Professional Documents

Culture Documents

Chapter 6 Dimensions and Areas

Chapter 6 Dimensions and Areas

Uploaded by

Hrishikesh NarasimhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 6 Dimensions and Areas

Chapter 6 Dimensions and Areas

Uploaded by

Hrishikesh NarasimhanCopyright:

Available Formats

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-00-00 (Rev 8)

DIMENSIONS AND AREAS - GENERAL

1. Scope

A. This chapter includes illustrations and statistical information concerning the Model 172 airplane. Provided are the overall

airplane dimensions, surface areas, station locations, zones and access plate locations.

B. Dimensions and measurements are presented to aid the operator and/or maintenance personnel in ground handling the

airplane and locating components.

2. Definition

A. Airplane Dimensions and Areas.

(1) The section on airplane dimensions and areas provides airplane dimensions and identifies areas of the airplane.

B. Airplane Stations.

(1) The section on stations provides illustrations to identify reference points on the airplane along a three axis division.

C. Airplane Zoning.

(1) The section on zoning provides illustrations of all airplane zones.

D. Access Plates/Panels.

(1) The section on access plates/panels provides numbering of all plates and panels based on specific airplane zones.

Copyright © Textron Aviation Inc. Page 1 of 1

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:40 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-10-00 (Rev 17)

AIRPLANE DIMENSIONS AND SPECIFICATIONS - DESCRIPTION AND OPERATION

1. General

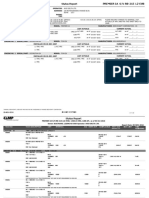

A. Airplane dimensions and specifications have been compiled to serve as a central reference point for airplane information. This

information is presented in tabular and illustrative form below. Refer to Figure 1 for an illustration of airplane dimensions.

AIRPLANE OVERALL

Length (Overall) 27’ - 2”

Height (Maximum) 8’ - 11”

Wing Span (Overall) 36’ - 0”

Tail Span 11’ - 4”

Landing Gear Track Width 8’ - 4 1/2”

FUSELAGE DIMENSIONS

Cabin Width (Maximum Sidewall to Sidewall) 3’ - 3 1/2”

Cabin Height (Floorboard to Headliner) 4’ - 0”

MAXIMUM WEIGHT

Ramp

172R 2457 Pounds

172S 2558 Pounds

(And 172R Airplanes Incorporating MK172-72-01)

Takeoff

172R 2450 Pounds

172S 2550 Pounds

(And 172R Airplanes Incorporating MK172-72-01)

Landing

172R 2450 Pounds

172S 2550 Pounds

(And 172R Airplanes Incorporating MK172-72-01)

FUEL CAPACITY

Total 56.0 Gallons

Usable 53.0 Gallons

ENGINE DATA

Type Lycoming IO-360-L2A

Oil Capacity 8.0 Quarts

Oil Filter CH48110

RPM (Maximum)

172R 2400 RPM

172S 2700 RPM

(And 172R Airplanes Incorporating MK172-72-01)

Horsepower

172R 160 HP

172S 180 HP

(And 172R Airplanes Incorporating MK172-72-01)

Copyright © Textron Aviation Inc. Page 1 of 4

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:41 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-10-00 (Rev 17)

PROPELLER

Type

172R McCauley 1C235/LFA7570

172S McCauley 1A170E/JHA7660

(And 172R Airplanes Incorporating MK172-72-01)

Diameter (Maximum to Minimum)

172R 75” - 74”

172S 76” - 75”

(And 172R Airplanes Incorporating MK172-72-01)

TIRE, STRUT AND WHEEL ALIGNMENT DATA

Main Tire Size

172R 6.00 X 6, 4-Ply Rating

172S 6.00 X 6, 6-Ply Rating

(And 172R Airplanes Incorporating MK172-72-01)

Main Tire Pressure

172R 28.0 PSI

172S 42.0 PSI

(And 172R Airplanes Incorporating MK172-72-01)

Nose Tire Size

172R, 172S 5.00 X 5, 6-Ply Rating

Nose Tire Pressure

172R 34.0 PSI

172S 45.0 PSI

(And 172R Airplanes Incorporating MK172-72-01)

Nose Gear Strut Pressure (Strut Extended) 45.0 PSI

Camber (Measured With Airplane Empty) 2 to 4 Degrees

Toe-In (Measured With Airplane Empty) 0.00 to 0.18”

CONTROL SURFACE TRAVELS/CABLE TENSION SETTINGS

AILERONS

Aileron Up Travel 20 Degrees, ±1 Degree

Aileron Down Travel 15 Degrees, ±1 Degree

Aileron Cable Tension (Carry Through) 40 Pounds, ±10 Pounds

RUDDER

Rudder Travel (Measured Parallel to Water Line)

Right 16 Degrees 10 Min; ±1 Degree

Left 16 Degrees 10 Min; ±1 Degree

Rudder Travel (Measured Perpendicular to Hinge Line)

Right 17 Degrees 44 Min; ±1 Degree

Left 17 Degrees 44 Min; ±1 Degree

ELEVATOR

Copyright © Textron Aviation Inc. Page 2 of 4

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:41 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-10-00 (Rev 17)

Up Travel (Relative to Stabilizer) 28 Degrees, +1 or -0 Degree

Down Travel (Relative to Stabilizer) 23 Degrees, +1 or -0 Degree

Elevator Cable Tension 30 Pounds, ±10 Pounds

ELEVATOR TRIM TAB

Up Travel 22 Degrees, +1 or -0 Degree

Down Travel 19 Degrees, +1 or -0 Degree

Elevator Trim Cable Tension 20 Pounds, +0 or -5 Pounds

FLAPS

Flap Setting:

0 Degree (UP) 0 Degree

10 Degrees 10 Degrees, +0 or -2 Degrees

20 Degrees 20 Degrees, +0 or -2 Degrees

30 Degrees (FULL) 30 Degrees, +0 or -2 Degrees

Flap Cable Tension 30 Pounds, ±10 Pounds

Copyright © Textron Aviation Inc. Page 3 of 4

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:41 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-10-00 (Rev 17)

Figure 1 : Sheet 1 : Airplane Dimensions

Copyright © Textron Aviation Inc. Page 4 of 4

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:41 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-15-00 (Rev 8)

AIRPLANE STATIONS - DESCRIPTION AND OPERATION

1. General

A. The airplane is laid out according to fuselage stations (FS) and wing stations (WS). These stations provide fixed reference

points for all components located on or within the airplane. Fuselage Stations begin at the firewall (FS 0.00) and extend to the

tailcone area (FS 230.18). Wing Stations begin at the root (WS 23.62) and extend to the tip (WS 208.00). Both Fuselage

Stations and Wing Stations are measured in inches. For example, FS 185.50 is 185.50 inches aft of the firewall (FS 0.00).

B. For an illustration of Fuselage Stations, refer to Figure 1. For an illustration of Wing Stations, refer to Figure 2.

Copyright © Textron Aviation Inc. Page 1 of 3

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:44 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-15-00 (Rev 8)

Figure 1 : Sheet 1 : Fuselage Stations

Copyright © Textron Aviation Inc. Page 2 of 3

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:44 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-15-00 (Rev 8)

Figure 2 : Sheet 1 : Wing Stations

Copyright © Textron Aviation Inc. Page 3 of 3

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:44 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-20-00 (Rev 15)

AIRPLANE ZONING - DESCRIPTION AND OPERATION

1. General

A. The Model 172 is divided into numbered zones to provide a method for locating components and/or placards throughout the

airplane. The zones are identified by a three-digit number as shown in the example below. The first digit in the sequence

denotes the major zone (300 series for aft of cabin, 500 series for left wing, etc.). The second digit in the sequence further

divides the zone into submajor zone (Zone 510 for inboard portion of the left wing and Zone 520 for outboard portion of the left

wing, etc..). The third digit further divides the submajor zones into subdivisions (if no subdivision is needed, this digit is typically

assigned as 0 (zero).

B. Major Zones.

(1) 100 - Forward side of firewall and forward.

(2) 200 - Aft side of firewall.

(3) 300 - Aft of cabin to end of airplane.

(4) 500 - Left wing.

(5) 600 - Right wing.

(6) 700 - Landing gear.

2. Description

A. For a breakdown of the airplane zones, refer to Figure 1.

Copyright © Textron Aviation Inc. Page 1 of 4

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:49 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-20-00 (Rev 15)

Figure 1 : Sheet 1 : Airplane Zones

Copyright © Textron Aviation Inc. Page 2 of 4

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:49 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-20-00 (Rev 15)

Figure 1 : Sheet 2 : Airplane Zones

Copyright © Textron Aviation Inc. Page 3 of 4

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:49 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-20-00 (Rev 15)

Figure 1 : Sheet 3 : Airplane Zones

Copyright © Textron Aviation Inc. Page 4 of 4

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:49 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-20-02 (Rev 22)

ACCESS/INSPECTION PLATES - DESCRIPTION AND OPERATION

1. General

A. There are access and inspection panels on the interior and exterior of the airplane. These panels give access to components

and airframe areas.

NOTE: Panels that have hinges attached to them (like the oil door for example) are not referred to as panels

and are not included in this section.

B. This section can be used in conjunction with inspection practices (Chapter 5) or standard maintenance practices to quickly find

related components throughout the airplane.

2. Access/Inspection Panel Numbering

A. All access/inspection panels have a series of numbers and letters which identify their zone location, sequence, and orientation.

(1) Zone Location - Zone location is identified by the first three numbers of any panels. This three-number sequence is

specified in Airplane Zoning - Description and Operation.

(2) Sequence - The sequence is identified by alphabetical letters follow the three-number sequence. The first panel is

identified as “A,” the second panel is identified as “B”, and so on.

(3) Orientation - The orientation for each panel is identified by one of four letters that come after the sequence letter. The

orientation letters are "T" for top, "B" for bottom, "L" for left, and "R" for right.

B. With access panel 510AB as an example, the breakdown is as follows:

(1) Zone Location = 510 (inboard portion of left wing)

(2) Sequence = A (the first panel within the zone)

(3) Orientation = B (located on the bottom of the zone).

3. Description

A. Access/Inspection Panels.

(1) For cabin floorboard panels, refer to Figure 1, Sheet 1, Figure 1, Sheet 2, and Table 1.

Table 1. Cabin Floorboard Panels

Panel Equipment Located In Area (Refer to Figure 1)

230AT Brake Line

230BT Fuel Pump and Reservoir

230CT Fuel Pump and Reservoir

230DT Fuel Lines, Wire Bundle

230ET Elevator Bellcrank, Fuel Lines

230FT Fuel Selector, Elevator Bellcrank

230GT Fuel Line

230HT Fuel Line

230JT Fuel Lines, Wire Bundles

230KT Elevator Trim Tab Pulley, ADF Antenna

230LT Fuel Lines

230PT Wire Bundle, Brake Line

230QT Rudder Cables, Elevator Cables, Elevator Trim Cables

230RT Brake Line

231AT Main Landing Gear Bulkhead

231BT Rudder Cables, Elevator Cables, Elevator Trim Cables

231CT Main Landing Gear Bulkhead

231DT Rudder Cables, Elevator Cables, Elevator Trim Cables

231ET Rudder Cables, Elevator Cables, Elevator Trim Cables

Copyright © Textron Aviation Inc. Page 1 of 9

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:58 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-20-02 (Rev 22)

231FT Transponder Antenna

231GT Rudder Cables, Elevator Cables, Elevator Trim Cables

231HT Structure

231JT Rudder Cables, Elevator Cables, Elevator Trim Cables

231KT Structure

Table 2. Fuselage Panels

Panel Equipment Located In Area (Refer to Figure 2)

120AT External Power

210AB Control Yoke/Elevator Attach

210BB Brake Line, Rudder Cables, Elevator Cables, Elevator Trim Cables, Wiring

210CB Rudder Cables, Elevator Cables, Elevator Trim Cables

310AL Elevator Pulleys, Elevator Trim Pulleys

310AR Elevator Pulleys, Elevator Trim Pulleys

310BR Rudder Cables, Elevator Cables, Elevator Trim Cables

320AB Elevator Trim Actuator

Table 3. Wing Access Panels

Panel Equipment Located In Area (Refer to Figure 3)

610AB Wiring

610BB Wiring

610CB Strut Bolt

610DB Fuel Lines, Fuel Transmitter

610EB Flap Controls

610FB Strut Bolt

610GB Flap Actuator

610HB Fuel Lines, Fuel Transmitter

610JB Wing Structure

610KB Wing Structure

610LB Flap Cables, Aileron Cables

610MB Flap Cables, Aileron Cables

610NB Aileron Cables

620AB Autopilot Roll Servo

620BB Aileron Cables, Trim Cables

620CB Aileron Cables

620DB Aileron Bellcrank

620EB Wing Structure

620FB Wing Structure

620GB Wing Structure

620HB Wing Structure

620JB Wing Structure

510AB Wiring

Copyright © Textron Aviation Inc. Page 2 of 9

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:58 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-20-02 (Rev 22)

510BB Wiring, Pitot Tube

510CB Strut Bolt

510DB Fuel Lines, Fuel Transmitter

510EB Flap Controls

510FB Strut Bolt

510GB Flap Actuator

510HB Fuel Lines, Fuel Transmitter

510JB Wing Structure, Courtesy Light

510KB Wing Structure, Flap Bellcrank

510LB Flap Cables, Aileron Cables

510MB Flap Cables, Aileron Cables

510NB Aileron Cables

520AB Aileron Cables, Trim Cables

520BB Aileron Cables, Aileron Bellcrank

520CB Wing Structure

520DB Wing Structure

520EB Wing Structure

520FB Wing Structure

520GB Wing Structure

520HB Magnetometer

610AT Fuel Bay

610BT Fuel Bay

610CT Fuel Bay

510AT Fuel Bay

510BT Fuel Bay

510CT Fuel Bay

Table 4. Flap Panels

Panel Equipment Located In Area (Refer to Figure 4)

511AT Flap Access

511BT Flap Access

511CT Flap Access

511DT Flap Access

611AT Flap Access

611BT Flap Access

611CT Flap Access

611DT Flap Access

Copyright © Textron Aviation Inc. Page 3 of 9

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:58 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-20-02 (Rev 22)

Figure 1 : Sheet 1 : Cabin Floorboard Panels

Copyright © Textron Aviation Inc. Page 4 of 9

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:58 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-20-02 (Rev 22)

Figure 1 : Sheet 2 : Cabin Floorboard Panels

Copyright © Textron Aviation Inc. Page 5 of 9

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:58 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-20-02 (Rev 22)

Figure 2 : Sheet 1 : Fuselage Panels

Copyright © Textron Aviation Inc. Page 6 of 9

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:58 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-20-02 (Rev 22)

Figure 3 : Sheet 1 : Wing Access Panels

Copyright © Textron Aviation Inc. Page 7 of 9

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:58 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-20-02 (Rev 22)

Figure 3 : Sheet 2 : Wing Access Panels

Copyright © Textron Aviation Inc. Page 8 of 9

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:58 CDT 2022

Model 172 (Series 1996 And On) Maintenance Manual (Rev 24)

6-20-02 (Rev 22)

Figure 4 : Sheet 1 : Flap Panels

Copyright © Textron Aviation Inc. Page 9 of 9

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Thu Aug 11 03:45:58 CDT 2022

You might also like

- Air Regs Question Bank (With Answers)Document116 pagesAir Regs Question Bank (With Answers)Yash Srivastava95% (21)

- Primus 1000 Cessna Ultra SDOM PDFDocument828 pagesPrimus 1000 Cessna Ultra SDOM PDFHrishikesh Narasimhan100% (3)

- IS BAO Internal Audit Manual PDFDocument100 pagesIS BAO Internal Audit Manual PDFHrishikesh NarasimhanNo ratings yet

- Post and Core IngleDocument29 pagesPost and Core IngleChintan MakadiaNo ratings yet

- Cirrus: Illustrated Parts Catalog Models Sr22 and Sr22TDocument12 pagesCirrus: Illustrated Parts Catalog Models Sr22 and Sr22Thector joel lizarragaNo ratings yet

- Chapter 4 Airworthiness LimitationsDocument3 pagesChapter 4 Airworthiness LimitationsHrishikesh NarasimhanNo ratings yet

- Piper Programmed Inspection 25 Hour CycleDocument58 pagesPiper Programmed Inspection 25 Hour CycleLeandro MenezesNo ratings yet

- Manual ELT 500 27Document17 pagesManual ELT 500 27Vitaly SheverinNo ratings yet

- SP7041M03T46 000 A PDFDocument5 pagesSP7041M03T46 000 A PDFPedro Casimiro GámizNo ratings yet

- Weight-Balance R66 V5Document694 pagesWeight-Balance R66 V5IjoeljuliantNo ratings yet

- Model 382 (Hercules) Transport Category Aircraft)Document20 pagesModel 382 (Hercules) Transport Category Aircraft)Jacob Jack Yosha100% (1)

- 10-1 Frankfurt EDDF FRA Ground ChartDocument1 page10-1 Frankfurt EDDF FRA Ground Chartnopafix0% (1)

- Phase Inspections PDFDocument141 pagesPhase Inspections PDFHrishikesh Narasimhan100% (2)

- Cabin Safety Inspector ChecklistDocument4 pagesCabin Safety Inspector ChecklistHrishikesh NarasimhanNo ratings yet

- Annex 6 - Part II - International General Aviation - Aeroplanes PDFDocument182 pagesAnnex 6 - Part II - International General Aviation - Aeroplanes PDFHrishikesh Narasimhan100% (2)

- SP7012M02D02 000 ADocument15 pagesSP7012M02D02 000 APedro Casimiro GámizNo ratings yet

- Afd 161003MQR PSD 1Document43 pagesAfd 161003MQR PSD 1MASOUDNo ratings yet

- Redbox: Model Rbl4000 LithiumDocument1 pageRedbox: Model Rbl4000 LithiumAbdullah SindhuNo ratings yet

- Premier 1A CAMP ReportDocument100 pagesPremier 1A CAMP ReportT/ROX0% (1)

- SP7011M00W01 000 A PDFDocument7 pagesSP7011M00W01 000 A PDFPedro Casimiro GámizNo ratings yet

- Department of Transportation Federal Aviation AdministrationDocument12 pagesDepartment of Transportation Federal Aviation AdministrationSamuel JiménezNo ratings yet

- Airborne Fuel Pump 2Document1 pageAirborne Fuel Pump 2Luis Martinez GerdingNo ratings yet

- P&WCS B No 47252R2Document17 pagesP&WCS B No 47252R2Jefferson CaizaNo ratings yet

- E00090EN Rev10-Engine-Type-CertificateDocument8 pagesE00090EN Rev10-Engine-Type-CertificateIgor MedeirosNo ratings yet

- Airworthiness Standards FAA FAR Part 29Document119 pagesAirworthiness Standards FAA FAR Part 29fuuadNo ratings yet

- Komala SBAS350760028ENR0Document30 pagesKomala SBAS350760028ENR0Chaidir AljarwizharNo ratings yet

- 06 - Wwamm RDocument21 pages06 - Wwamm RPedroRodriguezNo ratings yet

- Einn/Snn Shannon, Ireland: .SpeedDocument19 pagesEinn/Snn Shannon, Ireland: .SpeedTweed3A100% (1)

- Emissions From Combustion of Hydrocarbons in A Well-Stirred ReactorDocument12 pagesEmissions From Combustion of Hydrocarbons in A Well-Stirred Reactorvitorio netoNo ratings yet

- JEPPESEN Approach Chart, Rev.16Document134 pagesJEPPESEN Approach Chart, Rev.16sadman joyNo ratings yet

- Emb145 1Document16 pagesEmb145 1Emme PrabhudasNo ratings yet

- 407 ProductSpec 201302-Web PDFDocument49 pages407 ProductSpec 201302-Web PDFLuis_G_CondeNo ratings yet

- Catalogue Nacelle Tooling A320neoDocument31 pagesCatalogue Nacelle Tooling A320neoPablo RestrepoNo ratings yet

- Nickel-Cadmium Batteries For Aircraft ApplicationsDocument4 pagesNickel-Cadmium Batteries For Aircraft ApplicationsFernando U.No ratings yet

- Service Manual For The Wipline Model 4000 Amphibious and Seaplane Floats On Cessna A185e, A185f, and 206 SeriesDocument50 pagesService Manual For The Wipline Model 4000 Amphibious and Seaplane Floats On Cessna A185e, A185f, and 206 SeriesKrasakKrusuk Si MaulNo ratings yet

- 05 Brochure Dassault Falcon 7x PDFDocument7 pages05 Brochure Dassault Falcon 7x PDFJefferson Vieitas FragosoNo ratings yet

- TM 11-1520-217-34P-2 24-Oct-77 USAPADocument88 pagesTM 11-1520-217-34P-2 24-Oct-77 USAPAruiNo ratings yet

- V2500-Nac-70-0739 0am53 VSB 00Document8 pagesV2500-Nac-70-0739 0am53 VSB 00Kevin John PangilinanNo ratings yet

- UAS Engines: Reference SectionDocument3 pagesUAS Engines: Reference SectionMorgen GumpNo ratings yet

- CRJ200.SRM (38) .SRM57 72 00 01Document6 pagesCRJ200.SRM (38) .SRM57 72 00 01Dzmitry KavaliouNo ratings yet

- Index of Articles: Engine Model Article Title Article Number SectionDocument34 pagesIndex of Articles: Engine Model Article Title Article Number SectionLuis GuerreroNo ratings yet

- 03-2radar System Design ExampleDocument40 pages03-2radar System Design Exampleehsan1985No ratings yet

- 22 - Effective Pages: Beechcraft CorporationDocument24 pages22 - Effective Pages: Beechcraft CorporationMartín LaraNo ratings yet

- Atr: Number One Choice in The Regional MarketDocument2 pagesAtr: Number One Choice in The Regional MarketO GoogleNo ratings yet

- Pages From Pages From ETOPS CMP Nce - 116089Document90 pagesPages From Pages From ETOPS CMP Nce - 116089Kevin PangilinanNo ratings yet

- P 3 HF Antenna UpgradeDocument1 pageP 3 HF Antenna UpgradeLeon LellaNo ratings yet

- PrintDocument71 pagesPrintMico SilloNo ratings yet

- Pilots Information Sheet: MODEL BD 700 1A10 (BD 700)Document2 pagesPilots Information Sheet: MODEL BD 700 1A10 (BD 700)romixrayzenNo ratings yet

- Previous Pageblock Return To Previous Menu Next Pageblock: Pratt & WhitneyDocument3 pagesPrevious Pageblock Return To Previous Menu Next Pageblock: Pratt & WhitneyPedro Casimiro GámizNo ratings yet

- TASK 34-54-00-720-815-B Functional Test - ATC SystemDocument8 pagesTASK 34-54-00-720-815-B Functional Test - ATC Systemopiratova100% (1)

- A318/A319/A320/A321: Service BulletinDocument58 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- M250-C30R3M Inspection Check SheetsDocument15 pagesM250-C30R3M Inspection Check SheetsturboshaftNo ratings yet

- Installation Manual and Operating Instructions 4300-XXX Series Electric Attitude Indicator With Battery BackupDocument24 pagesInstallation Manual and Operating Instructions 4300-XXX Series Electric Attitude Indicator With Battery BackupMark Nash100% (1)

- pc-6 Tcds f56-107Document27 pagespc-6 Tcds f56-107Charles Francesc XavierNo ratings yet

- MMOPA Magazine Spring 209Document60 pagesMMOPA Magazine Spring 209gustavo rivasNo ratings yet

- Rolls-Royce M250 FIRST Network: 2015 Customer Support DirectoryDocument76 pagesRolls-Royce M250 FIRST Network: 2015 Customer Support Directoryale11vigarNo ratings yet

- SP7011M00D01 000 ADocument30 pagesSP7011M00D01 000 APedro Casimiro GámizNo ratings yet

- Williams SBDocument4 pagesWilliams SBlong chenNo ratings yet

- Report Metodo SchrenkDocument16 pagesReport Metodo SchrenkDario ForestiereNo ratings yet

- A316 CF6-80C2 GRD OpsDocument54 pagesA316 CF6-80C2 GRD OpsLuiz FerrazNo ratings yet

- Hydraulic Systems No. 1 or No. 2 - Fill With Hydraulic FluidDocument12 pagesHydraulic Systems No. 1 or No. 2 - Fill With Hydraulic FluidaliNo ratings yet

- Air Data Attitude Heading Reference System: FeaturesDocument2 pagesAir Data Attitude Heading Reference System: FeaturesIventNo ratings yet

- Service Bulletin: CFM InternationalDocument40 pagesService Bulletin: CFM InternationalMuhammadRohaniNo ratings yet

- Pas2144 Fab-011 Ska 200Document5 pagesPas2144 Fab-011 Ska 200Jose Luis Mamani CastroNo ratings yet

- Cessna Denali Product CardDocument2 pagesCessna Denali Product Cardlegoulu21100% (1)

- Previous Pageblock Return To Previous Menu Next Pageblock: Pratt & WhitneyDocument10 pagesPrevious Pageblock Return To Previous Menu Next Pageblock: Pratt & WhitneyPedro Casimiro GámizNo ratings yet

- Department of Transportation Federal Aviation AdministrationDocument32 pagesDepartment of Transportation Federal Aviation Administrationnabawi24No ratings yet

- Department of Transportation Federal Aviation AdministrationDocument31 pagesDepartment of Transportation Federal Aviation AdministrationAnthony FratelliNo ratings yet

- Cu FlashcardsDocument163 pagesCu FlashcardsHrishikesh Narasimhan100% (1)

- Form 'C': Arrival Report of Foreigner in HotelDocument2 pagesForm 'C': Arrival Report of Foreigner in HotelHrishikesh Narasimhan100% (2)

- Chapter 9 Towing and TaxiingDocument3 pagesChapter 9 Towing and TaxiingHrishikesh NarasimhanNo ratings yet

- Chapter 7 Lifting and ShoringDocument4 pagesChapter 7 Lifting and ShoringHrishikesh NarasimhanNo ratings yet

- FRRO Appication FormDocument3 pagesFRRO Appication FormHrishikesh Narasimhan100% (2)

- FDTL Kacpl Issue 03Document19 pagesFDTL Kacpl Issue 03Hrishikesh NarasimhanNo ratings yet

- Chapter 10 Parking and MooringDocument7 pagesChapter 10 Parking and MooringHrishikesh NarasimhanNo ratings yet

- H9R2YG: Date Flight From / Terminal To / Terminal Stops Departs Arrives Baggage Allowance ClassDocument1 pageH9R2YG: Date Flight From / Terminal To / Terminal Stops Departs Arrives Baggage Allowance ClassHrishikesh NarasimhanNo ratings yet

- Quotation: Customer Ref: Interior UpholsteryDocument6 pagesQuotation: Customer Ref: Interior UpholsteryHrishikesh NarasimhanNo ratings yet

- Vt-Ica Stock Report As On 31 Dec 2015Document18 pagesVt-Ica Stock Report As On 31 Dec 2015Hrishikesh NarasimhanNo ratings yet

- Get Payment Response PANAppDocument3 pagesGet Payment Response PANAppHrishikesh NarasimhanNo ratings yet

- Secondary Safe Flight Angle-Of-Attack System - Inspection/Check (Airplanes - 0400 Thru - 0538) 1. GeneralDocument16 pagesSecondary Safe Flight Angle-Of-Attack System - Inspection/Check (Airplanes - 0400 Thru - 0538) 1. GeneralHrishikesh NarasimhanNo ratings yet

- Hawker 900XP PartsDocument18 pagesHawker 900XP PartsHrishikesh Narasimhan100% (3)

- Flight Risk Assessment Tool Worksheet (Two-Sided)Document2 pagesFlight Risk Assessment Tool Worksheet (Two-Sided)Hrishikesh NarasimhanNo ratings yet

- Air India PartList 20190311 Lot9Document206 pagesAir India PartList 20190311 Lot9Hrishikesh NarasimhanNo ratings yet

- Flight Risk Assessment Tool Worksheet (Two-Sided)Document2 pagesFlight Risk Assessment Tool Worksheet (Two-Sided)Hrishikesh NarasimhanNo ratings yet

- Kunal Air Charter PVT LTD KAC/SWP/FW/01/19 Issue 1 Revision 0 Severe Weather Plan 1 April 2019Document1 pageKunal Air Charter PVT LTD KAC/SWP/FW/01/19 Issue 1 Revision 0 Severe Weather Plan 1 April 2019Hrishikesh NarasimhanNo ratings yet

- CH 17 Appendix 8Document1 pageCH 17 Appendix 8Hrishikesh NarasimhanNo ratings yet

- 8100 ChangesDocument2 pages8100 ChangesHrishikesh NarasimhanNo ratings yet

- Official Ncm0200 Baird Parker Agar Base Technical Specifications en UsDocument3 pagesOfficial Ncm0200 Baird Parker Agar Base Technical Specifications en UsBty SaGNo ratings yet

- Polymers 15 01581Document24 pagesPolymers 15 01581Tehreem IshtiaqNo ratings yet

- Basic Calculation of A Buck Converter 'S Power Stage: Application NoteDocument9 pagesBasic Calculation of A Buck Converter 'S Power Stage: Application NoteNestor GlezNo ratings yet

- GEV Organic ProductsDocument4 pagesGEV Organic ProductssubhashNo ratings yet

- ATT EL52203 UserManualDocument102 pagesATT EL52203 UserManualdalton95198285No ratings yet

- Programmes For School, Strengthening Environmental Education in School SystemDocument10 pagesProgrammes For School, Strengthening Environmental Education in School SystemRuhi waliaNo ratings yet

- Como Orar en InglesDocument2 pagesComo Orar en InglesLeo MoltoNo ratings yet

- Autoclaved Aerated ConcreteDocument4 pagesAutoclaved Aerated ConcreteArunima DineshNo ratings yet

- Design Process in ElectrochemistryDocument92 pagesDesign Process in ElectrochemistryWulan SariNo ratings yet

- GMW8 2019 03 (Hot Dip Zinc Coating Sheet Steel)Document8 pagesGMW8 2019 03 (Hot Dip Zinc Coating Sheet Steel)dpfloresNo ratings yet

- Research Article: An Improved Method of Particle Swarm Optimization For Path Planning of Mobile RobotDocument12 pagesResearch Article: An Improved Method of Particle Swarm Optimization For Path Planning of Mobile Robotmarcio pivelloNo ratings yet

- Garmin 530W QuickReferenceGuideDocument24 pagesGarmin 530W QuickReferenceGuideLuchohueyNo ratings yet

- Land Rover Discovery SportDocument2 pagesLand Rover Discovery SportnikdianaNo ratings yet

- EU Igus Dry-Tech BEA1 2023 Catalogue 02-05 Iglidur Food ContactDocument38 pagesEU Igus Dry-Tech BEA1 2023 Catalogue 02-05 Iglidur Food ContactDaniel Andrés ReigNo ratings yet

- Clay & Shale Industries in OntarioDocument193 pagesClay & Shale Industries in OntarioJohn JohnsonNo ratings yet

- Internal Audit Checklist Food Safety-MRDocument5 pagesInternal Audit Checklist Food Safety-MRRavi BaghelNo ratings yet

- Barbering M1 2nd SemDocument10 pagesBarbering M1 2nd Semjaymarnel1996No ratings yet

- 4.1 Basic Physics and Band Diagrams For MOS CapacitorsDocument5 pages4.1 Basic Physics and Band Diagrams For MOS CapacitorsvinodNo ratings yet

- Gothra PattikaDocument172 pagesGothra PattikaParimi VeeraVenkata Krishna SarveswarraoNo ratings yet

- Cat 336eh Hybrid ExcavatorDocument30 pagesCat 336eh Hybrid ExcavatorPHÁT NGUYỄN THẾ100% (1)

- The Lighting Cheat Sheet, by Andrew PriceDocument3 pagesThe Lighting Cheat Sheet, by Andrew PricekouzaNo ratings yet

- DONE LESSON PLAN - Weather and ClimateDocument5 pagesDONE LESSON PLAN - Weather and ClimateStygian DoggoNo ratings yet

- Transport Management PlanDocument13 pagesTransport Management Planprmrao100% (3)

- I Ran (So Far Away) : A Flock of SeagullsDocument9 pagesI Ran (So Far Away) : A Flock of SeagullsvanillablairNo ratings yet

- PDF Automatic Transmissions and Transaxles 7Th Edition James D Halderman Ebook Full ChapterDocument53 pagesPDF Automatic Transmissions and Transaxles 7Th Edition James D Halderman Ebook Full Chapterevon.gaskins482100% (3)

- Engine Control Toyota Cuiser 2007 - 1GR - FeDocument6 pagesEngine Control Toyota Cuiser 2007 - 1GR - Fe35.Hoàng Xuân TânNo ratings yet

- Amoxicillin Tri Hydrate Table FormatDocument3 pagesAmoxicillin Tri Hydrate Table FormatNico DonatoNo ratings yet

- Equivalence Relations - ADocument14 pagesEquivalence Relations - AMuhammad Kaleem50% (2)

- Fruit (A - An - Some)Document24 pagesFruit (A - An - Some)Breanna DavenportNo ratings yet