Professional Documents

Culture Documents

3.0 Maintenance Management

3.0 Maintenance Management

Uploaded by

GUADALUPE TIERRABLANCA GUDEAOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.0 Maintenance Management

3.0 Maintenance Management

Uploaded by

GUADALUPE TIERRABLANCA GUDEACopyright:

Available Formats

Production Excellence Asset Management

Maintenance Management

INTERNAL DL-08-PR-034-ENG Rev B 1|4

Revision Date Modification notes

Updated to included Key Process Parameters information from

B 28.09.2021

TMDM and PFMEA

Document Approval

Document approved through electronic system in Windchill (DES Library) by all relevant functions.

Document Owner is visible in the DES Portal.

1.0 Purpose

Defines the overall approach for maintenance management within GKN Automotive, and the framework within

which Autonomous and Planned Maintenance processes are executed.

2.0 Scope

This Procedure applies to all worldwide manufacturing locations and test sites of GKN business.

Deviation Control -06-PR-018).

Master files are stored electronically and are available to all team members. Printed copies of the master files are for reference only.

Revision control of this Document is managed by GKN PDM System (Windchill). For full details refer to GKN PDM System.

DL-08-PR-034-ENG/ Rev B (29.09.2021)

Production Excellence Asset Management

Maintenance Management

INTERNAL DL-08-PR-034-ENG Rev B 2|4

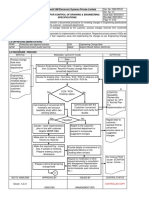

3.0 Process

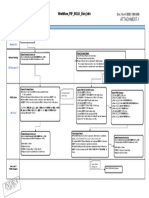

3.1 Preventive and Predictive Maintenance

Planned Maintenance can be divided into preventive and predictive maintenance.

Preventive maintenance are scheduled tasks (mechanical, electrical, hydraulic, etc) based on data in order to

maintain equipment reliability and/or increase equipment life.

Predictive maintenance is equipment condition monitoring and analysing (e.g. vibration monitoring,

thermography, oil analysis, etc) in order to efficiently organize preventive maintenance tasks.

Master files are stored electronically and are available to all team members. Printed copies of the master files are for reference only.

Revision control of this Document is managed by GKN PDM System (Windchill). For full details refer to GKN PDM System.

DL-08-PR-034-ENG/ Rev B (29.09.2021)

Production Excellence Asset Management

Maintenance Management

INTERNAL DL-08-PR-034-ENG Rev B 3|4

4.0 Definitions

GKN .................................................................................................................................... Guest, Keen, Nettlefolds

5.0 Records/Logs

NA

6.0 References

Autonomous Maintenance (DL-08-PR-052)

Planned Maintenance (DL-08-PR-053)

Manufacturing Key Parameters Preventive Maintenance: Welding (DL-08-GL-008)

Manufacturing Key Parameters Preventive Maintenance: Assembly (DL-08-GL-009)

Process - Induction Hardening of CVJ Components (DL-08-ST-029)

Process Carburizing, Carbonitriding, Neutral Hardening of CVJ Components (DL-08-ST-637)

Master files are stored electronically and are available to all team members. Printed copies of the master files are for reference only.

Revision control of this Document is managed by GKN PDM System (Windchill). For full details refer to GKN PDM System.

DL-08-PR-034-ENG/ Rev B (29.09.2021)

Production Excellence Asset Management

Maintenance Management

INTERNAL DL-08-PR-034-ENG Rev B 4|4

7.0 RACI

Responsibility

Process Step

Maintenance Manager

Value stream Manager

Plan 3.1 Define execution plan AR I

3.2 Review plan. Approve or reject? AR C

Do

3.3 Execute maintenance plan AR

Check 3.4 Maintenance activity achieves requirement? AR C

Act 3.5 Continual improvement review AR I

Master files are stored electronically and are available to all team members. Printed copies of the master files are for reference only.

Revision control of this Document is managed by GKN PDM System (Windchill). For full details refer to GKN PDM System.

DL-08-PR-034-ENG/ Rev B (29.09.2021)

You might also like

- Tronica CityDocument10 pagesTronica CitysahildoraNo ratings yet

- GTL-04-02 - Operating and Maintenance PhilosophyDocument18 pagesGTL-04-02 - Operating and Maintenance PhilosophySaravanan Varadarajan100% (1)

- TD Eg8110 Ba enDocument82 pagesTD Eg8110 Ba enWayne HoppeNo ratings yet

- Tata Starbucks Joint Venture - FinalDocument23 pagesTata Starbucks Joint Venture - FinalAnand Singh33% (3)

- Challenges in Qualifying Additive Manufacturing For Turbine - Components - A ReviewDocument22 pagesChallenges in Qualifying Additive Manufacturing For Turbine - Components - A Reviewbryan zhuoNo ratings yet

- 02-F-02 APQP Timing PlanDocument2 pages02-F-02 APQP Timing Planshobhit2310100% (1)

- Allied Bank v. Sia DigestDocument2 pagesAllied Bank v. Sia DigestkathrynmaydevezaNo ratings yet

- Various Stages of Venture Capital FinancingDocument68 pagesVarious Stages of Venture Capital Financingjoy9crasto91% (11)

- 1.0 Planned Maintenanca ProcedureDocument4 pages1.0 Planned Maintenanca ProcedureGUADALUPE TIERRABLANCA GUDEANo ratings yet

- 2.0 Autonomous MaintenanceDocument4 pages2.0 Autonomous MaintenanceGUADALUPE TIERRABLANCA GUDEANo ratings yet

- USER GUIDE - PM Module Page Wise Breakup 2.1 PDFDocument49 pagesUSER GUIDE - PM Module Page Wise Breakup 2.1 PDFrekhaNo ratings yet

- Batch03 DemoDocument713 pagesBatch03 DemoSAP PMNo ratings yet

- Eng GRP Gui 7011 23Document20 pagesEng GRP Gui 7011 23YOGESH GOPALNo ratings yet

- Project Management Plan Template TM-PP-01 V2.0 MAY 24, 2005Document68 pagesProject Management Plan Template TM-PP-01 V2.0 MAY 24, 2005dadecounty50% (2)

- ERP Project Management Primer: Quick Reference Guide To Best Practice Templates and Tips To Jumpstart Your ERP ProjectsDocument60 pagesERP Project Management Primer: Quick Reference Guide To Best Practice Templates and Tips To Jumpstart Your ERP ProjectsMahendra SinghNo ratings yet

- NORMARC 7033B-7034B Instrument Landing System: Commercial - in - ConfidenceDocument314 pagesNORMARC 7033B-7034B Instrument Landing System: Commercial - in - ConfidenceĐào Nguyên TuếNo ratings yet

- NASA: 179667main DCP-S-004Document16 pagesNASA: 179667main DCP-S-004NASAdocumentsNo ratings yet

- HB CP-802x CP-8000 ENGDocument648 pagesHB CP-802x CP-8000 ENGИгорьNo ratings yet

- Engineering Guide CDA300!12!99Document350 pagesEngineering Guide CDA300!12!99khawar mukhtarNo ratings yet

- SICAM A8000 Series CP-8000to8022 User ManualDocument614 pagesSICAM A8000 Series CP-8000to8022 User ManualMichael Parohinog GregasNo ratings yet

- SB SWUT 0007 J228 Device Manager InstallerDocument2 pagesSB SWUT 0007 J228 Device Manager Installermartin 123inktNo ratings yet

- Golf Renewal - Postmortem ReportDocument15 pagesGolf Renewal - Postmortem ReportPhuong LeNo ratings yet

- Apunte - Plantilla de Proyectos (Descripcion)Document81 pagesApunte - Plantilla de Proyectos (Descripcion)vamphyreNo ratings yet

- MAN002 FDE InventoryManagementCockpit v3.4Document43 pagesMAN002 FDE InventoryManagementCockpit v3.4bearpanzaNo ratings yet

- Disaster Recovery Procedure (Referred To CMSPRDDB) : IBM GTS, Service DeliveryDocument17 pagesDisaster Recovery Procedure (Referred To CMSPRDDB) : IBM GTS, Service DeliveryPrasadValluraNo ratings yet

- Standard Review Plan (SRP) : Construction Readiness Review ModuleDocument27 pagesStandard Review Plan (SRP) : Construction Readiness Review Modulekurtling100% (1)

- Maintenance Report HCI Mar 2021Document19 pagesMaintenance Report HCI Mar 2021Fery AndriansyahNo ratings yet

- Coating and Services: Interplan Asset IntegrityDocument22 pagesCoating and Services: Interplan Asset IntegritynarmathaNo ratings yet

- GBE-KPO-2-008-00 Cell DesignDocument50 pagesGBE-KPO-2-008-00 Cell DesignEduardo MaganaNo ratings yet

- SWAS Circular R EM 004 Elements of The Management System (QEHS)Document18 pagesSWAS Circular R EM 004 Elements of The Management System (QEHS)Karina OspinaNo ratings yet

- Maintenance Briefing Notes: Best PracticesDocument7 pagesMaintenance Briefing Notes: Best PracticespannNo ratings yet

- R&D Procedure - Control of Drawing Engg Specification P1Document1 pageR&D Procedure - Control of Drawing Engg Specification P1sumanNo ratings yet

- Suncor: Technical Standard No - FB - L-521 5Document13 pagesSuncor: Technical Standard No - FB - L-521 5rezzdezzNo ratings yet

- SD-19 Guide BookDocument48 pagesSD-19 Guide Bookv.allenNo ratings yet

- ILS 7013B-14B - Im - 23136-15 PDFDocument332 pagesILS 7013B-14B - Im - 23136-15 PDFĐào Nguyên TuếNo ratings yet

- NORMARC 7031B-7032B Instrument Landing System: Commercial - in - ConfidenceDocument300 pagesNORMARC 7031B-7032B Instrument Landing System: Commercial - in - Confidencechouchou chamaNo ratings yet

- Automatic and DDC Control Fundamentals and Energy Conservation For HVAC Equipment - Battelle - CompactDocument42 pagesAutomatic and DDC Control Fundamentals and Energy Conservation For HVAC Equipment - Battelle - Compactilikefree100% (2)

- 1ZVN938115-095 - RevH - SPT Final Inspection Work InstructionDocument5 pages1ZVN938115-095 - RevH - SPT Final Inspection Work InstructionNguyễn Thành TrungNo ratings yet

- Wrench Time Analysis: SeriesDocument27 pagesWrench Time Analysis: Seriespradeep1987coolNo ratings yet

- 4011-REP-ABE-079-442-0001 - Rev00 - DCS Auto Sequences For BSDGDocument51 pages4011-REP-ABE-079-442-0001 - Rev00 - DCS Auto Sequences For BSDGtskumarNo ratings yet

- Annex 1Document23 pagesAnnex 1Richu PaliNo ratings yet

- 3 Is ProjectsDocument23 pages3 Is Projectsimed.mhNo ratings yet

- MSG - Tuần 2Document16 pagesMSG - Tuần 2phuoc vanNo ratings yet

- QSP-05 Maintenance of Infrastructure TPM R2Document10 pagesQSP-05 Maintenance of Infrastructure TPM R2DhinakaranNo ratings yet

- Documenting Workflow To Manage Lifecycle v1.0Document17 pagesDocumenting Workflow To Manage Lifecycle v1.0Babajan BaigNo ratings yet

- Contingency Planning (CP) (CIO IT Security 06 29 Rev 6) 09-16-2022Document37 pagesContingency Planning (CP) (CIO IT Security 06 29 Rev 6) 09-16-2022Discovery Keluarga AsuhNo ratings yet

- Roject Nity: Project Unity Functional Specification - Process Order ConfirmationDocument31 pagesRoject Nity: Project Unity Functional Specification - Process Order ConfirmationsowjanyaNo ratings yet

- Excerpt KD62V12 Engine Operation Manual - Maintenance Intervals Standby Power ESPDocument9 pagesExcerpt KD62V12 Engine Operation Manual - Maintenance Intervals Standby Power ESPspamnest2No ratings yet

- Lesson 2 - IT Governance ControlDocument33 pagesLesson 2 - IT Governance ControlNathan GaleNo ratings yet

- Indra: Workflow - PIP - BULK - Dim - InfoDocument1 pageIndra: Workflow - PIP - BULK - Dim - InfoSefaNo ratings yet

- PS - Copy of Supplier PSODocument11 pagesPS - Copy of Supplier PSODesmond MahadeoNo ratings yet

- CPMCBL - Sop-05 ElecDocument5 pagesCPMCBL - Sop-05 ElecCA.PRAMOD SHRIKANTH DaithotaNo ratings yet

- Aircraft Parts PDFDocument9 pagesAircraft Parts PDFHisham BeltagyNo ratings yet

- Zud CD 06 0178 eDocument4 pagesZud CD 06 0178 epedroa.mddNo ratings yet

- LEC1 Maintenance DefinitionDocument35 pagesLEC1 Maintenance DefinitionabdulNo ratings yet

- Guide Page: FCR Capsula XL Ii / FCR Carbon Xl-2 / FCR Xl-2Document3 pagesGuide Page: FCR Capsula XL Ii / FCR Carbon Xl-2 / FCR Xl-2Ichraq NouarNo ratings yet

- LLD EdhDocument37 pagesLLD Edhjjellouli.obsNo ratings yet

- Guide PageDocument912 pagesGuide PagekrsrinivasarajuNo ratings yet

- WLPI022 Piping Isometric LifecycleDocument8 pagesWLPI022 Piping Isometric LifecycleChirag Shah100% (1)

- GS - ProSafe-RS Lite Safety Instrumented System OverviewDocument16 pagesGS - ProSafe-RS Lite Safety Instrumented System OverviewVijayNo ratings yet

- Lear-70-SSD Spec Characteristics GdlnesDocument10 pagesLear-70-SSD Spec Characteristics Gdlnesrpagarwal2No ratings yet

- Fermilab Change Management Process and ProceduresDocument47 pagesFermilab Change Management Process and ProceduresDaniel BibleNo ratings yet

- Phoenix - S4HANA - AP353 FD Report-RMC005-Report Daily Equipment Performance v1.00-xDocument36 pagesPhoenix - S4HANA - AP353 FD Report-RMC005-Report Daily Equipment Performance v1.00-xsueb suebNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Full Name: Example 1 No Summary Statement and Education Listed After ExperienceDocument3 pagesFull Name: Example 1 No Summary Statement and Education Listed After ExperienceGarimaBhandariNo ratings yet

- IBM-UNIT 3 NotesDocument37 pagesIBM-UNIT 3 Notesabhishek singhNo ratings yet

- Chapter 11Document101 pagesChapter 11Kim FloresNo ratings yet

- Chapter 7 Balance of PaymentsDocument14 pagesChapter 7 Balance of PaymentsNURUL FATIN NABILA BINTI MOHD FADZIL (BG)No ratings yet

- Problem Set 1Document4 pagesProblem Set 1Kacper BenedykcińskiNo ratings yet

- GJCPP5643 H: Income Tax Department Govt. of IndiaDocument1 pageGJCPP5643 H: Income Tax Department Govt. of Indiaswathi100% (1)

- Design and Fabrication of Grain Separator Using Solar Energy Project Reference No: 38S0809Document4 pagesDesign and Fabrication of Grain Separator Using Solar Energy Project Reference No: 38S0809roronoa zoroNo ratings yet

- Chapter 14Document33 pagesChapter 14p99123No ratings yet

- Applied Economics Theory of Consumer Behavior APDocument11 pagesApplied Economics Theory of Consumer Behavior APLulu BritanniaNo ratings yet

- Korzan IC NoteDocument4 pagesKorzan IC NoteMo El-KasarNo ratings yet

- Business Management Research PapersDocument4 pagesBusiness Management Research Papersafedymbwo100% (1)

- Dzexams Docs 3as 907161Document65 pagesDzexams Docs 3as 907161abdelillehbenammourNo ratings yet

- The Value of Common Stocks: Principles of Corporate FinanceDocument43 pagesThe Value of Common Stocks: Principles of Corporate FinanceMakar FilchenkoNo ratings yet

- Ipsas ThesisDocument4 pagesIpsas Thesisstephaniejohnsonsyracuse100% (1)

- Management: Organization StructureDocument26 pagesManagement: Organization StructureAlvin OroscoNo ratings yet

- The Tortuga Freeport ProjectDocument6 pagesThe Tortuga Freeport ProjectAlexNo ratings yet

- 2014 IOMA Derivatives Market SurveyDocument45 pages2014 IOMA Derivatives Market SurveyasifNo ratings yet

- Effect of Logistics Performance On The Store's Image and Consumers' SatisfactionDocument4 pagesEffect of Logistics Performance On The Store's Image and Consumers' SatisfactionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Group 2 KitabisaDocument28 pagesGroup 2 KitabisaDIKY RAHMANNo ratings yet

- BOP SlideDocument19 pagesBOP SlidePrajesh CalicutNo ratings yet

- Group Assignment MGT (AC1101A) LatestDocument6 pagesGroup Assignment MGT (AC1101A) LatestSyaza Aisyah0% (1)

- Rolls Royce TranscriptionDocument9 pagesRolls Royce TranscriptionDr-Akash SanthoshNo ratings yet

- Episode 1 - 5Document6 pagesEpisode 1 - 5Khôi HuỳnhNo ratings yet

- Rico 29319100 Corporate Strategy Case IndofoodDocument4 pagesRico 29319100 Corporate Strategy Case IndofoodMifta ZanariaNo ratings yet

- Onecard Statement (14 Aug 2022 - 13 Sep 2022) : Abhijeet PatilDocument3 pagesOnecard Statement (14 Aug 2022 - 13 Sep 2022) : Abhijeet PatilAbhijeet PatilNo ratings yet

- Principles & Practice of Accounting: Accounting For Special TransactionDocument60 pagesPrinciples & Practice of Accounting: Accounting For Special TransactionRashi thiNo ratings yet