Professional Documents

Culture Documents

WT4000 SteamTrap

WT4000 SteamTrap

Uploaded by

danielaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WT4000 SteamTrap

WT4000 SteamTrap

Uploaded by

danielaCopyright:

Available Formats

STEAM TRAPS

Steam Traps WT4000

Thermostatic Steam Trap Thermostatic

(Repairable)

Model WT4000 (Repairable)

Sizes 3/4”, 1”

Connections NPT, SW, FLG

Body Material Stainless Steel

Options Strainer, Blowdown Valve

PMO Max. Operating Pressure 300 PSIG

TMO Max. Operating Temperature Saturated Steam Temperature

PMA Max. Allowable Pressure 906 PSIG @ 100ºF

TMA Max. Allowable Temperature 750ºF @ 725 PSIG

Typical Applications Installation and Maintenance

PROCESS: The WT4000 is a high capacity version of the Trap can be installed in any orientation. All internal working

WT3000, for removing condensate and air from larger process components are extremely easy to replace and can be performed

applications. This steam trap is fully repairable while the body while the trap body remains connected in-line. Repair kit includes

remains in-line. Like all thermostatic traps, they are small, light ALL parts to fully rebuild the steam trap including thermal

weight, operate over a wide pressure range, and have excellent element, seat and gasket. The WT4000 does not contain a

air handling capabilities. Discharging air at start-up allows steam strainer. The WT4000S contains a strainer. WT4000SB contains

to quickly enter the system. All stainless steel construction and a blowdown valve for flushing dirt and scale from strainer.

integral strainer option make the WT4000 an excellent choice

for most process applications. Contains an extremely strong Helpful Selection Information

and rugged precision welded Stainless Steel thermal element

which is highly resistant to waterhammer. Two orifice sizes are available: 7/16” standard capacity and

5/16” reduced capacity. Select these models for steam systems

How It Works with maximum working pressure of 300 PSIG.

This thermostatic trap contains a welded stainless steel thermal

element that expands when heated and contracts when cooled Options

to 5˚F below saturated steam temperature. When air or sub-cooled Strainer, blowdown valve, and steam lock release.

condensate are present, the trap is in the open discharge position.

When steam reaches the trap, the element expands and closes S = Strainer (WT4001S)

off tightly. SB = Strainer and blowdown valve (WT4001SB)

Features SLR = Steam lock release

Customized flanged connections: Specify size, face-to-face

• The thermal element and seat can be easily removed and dimensions.

replaced in minutes with the trap body still in-line

• Operates at steam pressures up to 300 PSIG

• Thermostatic traps are excellent at discharging air, which How to Size / Order

allows steam to enter quickly; extremely important

during start-up Refer to the Capacity Chart to determine which model, the

WT4001 or WT4003 is required to satisfy the condensate load

• Welded stainless steel thermal element resists shock based on steam inlet pressure.

from waterhammer

• Freeze-proof when the trap is installed in a vertical Example:

orientation allowing for complete condensate drainage Application: 5610 lbs/hr at 100 PSIG steam inlet pressure

• Body is produced from stainless steel investment casting Size/Model: WT4001S, 5/16” orifice, and strainer

• Hardened stainless steel seat for extended service life Specify size & connections (NPT, SW, FLG)

• Available with integral strainer and blowdown valve Example Model Codes:

Sample Specification WT4001S-13-N 3/4” NPT with strainer, and 5/16” orifice

The steam trap shall be of thermostatic type with stainless steel WT4003SB-14-N 1” NPT with strainer and blowdown valve,

body, thermal element, and internal strainer. Trap must be in-line 7/16” orifice

repairable with a bolt-on type cover that is sealed with a spiral

wound Stainless Steel AISI 316 gasket. Seat and valve to be

hardened stainless steel.

56 www.watsonmcdaniel.com •• Pottstown PA • USA • Tel: 610-495-5131

Steam Traps

STEAM TRAPS

WT4000

Thermostatic Steam Trap Thermostatic

(Repairable)

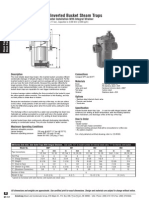

* Flanged face-to-face

dimension 9” standard. Cover Bolts

For custom sizes consult

3” Square factory (9” minimum).

Cover

Thermal Element

4.12” Orifice

FLOW

WT4000: 2.57”

WT4000S: 2.57”

WT4000SB: 3.12”

Strainer Strainer

Plug

4.81” (NPT, SW)

(Flanged as Req’d) *

Weight: 4.5 lbs.

M AT E R I A L S

Size/Connection* Model Code Orifice Size Description

Body Stainless Steel, AISI 316L

3/4” NPT WT4001-13-N 5/16” No Strainer Cover Stainless Steel, AISI 316L

1” NPT WT4001-14-N 5/16” No Strainer Cover Gasket Spiral Wound Stainless Steel, AISI 316

3/4” NPT WT4001S-13-N 5/16” Strainer Cover Bolts Steel, ASTM A193 GR B7 Nickel Plated

1” NPT WT4001S-14-N 5/16” Strainer Thermal Element Stainless Steel, AISI 302

3/4” NPT WT4001SB-13-N 5/16” Strainer & Blowdown Valve & Seat Hardened Stainless Steel, AISI 416

1” NPT WT4001SB-14-N 5/16” Strainer & Blowdown Seat Gasket Stainless Steel, AISI 316

Strainer* 0.046 Perforated Stainless Steel AISI 304

3/4” NPT WT4003-13-N 7/16” No Strainer

Blowdown Valve* Stainless Steel AISI 300

1” NPT WT4003-14-N 7/16” No Strainer

* Strainer and blowdown valve are optional

3/4” NPT WT4003S-13-N 7/16” Strainer

1” NPT WT4003S-14-N 7/16” Strainer

3/4” NPT WT4003SB-13-N 7/16” Strainer & Blowdown

1” NPT WT4003SB-14-N 7/16” Strainer & Blowdown

* For Socket Weld Connection change N to SW

C A PA C I T I E S – Condensate (lbs/hr)

Orifice Steam Inlet Pressure (PSIG)

Model Size 1 2 5 10 20 50 100 125 150 200 250 300

WT4001 5/16” 605 855 1350 1910 2705 4275 5610 6045 6425 7070 7615 8095

WT4003 7/16” 940 1325 2095 2960 4190 6620 8695 9365 9950 10955 11800 12540

Back Pressure as Percentage of Inlet Pressure 10 20 25 30 40 50 60 70 80 90

Percentage Decrease in Trap Capacity 0 0 0 2 5 12 20 30 40 55

Tel: 610-495-5131 • Pottstown PA • USA •• www.watsonmcdaniel.com 57

You might also like

- Trends1 Aio Ut1-L1Document2 pagesTrends1 Aio Ut1-L1Yolanda Csp77% (13)

- Nissan Primastar X83 (2002-2006) Service Manual #18Document115 pagesNissan Primastar X83 (2002-2006) Service Manual #18János ZávogyánNo ratings yet

- FTT FTTS SteamTrapDocument3 pagesFTT FTTS SteamTrapauxiliar.termicaNo ratings yet

- Trampas de Vapor FFTDocument5 pagesTrampas de Vapor FFTAndrés ChuquillaNo ratings yet

- Ficha Técnica TD600Document2 pagesFicha Técnica TD600Marcos Mezahuaman LaimeNo ratings yet

- SteamTraps WD700SDocument2 pagesSteamTraps WD700SfranzumarragaNo ratings yet

- (Repairable) : Clean Steam Thermostatic Steam TrapDocument1 page(Repairable) : Clean Steam Thermostatic Steam TrapPaulo CostaNo ratings yet

- Nicholson Thermostatic Steam TrapsDocument18 pagesNicholson Thermostatic Steam TrapsAli Fanani100% (1)

- Description Materials: Cast Iron For Horizontal InstallationDocument2 pagesDescription Materials: Cast Iron For Horizontal InstallationParth GosaiNo ratings yet

- IB SERIES Inverted Bucket Steam TrapDocument6 pagesIB SERIES Inverted Bucket Steam TrapThanh ThuNo ratings yet

- 200 Series Inverted Bucket Steam Traps: Cast Iron For Vertical InstallationDocument2 pages200 Series Inverted Bucket Steam Traps: Cast Iron For Vertical InstallationbhaskarbabaiNo ratings yet

- TD700S TDF700S SteamTrapDocument4 pagesTD700S TDF700S SteamTrapauxiliar.termicaNo ratings yet

- 501SHDocument2 pages501SHbhaskarbabaiNo ratings yet

- Yoshitake Steam Trap PDFDocument40 pagesYoshitake Steam Trap PDFDeni SuryaNo ratings yet

- How Steam Trap WorkDocument40 pagesHow Steam Trap Workdeny prasyamtyo100% (1)

- Ficha Tecnica Amstrong.1Document2 pagesFicha Tecnica Amstrong.1ANo ratings yet

- Watson 3Document3 pagesWatson 3Jair Alvarez ApaleNo ratings yet

- AI - Automatic Air Vent (Stainless Steel)Document1 pageAI - Automatic Air Vent (Stainless Steel)Rakhmad sugih hartonoNo ratings yet

- Fte S F & T S T: Eries Loat Hermostatic Team RapsDocument4 pagesFte S F & T S T: Eries Loat Hermostatic Team RapsAlvaro Yaciel Rodríguez LagunesNo ratings yet

- 880 Series Inverted Bucket Steam TrapsDocument2 pages880 Series Inverted Bucket Steam TrapsCherbee FerrerNo ratings yet

- AV2000 ThermostaticAirVentDocument1 pageAV2000 ThermostaticAirVentauxiliar.termicaNo ratings yet

- Trampadevapor Flotador y TermostaticaDocument9 pagesTrampadevapor Flotador y TermostaticaLuis Gutiérrez AlvarezNo ratings yet

- Trampas de Vapor Armstrong, Series880 PDFDocument2 pagesTrampas de Vapor Armstrong, Series880 PDFLuis Guillermo Gallardo BoscanNo ratings yet

- Serie WFTDocument3 pagesSerie WFTarmandolea.ventasNo ratings yet

- Control Valve Selection and SizingDocument16 pagesControl Valve Selection and SizingSnehashis BoseNo ratings yet

- Armstrong - SH Series Bimetallic TrapsDocument2 pagesArmstrong - SH Series Bimetallic TrapsTaylorNo ratings yet

- Steam Control Products: Inverted Bucket Float & Thermostatic Radiator TrapsDocument20 pagesSteam Control Products: Inverted Bucket Float & Thermostatic Radiator TrapssdvitkoNo ratings yet

- PRO 810124 12 A1-Steam-Traps enDocument30 pagesPRO 810124 12 A1-Steam-Traps enZulfadli RaniNo ratings yet

- Quicktrap Series: Lower Replacement CostsDocument2 pagesQuicktrap Series: Lower Replacement Costsalejandro obregonNo ratings yet

- Features Steam Traps GestraDocument2 pagesFeatures Steam Traps GestramsmimijohanaNo ratings yet

- Breather Valve 94020-3HDocument8 pagesBreather Valve 94020-3Hbuzz cmkyNo ratings yet

- Thermodynamic Steam TrapsDocument12 pagesThermodynamic Steam TrapsbuddhansamratNo ratings yet

- SHOT SleeveDocument2 pagesSHOT Sleeve박상길No ratings yet

- Conservation Vent (Pressure & Vacuum)Document8 pagesConservation Vent (Pressure & Vacuum)SudhirNo ratings yet

- Asco Series 290 Angle Body CatalogDocument10 pagesAsco Series 290 Angle Body CatalogcillongNo ratings yet

- All Stainless Steel For Horizontal Installation: Description ConnectionsDocument2 pagesAll Stainless Steel For Horizontal Installation: Description ConnectionsDavid MartinezNo ratings yet

- Steam TrapDocument10 pagesSteam TrapvictorvikramNo ratings yet

- High Flow Direct Acting Valves: FeaturesDocument2 pagesHigh Flow Direct Acting Valves: FeaturesBurhan AyubNo ratings yet

- Thermal Safety Drain Series STS and Draught Regulator Series RTDocument6 pagesThermal Safety Drain Series STS and Draught Regulator Series RTAngel YordanovNo ratings yet

- Materiales Serie XL PDFDocument1 pageMateriales Serie XL PDFcarolina PortocarreroNo ratings yet

- Fig - 3616 TI P160 04 ENDocument4 pagesFig - 3616 TI P160 04 ENAditomo PutrantoNo ratings yet

- ImmersionDocument164 pagesImmersionsvpd2006No ratings yet

- Model BPS-09: Back Pressure-Reducing ValveDocument4 pagesModel BPS-09: Back Pressure-Reducing Valveengp3077No ratings yet

- Head and Well RefDocument5 pagesHead and Well Refmehdi227No ratings yet

- Gestra Steam Trap - Thermostatic Steam Trap BK 29: Class Rating: ANSI 900 Available SizesDocument2 pagesGestra Steam Trap - Thermostatic Steam Trap BK 29: Class Rating: ANSI 900 Available SizesdcarunchioNo ratings yet

- SG Interspiro Spiromatic 90u DatasheetDocument2 pagesSG Interspiro Spiromatic 90u DatasheetSorin - Viorel MaresNo ratings yet

- Seriestvs 4000Document4 pagesSeriestvs 4000Jimit ShahNo ratings yet

- Thermostatic Steam Trap (Air Vent) : Size 3/8"-1/2" Screwed BSPDocument1 pageThermostatic Steam Trap (Air Vent) : Size 3/8"-1/2" Screwed BSPconstantin.iacomi3837No ratings yet

- Float & Thermostatic Steam Traps: For Efficient Condensate Drainage of Industrial Process and HVAC EquipmentDocument12 pagesFloat & Thermostatic Steam Traps: For Efficient Condensate Drainage of Industrial Process and HVAC Equipmentmember1000No ratings yet

- FT Series: Float & Thermostatic Steam TrapDocument2 pagesFT Series: Float & Thermostatic Steam TrapMarcos Mezahuaman LaimeNo ratings yet

- Ficha Tecnica Trampa Termostatica Archive B PDFDocument2 pagesFicha Tecnica Trampa Termostatica Archive B PDFAlexis PradoNo ratings yet

- Watlow Immersion HeatersDocument163 pagesWatlow Immersion HeatersEliasNo ratings yet

- L & M Series Ultra-Capacity Float & Thermostatic Steam Trap: Description How To OrderDocument2 pagesL & M Series Ultra-Capacity Float & Thermostatic Steam Trap: Description How To OrderJozsef MagyariNo ratings yet

- Contenido Tracepak Technical SpecsDocument20 pagesContenido Tracepak Technical SpecsMiguelNo ratings yet

- Valvula Presion y Vacio3100-Comprimido - CompressedDocument5 pagesValvula Presion y Vacio3100-Comprimido - CompressedAnonymous hEqjR5gNo ratings yet

- Valvula Presion y Vacio3100 - CompressedDocument5 pagesValvula Presion y Vacio3100 - CompressedAnonymous hEqjR5gNo ratings yet

- Valvula Presion y Vacio3100-ComprimidoDocument5 pagesValvula Presion y Vacio3100-ComprimidoAnonymous hEqjR5gNo ratings yet

- Valvula Presion y Vacio3100Document5 pagesValvula Presion y Vacio3100Anonymous hEqjR5gNo ratings yet

- Sizing Heat ExchangersDocument8 pagesSizing Heat Exchangerstyberius7No ratings yet

- Data Sheet Purgador PT65-40Document2 pagesData Sheet Purgador PT65-40Douglas Tondello100% (1)

- Amazon Cloudfront Faqs: GeneralDocument24 pagesAmazon Cloudfront Faqs: Generalnavvicky082079No ratings yet

- Pac 7000 ManualDocument209 pagesPac 7000 ManualprasadNo ratings yet

- Module 6 - Normalization PDFDocument10 pagesModule 6 - Normalization PDFJacob Satorious ExcaliburNo ratings yet

- Microcontrollers Applications Note 4Document37 pagesMicrocontrollers Applications Note 4dhikacelvinNo ratings yet

- MOS Capacitor - StructureDocument22 pagesMOS Capacitor - Structurerounak aliNo ratings yet

- Ruhrpumpen Reciprocating Plunger Pumps Brochure EN May20Document8 pagesRuhrpumpen Reciprocating Plunger Pumps Brochure EN May20hoseinNo ratings yet

- Marina Echave Del Carmen: EducationDocument2 pagesMarina Echave Del Carmen: Educationmax colbeNo ratings yet

- Oms-Mr 30 40.7 4Document5 pagesOms-Mr 30 40.7 4Farshad AbediNo ratings yet

- Panasonic SA-AK52Document80 pagesPanasonic SA-AK52Nilo BrasilNo ratings yet

- TDI Injection and Glow Plug System 6-Cyl 3 0 LTR 4-Valve Common Rail Generation IIDocument87 pagesTDI Injection and Glow Plug System 6-Cyl 3 0 LTR 4-Valve Common Rail Generation IIergdegNo ratings yet

- It Essentials Question Bank With Answers PDFDocument58 pagesIt Essentials Question Bank With Answers PDFMs. Meenakshi G M MCA. Associate ProfessorNo ratings yet

- ICGT Question Bank 13ME301 InternalDocument13 pagesICGT Question Bank 13ME301 Internalవిష్ణువర్ధన్రెడ్డిNo ratings yet

- Aws Route 53 and Elb: Syed Sameer AWS Enterprise ArchitectDocument41 pagesAws Route 53 and Elb: Syed Sameer AWS Enterprise ArchitectDebnath MajiNo ratings yet

- Optimus 8S ENDocument5 pagesOptimus 8S ENjanna ibrahimNo ratings yet

- Personal Record Book: Automotive Service TechnicianDocument26 pagesPersonal Record Book: Automotive Service TechnicianCertified Rabbits LoverNo ratings yet

- APG AuditingElectronicBasedMSDocument5 pagesAPG AuditingElectronicBasedMSmuzammil21_adNo ratings yet

- On The Security of Data Access Control For Multiauthority Cloud Storage Systems PDFDocument14 pagesOn The Security of Data Access Control For Multiauthority Cloud Storage Systems PDFsumalrajNo ratings yet

- Motorola gp580Document62 pagesMotorola gp580pwnuk wnukNo ratings yet

- Catalogo 5 KW 915 MHZDocument2 pagesCatalogo 5 KW 915 MHZMarcelo Neves GarofaloNo ratings yet

- CaglarGuldiken CVDocument2 pagesCaglarGuldiken CVismenhickime sNo ratings yet

- Computer Processing TechniquesDocument25 pagesComputer Processing Techniqueskomal4242No ratings yet

- Textbook E Commerce 2014 Business Technology Society Kenneth C Laudon Ebook All Chapter PDFDocument53 pagesTextbook E Commerce 2014 Business Technology Society Kenneth C Laudon Ebook All Chapter PDFjohn.bottorff939100% (14)

- Bpo2 PPT 3Document12 pagesBpo2 PPT 3Mary Lynn Dela PeñaNo ratings yet

- Divya Yerrabolu Experience LetterDocument3 pagesDivya Yerrabolu Experience LetterMuthu KrishnaNo ratings yet

- Project Report Hotel Management SystDocument63 pagesProject Report Hotel Management SystSubhash BajajNo ratings yet

- Dremel 398 Manual de Usuario PDFDocument76 pagesDremel 398 Manual de Usuario PDFlada1119No ratings yet

- Abraham Elijah Cv...Document2 pagesAbraham Elijah Cv...Elijah AbrahamNo ratings yet

- Land Rover Workshop Manuals L322 Range Rover System Description and Operation AUTOMATIC TRANSMISDocument1 pageLand Rover Workshop Manuals L322 Range Rover System Description and Operation AUTOMATIC TRANSMISMark ErskineNo ratings yet