Professional Documents

Culture Documents

17.tower Crane Checklist

17.tower Crane Checklist

Uploaded by

Malik MohammedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

17.tower Crane Checklist

17.tower Crane Checklist

Uploaded by

Malik MohammedCopyright:

Available Formats

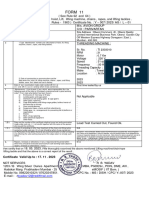

TA’AZEEZ ENTERPRISES

Po Box: 23, Pc: 103-AL Qurum North AL Ghoubra- Bowsher

Sultanate Of Oman

REPORT OF TEST / EXAMINATION OF TOWER CRANE

Date of thorough Examination: Works Order No:

Name & Address of Owner of Crane and its

Location

Premises at which thorough examination was

carried out

Scope of job

Reference Standards

Equipment Description :

( Eg. Diesel Powered Hydraulically Operated, Telesco pic/Lattice Boom, Mobile/Crawler )

Make

Model

Date of Manufacture of crane

Identification (e.g. makers serial number,

owners identifying mark)

Date of last previous Test of crane

Date of last previous thorough examination of

crane

Pre-Job Safety Checks and Risk assessment : Y N N/A Remarks

Site entry certifications done ?

Site induction done?

Safety briefing/tool box talk given

Correct PPE

Area checked for the following points:

Sharp objects

Ref. Procedure: SOP-03 Rev.0

TA’AZEEZ ENTERPRISES

Po Box: 23, Pc: 103-AL Qurum North AL Ghoubra- Bowsher

Sultanate Of Oman

Overhead hazard

Electrical wires

Chemicals

Slips/trips

Cleaniness

Falling objects

Any hot works

People working around

Area is barricaded

Good lighting

Well ventilated

Working at height

Confined spaces

Noice level

Vibrations from machines

Outside tempreture/humidity

Wind speed

Visibility

Legend: S – satisfactory, NS – not satisfactory, NA – not applicable, NT – not tested, NI – n ot installed

Description Condition Remarks

1 .DOCUMENTS

Manufacturers Documents

Previous Inspection Cert

Wire Rope Cert

Hook Block Cert

Maintenance Record

Operators Permit

General Requirements

SI NO :

Tower Crane is provided with markings of the Safe

1

Working Load, serial number and LM number.

2 Safe access and egress are provided to the crane

operator.

3 A load capacity chart is displayed in the operator

cabin.

Operator crane cabin is provided with a locking

4

mechanism so as to prevent unauthorised entry.

A safety bar is fitted across the operator’s cabin

5

window where there is likelihood of the operator

falling through it.

Fire extinguisher is fit for use and provided in the

6

operator cabin.

An updated Operation and Maintenance

7

log book is available in the operator cabin.

Ref. Procedure: SOP-03 Rev.0

TA’AZEEZ ENTERPRISES

Po Box: 23, Pc: 103-AL Qurum North AL Ghoubra- Bowsher

Sultanate Of Oman

Manufacturer Operating Manual and Maintenance

8

Manual are made available.

Tower crane is adequately grounded or protected

9

against lightning.

Other visual checks

10 Load charts and other symbols are available and

visible.

11 Hydraulic fluid level is sufficient.

12 Slewing oil level is sufficient.

13 All mounting bolts are in good condition.

14 Hydraulic system is free of leaks.

15 Boom sections are free of cracks or dents.

Ref. Procedure: SOP-03 Rev.0

TA’AZEEZ ENTERPRISES

Po Box: 23, Pc: 103-AL Qurum North AL Ghoubra- Bowsher

Sultanate Of Oman

16 Main and auxiliary wire ropes are well lubricated and that there

are no visible defects such as broken wires, kinks, excess wear,

crushing etc.

Winches, pulleys and wire ropes are in good working condition.

17

Crane hook is provided with a safety catch to prevent displacement

18

of the sling or load from the hook.

Safety and Operational Devices

19 Load radius indicator with warning alarm is installed.

20 Jib angle indicator is provided (For Luffing Jib Tower Crane).

21 Emergency stop button, which will terminate the operation of the

crane engine, is installed in the operator cabin and correctly

identified.

22 Effective braking mechanisms for the following is

maintained:

(a) Hoisting

(b) Derricking

(c) Slewing

(d) Trolley Travelling

Hoisting Limiter to prevent over-hoisting of the hook block is

23

functional.

Trolley Travelling limiter to prevent over-travelling of trolley is

24

functional.

Limit switches to prevent over-derricking and over-lowering of

25

jib (For Luffing Jib Tower Crane) is functional.

26 Slewing limiter to restrict slewing of crane is functional.

Overload Limiter to prevent overloading of crane is functional.

27

Load Moment Limiter to prevent over-turning moment is functional.

28

29 Anti-collision devices are tested to stop the tower crane’s operation

such that the crane-to-crane interference must be maintained at not

less than 3 metres.

Wind anemometer is installed and is in good working condition.

30

Ref. Procedure: SOP-03 Rev.0

TA’AZEEZ ENTERPRISES

Po Box: 23, Pc: 103-AL Qurum North AL Ghoubra- Bowsher

Sultanate Of Oman

Maintenance

Data logger for recording key operating parameters of the crane

31

is functional.

Tower Crane has a regular maintenance programme that is in

32

accordance with manufacturer’s specifications.

Maintenance work on the Tower Crane is carried out by

33

Competent Persons.

LOAD TEST

(i) (iii)

(ii)

Configuration of the crane at the time of Length of Test Safe

Radius

inspection and test : Jib Load Working

(m)

(m) (tonnes) Load( tonn

es)

Wire rope dia Main x falls:

Wire rope dia Aux x falls :

Wire rope certificate no Main:

Wire rope certificate no Aux:

Main hook serial no:

Main hook certificate no :

Aux.hook serial no:

Aux.hook certificate no:

Counterweight:

Over Load Warning

Over Load Cut Off

THOROUGH EXAMIN ATION AFTER LOAD TE ST

Permanent Deformation

Cracking

Paint Flaking

Measuring tools used

Loosening Of Structural Connections

Ref. Procedure: SOP-03 Rev.0

TA’AZEEZ ENTERPRISES

Po Box: 23, Pc: 103-AL Qurum North AL Ghoubra- Bowsher

Sultanate Of Oman

Comments:

Next inspection date

Next load test

Representative Name & Designation Signature Date

For

Customer

For TIS

Ref. Procedure: SOP-03 Rev.0

You might also like

- Crane Load Test ProcedureDocument3 pagesCrane Load Test Procedurealfonsodelar79% (19)

- Aon India SIS 28.2 - Key Highlights PDFDocument44 pagesAon India SIS 28.2 - Key Highlights PDFsantosh kumar100% (1)

- Routine Lift Plan For All Crane-Grove GMK 50 TonDocument1 pageRoutine Lift Plan For All Crane-Grove GMK 50 TonKannan Murugesan100% (1)

- Crane Pre Commissioning ITPDocument6 pagesCrane Pre Commissioning ITPAbdul Hamid TasraNo ratings yet

- Training Proposal Organic Chicken Production FgaDocument6 pagesTraining Proposal Organic Chicken Production Fgacerbito lydiaFGA2019100% (1)

- 4 SOP-Tank Farm Final Sent To ZonesDocument37 pages4 SOP-Tank Farm Final Sent To ZonesVijayNo ratings yet

- Examination Procedure For Offshore Crane InspectionDocument13 pagesExamination Procedure For Offshore Crane InspectionTrust Emma80% (5)

- ARB OHL CatalogueDocument84 pagesARB OHL CatalogueArdian Restu WicaksonoNo ratings yet

- Crane Insp Work SheetDocument3 pagesCrane Insp Work SheetPao Barillas100% (1)

- Suspended Personnel Platform Check List PDFDocument1 pageSuspended Personnel Platform Check List PDFmark lester caluzaNo ratings yet

- Cambridge IGCSE and O Level Business Studies (2nd Edition) Revision GuideDocument10 pagesCambridge IGCSE and O Level Business Studies (2nd Edition) Revision GuideRosetta Rose100% (1)

- Crawler Crane ChecklistDocument2 pagesCrawler Crane ChecklistAnuraj100% (1)

- Maz - PRJ - Hse - PRC 10 - Lifting Operations Procedures 001Document8 pagesMaz - PRJ - Hse - PRC 10 - Lifting Operations Procedures 001ghazi kallelNo ratings yet

- Pri-Hse-Frm-011 Lifting PermitDocument3 pagesPri-Hse-Frm-011 Lifting PermitTopeNo ratings yet

- Crane ChecklistsDocument8 pagesCrane ChecklistscuraajNo ratings yet

- Lifting Method StatementDocument22 pagesLifting Method StatementJanaka Kavinda100% (1)

- Zoomlion 80 Ton - 011Document2 pagesZoomlion 80 Ton - 011Susil Kumar SahooNo ratings yet

- Mobile CraneDocument18 pagesMobile CraneHarris Shehzad100% (1)

- Lifting Equipment - GeneralDocument1 pageLifting Equipment - GeneralVPN NetworkNo ratings yet

- Commissioning Procedure Vagen Screw Conveyor With Check ListDocument3 pagesCommissioning Procedure Vagen Screw Conveyor With Check Listrahmankhan823100% (1)

- 205 EOT CraneDocument9 pages205 EOT CraneElsayed Salah HamoudaNo ratings yet

- MS For Porta Cabin UnloadingDocument15 pagesMS For Porta Cabin Unloadingshamshad ahamedNo ratings yet

- AWS G2.1.tmpDocument12 pagesAWS G2.1.tmpgazaliNo ratings yet

- Luffing Tower Crane Preshift InspectionDocument1 pageLuffing Tower Crane Preshift InspectionEdmond KeraNo ratings yet

- Rfi & HPR Form - 12e-C01-Ce-0042 - FDT & Surveyor Inspection For 3rd Layer Backfilling Prior ToDocument4 pagesRfi & HPR Form - 12e-C01-Ce-0042 - FDT & Surveyor Inspection For 3rd Layer Backfilling Prior ToSarah AzizNo ratings yet

- Bridge Crane & Hoist InstallationDocument7 pagesBridge Crane & Hoist Installationnike_y2kNo ratings yet

- Ptw-Lifting Operation (Daily) : General Information OMC Permit NoDocument2 pagesPtw-Lifting Operation (Daily) : General Information OMC Permit NoKarthik KarunanithiNo ratings yet

- Liftting Plan - With Winch MachineDocument3 pagesLiftting Plan - With Winch Machineshahhussain1031No ratings yet

- Mobile CranesDocument7 pagesMobile CranesEr Faiyaz Ahmed100% (1)

- Switch Gears 134-149Document16 pagesSwitch Gears 134-149Vijaya Kumar100% (1)

- JPPL Ehs 19 03 SWP 02Document12 pagesJPPL Ehs 19 03 SWP 02MohamedSaidNo ratings yet

- T) Nited States Department of The Interior Minerals Management ServiceDocument6 pagesT) Nited States Department of The Interior Minerals Management ServiceOSDocs2012No ratings yet

- Technical Annexure - Fire Fighting SystemsDocument11 pagesTechnical Annexure - Fire Fighting SystemsBhushanNo ratings yet

- Checklist For Shunt ReactorDocument4 pagesChecklist For Shunt ReactorSanthosh Kumar VinayagamNo ratings yet

- PscChecklistImoNo_9737371Document3 pagesPscChecklistImoNo_9737371Alexandros KritsotakisNo ratings yet

- 10 Crane & Lifting Operation Procedure Rev.bDocument10 pages10 Crane & Lifting Operation Procedure Rev.bSyed Fawad ShahNo ratings yet

- Method Statement HP and LP Piping Erection - CD Bay Boiler and TG PDFDocument5 pagesMethod Statement HP and LP Piping Erection - CD Bay Boiler and TG PDFAmit SinghNo ratings yet

- Crawler Crane Checklist Rev 0Document2 pagesCrawler Crane Checklist Rev 0Maizatul Akmar Manshor100% (2)

- Suspended Personnel Platform Check List PDFDocument1 pageSuspended Personnel Platform Check List PDFDenease CrummieNo ratings yet

- 14-Weekly Tower Crane Check ListDocument2 pages14-Weekly Tower Crane Check ListJigarNo ratings yet

- CPA TCIG Safety Alert Cranes Out of and Back Into Service Rev 2 200514Document3 pagesCPA TCIG Safety Alert Cranes Out of and Back Into Service Rev 2 200514NageswarNo ratings yet

- Trip Coil Supervision RelayDocument8 pagesTrip Coil Supervision RelaybxteoNo ratings yet

- 14.03.2024 MM Handler F-15Document1 page14.03.2024 MM Handler F-15Susil Kumar SahooNo ratings yet

- Consolidated Construction Consortium LTD.: DOC No.:CCCL/HSE/003 OCP No.30 DateDocument1 pageConsolidated Construction Consortium LTD.: DOC No.:CCCL/HSE/003 OCP No.30 DateradhouaneNo ratings yet

- Site Test Procedure For Overhead Crane - r1Document8 pagesSite Test Procedure For Overhead Crane - r1Ismuliono I100% (1)

- Crane Anti Collision DeviceDocument15 pagesCrane Anti Collision DeviceMohamedSaidNo ratings yet

- 8 LV SwitchgearDocument2 pages8 LV SwitchgearsoorajNo ratings yet

- Lole Hse Perspective Total TucnDocument34 pagesLole Hse Perspective Total TucnOmosigho OsaroNo ratings yet

- Certificate of Avion GroupDocument2 pagesCertificate of Avion GroupAmit BhattNo ratings yet

- Window CradleDocument10 pagesWindow CradleHarris ShehzadNo ratings yet

- ALGAITH PU&LD Machine Property DamageDocument14 pagesALGAITH PU&LD Machine Property Damageosama nasrNo ratings yet

- Eot NotesDocument3 pagesEot NotessqssafetyNo ratings yet

- Bridge Load TestDocument4 pagesBridge Load Testvivek100% (1)

- 007 Mobile Crane ChecklistDocument2 pages007 Mobile Crane Checklistchandral86No ratings yet

- Site Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationDocument7 pagesSite Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationSyed Abbas100% (1)

- CTRA TK 64 003 Scaffolding Inside OutsideDocument6 pagesCTRA TK 64 003 Scaffolding Inside OutsideMohamed RizwanNo ratings yet

- NDT TS Mecon PDFDocument18 pagesNDT TS Mecon PDFgulu padhanNo ratings yet

- Tower Crane Safety DocsDocument43 pagesTower Crane Safety DocsKesavan Dhurai100% (4)

- Container Crane PresentationDocument62 pagesContainer Crane PresentationOussama radikiNo ratings yet

- 02-Side Boom-Tec00548Document2 pages02-Side Boom-Tec00548Mujahid AyyubNo ratings yet

- Diff Micom P543 GT1-3 Line Diff#Document20 pagesDiff Micom P543 GT1-3 Line Diff#Mohamed Wahid100% (1)

- LIFTING PERMITDocument2 pagesLIFTING PERMITRajivpaul PulidindiNo ratings yet

- (Draft) CLI-Superkrane - Engineering ForumDocument29 pages(Draft) CLI-Superkrane - Engineering ForumTatak Bay AhmedNo ratings yet

- Investment Opportunities in KelantanDocument30 pagesInvestment Opportunities in KelantanSyimir SyahmiNo ratings yet

- MN Wool World X LLC Quote Yg086d Yg026t Yg002c1 EtcDocument7 pagesMN Wool World X LLC Quote Yg086d Yg026t Yg002c1 EtcLyracism UguumurNo ratings yet

- Data Overview - LEADING FIREMAN PDFDocument2 pagesData Overview - LEADING FIREMAN PDFSoji JosephNo ratings yet

- Crisil Report On OMTDocument178 pagesCrisil Report On OMTMarquis HowellNo ratings yet

- 13-Health and Safety in Employment Petroleum Exploration and Extraction Regulations 20131 PDFDocument65 pages13-Health and Safety in Employment Petroleum Exploration and Extraction Regulations 20131 PDFJesus SanchezNo ratings yet

- Coal Industry ResearchDocument14 pagesCoal Industry ResearchSURABHI SUSHREE NAYAKNo ratings yet

- ChillRex02 Weekly Report Week 8 (6 January)Document13 pagesChillRex02 Weekly Report Week 8 (6 January)Sharifah NurriedaNo ratings yet

- AatmaNirbhar Bharat Full Presentation Part 4 16-5-2020Document21 pagesAatmaNirbhar Bharat Full Presentation Part 4 16-5-2020DeshGujaratNo ratings yet

- Winter Wheat Planning BudgetDocument2 pagesWinter Wheat Planning BudgetGeros dienosNo ratings yet

- China and India 1Document24 pagesChina and India 1Robert DygasNo ratings yet

- The Industrial RevolutionDocument2 pagesThe Industrial Revolutionboxovo2943No ratings yet

- The Apparel Market Overview 2009-2014Document15 pagesThe Apparel Market Overview 2009-2014Rommel AouadNo ratings yet

- Unwto All Data Download 112023Document1,063 pagesUnwto All Data Download 112023hljuristsinternationalNo ratings yet

- Stairs Construction ProcessDocument6 pagesStairs Construction ProcessTAN QIAO TING A20BE0303No ratings yet

- Consumer Buying Behavior and Brand Perception in Shopping Malls - A Study of Lulu Mall, CochinDocument2 pagesConsumer Buying Behavior and Brand Perception in Shopping Malls - A Study of Lulu Mall, CochinZara SabriNo ratings yet

- Agricultural and Rural Transformation in Ethiopia: Obstacles, Triggers and Reform ConsiderationsDocument55 pagesAgricultural and Rural Transformation in Ethiopia: Obstacles, Triggers and Reform ConsiderationsJermy YpteNo ratings yet

- Rajsthan Industrial DetailsDocument34 pagesRajsthan Industrial DetailsvidyanandNo ratings yet

- Risk Management in Delhi IGI AirportDocument2 pagesRisk Management in Delhi IGI AirportPranav Khalikar0% (1)

- OR02BU7259 - Car InsuranceDocument4 pagesOR02BU7259 - Car InsuranceDevdoot SahuNo ratings yet

- Distributed Generation in Nigerias New eDocument6 pagesDistributed Generation in Nigerias New eOlu OlanubiNo ratings yet

- (A) General Information DetailsDocument3 pages(A) General Information DetailsRMES ConsultancyNo ratings yet

- Optimization of The Load-And-Haul Operation at An Opencast CollieryDocument8 pagesOptimization of The Load-And-Haul Operation at An Opencast CollieryTimmy ChawazNo ratings yet

- Load PlansDocument10 pagesLoad PlansPenis Chicken TitsNo ratings yet

- Mandi Gobindgarh Hazardous Waste Report NGT April2021Document8 pagesMandi Gobindgarh Hazardous Waste Report NGT April2021arbaz khanNo ratings yet

- Transportation and Marketing of Petroleum and Petroleum ProductsDocument1 pageTransportation and Marketing of Petroleum and Petroleum ProductsadityamduttaNo ratings yet

- Swot Beekeeping BGDocument8 pagesSwot Beekeeping BGlorenzo1970No ratings yet