 VSL Datasheets US-Akmabd100% (1)

- Motor - Choising 2Document15 pagesMotor - Choising 2Cao Thắng NguyễnNo ratings yet

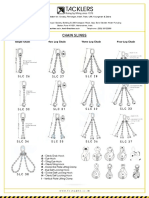

- Chain Chain SlingsDocument8 pagesChain Chain SlingsDharmendra MeenaNo ratings yet

- Grove GMK 4070-1Document6 pagesGrove GMK 4070-1philip_cadNo ratings yet

- Pipe Series: Wall Thickness and MassDocument24 pagesPipe Series: Wall Thickness and MassTammam HassanNo ratings yet

- Bolt and Screw Torque SpecsDocument3 pagesBolt and Screw Torque SpecsBilal TayyabNo ratings yet

- Vinidex PE Pipe Capability MatrixDocument1 pageVinidex PE Pipe Capability Matrixgusloh100% (1)

- Vinidex Capability & Pe100 Polyethylene Pipe Dimensions: (Based On AS/NZS 4130)Document1 pageVinidex Capability & Pe100 Polyethylene Pipe Dimensions: (Based On AS/NZS 4130)Christopher Kenneth ChoaNo ratings yet

- Productpage 3098Document2 pagesProductpage 3098rahmat hidayatNo ratings yet

- Online Classes FeesDocument2 pagesOnline Classes FeesavisheklochunNo ratings yet

- No. Description Material Material Designation Dimension Qty Weight/kgDocument1 pageNo. Description Material Material Designation Dimension Qty Weight/kgavisheklochunNo ratings yet

- Shifting List 19.11.2022Document1 pageShifting List 19.11.2022avisheklochunNo ratings yet

- Pending Work List On Level 0Document6 pagesPending Work List On Level 0avisheklochunNo ratings yet

- Pump ListDocument3 pagesPump ListavisheklochunNo ratings yet

- Ilovepdf MergedDocument20 pagesIlovepdf MergedavisheklochunNo ratings yet

- Savings Oman RialDocument2 pagesSavings Oman RialavisheklochunNo ratings yet

- Instructions For The Safe Use of Flat Woven Webbing SlingsDocument4 pagesInstructions For The Safe Use of Flat Woven Webbing SlingsavisheklochunNo ratings yet

- Polyester Webbing & Round Slings: Working Load Limits From 1 Tonne To 30 TonneDocument1 pagePolyester Webbing & Round Slings: Working Load Limits From 1 Tonne To 30 TonneavisheklochunNo ratings yet

- Project: Oman Sugar Refinery Company Job: 66729 - Equipment and Piping ErectionDocument2 pagesProject: Oman Sugar Refinery Company Job: 66729 - Equipment and Piping ErectionavisheklochunNo ratings yet

- TM-ZX1505HRS Lng-En Gen Spec 202103Document13 pagesTM-ZX1505HRS Lng-En Gen Spec 202103avisheklochunNo ratings yet

- WWWW PDFDocument3 pagesWWWW PDFavisheklochunNo ratings yet

- Description of Process - Nbsm-1Document10 pagesDescription of Process - Nbsm-1avisheklochun100% (1)

- Sizing 3Document3 pagesSizing 3avisheklochunNo ratings yet

- Sizing 2Document3 pagesSizing 2avisheklochunNo ratings yet

- QQQQQ PDFDocument3 pagesQQQQQ PDFavisheklochunNo ratings yet

- Calculation of Bolt Tension and Concrete Compression H H B F N M X X C TDocument3 pagesCalculation of Bolt Tension and Concrete Compression H H B F N M X X C TavisheklochunNo ratings yet

- Designofsteelstructures BS5950 PDFDocument100 pagesDesignofsteelstructures BS5950 PDFavisheklochunNo ratings yet

- Grimório - Modelo - GURPSDocument2 pagesGrimório - Modelo - GURPSRicardo AlexandreNo ratings yet

- A Review On Augmented Reality For Virtual HeritageDocument13 pagesA Review On Augmented Reality For Virtual HeritageSheikh Abdullah SaeedNo ratings yet

- A Study of The Flow Field of A Confined and Submerged Impinging JetDocument10 pagesA Study of The Flow Field of A Confined and Submerged Impinging JetEKKACHAI PRABNAKORNNo ratings yet

- COPS Coursework 2021Document35 pagesCOPS Coursework 2021Sharon MasikiNo ratings yet

- Business Security Lenovo Case StudyDocument2 pagesBusiness Security Lenovo Case StudyLunguLavi100% (1)

- LTP Case StudyDocument9 pagesLTP Case StudySyara BasriNo ratings yet

- Experiment # 01Document8 pagesExperiment # 01qamarNo ratings yet

- Inclusive Filipinnovation & Entrepreneurship Roadmap: PH Economic Transformation in The Digital AgeDocument40 pagesInclusive Filipinnovation & Entrepreneurship Roadmap: PH Economic Transformation in The Digital AgeAnthony John BalisiNo ratings yet

- General Product Information: Rocktech S (Slab) SeriesDocument4 pagesGeneral Product Information: Rocktech S (Slab) SeriesPhan LongNo ratings yet

- TELabDocument121 pagesTELabSrinu ReddyNo ratings yet

- Rotary Airlock Combined-Manual Final PDFDocument53 pagesRotary Airlock Combined-Manual Final PDFMechanical ShauryaNo ratings yet

- (Energy Science Engineering and Technology Series) Carter, Joel G-Solar Energy and Solar Panels - Systems, Performance and Recent Developments-Nova Publishers (2017)Document219 pages(Energy Science Engineering and Technology Series) Carter, Joel G-Solar Energy and Solar Panels - Systems, Performance and Recent Developments-Nova Publishers (2017)yordy yglesiasNo ratings yet

- Ezdsp f2812 Tutorial 3Document16 pagesEzdsp f2812 Tutorial 3Leroy Lionel SonfackNo ratings yet

- Case Fact LogDocument57 pagesCase Fact LogdamarlamcaNo ratings yet

- ImperfectionsDocument10 pagesImperfectionsFreddie KooNo ratings yet

- STS Chapter 1 6Document7 pagesSTS Chapter 1 6adlersolace61No ratings yet

- New DDL Week 4 June 27-30Document4 pagesNew DDL Week 4 June 27-30Josenia Constantino0% (1)

- Special Tools Special Tools: Instruction No Part. No. Instruction No Part. NoDocument47 pagesSpecial Tools Special Tools: Instruction No Part. No. Instruction No Part. NoAlex SibirnayaNo ratings yet

- MSDS - Union - I - Ni - 1 - MoCr - (EU) PDFDocument6 pagesMSDS - Union - I - Ni - 1 - MoCr - (EU) PDFEswaranNo ratings yet

- Simulation of N-Way Traffic Lights Using Arduino Uno EnvironmentDocument8 pagesSimulation of N-Way Traffic Lights Using Arduino Uno EnvironmentATSNo ratings yet

- InstallerDocument59 pagesInstallerDonna Rodelas PrietoNo ratings yet

- DIANA Elements Spring 2010 PDFDocument9 pagesDIANA Elements Spring 2010 PDFAlessandroAleottiNo ratings yet

- Instruction Manual: Made in The U.S.ADocument16 pagesInstruction Manual: Made in The U.S.ACarlos Rincon0% (2)

- 3rd Sem Syllabus MBA Punjabi UniversityDocument21 pages3rd Sem Syllabus MBA Punjabi UniversityHarwinder SinghNo ratings yet

- Contrabalance Walvoil CC10ADocument3 pagesContrabalance Walvoil CC10AMatias Oñate ArriagadaNo ratings yet

- C115 A DC1051-Rev01 IT-EN-ESDocument596 pagesC115 A DC1051-Rev01 IT-EN-ESLuis Bastias ChacanaNo ratings yet

- JMS TutorialDocument39 pagesJMS Tutorialsubrata_saha100% (3)