Professional Documents

Culture Documents

Adjunto 2 - 2009 - Golparvar-Fard Et Al.

Adjunto 2 - 2009 - Golparvar-Fard Et Al.

Uploaded by

Bryan Smith Cardenas RojasCopyright:

Available Formats

You might also like

- Digital Radiography Quiz ImportantDocument6 pagesDigital Radiography Quiz ImportantPalaniswamy Thinesh Shankar50% (2)

- The Project Manager's Checklist for Building Projects: Delivery Strategies & ProcessesFrom EverandThe Project Manager's Checklist for Building Projects: Delivery Strategies & ProcessesNo ratings yet

- 2009 - Visualization of Construction Progress Monitoring With 4D Simulation Model Overlaid On Time-Lapsed Photographs - Journal of CompuDocument14 pages2009 - Visualization of Construction Progress Monitoring With 4D Simulation Model Overlaid On Time-Lapsed Photographs - Journal of CompuDavid Fernandes de OliveiraNo ratings yet

- Cost and Schedule Monitoring of Industrial BuildingDocument10 pagesCost and Schedule Monitoring of Industrial BuildingNoelNo ratings yet

- Continuous Improvement The BasicsDocument23 pagesContinuous Improvement The BasicsAdonis PajarilloNo ratings yet

- 5 Otmc PDFDocument9 pages5 Otmc PDFjose_guerra_73No ratings yet

- Memo Web AppDocument8 pagesMemo Web Appyomi kwairangaNo ratings yet

- Why Software Requirements Traceability Remains A Challenge: July 2009Document7 pagesWhy Software Requirements Traceability Remains A Challenge: July 2009cjaramilNo ratings yet

- Knowledge-Based Standard Progress Measurement For Integrated Cost and Schedule Performance ControlDocument12 pagesKnowledge-Based Standard Progress Measurement For Integrated Cost and Schedule Performance ControlJuan EstebanNo ratings yet

- Togaf - Module 2 Assignment - SterneDocument1 pageTogaf - Module 2 Assignment - Sterneapi-471022021No ratings yet

- Optimizing Construction Scheduling ThrouDocument6 pagesOptimizing Construction Scheduling ThrouAwes SewsaNo ratings yet

- Cutover ManagementDocument3 pagesCutover ManagementJoydip MukhopadhyayNo ratings yet

- Schedule Optimization BrochureDocument4 pagesSchedule Optimization BrochurealdoqNo ratings yet

- Cloud Migration Strategy - Best Practices - Whitepaper - v2.0 PDFDocument20 pagesCloud Migration Strategy - Best Practices - Whitepaper - v2.0 PDFJeya kumar Devarajulu100% (1)

- Module 2Document43 pagesModule 2KhushiNo ratings yet

- Elazouni2011 2Document17 pagesElazouni2011 2Gurleen KaurNo ratings yet

- Start With The End in MindDocument6 pagesStart With The End in MinddexterNo ratings yet

- JASR 1 PublishedDocument11 pagesJASR 1 PublishedAbdul WazedNo ratings yet

- 2015 - A Formalism For Utilization of Autonomous Vision-Based Systems and Integrated Project Models For Construction Progress MonitoringDocument14 pages2015 - A Formalism For Utilization of Autonomous Vision-Based Systems and Integrated Project Models For Construction Progress MonitoringDavid Fernandes de OliveiraNo ratings yet

- Statistical Process Control Chart As A Project Management ToolDocument3 pagesStatistical Process Control Chart As A Project Management Toolkulpariya317No ratings yet

- Liu Et Al 2024 Framework of Digital Lean Construction and Implementation of Its Management Platform For TheDocument18 pagesLiu Et Al 2024 Framework of Digital Lean Construction and Implementation of Its Management Platform For Thek.persik89No ratings yet

- Project ApproachDocument2 pagesProject ApproachSurya TejaNo ratings yet

- Agile Consult of PMBookDocument8 pagesAgile Consult of PMBookDavid MartinezNo ratings yet

- Application of Virtual Design and Construction in Optimization of Construction ProjectsDocument1 pageApplication of Virtual Design and Construction in Optimization of Construction Projectsprateek buddyNo ratings yet

- Project Histories and Project Learning - A Knowledge Management ChallengeDocument10 pagesProject Histories and Project Learning - A Knowledge Management ChallengeSonmar SonmarNo ratings yet

- Chou 2010Document12 pagesChou 2010Diana ANo ratings yet

- The Key Performance Indicators of Construction: See Ahead Think Ahead Stay AheadDocument17 pagesThe Key Performance Indicators of Construction: See Ahead Think Ahead Stay AheadjasolanoroNo ratings yet

- Rajat Chawla: About MeDocument2 pagesRajat Chawla: About MeRajat ChawlaNo ratings yet

- Mobideo - BrochureDocument1 pageMobideo - BrochureomerNo ratings yet

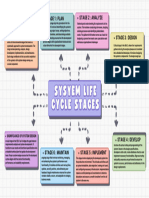

- Chapter 3 System Life Cycle StagesDocument1 pageChapter 3 System Life Cycle StagesPuteri Nur HannahNo ratings yet

- Commissioning and Startup - Increase Certainty Through Advanced PlanningDocument5 pagesCommissioning and Startup - Increase Certainty Through Advanced PlanningBramJanssen76100% (2)

- 2015 Yang - Construction Performance MonitoringDocument14 pages2015 Yang - Construction Performance MonitoringWilson EvaristoNo ratings yet

- RUP-Rational Unified ProcessDocument22 pagesRUP-Rational Unified ProcessFlash xlxNo ratings yet

- Analysis of A Knowledgemanagement-Based Process of Transferring Project Management SkillsDocument9 pagesAnalysis of A Knowledgemanagement-Based Process of Transferring Project Management Skillsvanny rumapeaNo ratings yet

- A Software Project Management FrameworkDocument9 pagesA Software Project Management FrameworkLogika123No ratings yet

- Opportunities in BFS: Location Cca / Operational Role Skill Set Grade HR SO#-line Item POCDocument10 pagesOpportunities in BFS: Location Cca / Operational Role Skill Set Grade HR SO#-line Item POCmanoj kumarNo ratings yet

- Cloud Computing Unit 5Document37 pagesCloud Computing Unit 5sachin jainNo ratings yet

- Togaf 1681172810Document7 pagesTogaf 1681172810SaudNo ratings yet

- Step 1: Planning: Phase 1: Analyzing Current Facility Management Systems, Processes, and PeopleDocument3 pagesStep 1: Planning: Phase 1: Analyzing Current Facility Management Systems, Processes, and PeopleAmirul Hakim SabriNo ratings yet

- 3b08efa7309d-Yogesh Kulkarni ResumeDocument3 pages3b08efa7309d-Yogesh Kulkarni ResumeAditya MujumdarNo ratings yet

- Leon 2018Document14 pagesLeon 2018Amanda PutraNo ratings yet

- Application of Knowledge Management To System Development: (Manuscript Received February 6, 2006)Document5 pagesApplication of Knowledge Management To System Development: (Manuscript Received February 6, 2006)umerNo ratings yet

- Online Project Monitoring System Based On Cloud Computing PlatformDocument10 pagesOnline Project Monitoring System Based On Cloud Computing PlatformAndrea DreaminNo ratings yet

- Project - One Project Management Platform: ProjectsDocument1 pageProject - One Project Management Platform: ProjectsArun GoyalNo ratings yet

- Project Management Methodology: Processes From The PMBOK Should Be Selected ForDocument10 pagesProject Management Methodology: Processes From The PMBOK Should Be Selected ForKaren Flores BartoloNo ratings yet

- Project Recovery It Can Be DoneDocument4 pagesProject Recovery It Can Be DoneSean Lee PaulNo ratings yet

- A3 DVCDocument11 pagesA3 DVCdaniel vazquezNo ratings yet

- NFR Trace1Document15 pagesNFR Trace1Nadia SuperssNo ratings yet

- ARC InsightsDocument6 pagesARC InsightsPinakeenNo ratings yet

- PowerPoint Timesaver v4Document93 pagesPowerPoint Timesaver v4littlebuddy039275No ratings yet

- JD - Lead CMMS Eng - ExpDocument2 pagesJD - Lead CMMS Eng - ExpNorai MagedNo ratings yet

- The Waterfall ModelDocument14 pagesThe Waterfall ModelMainan PribadiNo ratings yet

- Executive Summary Report For The OTRDocument28 pagesExecutive Summary Report For The OTRzuhditazmiNo ratings yet

- Chapter 13Document3 pagesChapter 13jane garciaNo ratings yet

- APP Primavera CloudDocument9 pagesAPP Primavera CloudN.a. M. TandayagNo ratings yet

- Computer Applications in Construction ManagementDocument53 pagesComputer Applications in Construction ManagementConie Catapan100% (1)

- APP Primavera CloudDocument9 pagesAPP Primavera CloudN.a. M. TandayagNo ratings yet

- Bridging The Gap Between Past and Future in RE: A Scenario-Based ApproachDocument8 pagesBridging The Gap Between Past and Future in RE: A Scenario-Based Approachvellingiri2008No ratings yet

- Feature-Driven Development Unleashed: Mastering the Art of Efficient and Collaborative Software EngineeringFrom EverandFeature-Driven Development Unleashed: Mastering the Art of Efficient and Collaborative Software EngineeringNo ratings yet

- LalalDocument4 pagesLalalHimanshu SharmaNo ratings yet

- John Collier, Malcolm Collier Visual Anthropology Photography As A Research Method 1986Document135 pagesJohn Collier, Malcolm Collier Visual Anthropology Photography As A Research Method 1986Paul Alexandru ChirilăNo ratings yet

- Strategic AllianceDocument5 pagesStrategic Alliancesuse2037No ratings yet

- Slotted SnowflakeDocument12 pagesSlotted SnowflakegabudeNo ratings yet

- Adobe Photoshop 7 - 2Document16 pagesAdobe Photoshop 7 - 2Afdoal Al BimaniNo ratings yet

- © Lothar Osterburg: Brief Outline of The Photogravure ProcessDocument9 pages© Lothar Osterburg: Brief Outline of The Photogravure ProcessfumandoangelesNo ratings yet

- SKIL FormDocument2 pagesSKIL Formfrenz_shiv31No ratings yet

- Ophthalmic Lens DesignDocument22 pagesOphthalmic Lens DesignBernardo LeñeroNo ratings yet

- Shopcart PlansDocument13 pagesShopcart Plansrevcarl777No ratings yet

- Ôn Tập Giữa Học Kì I- Review 1 - Test 1Document4 pagesÔn Tập Giữa Học Kì I- Review 1 - Test 1Tân PhanNo ratings yet

- BBC Sky at Night - September2016Document110 pagesBBC Sky at Night - September2016Peto BartosNo ratings yet

- Modeldocument PETDocument37 pagesModeldocument PETarun rajaramNo ratings yet

- Module For Finals Contemporary ArtsDocument27 pagesModule For Finals Contemporary ArtsYklim V Zepeda100% (2)

- What Is A Photo Essay 9 Photo Essay Examples You Can Recreate - Photo Contest InsiderDocument13 pagesWhat Is A Photo Essay 9 Photo Essay Examples You Can Recreate - Photo Contest Insiderapi-542976258No ratings yet

- RW 1 HihiDocument4 pagesRW 1 HihiMinh Thuy NguyenNo ratings yet

- The Outriggers of Indonesian CanoesDocument74 pagesThe Outriggers of Indonesian Canoesboon1961100% (2)

- Mapuche MnemonicsDocument13 pagesMapuche MnemonicsJoaquín Jiménez BarreraNo ratings yet

- Surveillance Security Camera Guide: by Guy Avital All Rights ReservedDocument16 pagesSurveillance Security Camera Guide: by Guy Avital All Rights ReservedArman Ul NasarNo ratings yet

- Museology Course Work NotesDocument25 pagesMuseology Course Work NotesCostin CroitoruNo ratings yet

- Camara Digital Sony MVC Fd73Document47 pagesCamara Digital Sony MVC Fd73luissanchezmNo ratings yet

- Unit 2: - Introduction To Machine VisionDocument4 pagesUnit 2: - Introduction To Machine VisionProphet TempestNo ratings yet

- Royal Victoria Ironstone Rose Bouquet PlateDocument6 pagesRoyal Victoria Ironstone Rose Bouquet Plateapi-5361499100% (2)

- Young Intach Jan Mar - 2014Document12 pagesYoung Intach Jan Mar - 2014d_sandhuNo ratings yet

- Welding DefectDocument17 pagesWelding DefectAna Hidayah Syuhada100% (1)

- Oct 8, Pennywise - Castlegar, Slocan ValleyDocument40 pagesOct 8, Pennywise - Castlegar, Slocan ValleyPennywise PublishingNo ratings yet

- 6 Must Have Images For Your Brand by Sandra ChauDocument11 pages6 Must Have Images For Your Brand by Sandra Chaumonkeygirl564No ratings yet

- OLTC FailureDocument18 pagesOLTC FailurevtpsNo ratings yet

- Humanity and Paper BalloonsDocument15 pagesHumanity and Paper BalloonsAlok Verma100% (1)

Adjunto 2 - 2009 - Golparvar-Fard Et Al.

Adjunto 2 - 2009 - Golparvar-Fard Et Al.

Uploaded by

Bryan Smith Cardenas RojasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adjunto 2 - 2009 - Golparvar-Fard Et Al.

Adjunto 2 - 2009 - Golparvar-Fard Et Al.

Uploaded by

Bryan Smith Cardenas RojasCopyright:

Available Formats

Visualization of Construction Progress Monitoring with 4D

Simulation Model Overlaid on Time-Lapsed Photographs

Mani Golparvar-Fard1; Feniosky Peña-Mora2; Carlos A. Arboleda3; and SangHyun Lee4

Abstract: The ability to effectively communicate progress information and represent as-built and as-planned progress discrepancies are

identified as key components for successful project management that allow corrective decisions to be made in a timely manner. However,

Downloaded from ascelibrary.org by Universidad de los Andes on 05/02/16. Copyright ASCE. For personal use only; all rights reserved.

current formats of reporting 共e.g., textual progress reports, progress curves, and photographs兲 may not properly and quickly communicate

project progress. Current monitoring methods also require manual data collection and extensive data extraction from different construction

documents, which distract managers from the important task of decision making. Therefore, to facilitate progress monitoring, this paper

proposes visualization of performance metrics that aims to represent progress deviations through superimposition of four-dimensional

共4D兲 as-planned model over time-lapsed photographs in single and comprehensive visual imagery. As a part of the developed system,

registration of the 4D model with photographs, augmenting photographs, and occlusion removal for progress images are presented. While

contextual information is preserved, the as-built photographs are enhanced and augmented with 4D as-planned model in which the

performance metrics are visualized. The augmented photographs provide a consistent platform for representing as-planned, as-built, and

progress discrepancies information and facilitate communication and reporting processes.

DOI: 10.1061/共ASCE兲0887-3801共2009兲23:6共391兲

CE Database subject headings: Monitoring; Imaging techniques; Computer aided simulation; Information technology 共IT兲; Con-

struction management; Registration.

Introduction schedule delay and cost overrun which challenge construction

operations productivity Peña-Mora et al. 2008兲.

Accomplishing desired performance during construction is a chal- For the purpose of effectively managing project development,

lenging task. Most construction projects or their individual work a systematic and comprehensive approach for progress monitor-

phases are relatively short duration and are performed at variable ing needs to be developed so that discrepancies between as-

planned and as-built progress are identified and reported to the

locations by a temporary alliance among multiple organizations

project managers as early as possible 共Lee and Peña-Mora 2006兲.

共Slaughter 1998兲. Operations are generally conducted outdoors

In this paper, monitoring is defined as collecting, recording, and

and are subject to interruptions and variations in site conditions

reporting information concerning any or all aspects of project

and other difficulties such as unforeseen weather conditions performance which highlights presence of progress discrepancies

共Oglesby et al. 1989兲. These circumstances cause errors and and facilitates project managers and decision makers to take cor-

changes within a project and their corresponding results are rective actions in a timely manner 共Meredith and Mantel 2003兲.

Today, decision making for corrective actions and schedule

1

William E. O’Neil Pre-Doctoral Candidate in Construction Manage- revisions usually takes place in coordination meetings where a

ment and Master of Computer Science Student, Univ. of Illinois, Urbana- wide range of individuals 共e.g., from the owners to subcontractor

Champaign, 205 N. Mathews Ave., Urbana, IL 61801 共corresponding organizations兲 with diverse expertise and interest attend the meet-

author兲. E-mail: mgolpar2@illinois.edu ing. In these face-to-face communications, progress information

2

Dean of The Fu Foundation School of Engineering and Applied Sci-

needs to be easily and quickly communicated among the partici-

ence and Morris A. and Alma Schapiro Professor of Civil Engineering

pants. Currently, none of the existing reporting methods 共e.g.,

and Engineering Mechanics, Earth and Environmental Engineering,

Columbia Univ., 510 S.W. Mudd Bldg., 500 W. 120th St., New York, NY progress S curves, schedule bar charts, and photographs and tex-

10027. E-mail: feniosky@columbia.edu tual reports兲 effectively present and visualize multivariable infor-

3

Visiting Assistant Professor, Dept. of Civil and Environmental Engi- mation 共i.e., schedule, cost, and performance兲 in a holistic manner

neering, Construction Management and Information Technology, Univ. of nor do they intuitively and simultaneously reflect information per-

Illinois, Urbana-Champaign, 205 N. Mathews Ave., Urbana, IL 61801. taining to the as-planned and as-built spatial and visual aspects of

E-mail: carboled@illinois.edu construction as well as their associated complexities 关as stated by

4

Assistant Professor, Dept. of Civil and Environmental Engineering, Lee and Peña-Mora 共2006兲, Poku and Arditi 共2006兲, Korde et al.

Hole School of Construction Engineering, Univ. of Alberta, 3-009 共2005兲, Song et al. 共2005兲, Kamat and Martinez 共2002兲, and Koo

Markin/CNRL Natural Resources Engineering Facility, Edmonton, AB and Fischer 共2000兲兴. These representations result in significant

T6G 2W2, Canada. E-mail: sanghyun@ualberta.ca

amount of information to be inefficiently presented in meetings

Note. This manuscript was submitted on July 25, 2007; approved on

July 23, 2008; published online on October 15, 2009. Discussion period and as a result, time is spent on describing existing problems and

open until April 1, 2010; separate discussions must be submitted for explaining the rationale of decisions rather than evaluating alter-

individual papers. This paper is part of the Journal of Computing in natives and discussing what-if scenarios and corrective actions

Civil Engineering, Vol. 23, No. 6, November 1, 2009. ©ASCE, ISSN 共Golparvar-Fard et al. 2006兲. With textual representations, it is

0887-3801/2009/6-391–404/$25.00. difficult to understand the situation clearly and quickly. It is even

JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2009 / 391

J. Comput. Civ. Eng., 2009, 23(6): 391-404

more troubling when the need for frequent remote and quick de- Challenges with Construction Progress Monitoring

cision making in construction is considered 共Lee and Peña-Mora

2006兲. Besides, most organizations do not have standardized re- Project managers require a robust monitoring system that ensures

porting procedures or employ different control systems which cre- most up-to-date design, schedule, cost, and progress performance

ate miscommunication in progress reporting. In this case, the data are delivered and represented in a timely and a comprehen-

ability to effectively communicate progress information and rep- sive manner so that control decisions could be made as quickly

resent the discrepancies is a definite prerequisite for a successful and easily as possible. Proper implementation of such a system

project management. reduces the time for routine decision makings and in turn overall

Visualization of progress through visual imagery has been rec- project cost and duration. According to Barrie and Paulson 共1992兲

ognized by a number of researchers as an effective way to com- such a system should have these characteristics

municate progress monitoring metrics 共Lee and Peña-Mora 2006; 1. To provide an efficient and effective means of measuring,

Poku and Arditi 2006; Kerzner 2005; Song et al. 2005; Abeid et collecting, verifying, and quantifying as-built data reflecting

the progress and operations with respect to schedule, cost,

Downloaded from ascelibrary.org by Universidad de los Andes on 05/02/16. Copyright ASCE. For personal use only; all rights reserved.

al. 2003兲. For the purpose of progress monitoring, this requires

both as-planned and as-built information to be integrated and vi- resources, procurement and quality.

sualized to provide a holistic view of all processes during con- 2. To accurately convert as-built progress data from construc-

struction progress. Therefore in this paper, a visualization tion operation into information. The system should be realis-

tic and should recognize means of processing the

technique for progress monitoring is presented that visualizes

information, the skills available, and the value of information

progress deviations through superimposition of four-dimensional

compared with the cost of obtaining it.

共4D兲 as-planned model on real time-lapsed photographs in single

3. To identify and assess the critical information from a given

and comprehensive visual imagery.

progress situation.

Visualization of the as-planned progress in 4D environment

4. To report the information to managers in time and in a form

enables project participants and clients—regardless of their level which can best be interpreted by management, and at an

of construction knowledge and expertise—to understand spatial appropriate level of detail for the individuals who will be

constraints and explore design and construction alternatives be- using it so that corrective action could be taken on the

fore construction starts. It provides a consistent visual platform progress situation that generated the data in the first place.

and a common language of as-planned construction that could be 5. To record the control action taken; to represent the as-built

extended to the monitoring phase 共Song et al. 2005兲. performance of the project.

In addition, visualization of as-built progress in photographs Without data collection, thorough comparison of the planned

not only has the advantage of being understandable to those who and as-built performance and a proper communication and re-

are not well versed in studying written material or numerical data cording, there may be no basis for proper project control and

analysis or even those who question verbal or written reports decision making. This requires progress data to be analyzed and

共Oglesby et al. 1989兲, but also allows large amount of data to be maintained in a desired level of detail 共i.e., according to decision

understood and absorbed quickly. Compared with progress report- maker’s needs兲 so that understanding the progress would be easier

ing techniques which generate words and numbers, techniques 共Jung and Kang 2007兲; however the process of monitoring is

such as time-lapse photography and videotaping provide a rich faced with a series of challenges such as

data set that can be a good source for as-built data collection and 1. Current progress monitoring is time consuming and labor

act as good communication tools for progress monitoring among intensive. Projects are not constantly monitored making it

the project participants. very difficult to take corrective actions in a timely basis.

Considering these advantages, the presented visualization Current methods require manual data collection and also ex-

model integrates the 4D model and time-lapsed photographs tensive data extraction from construction drawings, sched-

within an augmented reality 共AR兲 environment where progress ules, and budget information produced by project teams in

discrepancies are identified and visualized. To present this model, which none is independent 共Navon 2007兲. Field staffs collect

this paper begins with introducing the challenges of progress progress data from the construction site, analyze, and deliver

monitoring followed by the proposed methodology that visualizes them to project managers in a format specific to their areas of

discrepancies between the as-planned and as-built progress. In the expertise, e.g., construction drawings, spreadsheets, bar

charts, critical path method 共CPM兲, or progress site photo-

subsequent sections, three important steps for the augmented pho-

graphs or videos. Such discrete and exhaustive reports could

tograph are explained in details: 共1兲 4D simulation as the under-

be produced but do not explicitly convey level of perfor-

lying context for representing visualized metrics; 共2兲 Time-lapse

mance, problems, and their causes and impacts on construc-

photography and real-time filming for as-built progress data col-

tion situation 共Song et al. 2005兲. Consequently, project

lection; and 共3兲 visualization techniques to represent performance managers need to devote significant amount of time and ef-

metrics on augmented photograph. As a part of the system, reg- fort to sort out, prioritize, and interpret these data.

istration of the 4D model with photographs, augmenting photo- 2. Quality of manually collected and extracted progress data are

graphs and occlusion removal for progress images of the building low. Manual collection of progress information—usually ac-

structure and façade are presented. While contextual information quired by field staff—is dependent on the status seen on site

in photographs is preserved, the real-world image is enhanced and and the information collected, which in turn makes it subjec-

augmented with 4D simulation model where performance metrics tive and may not reveal the impact of site circumstances on

are visualized. The augmented photographs provide a consistent construction 共personal communication with field staffs on

platform for representing as-planned, as-built, and progress dis- five different projects 共9/2006–6/2007兲; Navon and Sacks

crepancies information and facilitate communication and report- 2007兲. This may affect the quality of the collected data and

ing processes. makes it error prone since the ability of anticipating possible

392 / JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2009

J. Comput. Civ. Eng., 2009, 23(6): 391-404

outcomes based on the collected information, depends on the section, components of the visualization technique which results

ability and expertise of the project manager. in augmented photographs are discussed.

3. Existing methods of measuring progress are nonsystematic

and generic. Accurate measurement of the progress perfor-

mance usually poses the most difficult data gathering prob- Visualization of Progress Monitoring

lem as there may be a tendency to let project inputs serve as

surrogate measures for output 共Meredith and Mantel 2003兲. Visualization techniques have been widely adopted in construc-

For example, a concrete subcontractor reports to the project tion, from visualizing construction management data 共e.g., Korde

manager that they have completed 60% of their work or et al. 2005; Songer and Heys 2003兲 to the physical artifacts that

reached 60% of their performance goal. Does it mean 60% of are to be built to facilitate constructability reasoning or workabil-

the planned area/volume of concrete pouring is finished? Is it ity of the operation methods selected for its construction 共e.g.,

60% of the planned concrete that has been used? Or is it 60% Kamat and Martinez 2003兲. However the focus of the visualiza-

of the planned man hour that is spent? If the item being tion techniques in this paper is on their application of as-planned

Downloaded from ascelibrary.org by Universidad de los Andes on 05/02/16. Copyright ASCE. For personal use only; all rights reserved.

referenced is a small work unit, it may not have a significant 4D simulations to augment as-built progress photographs with the

difference; however, in case where the references are to the purpose of project monitoring and control. In this context, Song et

whole task or project, assumption of input/output proportion- al. 共2005兲 introduced project dashboard as a three-dimensional

ality could be very misleading 共Meredith and Mantel 2003兲. 共3D兲 model visual representation to show a holistic picture of a

Thus, the most commonly used methods to monitor progress project by applying the multiple project data sets to the geometric

are: 共a兲 Monitoring physical progress in percentile: used in attributes 共e.g., shape, faces, and edges兲 of the building product

most construction fields that heavily relies on experience and model through color-tone variations and motion. It was suggested

knowledge of the project management personnel. This metric that consistent application of colors would allow project perfor-

is used subjectively and is inefficient at presenting progress mance metrics to be represented easily. This would also purge

due to its abstract nature representation of physical progress visual complexities which could be caused by complexities asso-

共Song et al. 2005兲; 共b兲 Budget based monitoring: based on ciated with large and sophisticated building product models.

percentage of the budget paid to contractors according to the Nonetheless in their presented system, as-built progress was not

schedule-based inspections. This method of monitoring cre- visualized using photographs or any other means different from

ates time lag between progress estimations and schedule up- that of as-planned model. Rather, geometric attributes of the

dates; besides, judgments are usually subjective and building product model were used to communicate progress.

misleading especially if a field manager makes any erroneous Based on the same concept of consistent visual representation,

decision 共Shih and Wang 2004兲. Without a specific compara- Lee and Peña-Mora 共2006兲 superimposed planned product models

tive analysis on construction plan, resources, and cost data, with photographs and initiated a new paradigm on visualization of

wrong assumption and inaccurate measurement on the construction progress monitoring where deviations between

progress status could be made. Mistakes such as over paying planned and as-built performance models were conceptually rep-

and overlook of expected delay might appear. resented in an AR environment. AR is an environment wherein

4. Progress monitoring reports are visually complex. Kerzner virtual and real world are combined to enhance user’s experience

共2005兲 argued that 30 to 40 different data representations are of the virtual world through contextual information 共Wang and

currently being used in construction industry. These graphi- Dunston 2005; Azuma 1997兲. It gives the user the ability of ob-

cal representations can serve several functions such as show- serving the background environment and superimposes virtual

ing data, analysis methodology, and communication means model over the real-world background. Considering the benefits

共Oglesby et al. 1989兲. These methods require drawing, of visualization techniques and AR environment for visualization

sketches 共to show layout and physical details兲, and graphs and automation of progress monitoring specifically assisting

and charts 共which present numerical data and the results ob- project managers, a new approach is presented which integrates

tained by observation兲 to represent schedule, cost, and per- three different modules.

formance. The choice among them is dependent on the 1. 4D Simulation as the as-planned progress information,

intended audience. For example, upper level management 2. Time-lapse photography and videotaping as the as-built

may be interested in costs and integration of activities with progress data collection, and

very little detail; hence summary-type charts normally suffice 3. Visualizing progress through augmenting the as-built photo-

for this purpose. Daily practitioners, on the other hand, may graph with the as-planned data

require as much detail as possible in daily schedules. In ad-

dition, understanding the situation only based on the sched-

4D Simulation as the As-Planned Progress Data

ules may be difficult as they lack information relating to

spatial context and complexities of project components 共Koo 4D simulations have been developed for the main purposes of

and Fischer 2000兲. None of the existing reporting methods detecting spatial and temporal conflicts, understand construction

effectively present multivariable information 共i.e., schedule, logistics, coordinate the construction with subcontractors and

cost, and performance兲 in a holistic manner nor do they re- trades, and demonstrate the planned progress to the owners

flect the spatial and visual aspects of as-planned and as-built 共Tabesh and Staub-French 2006; Kamat and Martinez 2003; Kam

construction and their associated complexities simulta- and Fischer 2002兲. This kind of a time-based monitoring focuses

neously. Consequently it affects the ability of communicating on a preconstruction study that will allow for better management

effective progress information which is a definite prerequisite of a site afterward 共Haymaker and Fischer 2001兲. So far, 4D tools

for successful project management. have not been used for project progress management through as-

Based on the deficiencies mentioned and considering chal- built data collection during the construction phase 共Chin et al.

lenges with current reporting formats and communications, the 2005兲. Currently 4D applications are able to detect some sched-

visualization of progress monitoring is presented. In the following uling errors in the construction and enable project participants and

JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2009 / 393

J. Comput. Civ. Eng., 2009, 23(6): 391-404

Downloaded from ascelibrary.org by Universidad de los Andes on 05/02/16. Copyright ASCE. For personal use only; all rights reserved.

Fig. 1. Augmented progress images: 4D simulation superimposed on time-lapsed photographs of a building construction project clockwise from

10/03/2006 to 12/02/2006 共Photograph subject: College of Business Instructional Facility, UIUC. Source: Facilities and Services, UIUC.兲

clients, regardless of their level of construction knowledge, to rain and snow weather conditions respectively and shows how

understand the spatial constraints and explore design and con- weather conditions can affect the quality of time-lapsed photo-

struction alternatives before construction starts. However, a pre- graphs in a construction site.

construction simulation cannot necessarily take into account Shadow is another problem which is caused by adjacent build-

every incident that might occur to the parts of a building under ings or elements 共temporary or permanent兲 and affects visual

construction but could be used as a base for the as-planned infor- quality of photographs. Figs. 4共a–c兲 show three photographs that

mation. 3D and 4D models can provide realistic visual expres- are selected out of a working day photo log. These photographs

sion, a consistent visual platform, and a common language of show how shadow affects the visibility of the work site and how

as-planned information for all parties involved within a project these effects may reduce visibility of the elements on a photo-

共Song et al. 2005兲. Specifically, an industry foundation classes graph. However since a full set of photographs are collected dur-

共IFC兲-based 4D system that contains all the information of the ing working hours, different zones and locations on the jobsite

as-planned parts and their relationships, not only can serve as a could be studied at different times.

complete as-planned database but also serves as the underlying Since progress is usually measured within weeks or even days

structure for monitoring progress where deviation between the 共not hours兲, this allows the selection of more visible photographs

as-planned and as-built progress could be visualized. Fig. 1 dem- for the purpose of analysis and representation. Furthermore, ap-

onstrates snapshots of a 4D simulation superimposed on time- plication of robust image analysis and pattern recognition tech-

lapsed photographs.

Time-Lapse Photography and Videotaping

as the As-Built Progress Data Collection Techniques

Photography and filming have proved for many years to be very

useful means for recording site progress photo logs and work-face

activities 共Brilakis et al. 2005兲. With the advances of digital pho-

tography and webcams, these methods of information gathering

are more cost-effective, practical, and acquiring a substantial foot-

age is not costly. They have all the advantages found in time

studies without the disadvantage of high data gathering costs.

Owners and contractors usually acquire construction site time-

lapsed photographs from a fixed location or capture videos for a

series of functions 共1兲 to create a photo log for dispute resolutions

and litigation purposes and 共2兲 permanently record certain field

operations of an individual or a crew or a machine and the inter-

actions among them for progress monitoring records and reports.

Fig. 2 shows four construction progress photographs out of a

time-lapsed photograph collection for a construction site over a

two year period.

Table 1 demonstrates the advantages/drawbacks of time-lapse Fig. 2. Progress images from a construction site time-lapse photog-

photography and videotaping. Despite their various advantages, raphy camera clockwise from August 4, 2004 to August 4, 2006

photographs may not demonstrate construction site information in 共Photograph subject: Institute of Genomics Biology, UIUC. Source:

very severe weather, illumination and shadow conditions. For ex- Information, Technology and Communication Services, College of

ample, Figs. 3共a–c兲 demonstrate the construction site under fog, ACES, UIUC.兲

394 / JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2009

J. Comput. Civ. Eng., 2009, 23(6): 391-404

Table 1. Advantages and Drawbacks of Time-Lapsed Photography and Videotaping

Advantages Drawbacks

•Easy to obtain progress images •Distortion of images—make it challenging to superimpose images

•Inexpensive •Show what is not obstructed by objects such as construction

machinery or scaffoldings

•Time-lapsed photography continuously records and yields benefits •Show what is within range and view field

of filming without diminishing understanding of the operations

that is recorded

•Easily understandable by any visually able person •Various illumination, shadows, weather and site conditions makes

it difficult for image analysis

•Provide more detailed and dependant information •Storage of digital photographs/videos

•Making possible review and study by analysts, management, or

Downloaded from ascelibrary.org by Universidad de los Andes on 05/02/16. Copyright ASCE. For personal use only; all rights reserved.

other groups away from hustle and bustle of the work site

•Suitable for progress monitoring and productivity analysis

niques such as Gaussian filters 共Forsyth and Ponce 2003兲 allows geted in time-phased planning value increment, it can constitute a

the photographs to be enhanced which in turn reduces and/or performance measurement baseline 共Abba 1997兲 which is useful

neutralizes these effects. for comparison. EVA provides information in terms of as-built

Overall, compared with techniques that generate only words conditions, potential issues, prior concerns, and future scenarios

and numbers, photography has the advantage of being easily un- in one construct. Along with time photography as an automated

derstandable and believable to those who are not well versed in data collection method, 4D model and cost database, for every

studying material or numerical data analysis or who question ver- decision making, EVA performance metrics needs to be calculated

bal and written reports 共Oglesby et al. 1989兲. This technique is and visualized. The scheme of using this methodology is further

particularly useful when the activities depicted are not going as explained in the subsequent section.

smoothly as they might, since it is difficult for anyone to argue

successfully that the photographs do not portray the as-built work

situation.

Progress Monitoring Visualization System Scheme

Visualizing Construction Progress Visualization process consists of a series of modules which results

Considering the existing generic progress monitoring methods, in color coded time-lapsed AR imageries. Fig. 5 summarizes the

earned value analysis 共EVA兲 can provide a monitoring basis and information action-representation-environment perspectives for

allows the future performance to be forecasted. Although EVA has the proposed system. As represented in Fig. 5, raw data are col-

some limitations as referred in Kim and Ballard 共2000兲, but since lected from two different sources: the as-planned and the as-built

in EVA, all the construction work is planned, scheduled, and bud- performance environments. The collected information represents

Fig. 3. Different weather conditions during a construction project: 共a兲 fog; 共b兲 rainy; and 共c兲 snow 共Photograph subject: Institute of Genomics

Biology, UIUC. Source: Information, Technology and Communication Services, College of ACES, UIUC.兲

Fig. 4. Effect of shadow on a single working day 共Photograph subject: Institute of Genomics Biology, UIUC. Source: Information, Technology

and Communication Services, College of ACES, UIUC.兲

JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2009 / 395

J. Comput. Civ. Eng., 2009, 23(6): 391-404

Downloaded from ascelibrary.org by Universidad de los Andes on 05/02/16. Copyright ASCE. For personal use only; all rights reserved.

Fig. 5. Information action-representation-environment perspectives for visualization of construction progress monitoring

product models, i.e., IFC 3D as-planned model and site photo- namics of the construction operations and the site, such as tem-

graphs 共Fig. 5, 1-A and 1-C兲, process models, i.e., working sched- porary structures and site layout. In this case, a more detailed

ule and operation process 共Fig. 5, 3-A and 3-C兲 and cost modules, progress measurement is possible. However, visualizing detailed

i.e., estimated and performed costs 共Fig. 5, 4-A and 4-C兲. construction activities such as electrical rough-ins may not be

Collected information from these two environments is merged possible and therefore at this stage, the proposed model only in-

to produce a 4D as-planned simulation and time-lapsed photo- corporates construction schedules with a visible physical progress

graphs 共Fig. 5, 2-A and 2-C, respectively兲. For any given time, level in terms of the building structure and façade. Based on the

the as-planned model is superimposed on the as-built perfor- guideline set during the planning phase and generation of the

mance model 共i.e., site photograph兲 共Fig. 5, 2-B兲. This process as-planned model, interpretation and assessment of the data

involves proper registration of the 3D virtual world and photo- would be performed in the subsequent steps.

graph coordinates. The superimposed imagery would allow dis- At the following step, a series of visualization techniques is

crepancy to be either manually or automatically detected and applied to visualize EVA metrics 共Fig. 5, 5-B兲; i.e., according to

quantified 共Fig. 5, 3-B and 4-B兲. At this stage, cost values are the status of the progress, the as-planned model would be color

extracted from estimated and actual construction cost modules coded and superimposed on top of the photograph. Once the sta-

and are integrated to the system 共Fig. 5, 4-A and 4-C兲. This would tus of the progress is represented on the superimposed image, any

allow cost information required for EVA to be derived. This in- occlusion and blockage caused by the superimposition should be

formation is appended to the known as-planned and as-built in- removed. Therefore depth and perspective integrity of the virtual

formation and allows the budget spent to be properly assessed and and actual environments is maintained 共Fig. 5, 6-C兲. The final

the cost discrepancies to be understood. imageries are represented for decision making and are kept as a

The next step is to monitor progress against the performance record for progress monitoring photo log. Fig. 6 shows a color-

measurement baseline, or the planned value. The physical earned coded superimposed image where the progress status is visual-

value performed is then related to the actual costs spent to accom- ized. In this figure, on-schedule entities are represented in light-

plish the physical work performed, providing a measure of the green entities, ahead of schedule entities in dark green, and

project’s cost performance. To establish the guideline for the pro- behind-schedule entities in red color.

posed system, the IFC as-planned model and the work break This reporting process is repeated for every coordination cycle

down structure in the schedule are considered as the basis of where control actions are taken and the construction schedule is

monitoring 共Fig 5, 2-A兲. The level of details is based on the revised and updated by project participants. For example, if

product and process work breakdown structures and cost estimat- architectural/engineering/construction teams have coordination

ing scheme in the as-planned model. For example if a general meeting every other week, this report would provide progress

contractor schedule is provided, only major activities associated information from the last meeting to the current meeting consid-

with building elements are visualized in the 4D model and moni- ering the same time period for future activities that may have

toring system only involves that level of details in the schedule as been performed in the project. In this section, an overview of the

the baseline for measurements. If a detailed daily schedule is data collection, comparison baseline, and assessment processes

available, the 4D as-planned model may further visualize the dy- have been discussed. In the sections that follow, each of the steps

396 / JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2009

J. Comput. Civ. Eng., 2009, 23(6): 391-404

Fig. 6. Color-coded superimposed image visualizing the progress status: entities that are in light green are on schedule, entities on dark green

Downloaded from ascelibrary.org by Universidad de los Andes on 05/02/16. Copyright ASCE. For personal use only; all rights reserved.

ahead of schedule, and red entities are behind schedule 共Photograph subject: College of Business Instructional Facility, UIUC. Source: Facilities

and Services, UIUC.兲

共i.e., registration, assessment, representation, and recording兲 is Then after knowing the camera is fixed, correspondence be-

discussed in detail. tween the 3D model and photograph needs to be set. The photo-

graph and camera coordinate systems are related by a set of

physical parameters, such as the focal length of the camera lens,

Geometric Camera Calibration

the size of the pixels, the position of the principle point 共of the

The first task in generating superimposed images is to relate the lens兲, and the position and orientation of the real world 共Forsyth

3D virtual model to the two-dimensional photograph. This means and Ponce 2003兲. In order to register the camera, these intrinsic

any point in the 3D model such as P共x , y兲 needs to be precisely and extrinsic parameters of the camera should be defined. Intrin-

related to image coordinates p共u , v兲. In the case of time-lapsed sic parameters relate the camera coordinate system to the ideal-

photographs, the camera location is fixed on the construction site, ized coordinate system 共i.e., effective focal length, aspect ratio,

therefore, ideally, if camera is registered once, the correspon- image center coordinates, and radial distortion coefficient兲 and

dences between the photographs and the virtual model would be extrinsic parameters relate camera’s coordinate system to a fixed

set for all subsequent images; i.e., with the same correspondence camera coordinate system and specify its position and orientation

relationship, all the images of the 4D environment could be su- in space 共i.e., rotation matrix and translation vector兲 共Forsyth and

perimposed on the photographs. However, photographic cameras, Ponce 2003兲. Estimating these parameters of a camera is called

webcams, and/or video recorders similar to any surveying camera geometric camera calibration 共Forsyth and Ponce 2003兲. If we

are subject to displacement and vibration caused by gravity and consider p = 共u , v , 1兲 and P = 共x , y , z , 1兲 to be the homogenous co-

lateral forces such as wind. Fig. 7 shows the camera registration ordinates of the points in the photograph and the virtual world,

error. A deviation in camera angle can make a major error in the relationship between these points in general terms can be

registration. As seen, perspective views A and B are seen from the represented as

same location with different view angles.

Due to these potential registration errors, the camera needs to 1

be regularly adjusted. In this scenario, it is assumed that the lo- p = MP 共1兲

z

cation of the camera will be regularly fixed at all times and the

same correspondence relationship between the 3D virtual world where M 3⫻4 = projection matrix and z = depth of the point.

and the photograph coordinates could be applied to all time- To solve Eq. 共1兲 for M, a set of features 共i.e., points兲 with

lapsed photographs. known positions in the photograph and the 3D environment are

required. In order to achieve good and predictable results for M,

there is a certain amount of preparation that needs to be done

manually. This preparation consists of two main areas: 共1兲 Iden-

tifying “matchable” features in the photograph and 共2兲 associating

3D features 共from the virtual model兲 to the features chosen in the

photograph.

It is extremely important for setting correspondences and solv-

ing the equation to choose accurate features 共points兲 within pho-

tograph and 3D model. However, since photographs are formed in

pixels, finding the accurate positions for features could be a very

challenging task. For example, let’s assume that the selected fea-

ture to be the top corner of two converging concrete walls. In a

low quality photograph, this point could be located in-between

pixels and it affects the quality of the preferred location for reg-

Fig. 7. Camera registration error: a deviation in the camera angle istration purposes which affect preciseness and quality of regis-

within the distance of the camera to the site could generate a major tration. An alternative to increase the accuracy for solving this

error in registration. Perspective views A and B show the result equation is to extract more features from the photograph. There-

of deviation in the photograph taken by the camera from the same fore, by selecting more features to establish the correspondence,

location. the error in a single feature selection would not significantly af-

JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2009 / 397

J. Comput. Civ. Eng., 2009, 23(6): 391-404

Fig. 8. Feature selection and setting correspondences between a part

of a photograph and 3D coordinate system. Plus symbols 共+兲 in 共a兲

show the pixels correspondences of cross symbols 共⫻兲 within the 3D

coordinate system in 共b兲.

Downloaded from ascelibrary.org by Universidad de los Andes on 05/02/16. Copyright ASCE. For personal use only; all rights reserved.

fect the overall registration outcome and therefore the cumulative

error in feature selection would be minimized. Fig. 8 shows an

example of feature selection and setting correspondence relation-

ships for three points. As shown in Fig. 8, the points extracted

from photograph pixels with plus symbols 共+兲 are related to 3D

world coordinates indicated with cross symbols 共⫻兲.

In this situation where more than minimum required features

are selected, instead of directing solving the equation, camera

calibration 关Eq. 共1兲兴 would turn to an optimization process for the

error function where the discrepancy between image features and

their positions in the virtual world with respect to the camera’s

intrinsic and extrinsic parameters is minimized. It is also impera-

tive to have features spread out evenly throughout the

photograph—which represent the space from foreground to back-

ground as well as the side-to-side and up and down distance—to

allow a more accurate calibration. To automatically perform the

registration, Autodesk Viz 共2007兲 camera matching toolbox has

been used. This toolbox requires at least five points to calculate a

solution based on aforementioned error function; however, it is

better to choose more features to refine the matching through the

iteration. Fig. 9 shows how feature selection and the correspon-

dence setting is performed for a photograph. In this case, survey-

ing information of the site 共location of the benchmarks兲 is not

known and the matching needs to be performed given the photo- Fig. 9. From top to bottom: 共a兲 Site photograph superimposed with

graph information and the 4D model. Therefore, first, an IFC- 3D model in Autodesk Viz environment; 共b兲 site photograph; 共c兲

based model of the building at an early stage of the 4D close view on feature selection and matching between the photograph

environment is imported to Autodesk Viz. 共2007兲 A photograph of and the 3D model; and 共d兲 superimposed 3D model on the site pho-

the same time frame of construction in which various features of tograph 共Photograph subject: College of Business Instructional Facil-

the construction entities could be detected is placed as the back- ity; Facilities and Services, UIUC; Application: Autodesk Viz兲

ground in the matching window. Now a set of features are se-

lected from the photograph and will be matched to their

correspondence in the 3D model. Particularly, corners of converg- registration error of 1.45 pixels is achieved which has resulted in

ing entities 共e.g., top and bottom corners of converging founda- a visually precise registration. The superimposed 3D on the pho-

tion walls兲 would be a good choice. Despite diminishing effects tograph is shown in Fig. 9共d兲.

of shadow with reducing visibility of the images, shadow could

be very helpful in camera calibration, since it would allow corners

Progress Assessment on the Superimposed Imageries

of any selected entity to be easily chosen. To increase the accu-

racy of registration and minimize the effect of pixelized photo- Once the camera is registered, the as-planned model can be su-

graphs, fifteen features are selected from various surfaces and perimposed on the photograph. At this step, discrepancies be-

different elevations within the photograph 共i.e., top and bottom tween the as-planned model and the photograph 共as-built兲 can be

corners of converging foundation walls and converging walls/ easily identified. Given the deviations observed, EVA metrics are

columns兲. The number of features required to achieve a precise obtained 共compared to schedule or cost information, Fig. 5兲 and a

registration 共in this case 15 features兲 is selected through an itera- color 共depending on the progress status兲 is assigned to the

tive process in which a desired visual registration is achieved, i.e., planned model. Fig. 10 shows the assessment of the schedule

a minimal error in the matched figure visually resides. Fig. 9共c兲 deviation on a building project. Before a coordination meeting, a

shows some of these selected features where the plus sign shows series of actions are performed to prepare the visualized progress

the location in the photograph and the cross sign, the location of monitoring status. A photograph of the basement level of a build-

those features within the 3D model. In this case, a cumulative ing taken on December 2, 2006; 1:13 p.m. and a registered snap-

398 / JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2009

J. Comput. Civ. Eng., 2009, 23(6): 391-404

Downloaded from ascelibrary.org by Universidad de los Andes on 05/02/16. Copyright ASCE. For personal use only; all rights reserved.

Fig. 10. From top to bottom: 共a兲 the site photograph taken on December 2, 2006, 1:13:27 p.m.; 共b兲 snapshot of the 4D model at the same time

as the photograph; 共c兲 superimposed image; 共d兲 schedule deviation detected and color coded according to the schedule in 共e兲; and 共f兲 color-coded

superimposed 3D model on the site photograph 共Photograph subject: College of Business Instructional Facility, UIUC. Source: Facilities and

Services, UIUC.兲

shot of the 4D as-planned model taken on the same time are different colors 共light green for on schedule and red for behind

represented in Figs. 10共a and b兲, respectively. Based on the visual schedule兲 are assigned to each of the components depending on

comparison between the photograph and the as-planned model, its progress status.

discrepancies are identified. These discrepancies have been manu- It is clear that as more components are constructed or install

ally analyzed and the physical components of the basement level on the site, the number of 3D model components in the 4D envi-

that are behind or on-schedule are identified. The schedule devia- ronment increases and as a result visual representation could po-

tion is quantified by the management team based on the construc- tentially become more complex. Given the identified deviations, a

tion schedule and based on the EVA analysis performed. Then, consistent visual scheme is required to simplify and facilitate its

JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2009 / 399

J. Comput. Civ. Eng., 2009, 23(6): 391-404

Downloaded from ascelibrary.org by Universidad de los Andes on 05/02/16. Copyright ASCE. For personal use only; all rights reserved.

Fig. 11. Critical information sets for project managers during construction phase and the color spectrum

interpretation. Therefore, in order to effectively and consistently Static Feature Extraction

use these visualization techniques, a single color spectrum rang- Some visual features, such as excavation profile, fixed compo-

ing from dark red to dark green for all possible EVA monitoring nents on the site such as light towers and/or trees are static on the

and project performance metrics based on an underlying meta-

phor of a traffic light is proposed 共Fig. 11兲. This metaphor can

manually or automatically visualize various project metrics with

discrete values. For example it categorizes building elements

based on their schedule deviations in three distinct categories:

ahead of schedule, on schedule, and behind schedule 共Fig. 11兲.

According to Fig. 11, light green is used to represent those com-

ponents that their performance is “as-expected,” dark green for

those components that are performing “above expectation,” and

they need the least management effort, while red color represents

components that need corrective action. Once the status of

progress for each building component is identified, these colors

are assigned to the 3D components and the color coded 3D as-

planned model is superimposed on the photograph. Fig. 12 shows

the site and superimposed photographs representing as-built and

progress status respectively. As seen in Fig. 12共b兲, behind-

schedule 3D entities that are color coded in red, on-schedule 3D

entities in light green and ahead of schedule in dark green. In Fig.

12共d兲, behind schedule steel members along with parts of the

foundation components are color coded in red which represent

that these components may need corrective actions in order for

the project to be on schedule. The application of color gradients

and color quadrangles to visualize multiple progress parameters

together or ranges values for a progress situation has also been

considered 关please refer to Golparvar-Fard et al. 共2007兲兴. Authors

have implemented a “MouseOver” action on these augmented

photos to make these imageries are interactive and provide

progress status information associated with the colors. This po-

tentially allows the user to also extract progress monitoring data

from the visualization system.

Feature Extraction „Occlusion Removal Techniques…

Once the augmented photographs are generated, in order to keep

the realism of the scene and perspective integrity of the virtual Fig. 12. From top to bottom: 共a兲 the site photograph taken on Janu-

and actual environments, the occluding objects needs to be placed ary 3, 2007; 12:35:13 a.m.; 共b兲 the color-coded superimposed photo-

on the original depth in which they appear from the perspective of graph at the same time as the photograph 共a兲; 共c兲 the site photograph

the viewer 共Fig. 5, 6-C兲. This requires two types of features to be taken on January 8, 2007; 4:08:21 p.m.; and 共d兲 the color-coded su-

extracted: 共1兲 Static features and 共2兲 dynamic features. These fea- perimposed photograph at the same time as the photograph 共c兲

tures are explained as follows. 共Source of the photographs: Univ. of Illinois, Facilities and Services兲

400 / JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2009

J. Comput. Civ. Eng., 2009, 23(6): 391-404

Fig. 13. 共a兲 Cropped portion of the photograph taken on January 3, 2007, 11:22:55 a.m.; 共b兲 the image after applying SUSAN edge detection

algorithm 共threshold= 20兲; as seen the excavation line, lamp posts, truck on the left site of the photograph, and the cars parked are recovered

Downloaded from ascelibrary.org by Universidad de los Andes on 05/02/16. Copyright ASCE. For personal use only; all rights reserved.

time-lapsed photographs, i.e., the shape or location of these fea- Dynamic Feature Extraction

tures, do not change rapidly. Once the superimposition of the Along with aforementioned static features, dynamic features also

colored as-planned model on the site photograph is performed, exist within photographs such as construction machinery, tempo-

some of these features are overlaid with the color coded 3D rary structures, and work crew. These features also need to be

model, while in camera’s line of sight, these features are located extracted to be overlaid back on the photograph to preserve depth

in front of the as-planned 3D model and should not be occluded and perspective within the superimposed photograph. The same

by the model. Hence these features need to be extracted from the feature detection technique i.e., SUSAN are applied to dynamic

original site photograph and overlaid on the superimposed image. feature extraction. As seen in Fig. 13 the truck in front of the

Since these static features do not frequently change throughout foundation wall is also recovered. This method required manual

the period of construction, once they are recovered, the same supervision and could be time consuming while other techniques

process could be applied to the rest of the time-lapsed photo- such as identification of moving objects between consecutive im-

graphs. In computer vision, there are many different edge detec- ages or using different points of view that do not have the ma-

tion techniques that could help in finding these features within chinery crossing their field of view could also be considered for

photograph. These methods include but are not limited to Canny, future implementations to reduce such overheads. 共The writers

Sobel, Robert, Laplacian of Gaussian, and SUSAN 共smallest uni- would like to acknowledge that this idea was suggested by one of

value segment assimilating nucleus兲 edge detection techniques the anonymous reviewers of the paper.兲

共Shin et al. 2001; Smith and Brady 1997兲. All these methods

could be used to detect corners of the features and localize them.

Visualized Progress Report

Among these methods, SUSAN edge detector had been applied in

this research due to its good detection, localization, response, and Fig. 14 illustrates a visualized report of progress monitoring. In

speed to be usable for image processing systems compared to the this figure, the photographs and 4D snapshots are presented and

rest of the mentioned edge detection techniques 共Shin et al. 2001; based on the work schedule and the comparison performed, de-

Smith and Brady 1997兲. In this method, nonlinear filtering is used viations are identified and are color coded. The deviations are also

to define image parts that are closely related to each individual quantified based on the number of days according to the schedule

pixel. These pixels are associated with their local regions within and are reported. Finally, based on the actual cost occurred and

the photograph that have similar brightness to that pixel. Feature the planned costs, cost performance index 共CPI兲 and schedule

detectors are based on minimization of local regions and noise performance index 共SPI兲 are calculated and presented 关Fig. 14共f兲兴.

reduction. The detail of this method is not scope of this paper and These forms of reporting can facilitate the coordination process

could be found in Smith and Brady 共1997兲; rather the applicabil- by reducing the time to inform the participants as to what the

ity of the method to extract static features is described in the AR situation is. Once the superimposed photographs are ready, the

model. Fig. 13 shows the result of applying the SUSAN edge report table could be generated. This sort of representation does

detection in recovering the excavation line, light poles, and some not require the observer to have any expertise or knowledge about

machinery located on the construction site. The recovery of the construction operations.

information below excavation line in the photograph has been Based on the positive feedback received from the profession-

done in a supervised manner, i.e., the required recovery section is als and executives of the five construction case studies in this

manually selected and it is automatically applied to subsequent research as well as other executives from leading construction

time-lapsed photographs. companies, writers believe the visualization will facilitate

Another possible way to overcome static occlusion problem is progress monitoring process.

to model the static occluding objects in 3D model and have them

hide the geometry of the augmented images just as any real object

hides the background in photographs. 共The writers would like to Conclusions

acknowledge that this idea was suggested by one of the anony-

mous reviewers of the paper.兲 However this method may increase This preliminary method has shown that AR environment can

the level of details required for 3D modeling and would not be successfully represent progress monitoring information in forms

suitable for cases where the occluding objects, themselves needs of as-planned, as-built information along with their comparison in

to be detected and/or tracked. a holistic manner. The superimposed images retain all the con-

JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2009 / 401

J. Comput. Civ. Eng., 2009, 23(6): 391-404

Downloaded from ascelibrary.org by Universidad de los Andes on 05/02/16. Copyright ASCE. For personal use only; all rights reserved.

Fig. 14. Visualized monitoring report: 共a兲 as-built photographs; 共b兲 4D snapshots; 共c兲 color coded virtual components; 共d兲 quantification of the

deviation; 共e兲 augmented photographs; and 共f兲 measured EVA performance metrics 共CPI and SPI兲

struction site information while the planned information along AR environment that automatically and distinctively recognize

with the status of progress is enriching the contextual information visual construction content within site photographs, compare with

within these photographs. The registration method gives the op- the as-planned 4D model and visualize the status of progress

portunity for image processing to be applied to specific regions using visualization and project management techniques. Consid-

within the photograph to assess the status of the progress based on ering application of time-lapsed photographs for visualization of

material and shape recognition techniques. Color-coding meta- as-built data collection, two major challenges are identified.

phors give the end users of the superimposed photograph the

opportunity of grasping progress status based only on a single

representation form and could facilitate the communication of Challenges with Time-Lapsed Photographs for

progress status within a coordination meeting, allowing more Visualization and Assessment of the As-Built Data

time to be spent on control decision making. Moreover prelimi-

nary results of applying feature detection technique preserves Occlusion/Proximity Problems for Data Collection

depth and perspective within the superimposed photograph allow- Type of structures 共e.g., steel, concrete, and composite兲, camera

ing a more realistic picture of the progress status to be repre- location for taking time-lapsed photographs 共e.g., ground level

sented. The overall methodology and reporting addresses the versus upper levels, proximity of components to the camera兲,

issues related to data collection and reporting steps of a robust horizontal and vertical obstacles 共e.g., static objects on site or

progress monitoring. blockage of the view of one element by the others兲, and outdoor

versus indoor monitoring are all among the challenges of visual-

izing as-built data. Fig. 15 shows two different scenarios on hori-

Future Work zontal and vertical occlusions and the challenges of visualizing

progress only on a single view. As seen in Figs. 15共a and b兲, a

This work is part of a larger project that aims to automatically column is occluded since there is another column which is block-

generate superimposed photographs for progress monitoring. ing camera’s line of sight toward to the specific column under

Overall, the aim is to develop methods and processes within an study. This situation has been solved by moving the camera to a

402 / JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2009

J. Comput. Civ. Eng., 2009, 23(6): 391-404

Downloaded from ascelibrary.org by Universidad de los Andes on 05/02/16. Copyright ASCE. For personal use only; all rights reserved.

Fig. 15. 共a兲 Plan view of two column grids while one of the columns has occluded camera’s point of view on the other column; 共b兲 photograph

of the occluded column; 共c兲 position of the camera was changed and the column is not occluded; 共d兲 photograph of nonoccluded view; and 共e兲

camera pose problem in vertical situations, from ground level the highlighted beam is not visible

new location. The vertical occlusion case is also shown in Fig. with such level of detail depends on the robustness of image

15共e兲 where the slab has blocked the view toward the beam. There processing techniques in overcoming data collection problems

is a need for finding the optimum locations of a network of cam- and considering the occlusions.

eras both for outdoor and indoor progress monitoring to make Based on these challenges, the future work and automation of

sure all the elements could be monitored and data required for the visualization falls in four categories: 共1兲 exploring more visu-

as-built progress is collected. In addition, authors suggest using alization techniques and perform testability and applicability of

an unordered set of registered photographs that are taken from these techniques in communication of progress monitoring infor-

various viewpoints to tackle the occlusion issue, and/or using a mation on concurrent representation of performance metrics and

remote helicopter to capture photographs in order to avoid angle work sequence visualization; 共2兲 exploring time-lapsed photo-

and line of sight issues for higher elevations. graphing for data collection, optimum locations for exterior and

interior data collection considering all the challenges discussed;

Automatic Photograph Analysis for Progress Monitoring 共3兲 addressing measurement, quantification, and assessment of

Considering all the challenges with shadow and illuminations, a progress status using effective image processing and computer

series of image processing and pattern recognition techniques is vision concepts along with using edge detection techniques from

required to make sure progress of any type of element regardless one side and on the other hand, formalizing a database for the

of the material used or the texture of the surface could be detected system based on IFC; and 共4兲 applying the technique on various

under nonsevere noise in the photograph. construction projects. Ultimately, an all-inclusive methodology

will be developed that not only visualized progress status, but

Challenges with As-Planned Data automatically collects data, analyses the photographs, compares

them to as-planned model database and visualizes progress status.

Although the baseline for progress monitoring would be the as-

planned model, the correspondence between the schedule infor-

mation and a product model on one side and the level of details

within the 4D model on the other side, creates two major chal-

lenges for its application as a baseline for monitoring: 共1兲 Activi- Acknowledgments

ties with no correspondence in the 4D model: The 4D as-planned

model does not represent all the information within the schedule. The writers acknowledge the financial support for this research

It may not show activities within schedule that do not have cor- received from the National Science Foundation Awards Grant

responding components. For example there is no way to commu- Nos. CMS-0324501 and CMS-0427089. The contribution to this

nicate quality control activities within the current 4D models; and paper by Kipling Mecum, director of Emergency Planning, Clif-

共2兲 Level of details in the 4D model: The major challenge with ford Carey, project manager of University of Illinois Service and

the as-planned data are mostly related to the level of detail for Facilities, University of Illinois College of Business, Post Ge-

progress monitoring. Most of the 4D models can be viewed only nomics Institute, Brian Stauffer, photographer, Steve Hass, assis-

in one level of detail. For example, it many only communicate tant director of office for Information Management, as well as

schedule information within the general contractor’s interest and Aravind Sridharan, Sangwon Han, Edgar Matta, Sebastian Derza,

it may not include all the shop drawing details, however for Joe Garb, Joe Blecha, JR Patton and Lesley Santa at University of

progress monitoring these details could affect the decision made Illinois, Urbana-Champaign is also acknowledged. Any opinions,

on the progress observed. For instance, considering a steel struc- findings, and conclusions or recommendations expressed in this

ture, the level of details within joints between columns and beams publication are those of the authors and do not necessarily reflect

could be modeled but it may not be possible to perform the com- the views of the National Science Foundation or any of the afore-

parison in that level of details. The applicability of a 4D model mentioned people.

JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2009 / 403

J. Comput. Civ. Eng., 2009, 23(6): 391-404

References Koo, B., and Fischer, M. 共2000兲. “Feasibility study of 4D in commercial

construction.” J. Constr. Eng. Manage., 126共4兲, 251–260.

Abba, W. 共1997兲. “Earned value management—Reconciling government Korde, T., Wang, Y., and Russell, A. 共2005兲. “Visualization of construc-

and commercial practices.” Program Manager Magazine, 26, 58–63. tion data.” Proc., 6th Construction Specialty Conf., Canadian Society

Abeid, J., Allouche, E., Arditi, D., and Hayman, M. 共2003兲. “Photo-net II: of Civil Engineering, Toronto, 1–11.

A computer-based monitoring system applied to project manage- Lee, S., and Peña-Mora, F. 共2006兲. “Visualization of construction

ment.” J. Automation Construction, 12共5兲, 603–616. progress monitoring.” Proc., Joint Int. Conf. on Computing and De-

Autodesk Viz. 共2007兲. “Autodesk Viz 2007.” 具www.autodesk.com典 共April cision Making in Civil and Building Engineering, ASCE, Reston, Va.,

29, 2007兲. 2527–2533.

Azuma, R. 共1997兲. “A survey of augmented reality.” J. Teleoperators and Meredith, J., and Mantel, S. 共2003兲. Project management: A managerial

Virtual Env., 6共4兲, 355–385. approach, 5th Ed., Wiley, New York.