Professional Documents

Culture Documents

As 1921 - 1976

As 1921 - 1976

Uploaded by

Sin Quee CheCopyright:

Available Formats

You might also like

- As 3100 General Requirements For Electrical EquipmentsDocument9 pagesAs 3100 General Requirements For Electrical EquipmentsJosh Zhang0% (1)

- AS1755-2000 Conveyors Safety RequirementsDocument91 pagesAS1755-2000 Conveyors Safety RequirementsVinceS2100% (8)

- As 2758.1-1998 Concrete AggregatesDocument28 pagesAs 2758.1-1998 Concrete AggregatesArogya Raju Pudhota100% (3)

- Boating Skills and Seamanship, 14th EditionFrom EverandBoating Skills and Seamanship, 14th EditionNo ratings yet

- Wig Hoverwing 19xrw-RedDocument5 pagesWig Hoverwing 19xrw-RedFloreia SileNo ratings yet

- Australian Standard: Liquefied Natural Gas-Storage and HandlingDocument10 pagesAustralian Standard: Liquefied Natural Gas-Storage and HandlingSalim Chohan100% (1)

- 3774Document8 pages3774Valter AraujoNo ratings yet

- As 1746-1991Document15 pagesAs 1746-1991Quantudogon DangNo ratings yet

- As 1160 1996 Bituminous Emulsions For The Construction and Maintenance of PavementsDocument7 pagesAs 1160 1996 Bituminous Emulsions For The Construction and Maintenance of PavementsaskarahNo ratings yet

- NZS 2295-2006 PDFDocument10 pagesNZS 2295-2006 PDFElmira Siroospour50% (2)

- As 1576.1-2010 Scaffolding General RequirementsDocument69 pagesAs 1576.1-2010 Scaffolding General Requirementsanon_399144888100% (1)

- Australian Standard: Pipe Threads of Whitworth Form Part 1: Sealing Pipe Threads (Metric Units)Document7 pagesAustralian Standard: Pipe Threads of Whitworth Form Part 1: Sealing Pipe Threads (Metric Units)Sancb0% (1)

- Zonestar P802CR2 Reprap Prusa I3 English User ManualDocument54 pagesZonestar P802CR2 Reprap Prusa I3 English User ManualAlexander VasNo ratings yet

- Mitchell 6500 ManualDocument64 pagesMitchell 6500 Manualcanelo45No ratings yet

- As 1692 Tanks For Flammable Combustible LiquidsDocument25 pagesAs 1692 Tanks For Flammable Combustible LiquidsNacho Orden MoyaNo ratings yet

- AS - NZS 4200.1-1994 MaterialsDocument15 pagesAS - NZS 4200.1-1994 MaterialsMorten PedersenNo ratings yet

- Commercial Yacht Code - LY3Document192 pagesCommercial Yacht Code - LY3naufragatoNo ratings yet

- As NZ 2743 1996 Valves For CNGDocument67 pagesAs NZ 2743 1996 Valves For CNGTim WilsonNo ratings yet

- As 1576.4 Scaffolding Suspended Scaf PDFDocument17 pagesAs 1576.4 Scaffolding Suspended Scaf PDFtheNo ratings yet

- Australian Standard: Structural Steel Hollow SectionsDocument26 pagesAustralian Standard: Structural Steel Hollow Sectionstedi mardetaNo ratings yet

- AS 1170-Part 1Document7 pagesAS 1170-Part 1Thaiminh Vo33% (3)

- AS - NZS 4200.2-1994 Installation RequirementsDocument11 pagesAS - NZS 4200.2-1994 Installation RequirementsMorten PedersenNo ratings yet

- AS1755-1986 ConveyorDocument66 pagesAS1755-1986 Conveyorjustinxxuu86No ratings yet

- LY3 - Final VersionDocument190 pagesLY3 - Final VersionAlexNo ratings yet

- AS 1273-1991 (UPVC Downpipes and Fittings For Rainwater)Document11 pagesAS 1273-1991 (UPVC Downpipes and Fittings For Rainwater)Sanil SamiNo ratings yet

- As 2159 Supp1-1996 Piling-Design and Installation-GuidelinesDocument36 pagesAs 2159 Supp1-1996 Piling-Design and Installation-GuidelinesArogya Raju PudhotaNo ratings yet

- As 1755-1986 Conveyors-Design, Construction, Installation, and Operation-Safety RequirementsDocument14 pagesAs 1755-1986 Conveyors-Design, Construction, Installation, and Operation-Safety RequirementsallovidNo ratings yet

- Concrete LNG Terminal Structures and Containment Systems: Standard DNV-OS-C503Document58 pagesConcrete LNG Terminal Structures and Containment Systems: Standard DNV-OS-C503Vivi GouriotiNo ratings yet

- Australian Standard: Roof TilesDocument10 pagesAustralian Standard: Roof TilesVeetoau Joseph100% (1)

- AS 1735.7-1998 Stairway LiftsDocument14 pagesAS 1735.7-1998 Stairway LiftsMorten PedersenNo ratings yet

- Australian Standard: SAA Lift Code Part 11: Fire-Rated Landing DoorsDocument0 pagesAustralian Standard: SAA Lift Code Part 11: Fire-Rated Landing DoorsGuha ArnabNo ratings yet

- 2903Document5 pages2903iso9002No ratings yet

- MSN - 1792 - Edition - 2 (LY2 Code)Document179 pagesMSN - 1792 - Edition - 2 (LY2 Code)kees1961No ratings yet

- Statutory Equipment-Part 10Document223 pagesStatutory Equipment-Part 10ANTON NEAGUNo ratings yet

- AS 1735.3-2002 Passenger & Goods Lifts - ElectrohydraulicDocument88 pagesAS 1735.3-2002 Passenger & Goods Lifts - ElectrohydraulicMorten PedersenNo ratings yet

- As 1666.2-1995 Wire-Rope Slings - Care and UseDocument25 pagesAs 1666.2-1995 Wire-Rope Slings - Care and UseThaiminh Vo100% (1)

- As 1160-1996Document18 pagesAs 1160-1996Alexandru LetNo ratings yet

- National Standard For Commercial Vessels: Australian Transport CouncilDocument26 pagesNational Standard For Commercial Vessels: Australian Transport CouncilCarl FranksNo ratings yet

- AS 1735.8-1986 Inclined LiftsDocument28 pagesAS 1735.8-1986 Inclined LiftsMorten PedersenNo ratings yet

- CFTS Exep Ins Spe 00000 02 - R01Document15 pagesCFTS Exep Ins Spe 00000 02 - R01Kenneth EmbeleNo ratings yet

- Builders PlateDocument22 pagesBuilders PlateCostin RotaruNo ratings yet

- GS126-2 Air-Cooled Heat Exchangers To API 661Document46 pagesGS126-2 Air-Cooled Heat Exchangers To API 661DH B75% (4)

- 1014-1986 - Gauging of Metric Screw ThreadsDocument41 pages1014-1986 - Gauging of Metric Screw ThreadsMark Carroll-ChiltsNo ratings yet

- Australian Standard: National Plumbing and Drainage Part 1.1: Water Supply - Performance RequirementsDocument8 pagesAustralian Standard: National Plumbing and Drainage Part 1.1: Water Supply - Performance RequirementsVăn AnhNo ratings yet

- Australian Standard: Design of Steel Lattice Towers and MastsDocument7 pagesAustralian Standard: Design of Steel Lattice Towers and Mastsalsager14No ratings yet

- Australian Offshore Support Vessel Code of Safe Working PracticeDocument81 pagesAustralian Offshore Support Vessel Code of Safe Working PracticeHIPAP100% (1)

- Spwcode TocDocument12 pagesSpwcode TocKweku AsieduNo ratings yet

- ALU EN 2017 CompletesetDocument216 pagesALU EN 2017 CompletesetNico LomibaoNo ratings yet

- 4037 PDFDocument10 pages4037 PDFMin MinNo ratings yet

- As Nzs 1576-1-2010 ScaffoldingDocument8 pagesAs Nzs 1576-1-2010 ScaffoldingAnil KumarNo ratings yet

- Ameron 2000m and 7000mDocument28 pagesAmeron 2000m and 7000mhadrijkNo ratings yet

- Agma 926-C99Document16 pagesAgma 926-C99Mehul Bansal100% (2)

- Attachment 1 Dry Dock Specs 2019Document51 pagesAttachment 1 Dry Dock Specs 2019GabrielNo ratings yet

- Nema Ics 4Document34 pagesNema Ics 4Egyptman Jan100% (1)

- 02-747 Part 3Document38 pages02-747 Part 3jra9090No ratings yet

- Abs Condition of ClassDocument16 pagesAbs Condition of ClassJon LopezNo ratings yet

- Aviation Weather: FAA Advisory Circular (AC) 00-6BFrom EverandAviation Weather: FAA Advisory Circular (AC) 00-6BRating: 3.5 out of 5 stars3.5/5 (11)

- Aviation Weather: FAA Advisory Circular (AC) 00-6B (Blackridge Press FAA Series)From EverandAviation Weather: FAA Advisory Circular (AC) 00-6B (Blackridge Press FAA Series)No ratings yet

- Stirling Cycle Engines: Inner Workings and DesignFrom EverandStirling Cycle Engines: Inner Workings and DesignRating: 3 out of 5 stars3/5 (1)

- FINAL - Exhaust Fan Control Systems For LaboratoriesDocument53 pagesFINAL - Exhaust Fan Control Systems For LaboratoriesSin Quee CheNo ratings yet

- Honeywell DDC Panel ManualDocument512 pagesHoneywell DDC Panel ManualSyed ZakiuddinNo ratings yet

- Bahamas RegulationsDocument44 pagesBahamas RegulationsSin Quee CheNo ratings yet

- Eeha Arcia White Paper Ver 1.1 Jan16Document66 pagesEeha Arcia White Paper Ver 1.1 Jan16Sin Quee CheNo ratings yet

- Australian - New Zealand StandardDocument6 pagesAustralian - New Zealand StandardSin Quee CheNo ratings yet

- Mep 2020 NovDocument1 pageMep 2020 NovAnakin SkywalkerNo ratings yet

- Schedule of Loads and ComputationDocument3 pagesSchedule of Loads and ComputationLeovigildo I. LumioNo ratings yet

- DMW PowerDocument4 pagesDMW PowerHari Krishna.MNo ratings yet

- Uros Hand Made Reed Floating IslandsDocument12 pagesUros Hand Made Reed Floating IslandstudorimaNo ratings yet

- Plumbing - Lec.01Document63 pagesPlumbing - Lec.01Omed Juma'aNo ratings yet

- MEP Co-Ordination Check List.Document6 pagesMEP Co-Ordination Check List.nandeeshNo ratings yet

- Naphtthenes ASTM D 1319Document8 pagesNaphtthenes ASTM D 1319Hassan HaiderNo ratings yet

- SG City 63A Multipager - 12.07.2022Document24 pagesSG City 63A Multipager - 12.07.2022HarneetNo ratings yet

- Schneider Short Circuit CalculationDocument36 pagesSchneider Short Circuit Calculationincobar100% (2)

- Brosur ToyotaDocument8 pagesBrosur Toyotayuliani fitriaNo ratings yet

- Fyp 001Document2 pagesFyp 001Moazzam IrshadNo ratings yet

- M 385 ContentDocument47 pagesM 385 ContentSalmanul FareziNo ratings yet

- Transformer ModuleDocument35 pagesTransformer ModuleHasyim PribadiNo ratings yet

- Lec 28Document18 pagesLec 28elene shopovaNo ratings yet

- Wiring Diagram of Front SAM Control Unit With Fuse and Relay Module (N10 - 1) 2Document5 pagesWiring Diagram of Front SAM Control Unit With Fuse and Relay Module (N10 - 1) 2Сергей АзаренкоNo ratings yet

- Basic Electronics: Submitted To: Ma'am Qudsia Memon Submitted by Usama Memon 19ME138Document10 pagesBasic Electronics: Submitted To: Ma'am Qudsia Memon Submitted by Usama Memon 19ME138Dhanaish kumarNo ratings yet

- Experiment No. 2Document7 pagesExperiment No. 2noteasytobebooNo ratings yet

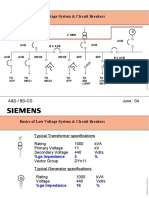

- Basics of Low Voltage System & Circuit Breakers: A&D / BD-CD June 04Document17 pagesBasics of Low Voltage System & Circuit Breakers: A&D / BD-CD June 04kodandaram100% (1)

- Green Roof 2021-S1Document39 pagesGreen Roof 2021-S1Dimas Kharizmi Albar IPBNo ratings yet

- Electric EquipmentDocument221 pagesElectric EquipmentCarlos Andrés Sánchez Vargas100% (1)

- CH 13Document9 pagesCH 13indaNo ratings yet

- Senturian BrochureDocument5 pagesSenturian BrochureMaryleen Ndu MlynNo ratings yet

- 10 Govt Model Question I Science emDocument9 pages10 Govt Model Question I Science emVelu ManiNo ratings yet

- CBSE Class 8 Science WorksheetDocument3 pagesCBSE Class 8 Science Worksheetravilulla60% (5)

- Manufacture of Linear Alkyl Benzene Sulphonic Acid (Labsa) : S. B. Dayanethi (Reg. No: 810018239008)Document137 pagesManufacture of Linear Alkyl Benzene Sulphonic Acid (Labsa) : S. B. Dayanethi (Reg. No: 810018239008)9024 MUGESHNo ratings yet

- Half Wave and Full Wave RectifierDocument6 pagesHalf Wave and Full Wave RectifierBilal KhanNo ratings yet

- SUBTOPIC 1 - Electrical Design and Standard For Commercial EstablishmentDocument30 pagesSUBTOPIC 1 - Electrical Design and Standard For Commercial EstablishmentJasperNo ratings yet

As 1921 - 1976

As 1921 - 1976

Uploaded by

Sin Quee CheOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

As 1921 - 1976

As 1921 - 1976

Uploaded by

Sin Quee CheCopyright:

Available Formats

COPYRIGHT NOTICE

This material is electronically reproduced by ILI under license from

Standards Australia who retain full copyright in the document.

No part of the printed publication, nor any part of this electronic file,

may be reproduced or transmitted in any form, including transmittal

by e-mail, by file transfer protocol (FTP), or by being made part of a

network-accessible system, without the prior written permission of the

Publisher or ILI.

ILI makes no guarantees or warranties as to the correctness of the

document or as to the results arising from the purchase and use of

the document and is not responsible for problems in the delivery of

the document. Any difficulties or queries should be addressed to ILI

below.

In USA and Canada Contact:-

ILI INFODISK INC, 610 Winters Avenue, Paramus, NJ 07652

Toll Free 1-888-454-2688 or 201-986-1131 Fax: 201-986-7886 E-mail: sales@ili-info.com

Web: www.ili-info.com

In Rest of World Contact:-

ILI, Index House, Ascot, Berks, SL5 7EU, UK

: +44 (0)1344 636400 Fax: +44 (0)1344 291194 E-mail: standards@ili.co.uk

Web: www.ili.co.uk

Copyrighted material, for licensee's use only.

AS 1921—1976

Australian Standard

AIR CONDITIONING

AND VENTILATION IN SHIPS

CABINS AND

LIVING SPACES OF

MERCHANT SHIPS

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

The following scientific, industrial and governmental organizations and departments

were officially represented on the committee entrusted with the preparation of this

standard:

American Bureau of Shipping

Australian Chamber of Shipping

Australian Shipbuilders Association

Australian Shipbuilding Board

Australian Shipping Commission

Bureau Veritas

Commonwealth Scientific and Industrial Research Organization

Department of Defence

Department of Industry and Commerce

Department of Transport

Designers and Manufacturers of Marine Air Conditioning Systems

Institute of Marine Engineers

Lloyds Register of Shipping

Royal Institute of Naval Architects

This standard, prepared by Committee MS/22, Shipbuilding Details, was approved on

behalf of the Council of the Standards Association of Australia on 5 May 1976, and

was published on 1 January 1977.

Review of Australian Standards. To keep abreast of progress in industry, Australian Standards are subject

to periodic review and are kept up to date by the issue of amendments or new edit ions as necessary. It is

important therefore that Standards users ensure that they are in possession of the latest edit ion, and any

amendments thereto.

Full details of all Australi an Standards and related publications will be found in the Standards Australia

Catalogue of Publi cati ons; this informati on is supplemented each month by the magazine ‘The Australi an

Standard’, which subscribing members receive, and which gives detail s of new publications, new edit ions

and amendments, and of withdrawn Standards.

Suggesti ons for improvements to Australi an Standards, addressed to the head offi ce of Standards Australia,

are welcomed. Noti fi cati on of any inaccuracy or ambiguity found in an Australian Standard should be made

without delay in order that the matter may be investigated and appropriate action taken.

This standard was issued in draft form for public review as DR 75086.

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

AS 1921—1976

Australian Standard

AIR CONDITIONING

AND VENTILATION IN SHIPS

CABINS AND

LIVING SPACES OF

MERCHANT SHIPS

First publi shed . . . . . . . . . . . . . . . . . . . . . . . . 1976

Incorporating:

Amdt 1—1984

PUBLISHED BY STANDARDS AUSTRALIA

(STANDARDS ASSOCIATION OF AUSTRALIA)

1 THE CRESCENT, HOMEBUSH, NSW 2140

ISBN 0 7262 0999 6

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

AS 1921—1976 2

PREFACE

This standard was prepared by the Association’s Committee on Shipbuilding Details

at the request of the Whyalla Shipbuilding and Engineering Works.

The standard has been based on Swedish Standard VIS 376, Air Conditioning in

Cabins — Conditions and Calculation Fundamentals, with suitable changes for

Australian conditions. Assistance was obtained from CSIRO Division of Mechanical

Engineering in regard to conditions applying in Australia ports and acceptable

conditions of comfort. The air condition charts given in Appendix A were made

available from a CSIRO Division of Mechanical Engineering Technical Report (in

press) by Wooldridge M., and Kaschmeider D., entitled ‘Climatic Data for Several

Australian Locations for Use in Air Conditioning Design’.

The standard specifies the design conditions for vessels operating generally on the

Australian coast in terms of overall summer conditions, and zoned winter conditions.

Recommendations are also given in regard to the summer conditions for ships

operating in restricted geographical locations.

The standard is intended to apply to new ships, and to ships that are to be

extensively modified or converted.

Users of the standard should note that while observing the requirements of this

standard, they should at the same time ensure compliance with such statutory and

classification society requirements, rules and regulations as are applicable to the

individual ships concerned.

For requirements for air conditioning and ventilation of machinery control rooms

of merchant ships, reference should be made to AS 1925.

This standard requires reference to —

AS 1150 Artificial Illumination in Ships.

AS 1806 Seawater Temperatures for Cooling of Ships Machinery

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

3 AS 1921—1976

CONTENTS

SPECIFICATION Page

1 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . .. .. .. ... .. . . ... 4

2 Design Conditions . . . . . . . . . . . . . . . . . . .. . . .. ... .. . . ... 4

3 Calculation of Heat Gain and Heat Loss . . .. .. .. . .. .. . . . .. 5

4 Transmission . . . . . . . . . . . . . . . . . . . . . .. .. .. ... .. . . ... 5

5 Solar Heat Gain . . . . . . . . . . . . . . . . . . . .. .. .. ... .. . . ... 8

6 Heat from Persons . . . . . . . . . . . . . . . . . . .. .. .. ... .. . . .. . 10

7 Heat Gain from Lighting and Appliances . . .. .. .. . .. .. . . . .. 10

8 Heat Gain from Other Sources . . . . . . . . . .. .. .. . .. .. . . ... 11

9 Number of Persons . . . . . . . . . . . . . . . . . .. .. .. ... .. . . ... 11

10 Air Flow Calculation . . . . . . . . . . . . . . . . .. .. . . ... .. . . ... 11

11 Refrigeration Machinery . . . . . . . . . . . . . .. . . .. .. . .. . . ... 15

12 Air Movement in the Occupied Zone . . . . . .. .. .. ... . . . . .. . 16

13 Noise from Unit . . . . . . . . . . . . . . . . . . . .. .. .. ... .. . . ... 16

APPENDICES

A Recommendations for the Design of Air Conditioning Systems

for Ships Operating in Restricted Geographical Locations on

the Australian Coast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

B Termal Conductivities and Conductances . . . . . . . . . . . . . . . . . . 28

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

AS 1921—1976 4

STANDARDS ASSOCIATION OF AUSTRALIA

Australian Standard Specification

for

AIR CONDITIONING AND VENTILATION IN SHIPS—

CABINS AND LIVING SPACES OF MERCHANT SHIPS

1 SCOPE. This standard specifies the design conditions for the air conditioning of

cabins and living spaces of merchant ships operating on the Australian coast, and also

in all global waters except arctic and antarctic waters in winter, and provides data and

suitable methods of calculation for use in designing to meet these conditions.

The ‘cabins and living spaces’ referred to in this standard are intended to include

the following:

Cabins

Saloons and mess rooms

Smoke rooms and recreation room

Day rooms

Games room and gymnasium

Hospital and first aid rooms

Radio office

Other offices

Pantry.

Appropriate requirements are specified for other spaces which may be ventilated

from the air conditioning system, or which may affect the operation of the system.

The standard also includes recommendations for the design of air conditioning

systems for ships operating in restricted geographical locations on the Australian coast,

e.g. ports and adjacent waters. These are given in Appendix A.

2 DESIGN CONDITIONS.

2.1 Summer. The design conditions for summer shall be as follows:

(a) High enthalpy condition —

Outside: 35°C dry bulb and 30°C wet bulb

Inside: 29°C dry bulb with a wet bulb temperature less than 24°C.

(b) Low enthalpy condition —

Outside: 35°C dry bulb and 22°C wet bulb

Inside: 24°C dry bulb with a wet bulb temperature less than 19°C.

The system shall be designed to meet both sets of conditions.

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

5 AS 1921—1976

2.2 Winter.

2.2.1 Zones. For winter the ship shall be air conditioned for the operating zones

specified by the purchaser, as follows:

Zone A — Ships primarily operating in tropical waters

Zone B — Ships primarily operating on the Australian coast or in similar

temperature zones

Zone C — Ships operating in all waters except arctic and antarctic waters in

winter.

2.2.2 Conditions. The design conditions shall be as follows:

(a) Outside —

Zone A: Heating not required

Zone B: −1°C

Zone C: −15°C

(b) Inside —

All Zones: 22°C.

3 CALCULATION OF HEAT GAIN AND HEAT LOSS.

3.1 Summer Conditions. The calculation for summer conditions shall be based

on the heat gain from the following sources:

(a) Transmission (see Clause 4)

(b) Solar Heat Gain (see Clause 5)

(c) Heat from Persons and Food (see Clause 6)

(d) Heat Gain from Lighting and Appliances (see Clause 7)

(e) Heat Gain from Other Sources (see Clause 8).

3.2 Winter Conditions. The calculation for winter conditions shall be based on

the transmission (see Clause 4). Any solar heat gain, heat gain from persons and food,

lighting and appliances, or other heat sources, shall not be included.

4 TRANSMISSION.

4.1 Method of Calculation. The following formula should be used for calculating

the transmission loss or gain:

Pt = ∆t o [(A v × hv ) + (Ag × hg )]

where

Pt = transmission loss or gain, in watts

∆to = temperature difference to adjoining space (see Clause 2 for external

spaces, and Clause 4.2 for internal spaces), in degrees Celsius

Av = surface exclusive of any glass surface, in square metres

hv = heat transfer coefficient for the surface, in watts per square metre

kelvin (W/m2 .K)

Ag = free glass surface, in square metres

hg = heat transfer coefficient for glass surface, in watts per square metre

kelvin (W/m2 .K).

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

AS 1921—1976 6

TABLE 1

TEMPERATURE DIFFERENCES TO ADJOINING INTERNAL

SPACES

degrees Celsius

High Low

Zone C Zone B

enthalpy enthalpy

winter winter

Surface against adjoining space summer summer

ti − ta ti − t a

ta − t i ta − t i

°C °C

°C °C

Group 1

Deck above hot tanks 41 41 17 11

Deck and bulkhead against boil er room 26 31 17 11

Deck and bulkhead against engine room or

non-air- condit ioned gall ey 16 21 17 11

Deck and bulkhead against cargo space or equivalent

large spaces (venti lated wit h outside air) 11 16 37 23

Deck and bulkhead against laundry or like size spaces

(venti lated wit h outside air) 11 16 17 11

Group 2*

Deck and bulkhead against common sanitary spaces

and like (venti lated wit h outside air and heated) 6 8 0 0

Deck and bulkhead against private sanitary spaces and

li ke (ventil ated by exhaust of condit ioned air from

cabins) —

(a) with any part against exposed outl et surface 2 2.4 3 2

(b) not exposed 1 1.2 0 0

Bulkhead against all ey way (venti lated by exhaust of

condit ioned air fr om cabins) — 3 3.6 6 4

(a) adjoining engine room or boil er room or like 2 2.4 8 5

(b) not adjoining engine room or boil er room or like

* Adjoining spaces referr ed to in Group 2 with surfaces exposed to outside or cold or warm spaces are

assumed to have these surfaces insulated in the same way as air -conditi oned spaces.

LEGEND:

ta = temperature in adjoining space; ti = temperature in the air -conditi oned space.

4.2 Temperature Differences to Adjoining Internal Spaces. Unless otherwise

advised by the purchaser, the values given in Table 1 shall be used as the temperature

difference between adjoining air-conditioned and non-air conditioned internal spaces.

4.3 Insulation. Insulation shall be provided for all surfaces exposed to outside

conditions or adjoining warm or cold spaces. Increased insulation shall be provided for

surfaces adjoining hot pipes, boilers, etc.

The maximum heat transfer coefficients for surfaces commonly involved in air

conditioning calculations are given in Table 2. Allowance shall be made for any

deviations advised by the purchaser.

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

7 AS 1921—1976

TABLE 2

MAXIMUM HEAT TRANSFER COEFFICIENTS

Maximum heat transfer

Surface coeffi cient

W/ m2.K

Glass windows, single pane 4.7

Glass windows, double pane 3.5

Deck and bulkhead against alleyway, sanitary space, etc

(Table 1, Group 2) 2.3

Ship’s side, outer bulkhead or weather deck with sun awning 0.9

Deck and bulkhead against engine room, cargo space or 0.8

other non-air -conditi oned spaces

Deck and bulkhead against boil er room or near boil er in 0.7

engine room

Deck against open air or weather deck without sun awning 0.6

and deck above hot tanks

4.4 Heat Transfer Coefficient. The following formula should be used for

calculating the heat transfer coefficient:

where

h = heat transfer coefficient, in watts per square metre kelvin (W/m2 .K)

a = heat transfer coefficient for surface to air

= 80 W/m2.K for surfaces exposed to wind (≈ 20 m/s), outside

= 8 W/m 2.K for surfaces not exposed to wind (≈ 0.5 m/s), inside

d = thickness of material, in metres

λ = thermal conductivity, in watts per metre kelvin (W/m.K)

ML = thermal resistance in air layer, in square metre kelvins per watt (m 2 .K/W)

Mb = contact resistance between different layers of material, in square metre

kelvins per watt (m 2 .K/W)

µ = correction factor for steel frame

= 1.2 for insulation according to Fig. 1

= 1.45 for insulation according to Fig. 2.

NOTE: Figs 1 and 2 are intended to be typical examples. Factor µ must be derived for other types of

constr ucti on.

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

AS 1921—1976 8

Practical values of thermal conductivity for commonly used materials are given

in Appendix A.

For thermal resistance of a non-ventilated air layer, see Table 3.

The contact heat resistance between different layers of material is normally taken

as 0.09 m2 .K/W for common types of construction.

Fig. 1. PLAIN INSU LATION OF UN IFORM THICK NE SS

Fig. 2. CO RR UG ATED INSU LATION OF UNIFORM THICKN ES S

TABLE 3

THERMAL RESISTANCE OF NON-VENTILATED AIR LAYER

Boundary surfaces of Air thickness Thermal resistance

air layer mm m 2.K/W

Non-metall ic material 5 0.10

10 0.13

20 0.17

50 0.17

One surf ace of aluminium foil 5 0.17

10 0.30

20 0.43

50 0.47

Both surfaces of aluminium foil 5 0.17

10 0.34

20 0.47

50 0.52

4.5 Measurement of Transmission Surfaces. Height shall be measured from

steel deck to steel deck. Length shall be measured from steel bulkhead to steel

bulkhead where applicable, otherwise to the centre of the partition.

5 SOLAR HEAT GAIN. The following formula should be used for calculating

solar heat gain:

Ps = A v × h × ∆t r + Ag × G s

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

9 AS 1921—1976

where

Ps = solar heat gain, in watts

Av = surface exposed to solar radiation excluding glass windows (possible shadow

from overhanging deck or sun awning is to be considered), in square metres

h = heat transfer coefficient for the surface, in watts per square metre kelvin

(W/m2 .K)

∆t r = excess temperature (above the outside temperature), caused by solar radiation

on surfaces according to Table 4, in degrees Celsius

TABLE 4

EXCESS TEMPERATURE CAUSED BY SOLAR RADIATION

Excess temperature

Surface Time

°C

Hori zontal 0800 14

1000 25

1200 30

Vert ical dark 0800 28

1000 18

1200 —

Vert ical li ght 0800 14

1000 9

1200 —

Ag = free glass surface of window (possible shadow from overhanging deck or sun

awning is to be considered), in square metres

G s = additional heat gain from glass surface

= 350 W/m2 at 0800 hours

= 235 W/m2 at 1000 hours.

NOTE: If solar radiation reflecting glass is used, G s may be reduced.

The calculations shall be made as at 0800, 1000 and 1200 hours, allowing angles

of incidence of solar radiation of 30, 60 and 90 degrees, respectively, to the horizontal,

and the maximum value shall be taken. For the purposes of this standard, the afternoon

conditions shall be deemed to be covered by these calculations.

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

AS 1921—1976 10

6 HEAT FROM PERSONS AND FOOD.

6.1 Heat from Persons. The sensible and latent heats from persons shall be as

given in Table 5.

TABLE 5

HEAT EMITTED PER PERSON

Heat emitt ed per person, W

Typical Heat

Acti vity High enthalpy Low enthalpy

application type

condit ion (29°C) condit ion (24°C)

Low Cabin, TV room Sensible 50 70

Latent 50 30

Moderate Recreati on room, Sensible 54 74

mess room, Latent 86 66

pantri es

High Games room, Sensible 70 110

gymnasium Latent 230 190

6.2 Heat from Food. The heat gain from food in the saloons and mess rooms

shall be taken as 18 W per person (9 W sensible, 9 W latent).

7 HEAT GAIN FROM LIGHTING AND APPLIANCES.

7.1 Lighting. The heat gain from lighting shall be calculated from the rated

wattage of the lamps and fluorescent ballast provided for lighting purposes as advised

by the purchaser.

Where the rated output from lighting is not advised by the purchaser, the heat

from general lighting shall be calculated on the basis of the minimum illumination

levels specified for new ships in Table 1 of AS 1150, Artificial Illumination in Ships,

using a value of 8.5 W/m 2 of floor area per 100 lx, and an appropriate allowance shall

be made for special purpose lighting (this implies fluorescent lighting, and includes

ballast losses).

7.2 Appliances. The heat gain from appliances shall be calculated on the basis

of information supplied by the purchaser in regard to the type, number and output of

all heat producing appliances, their periods of operation, and whether they are provided

with an exhaust hood.

The heat gain shall be calculated at the value at which the appliance generates

sensible and latent heat under normal use at the time of peak cooling load, or in most

cases where a properly designed mechanical exhaust hood is fitted, at half the value.

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

11 AS 1921—1976

If the output from refrigerators, television sets or hot water urns is not stated, it

shall be calculated on the following basis:

(a) Refrigerators — 0.3 W per litre of storage capacity, continuous.

(b) Television sets — 250 W continuous, with an allowance of 2 W/m2 of floor

area for lighting during night hours, and in spaces without natural lighting.

(c) Hot water urns fitted with an effective exhaust hood — in accordance with

Table 6.

TABLE 6

HEAT GAIN FROM URNS

Heat gain, W

Heat type

10-l it re urn 20-l it re urn

Sensible 400 500

Latent 200 250

8 HEAT GAIN FROM OTHER SOURCES.

8.1 Air Ducts. The average rates of air temperature rise and air leakage for the

air distribution ducts shall be determined, and shall be taken into account when

calculating the necessary air flow for summer conditions for each space, and in

calculating the total system heat gain.

8.2 Fans. The heat gain from fans shall be included in the total system heat gain.

If a fan motor is outside the air stream, the heat gain shall be calculated as the shaft

power in watts. If the fan motor is inside the air stream, the heat gain shall be

calculated as the input power to the motor in watts.

8.3 Radio Offices. Unless otherwise advised by the purchaser, a heat gain of

1 kW shall be allowed in radio offices, exclusive of the radio transmitter for which it

is assumed that a separate exhaust duct will be provided.

9 NUMBER OF PERSONS. The number of persons to be accommodated shall be

calculated in accordance with Table 7.

10 AIR FLOW CALCULATION.

10.1 Volume of Space. Furniture, wardrobes, etc shall not be deducted in

calculating the gross volume of cabins and other spaces.

The air to the room shall be based upon given conditions with regard to the

character of surrounding surfaces. Consequently, spaces with the same volume may

have a different number of air changes, depending on the heat leakage through the

boundary surfaces, e.g. heated tanks, engine rooms or other bulkheads.

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

AS 1921—1976 12

TABLE 7

NUMBER OF PERSONS

Space Number to be accommodated

Cabins The number of persons normally living in the cabin*

Saloons, messrooms The number of persons who can be seated*

Smoke rooms, recreation rooms The number of persons who can be seated*

Dayrooms (captain and chief engineer) 4 persons

Dayrooms (chief off icer, second engineer, 3 persons

chief steward and other similar personnel)

Gymnasium, games room 4 persons

Hospit al The number of beds plus two

First aid room 2 persons

Radio and other off ices 2 persons unless otherwise stated by the purchaser

* As stated by the purchaser.

10.2 Supply Air for Cabins and Living Spaces.

10.2.1 Cabins and living spaces except radio offices and pantries. The supply

air shall be calculated using whichever of the following criteria gives the highest

value:

(a) Necessary air flow for summer conditions (having regard to Clause 10.7).

(b) Necessary air flow for winter conditions.

(c) The air flows given in Table 8 at an air density of 1.20 kg/m 3.

NOTE: The air flow is usuall y determined by the ‘necessary air flow for summer condit ions’.

10.2.2 Radio offices. Sufficient air shall be supplied to maintain the summer

and winter design conditions up to a maximum of 12 air changes per hour, with a

minimum air flow per person of 17 litres/s, and a minimum of 6 air changes per hour.

10.2.3 Pantries. The following conditions shall apply to pantries:

(a) At least 5 air changes per hour shall be supplied.

(b) With all equipment and appliances except hot water urns not operating, the

summer design conditions shall be met.

(c) With all equipment and appliances operating, the summer design

conditions shall be met up to a nominal maximum of 8 air changes per

hour, beyond which the temperatures may be permitted to rise to a

maximum of 6 K above the design temperatures.

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

13 AS 1921—1976

TABLE 8

SUPPLY AIR FLOW

Minimum air fl ow Minimum number

Area per person of air changes

li tres/s per hour

Cabins 17 3

Saloons and messrooms 7 5

Dayrooms 7 4

Smoke rooms and 17 6

recreati on rooms

Gymnasium and 17 6

games room

Hospit al and 17 4

fi rst aid room

Other off ices 17 4

10.3 Supply Air for Associated Spaces.

10.3.1 Wheel houses. Where wheel houses are ventilated with air taken from

the air-conditioning system, the design dry bulb temperature condition should be met

using a minimum of 4 air changes per hour up to a nominal maximum of 8 air changes

per hour, beyond which the temperature may be permitted to rise to maximum of 6 K

above the design temperature.

10.3.2 Laundries. Where laundries are ventilated with air taken from the

air-conditioning system, the following conditions should be met:

(a) At least 4 air changes per hour should be applied.

(b) With all equipment and appliances not operating, the summer design

conditions should be met.

(c) With all equipment and appliances operating, the summer design dry bulb

temperature condition should be met up to a nominal maximum of 8 air

changes per hour, beyond which the temperature may be permitted to rise

to a maximum of 6 K above the design temperature.

10.3.3 Change rooms and store rooms. Where change rooms and store rooms

are ventilated from the air-conditioning system, they should be supplied with at least

4 air changes per hour up to a maximum of 8 air changes per hour.

10.4 Air Balance. A positive air balance shall be maintained between supply and

exhaust air, i.e. a slight positive pressure shall be maintained in all air conditioned

spaces and associated corridors.

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

AS 1921—1976 14

10.5 Exhaust Air.

10.5.1 Air not to be recirculated. Air-conditioned spaces which are the source

of smells, steam or other contaminants, such as pantries, sanitary spaces, and hospitals,

shall be exhausted to atmosphere, and shall be held at a slightly lower pressure than

that obtaining in the adjoining accommodation. In addition, urns, clothes dryers and

other equipment producing steam should be efficiently exhausted to atmosphere.

10.5.2 Sanitary spaces. The quantity of air to be exhausted from sanitary

spaces shall be calculated on the basis of Table 9.

TABLE 9

EXHAUST AIR QUANTITIES

Space Minimum exhaust air quantit ies

Common sanit ary spaces, containing bath, 10 air changes per hour

shower, uri nal and water closet

Private sanit ary spaces, att ached to private

dayrooms and cabins sleeping not more than

3 persons and —

(a) which may include all of water closet, 17 li tr e/s

handbasin, and/or shower

(b) which includes only a water closet 9 lit re/s

10.5.3 Adjoining ventilated spaces. Adjoining ventilated spaces shall be

effectively isolated from air-conditioned spaces.

Adjoining ventilated spaces, except engine rooms and similar spaces, should be

exhaust ventilated and held at a pressure slightly lower than the accommodation.

Where such spaces need large air quantities, e.g. as in galleys, they should be isolated

from the accommodation by airtight boundaries and self-closing doors or air locks, and

provided with a separate mechanical supply of ventilation air.

Engine rooms and similar spaces which are required to be ventilated at a pressure

higher than the accommodation should be effectively isolated from the accommodation

by airtight boundaries and air locks with self-closing doors.

10.6 Fresh Air Requirements.

10.6.1 Determination of requirements. For each fan unit in the air-conditioning

system in which the total flow of fresh air into the unit is expected to be substantially

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

15 AS 1921—1976

constant, the minimum fresh air requirements shall be determined by the greatest of

the following:

(a) The requirement to maintain a positive air balance (see Clause 10.4).

(b) 1.5 changes of fresh air per hour calculated for the volume of all spaces

directly ventilated by one fan unit.

(c) The following personal requirements based on the maximum simultaneous

number of persons in all spaces served by the fan unit:

Number of persons Fresh air requirement

served by fan unit litre/s

1 .... .. .. . . . .. . . . . . . . . . . . . . . . 17

2 .... .. .. . . . .. . . . . . . . . . . . . . . . 21

3 .... .. .. . . . .. . . . . . . . . . . . . . . . 25

4 .... .. .. . . . .. . . . . . . . . . . . . . . . 29

More than 4 . . .. . . . .. . . . . . . . . . . 7 per person

10.6.2 Applications. The basis given in Clause 10.6.1 shall apply to constant

volume single duct systems, terminal reheat systems and dual duct systems, and to

variable air volume systems where means are provided to keep the flow of fresh air

into the system constant down to the level where the fresh air flow comprises

100 percent of the reduced air flow in the system.

In variable air volume systems, which also permit the flow of fresh air into the

system to vary, the rates in Clause 10.6.1 (b) and (c) shall be doubled for full flow

conditions, provided that this does not result in the total air flow as calculated in

Clause 10.2 being exceeded, in which case the system shall be based on 100 percent

fresh air.

10.7 Temperature of Supply Air. The following temperature limits shall be used

when calculating the necessary air flow for summer conditions:

(a) Where the outside air condition corresponds to the high enthalpy summer

condition, the temperature of the supply air, measured in the core of the

air flow 300 mm from the supply opening, shall be not more than 10 K

lower than the cabin temperature.

(b) Where the outside air condition corresponds to the low enthalpy summer

condition, the temperature of the supply air, measured in the core of the

air flow 300 mm from the supply opening, shall not be less than 12°C.

11 REFRIGERATION MACHINERY. The refrigeration machinery shall comply

with the following requirements:

(a) For a sea water system, the size of the condenser shall be based on an inlet

water temperature of 33°C, and the compressor motor shall be capable of

driving the compressor at an inlet water temperature of 35°C.

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

AS 1921—1976 16

(b) For a fresh water system, the size of the condenser shall be based on an

inlet water temperature of 36°C, and the compressor motor shall be

capable of driving the compressor at an inlet water temperature of 38°C.

The appropriate fouling factor given in Table 10 shall be used for calculating the

heat transfer coefficient of the condenser.

An air density of 1.20 kg/m 3 shall be used in calculating the cooling effect.

12 AIR MOVEMENT IN THE OCCUPIED ZONE. The air velocity in the

occupied zone of a room not being a pantry shall be not more than 0.3 m/s. The

occupied zone shall be the berths and the normal seating locations.

13 NOISE FROM UNIT. The internal and external sound levels shall be in

accordance with AS 2254, Recommended Noise Ratings for Various Areas of

Occupancy in Vessels.

TABLE 10

FOULING FACTOR (UNITS OF RESISTANCE) FOR CONDENSERS

Thermal resistance

Application of condenser

m 2.K/W

Sea water system 0.000 35

Fresh water system 0.000 086

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

17 AS 1921—1976

APPENDIX A

RECOMMENDATIONS FOR THE DESIGN OF AIR

CONDITIONING SYSTEMS FOR SHIPS OPERATING

IN RESTRICTED GEOGRAPHICAL LOCATIONS ON

THE AUSTRALIAN COAST

A1 GENERAL. Where a vessel is to operate in a restricted geographical location

on the Australian coast, the purchaser may specify summer design conditions suitable

for the restricted location in which the vessel is to operate.

The changed design conditions should be stated in the form given in Clause 2(a),

although in many locations it may be possible to avoid the need to state two design

conditions. Table 1 and 5 should be interpolated or extrapolated by the purchaser for

the specific design conditions. The other criteria should also be checked to ensure that

they remain valid for the specified conditions in the restricted location. In particular,

Clause 11 should be reviewed having regard to AS 1806, Seawater Temperatures for

Cooling of Ships Machinery.

Alteration of the basic design conditions as given in Clause 2.1 is not

recommended if there is any reasonable likelihood that the vessel may be used by the

purchaser outside the restricted geographical location, or may later be sold for such

use, as this will require re-sizing of the air distribution system, which is both difficult

and expensive. In cases of doubt, the full-size air distribution system should be

installed.

A2 METEOROLOGICAL DATA. Suitable meteorological data to guide the

purchaser in the selection of suitable design conditions for the principal Australian

ports are given in the charts of Figs A1 to A9. Other meteorological data may be used.

NOTE: The wet bulb temperature used in these charts was that measured by the Australi an Bureau

of Meteorology, and no correction factor has been applied. The data on the charts have been

normalized to 8760 hours/year base.

A3 RECOMMENDED DESIGN CRITERIA. For the ports of Sydney, Melbourne,

Adelaide and Perth and adjacent coast lines, the plant may be designed using the low

enthalpy summer design condition given in Clause 2.1(b), the high enthalpy condition

being disregarded.

For those areas where the meteorological data indicate that there are more than

50 h in an average year during which the dry bulb temperature exceeds 35°C or the

wet bulb temperature exceeds 25°C, the high enthalpy design condition for summer

(see Clause 2.1(a)) may be selected by the purchaser with the aim of maintaining an

inside condition of dry bulb temperature at least 5 K above the wet bulb temperature

for all but about 50 h in the year, the design condition of inside dry bulb temperature

being the maximum given by the following formulas:

ti = tw − 1

ti = 0.6td + 3

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

AS 1921—1976 18

where

ti = inside dry bulb temperature, in degrees Celsius

tw = an outside wet bulb temperature which is not reasonably expected to be

exceeded for more than 50 h per year, in degrees Celsius

td = an outside dry bulb temperature which is not reasonably expected to be

exceeded for more than 50 h per year, in degrees Celsius.

The low enthalpy design condition for summer should not be altered in these

areas.

For those areas where the meteorological data indicate that there are less than 50 h

in an average year during which the dry bulb temperature exceeds 35°C or the wet

bulb temperature exceeds 25°C, a single summer design condition may be selected by

the purchaser with the aim of maintaining an inside dry bulb temperature of 24°C with

a wet bulb temperature not exceeding 19°C for all but about 50 h in the year.

For other areas, the purchaser should evaluate the conditions from the

meteorological data given in Figs A1 to A10 (or other data) and determine the revised

summer design conditions.

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

19 AS 1921—1976

Fig. A1. AIR CO ND ITION CH AR T — SYD NE Y

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

AS 1921—1976 20

Fig. A2. AIR CO ND ITION CH AR T — MELBO UR NE

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

21 AS 1921—1976

Fig. A3. AIR CO ND ITION CH AR T — BRISB AN E

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

AS 1921—1976 22

Fig. A4. AIR CO ND ITION CH AR T — ADE LAIDE

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

23 AS 1921—1976

Fig. A5. AIR CO ND ITION CH AR T — PER TH

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

AS 1921—1976 24

Fig. A6. AIR CO ND ITION CH AR T — HOB AR T

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

25 AS 1921—1976

Fig. A7. AIR CO ND ITION CH AR T — DAR WIN

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

AS 1921—1976 26

Fig. A8. AIR CO ND ITION CH AR T — TOWNS VILLE

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

27 AS 1921—1976

Fig. A9. AIR CO ND ITION CH AR T — POR T HED LAND

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

AS 1921—1976 28

APPENDIX B

THERMAL CONDUCTIVITIES AND CONDUCTANCES

B1 THERMAL CONDUCTIVITIES OF COMMONLY USED CONSTRUCTION

MATERIALS.

Densit y Thermal Normal Practi cal

of conducti vity moisture value of

dry of dry content thermal

material material by mass conducti vity

Material λ

at normal

moisture

content

kg/m 3 W/ m.K percent W/ m.K

Concrete 2300 0.93 2 1.7

Site cast lightweight concrete, 1200 0.29 2 0.35

in dry premises 500 0.116 2 0.14

400 0.093 2 0.12

300 0.082 2 0.09

200 0.058 2 0.08

Lightweight concrete ballasted with 700 0.17 4 0.21

expanded burnt clay, internal 600 0.14 4 0.17

insulati on 500 0.12 4 0.15

Aluminium 200

Mild steel 50

Windows glass 2600 0.81

Wood (heat fl ow at ri ght angles

to fi bres) —

fi r, pine 500 0.12 16 0.14

beech, oak 700 0.14 18 0.16

Chipboards 600 0.13 10 0.14

400 0.11 10 0.12

Wood fi bre sheets—

hard 1000 0.12 8 0.13

medium hard 600 0.0075 9 0.08

soft 300 0.047 10 0.052

Cork sheets (expanded) 140 0.041 3 0.04

(Notes 1 and 2) 210 0.047 3 0.05

Cork flooring 500 0.075 10 0.08

Mineral wool (Notes 1 and 3)

glass wool —

fi bre dia. 6 µm 15-100 0.035 1 0.05

fi bre dia. 20 µm 40-200 0.035 1 0.05

slag wool, rock wool 35-200 0.035 1 0.05

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

Copyrighted material, for licensee's use only.

29 AS 1921—1976

B1 (continued).

Densit y Thermal Normal Practi cal

of conducti vity moisture value of

dry of dry content thermal

material material by mass conducti vity

Material λ

at normal

moisture

content

kg/m 3 W/ m.K percent W/ m.K

Mineral fi bre sheets 400 0.041 0.06

Asbestos ship board consolidated 576 0.112

fr om a combinati on of asbestos fibre, 720 0.13

hydrated li me and sil ica

Sprayed li mpet asbestos 120 0.045 0.06

Semtex and simil ar 0.75

levell ing compounds

NOTES:

1. The indicated thermal conducti vity only applies where a fl ow of air which can make an appreciable

diff erence to the insulati on cannot arise in the material or flow through it.

2. The thermal conducti vity indicated is only vali d where no air flow is possible in the joints between

the sheets.

3. If the insulati on is compressed the thickness in the compressed state is to be used as the basis for the

calculation of the heat tr ansfer coeffi cient.

B2 THERMAL CONDUCTANCE OF FLOOR COVERINGS (λ/d).

Carpet and fibrous underlay = 2.7 W/m2

Cork tile—

3 mm = 26 W/m2 .K

6 mm = 13 W/m2 .K

Rubber or plastic tile, 3 mm = 240 W/m2 .K

Ceramic tile or terrazzo, 25 mm = 71 W/m 2 .K.

Copyrighted material, for licensee's use only.

Single user license only, copying prohibited.

You might also like

- As 3100 General Requirements For Electrical EquipmentsDocument9 pagesAs 3100 General Requirements For Electrical EquipmentsJosh Zhang0% (1)

- AS1755-2000 Conveyors Safety RequirementsDocument91 pagesAS1755-2000 Conveyors Safety RequirementsVinceS2100% (8)

- As 2758.1-1998 Concrete AggregatesDocument28 pagesAs 2758.1-1998 Concrete AggregatesArogya Raju Pudhota100% (3)

- Boating Skills and Seamanship, 14th EditionFrom EverandBoating Skills and Seamanship, 14th EditionNo ratings yet

- Wig Hoverwing 19xrw-RedDocument5 pagesWig Hoverwing 19xrw-RedFloreia SileNo ratings yet

- Australian Standard: Liquefied Natural Gas-Storage and HandlingDocument10 pagesAustralian Standard: Liquefied Natural Gas-Storage and HandlingSalim Chohan100% (1)

- 3774Document8 pages3774Valter AraujoNo ratings yet

- As 1746-1991Document15 pagesAs 1746-1991Quantudogon DangNo ratings yet

- As 1160 1996 Bituminous Emulsions For The Construction and Maintenance of PavementsDocument7 pagesAs 1160 1996 Bituminous Emulsions For The Construction and Maintenance of PavementsaskarahNo ratings yet

- NZS 2295-2006 PDFDocument10 pagesNZS 2295-2006 PDFElmira Siroospour50% (2)

- As 1576.1-2010 Scaffolding General RequirementsDocument69 pagesAs 1576.1-2010 Scaffolding General Requirementsanon_399144888100% (1)

- Australian Standard: Pipe Threads of Whitworth Form Part 1: Sealing Pipe Threads (Metric Units)Document7 pagesAustralian Standard: Pipe Threads of Whitworth Form Part 1: Sealing Pipe Threads (Metric Units)Sancb0% (1)

- Zonestar P802CR2 Reprap Prusa I3 English User ManualDocument54 pagesZonestar P802CR2 Reprap Prusa I3 English User ManualAlexander VasNo ratings yet

- Mitchell 6500 ManualDocument64 pagesMitchell 6500 Manualcanelo45No ratings yet

- As 1692 Tanks For Flammable Combustible LiquidsDocument25 pagesAs 1692 Tanks For Flammable Combustible LiquidsNacho Orden MoyaNo ratings yet

- AS - NZS 4200.1-1994 MaterialsDocument15 pagesAS - NZS 4200.1-1994 MaterialsMorten PedersenNo ratings yet

- Commercial Yacht Code - LY3Document192 pagesCommercial Yacht Code - LY3naufragatoNo ratings yet

- As NZ 2743 1996 Valves For CNGDocument67 pagesAs NZ 2743 1996 Valves For CNGTim WilsonNo ratings yet

- As 1576.4 Scaffolding Suspended Scaf PDFDocument17 pagesAs 1576.4 Scaffolding Suspended Scaf PDFtheNo ratings yet

- Australian Standard: Structural Steel Hollow SectionsDocument26 pagesAustralian Standard: Structural Steel Hollow Sectionstedi mardetaNo ratings yet

- AS 1170-Part 1Document7 pagesAS 1170-Part 1Thaiminh Vo33% (3)

- AS - NZS 4200.2-1994 Installation RequirementsDocument11 pagesAS - NZS 4200.2-1994 Installation RequirementsMorten PedersenNo ratings yet

- AS1755-1986 ConveyorDocument66 pagesAS1755-1986 Conveyorjustinxxuu86No ratings yet

- LY3 - Final VersionDocument190 pagesLY3 - Final VersionAlexNo ratings yet

- AS 1273-1991 (UPVC Downpipes and Fittings For Rainwater)Document11 pagesAS 1273-1991 (UPVC Downpipes and Fittings For Rainwater)Sanil SamiNo ratings yet

- As 2159 Supp1-1996 Piling-Design and Installation-GuidelinesDocument36 pagesAs 2159 Supp1-1996 Piling-Design and Installation-GuidelinesArogya Raju PudhotaNo ratings yet

- As 1755-1986 Conveyors-Design, Construction, Installation, and Operation-Safety RequirementsDocument14 pagesAs 1755-1986 Conveyors-Design, Construction, Installation, and Operation-Safety RequirementsallovidNo ratings yet

- Concrete LNG Terminal Structures and Containment Systems: Standard DNV-OS-C503Document58 pagesConcrete LNG Terminal Structures and Containment Systems: Standard DNV-OS-C503Vivi GouriotiNo ratings yet

- Australian Standard: Roof TilesDocument10 pagesAustralian Standard: Roof TilesVeetoau Joseph100% (1)

- AS 1735.7-1998 Stairway LiftsDocument14 pagesAS 1735.7-1998 Stairway LiftsMorten PedersenNo ratings yet

- Australian Standard: SAA Lift Code Part 11: Fire-Rated Landing DoorsDocument0 pagesAustralian Standard: SAA Lift Code Part 11: Fire-Rated Landing DoorsGuha ArnabNo ratings yet

- 2903Document5 pages2903iso9002No ratings yet

- MSN - 1792 - Edition - 2 (LY2 Code)Document179 pagesMSN - 1792 - Edition - 2 (LY2 Code)kees1961No ratings yet

- Statutory Equipment-Part 10Document223 pagesStatutory Equipment-Part 10ANTON NEAGUNo ratings yet

- AS 1735.3-2002 Passenger & Goods Lifts - ElectrohydraulicDocument88 pagesAS 1735.3-2002 Passenger & Goods Lifts - ElectrohydraulicMorten PedersenNo ratings yet

- As 1666.2-1995 Wire-Rope Slings - Care and UseDocument25 pagesAs 1666.2-1995 Wire-Rope Slings - Care and UseThaiminh Vo100% (1)

- As 1160-1996Document18 pagesAs 1160-1996Alexandru LetNo ratings yet

- National Standard For Commercial Vessels: Australian Transport CouncilDocument26 pagesNational Standard For Commercial Vessels: Australian Transport CouncilCarl FranksNo ratings yet

- AS 1735.8-1986 Inclined LiftsDocument28 pagesAS 1735.8-1986 Inclined LiftsMorten PedersenNo ratings yet

- CFTS Exep Ins Spe 00000 02 - R01Document15 pagesCFTS Exep Ins Spe 00000 02 - R01Kenneth EmbeleNo ratings yet

- Builders PlateDocument22 pagesBuilders PlateCostin RotaruNo ratings yet

- GS126-2 Air-Cooled Heat Exchangers To API 661Document46 pagesGS126-2 Air-Cooled Heat Exchangers To API 661DH B75% (4)

- 1014-1986 - Gauging of Metric Screw ThreadsDocument41 pages1014-1986 - Gauging of Metric Screw ThreadsMark Carroll-ChiltsNo ratings yet

- Australian Standard: National Plumbing and Drainage Part 1.1: Water Supply - Performance RequirementsDocument8 pagesAustralian Standard: National Plumbing and Drainage Part 1.1: Water Supply - Performance RequirementsVăn AnhNo ratings yet

- Australian Standard: Design of Steel Lattice Towers and MastsDocument7 pagesAustralian Standard: Design of Steel Lattice Towers and Mastsalsager14No ratings yet

- Australian Offshore Support Vessel Code of Safe Working PracticeDocument81 pagesAustralian Offshore Support Vessel Code of Safe Working PracticeHIPAP100% (1)

- Spwcode TocDocument12 pagesSpwcode TocKweku AsieduNo ratings yet

- ALU EN 2017 CompletesetDocument216 pagesALU EN 2017 CompletesetNico LomibaoNo ratings yet

- 4037 PDFDocument10 pages4037 PDFMin MinNo ratings yet

- As Nzs 1576-1-2010 ScaffoldingDocument8 pagesAs Nzs 1576-1-2010 ScaffoldingAnil KumarNo ratings yet

- Ameron 2000m and 7000mDocument28 pagesAmeron 2000m and 7000mhadrijkNo ratings yet

- Agma 926-C99Document16 pagesAgma 926-C99Mehul Bansal100% (2)

- Attachment 1 Dry Dock Specs 2019Document51 pagesAttachment 1 Dry Dock Specs 2019GabrielNo ratings yet

- Nema Ics 4Document34 pagesNema Ics 4Egyptman Jan100% (1)

- 02-747 Part 3Document38 pages02-747 Part 3jra9090No ratings yet

- Abs Condition of ClassDocument16 pagesAbs Condition of ClassJon LopezNo ratings yet

- Aviation Weather: FAA Advisory Circular (AC) 00-6BFrom EverandAviation Weather: FAA Advisory Circular (AC) 00-6BRating: 3.5 out of 5 stars3.5/5 (11)

- Aviation Weather: FAA Advisory Circular (AC) 00-6B (Blackridge Press FAA Series)From EverandAviation Weather: FAA Advisory Circular (AC) 00-6B (Blackridge Press FAA Series)No ratings yet

- Stirling Cycle Engines: Inner Workings and DesignFrom EverandStirling Cycle Engines: Inner Workings and DesignRating: 3 out of 5 stars3/5 (1)

- FINAL - Exhaust Fan Control Systems For LaboratoriesDocument53 pagesFINAL - Exhaust Fan Control Systems For LaboratoriesSin Quee CheNo ratings yet

- Honeywell DDC Panel ManualDocument512 pagesHoneywell DDC Panel ManualSyed ZakiuddinNo ratings yet

- Bahamas RegulationsDocument44 pagesBahamas RegulationsSin Quee CheNo ratings yet

- Eeha Arcia White Paper Ver 1.1 Jan16Document66 pagesEeha Arcia White Paper Ver 1.1 Jan16Sin Quee CheNo ratings yet

- Australian - New Zealand StandardDocument6 pagesAustralian - New Zealand StandardSin Quee CheNo ratings yet

- Mep 2020 NovDocument1 pageMep 2020 NovAnakin SkywalkerNo ratings yet

- Schedule of Loads and ComputationDocument3 pagesSchedule of Loads and ComputationLeovigildo I. LumioNo ratings yet

- DMW PowerDocument4 pagesDMW PowerHari Krishna.MNo ratings yet

- Uros Hand Made Reed Floating IslandsDocument12 pagesUros Hand Made Reed Floating IslandstudorimaNo ratings yet

- Plumbing - Lec.01Document63 pagesPlumbing - Lec.01Omed Juma'aNo ratings yet

- MEP Co-Ordination Check List.Document6 pagesMEP Co-Ordination Check List.nandeeshNo ratings yet

- Naphtthenes ASTM D 1319Document8 pagesNaphtthenes ASTM D 1319Hassan HaiderNo ratings yet

- SG City 63A Multipager - 12.07.2022Document24 pagesSG City 63A Multipager - 12.07.2022HarneetNo ratings yet

- Schneider Short Circuit CalculationDocument36 pagesSchneider Short Circuit Calculationincobar100% (2)

- Brosur ToyotaDocument8 pagesBrosur Toyotayuliani fitriaNo ratings yet

- Fyp 001Document2 pagesFyp 001Moazzam IrshadNo ratings yet

- M 385 ContentDocument47 pagesM 385 ContentSalmanul FareziNo ratings yet

- Transformer ModuleDocument35 pagesTransformer ModuleHasyim PribadiNo ratings yet

- Lec 28Document18 pagesLec 28elene shopovaNo ratings yet

- Wiring Diagram of Front SAM Control Unit With Fuse and Relay Module (N10 - 1) 2Document5 pagesWiring Diagram of Front SAM Control Unit With Fuse and Relay Module (N10 - 1) 2Сергей АзаренкоNo ratings yet

- Basic Electronics: Submitted To: Ma'am Qudsia Memon Submitted by Usama Memon 19ME138Document10 pagesBasic Electronics: Submitted To: Ma'am Qudsia Memon Submitted by Usama Memon 19ME138Dhanaish kumarNo ratings yet

- Experiment No. 2Document7 pagesExperiment No. 2noteasytobebooNo ratings yet

- Basics of Low Voltage System & Circuit Breakers: A&D / BD-CD June 04Document17 pagesBasics of Low Voltage System & Circuit Breakers: A&D / BD-CD June 04kodandaram100% (1)

- Green Roof 2021-S1Document39 pagesGreen Roof 2021-S1Dimas Kharizmi Albar IPBNo ratings yet

- Electric EquipmentDocument221 pagesElectric EquipmentCarlos Andrés Sánchez Vargas100% (1)

- CH 13Document9 pagesCH 13indaNo ratings yet

- Senturian BrochureDocument5 pagesSenturian BrochureMaryleen Ndu MlynNo ratings yet

- 10 Govt Model Question I Science emDocument9 pages10 Govt Model Question I Science emVelu ManiNo ratings yet

- CBSE Class 8 Science WorksheetDocument3 pagesCBSE Class 8 Science Worksheetravilulla60% (5)

- Manufacture of Linear Alkyl Benzene Sulphonic Acid (Labsa) : S. B. Dayanethi (Reg. No: 810018239008)Document137 pagesManufacture of Linear Alkyl Benzene Sulphonic Acid (Labsa) : S. B. Dayanethi (Reg. No: 810018239008)9024 MUGESHNo ratings yet

- Half Wave and Full Wave RectifierDocument6 pagesHalf Wave and Full Wave RectifierBilal KhanNo ratings yet

- SUBTOPIC 1 - Electrical Design and Standard For Commercial EstablishmentDocument30 pagesSUBTOPIC 1 - Electrical Design and Standard For Commercial EstablishmentJasperNo ratings yet