Professional Documents

Culture Documents

BG-DWG-2017-0171-R0 AL TATWIR CONTRACTING 10-18-2017-Layout1

BG-DWG-2017-0171-R0 AL TATWIR CONTRACTING 10-18-2017-Layout1

Uploaded by

DanielCopyright:

Available Formats

You might also like

- Aashto HB-17 Division Ii Sec 22Document6 pagesAashto HB-17 Division Ii Sec 22sofiane mokhtariNo ratings yet

- Section 034900 Glass Fiber Reinforced Concrete (EI 2017-04-02)Document13 pagesSection 034900 Glass Fiber Reinforced Concrete (EI 2017-04-02)Nagarjuna MuthineniNo ratings yet

- G+12 Design Basis ReportDocument38 pagesG+12 Design Basis ReportvinujohnpanickerNo ratings yet

- BG-DWG-2017-0171-R0 AL TATWEER CONTRACTING 30-OCT-2017-Layout1Document1 pageBG-DWG-2017-0171-R0 AL TATWEER CONTRACTING 30-OCT-2017-Layout1DanielNo ratings yet

- NCMA Annotated D&C ManualDocument306 pagesNCMA Annotated D&C ManualestanilorenteNo ratings yet

- DVC Collaborating Plate Installation ProcedureDocument17 pagesDVC Collaborating Plate Installation ProcedureScribdTranslationsNo ratings yet

- 720097-8310-SP-0003 (En) - 1.0 - Specification For GroutingDocument9 pages720097-8310-SP-0003 (En) - 1.0 - Specification For Groutingjohn.woosey48No ratings yet

- Ethane Furnace Erection SequenceDocument5 pagesEthane Furnace Erection SequenceAleem QureshiNo ratings yet

- The Ashenheim Residence - Structural Package - 061623Document45 pagesThe Ashenheim Residence - Structural Package - 061623LSF StructuresNo ratings yet

- Section 031100 FormworkDocument10 pagesSection 031100 Formwork刘盘石No ratings yet

- WMS-Cable Tray & TrunkingDocument3 pagesWMS-Cable Tray & TrunkingLeoj Saliw-an PalaoagNo ratings yet

- Annexure 24-As-Built RequirementsDocument17 pagesAnnexure 24-As-Built RequirementsTayyab KhanNo ratings yet

- Setc - WRKS - RS - 264 - Hyd - DRW - Sag - 2265 - E00 - en - Final 240109Document6 pagesSetc - WRKS - RS - 264 - Hyd - DRW - Sag - 2265 - E00 - en - Final 240109Sanjay SwamiNo ratings yet

- TS For 33kv Transmission LineDocument19 pagesTS For 33kv Transmission LineRamaKrishna ANo ratings yet

- JFD Paint Schedules DivingDocument16 pagesJFD Paint Schedules DivingakashmalayiNo ratings yet

- Arch Girder - Repair Calculation SheetDocument74 pagesArch Girder - Repair Calculation Sheetmohamed ellithyNo ratings yet

- High 5 PQDocument175 pagesHigh 5 PQsyed hadiNo ratings yet

- Technical Requirement For Pre-Engineered Building Works: M/S Design SanyojakaDocument4 pagesTechnical Requirement For Pre-Engineered Building Works: M/S Design SanyojakaHARSHADNo ratings yet

- RFIs To Date - 120823Document5 pagesRFIs To Date - 120823Amogh SwamyNo ratings yet

- Calculation NoteDocument51 pagesCalculation NoteALBERTNo ratings yet

- Release Note Gen 2023 v1.1Document11 pagesRelease Note Gen 2023 v1.1Aleksiey PellicciaNo ratings yet

- E-Construct: Design Basis ReportDocument16 pagesE-Construct: Design Basis ReportAdNo ratings yet

- TMS 402 - Chapter 1Document4 pagesTMS 402 - Chapter 1Alina ShresthaNo ratings yet

- Drying and Cooling Plant ReportDocument47 pagesDrying and Cooling Plant ReportMonsur AlamNo ratings yet

- Bac5583 Process For Potting InsertsDocument54 pagesBac5583 Process For Potting InsertsdkirNo ratings yet

- DBR of 2PX8 Table 30D 0.5 NGL Ground Mount MMSDocument8 pagesDBR of 2PX8 Table 30D 0.5 NGL Ground Mount MMSSalauddinAnsariNo ratings yet

- E-Construct: Design Basis ReportDocument16 pagesE-Construct: Design Basis ReportKuldeepLalwaniNo ratings yet

- Det 1020 PDFDocument1 pageDet 1020 PDFLaurence SarmientoNo ratings yet

- Detailed Structural Analysis and Design: NSEC SS Outdoor Lighting PostDocument19 pagesDetailed Structural Analysis and Design: NSEC SS Outdoor Lighting PostArchilles P. Adverderada100% (1)

- Moti SS 421Document22 pagesMoti SS 421jennifergiannouNo ratings yet

- Material Approval & Specification Comparison SheetDocument3 pagesMaterial Approval & Specification Comparison Sheetfrancisbautista100% (1)

- D1D2-MAR-A-0348 Rev.00Document54 pagesD1D2-MAR-A-0348 Rev.00francisbautistaNo ratings yet

- SKEB-ED-MS-003 (Method Statement For Reinforcement Work, 08.09.2021)Document174 pagesSKEB-ED-MS-003 (Method Statement For Reinforcement Work, 08.09.2021)Tira LakNo ratings yet

- SS RailingDocument27 pagesSS RailingPrasad kapureNo ratings yet

- Detailed Structural Analysis and Design: MAEC SS Outdoor Lighting PostDocument19 pagesDetailed Structural Analysis and Design: MAEC SS Outdoor Lighting PostArchilles P. AdverderadaNo ratings yet

- Design Long Hand Flanged Beam PDFDocument66 pagesDesign Long Hand Flanged Beam PDFMauricio Bustamante HuaquipaNo ratings yet

- BS 8110 ETAbsDocument63 pagesBS 8110 ETAbsnabnaj100% (1)

- Design Calculation of UMW INDUSTRIES WAREHOUSE R00Document28 pagesDesign Calculation of UMW INDUSTRIES WAREHOUSE R00Việt QuốcNo ratings yet

- Comm BLDG ReportDocument40 pagesComm BLDG Reportsafsf100% (1)

- D-Bottom Bracket Anchor DesignDocument8 pagesD-Bottom Bracket Anchor Designmayeshayesh83No ratings yet

- Supplier Data Requirements - Furnace RefractoriesDocument6 pagesSupplier Data Requirements - Furnace RefractoriesAleem QureshiNo ratings yet

- General Notes: Submittal For ApprovalDocument6 pagesGeneral Notes: Submittal For ApprovalMyo AungNo ratings yet

- Roof Level: QiblaDocument1 pageRoof Level: QiblaMostafaHeshmatNo ratings yet

- Milliken Carpets To Be Used: S.N. Shade Design Size Category TextureDocument17 pagesMilliken Carpets To Be Used: S.N. Shade Design Size Category TexturePoshan GautamNo ratings yet

- Bound Brook 300 - Structural PackageDocument25 pagesBound Brook 300 - Structural PackageGuillermo Romero HuertasNo ratings yet

- Comments Replies 31-10-2021Document2 pagesComments Replies 31-10-2021tauqeer544gmailcomNo ratings yet

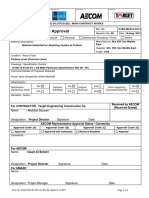

- Material Approval: For CONTRACTOR-Target Engineering Construction Co. Received by AECOM (Received Stamp)Document46 pagesMaterial Approval: For CONTRACTOR-Target Engineering Construction Co. Received by AECOM (Received Stamp)francisbautistaNo ratings yet

- Larsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreDocument1 pageLarsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreOuseppachan AmbookenNo ratings yet

- Sezad Structural GuidelinesDocument36 pagesSezad Structural GuidelinesFateh QuadriNo ratings yet

- 2-General Layout Key Plan_DS2Document1 page2-General Layout Key Plan_DS2Ahmad BelalNo ratings yet

- 5 Why's Analysis Worksheet: Date: 21-Dec-20 Area: DMB 14+320 & 15+094Document1 page5 Why's Analysis Worksheet: Date: 21-Dec-20 Area: DMB 14+320 & 15+094NickNo ratings yet

- CDB2 CCMi Malabar Gold D015Document20 pagesCDB2 CCMi Malabar Gold D015BAVITH KAMMANA MEETHALNo ratings yet

- Civil - Structural DBRDocument20 pagesCivil - Structural DBRUmesh MaheshwariNo ratings yet

- Tender - Civil Works Panel Technical SpecificationDocument52 pagesTender - Civil Works Panel Technical Specificationmxolisi zumaNo ratings yet

- Burj Dubai - The Residences Emaar PropertiesDocument4 pagesBurj Dubai - The Residences Emaar PropertiesAhmedNo ratings yet

- CNCI (C) - 03 - Implementing Standards Through InstallationDocument14 pagesCNCI (C) - 03 - Implementing Standards Through InstallationDjDiggoNorderNo ratings yet

- General Arrangement LegendDocument7 pagesGeneral Arrangement LegendAtiq Ur RehmanNo ratings yet

- 03 230000 4200000011 Ido Civ DRG 013203 - 01Document1 page03 230000 4200000011 Ido Civ DRG 013203 - 01Anuar ChinNo ratings yet

- E-Wall Bracket Above DL DoorDocument9 pagesE-Wall Bracket Above DL DoorMohammed AyeshNo ratings yet

- 4 Process - Analysis - Practice - Problem - SolutionsDocument7 pages4 Process - Analysis - Practice - Problem - SolutionsHEMANT KUMARNo ratings yet

- Motivational SpeakersDocument7 pagesMotivational Speakersapi-549322745No ratings yet

- Practice Test CDocument64 pagesPractice Test CAneri100% (1)

- Staad Pro Stainless Steel ReportDocument29 pagesStaad Pro Stainless Steel ReportRaviteja Girijala100% (1)

- Decision Trees - 2022Document49 pagesDecision Trees - 2022Soubhav ChamanNo ratings yet

- MENTOR FEEDBACK FORM March 2022Document2 pagesMENTOR FEEDBACK FORM March 2022Darius NixNo ratings yet

- Financial Behavior of Millenial Genration On Investment DecisionDocument8 pagesFinancial Behavior of Millenial Genration On Investment DecisionYuslia Nandha Anasta SariNo ratings yet

- AnalysisofUnder reamedPilesSubjectedtoDifferentTypesofLoadinClayeySoil 1 8 PDFDocument9 pagesAnalysisofUnder reamedPilesSubjectedtoDifferentTypesofLoadinClayeySoil 1 8 PDFAkhilesh Kumar SinghNo ratings yet

- Why Nokia FailedDocument4 pagesWhy Nokia FailedNational Star Montessori SchoolNo ratings yet

- Impacts of Economic, Cultural, Social, Individual and Environmental Factors On Demands For Cinema: Case Study of TehranDocument15 pagesImpacts of Economic, Cultural, Social, Individual and Environmental Factors On Demands For Cinema: Case Study of Tehran14-Fy arts Div A Nikhil SharmaNo ratings yet

- Sam Report 12Document18 pagesSam Report 12Sabab ZamanNo ratings yet

- Z370 AORUS Gaming 3: User's ManualDocument48 pagesZ370 AORUS Gaming 3: User's ManualAtrocitus RedNo ratings yet

- UTAMU Procurement and Disposal of Assets Policy 2017Document46 pagesUTAMU Procurement and Disposal of Assets Policy 2017Abdulai WakoNo ratings yet

- Salleh2021 Article TheEmergenceOfVeryLargeContainDocument21 pagesSalleh2021 Article TheEmergenceOfVeryLargeContainSajid KhanNo ratings yet

- Cl400e VDocument2 pagesCl400e VCá ThuNo ratings yet

- Population Control Measures in India Explained PointwiseDocument8 pagesPopulation Control Measures in India Explained PointwiseGAUTAM NATHNo ratings yet

- Quick Start PF70Document18 pagesQuick Start PF70selvan_rsk761No ratings yet

- Ready To Use 101 Powerful Excel VBA Code Just Copy - Paste - Run (For Functional Users) (Anil Nahar) (Z-Library)Document152 pagesReady To Use 101 Powerful Excel VBA Code Just Copy - Paste - Run (For Functional Users) (Anil Nahar) (Z-Library)rahulNo ratings yet

- Kahn's Light: The Measurable and The Unmeasurable of The Bangladesh National Assembly BuildingDocument14 pagesKahn's Light: The Measurable and The Unmeasurable of The Bangladesh National Assembly BuildingbilibiliNo ratings yet

- Personality DevelopmentDocument28 pagesPersonality Developmentmaverick-riouNo ratings yet

- Mispa I2 User ManualDocument43 pagesMispa I2 User ManualJosef GrapesNo ratings yet

- 214.039 Operation of Sieve Shaker2012Document3 pages214.039 Operation of Sieve Shaker2012Pradeep KumarNo ratings yet

- PVC-O PipesDocument40 pagesPVC-O PipesMichaelNo ratings yet

- F520Document2 pagesF520Marcos AldrovandiNo ratings yet

- Chapter 5 - Welding Joint Design and Welding SymbolsDocument43 pagesChapter 5 - Welding Joint Design and Welding Symbolsyves suarezNo ratings yet

- Friction ChartDocument4 pagesFriction ChartSupawat RangsiwongNo ratings yet

- Foundation Design ProjectDocument31 pagesFoundation Design ProjectChoco Late100% (1)

- Once There Were Wolves - AnalysisDocument5 pagesOnce There Were Wolves - AnalysisДаниела ИсаевичNo ratings yet

- Physics Project of Class 11 IscDocument1 pagePhysics Project of Class 11 Iscpratima patelNo ratings yet

- QuestionsDocument20 pagesQuestionsmaheshNo ratings yet

BG-DWG-2017-0171-R0 AL TATWIR CONTRACTING 10-18-2017-Layout1

BG-DWG-2017-0171-R0 AL TATWIR CONTRACTING 10-18-2017-Layout1

Uploaded by

DanielOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BG-DWG-2017-0171-R0 AL TATWIR CONTRACTING 10-18-2017-Layout1

BG-DWG-2017-0171-R0 AL TATWIR CONTRACTING 10-18-2017-Layout1

Uploaded by

DanielCopyright:

Available Formats

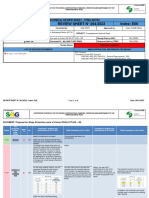

GENERAL NOTES

ACCESS ONLY MAX This drawing is confidential and is the property of Brogan Group. The drawing is supplied subject to the Company's standard

Conditions as applicable. No unauthorised use, copy or disclosure is to be made without written permission.

LIVE LOAD = 0.75kN/m2

Design Basis

This drawing has been prepared from information supplied to us by, or on behalf of the Client, who should check that their

requirements have been correctly interpreted and that all loadings, dimensions, details, erection, and striking sequences etc. are as

required and practicable.

The following documents obtained on loan have been used to prepare this scheme

..........................................................................................................

This drawing has been prepared in accordance with the following:

TRANSOM SPACING

BS 1139* Metal scaffolding

BS 2482 Timber scaffold boards

BS 5950-1:1990* Structural Steelwork

1.20M C/C BS EN 1999-1-1-4:2005 + A1:2010

BS EN 12810-1:2003 Façade scaffolds made of prefabricated components - products specifications

BS EN 12811-1:2003 Temporary works equipment: Scaffolds - Performance requirements and general design

WORKING PLATFORMS: 5 NOS. BS EN 13374:2004 Temporary Edge Protection Systems - Product Specification, test methods

TG4:11 Anchoring systems for scaffolding

BS 5975: 2008 Code of practice for temporary works procedures and the permissible stress design of falsework.

TG20:08 NASC Technical Guidance on the use of BS EN 12811-1

TG20:08

Table 9 Erection tolerances

Feature

Standards Vertical to within ± 20mm in 2m (subject to max. deviation of 50mm)

Bay length and width ± 200mm on designated lengths Levl to within ± 20mm in 2m

(subject to max. deviation of 50mm) (1)

Lift height ± 100mm on designated height

Nodes <Generally 150mm between coupler centres,

Bracing <300mm from the node

(1) Foot ties may follow the general slope of the ground on which the scaffold is founded.

Note

1.30m 1.30m 1.80m

Design Loads

The structure detailed on this drawing has been designed to support the following imposed Loads only

* For Soffits:

Self Weight of Concrete ............ 25.0 kN/m³

W1

Self Weight of Formwork ............0.50 kN/m²

1.30m 1.30m 1.80m

Live load......................................1.50 kN/m²

* For Shores: Maximum Allowable leg load = 30kN/ Leg

Foundations / Supports

The Client must ensure that the foundations provided are adequate and that they are capable of taking the imposed scaffold loads.

Where Brogan Group equipment is supported, anchored, suspended or tied to an existing structure or the ground, the Client must

1.30m 1.30m 1.80m ensure that the structure is adequate to safely support the additional imposed loads.

Maximum Calculated Leg Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . kN

Maximum Lift Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . m

Tying

Ties on Plan, Elevation and Section are denoted thus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Client is to ensure that no ties or braces are removed without the approval of Brogan Group.

CP4 All ties to be fixed with load-bearing couplers.

Where proprietary anchors are specified they should be fixed and tested in accordance with the manufacturers recommendations.

Making good of tie locations by client

Maximum anchor load = . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.10 kN

00

25

C7

25

Assumptions

00

1.30m 1.30m 1.80m

.The

. . . following

. . . . . . . .assumptions

. . . . . . . . . . affecting

. . . . . . . .the

. . use

. . . of

. . equipment

. . . . . . . . . shown

. . . . . . on

. . .this

. . .drawing

. . . . . . .have

. . . .been

. . . . made.

............................ ...

Permanent Structure

Brogan Group cannot and will not pass comment on the building structure being scaffolded as this involves matters beyond our knowledge.

It is the clients responsibility to ensure that the existing structure can safely withstand all additional imposed loads from scaffold structure

1.30m 1.30m 1.80m

Sheeting/Fans

No wind protection, sheeting or fans etc. to are to be added to the scaffolding structure unless otherwise stated on this drawing or

agreed with Brogan Group.

Modifications

1.30m 1.30m 1.80m

No alterations to components, assembly, loading or any other aspect are to be made to the scaffold structure detailed on this

drawing except by Brogan Group employees authorised to do so.

Dimensions

Written dimensions shall take precedence over scaled dimensions.

The contractor should verify all site dimensions and notify Brogan Group of any discrepancies.

The contractor is responsible for accurate setting out dimensions of the position of the scaffold structure.

Drawing Status

Working Drawing - for construction purposes.

Preliminary Drawing - should not be used for construction

25

25

00

Permits

00

1.30m 1.30m 1.80m

The Client is responsible for obtaining all permits and permissions necessary prior to construction.

All ancillary work to scaffolds e.g. hoarding, lighting, baulk timber, plykentledge etc to be supplied by the Client.

Inspection: The scaffold must be inspected by the Client at 7No. day intervals (Statuatory Inspection) .

D3

CDM Regulations and Obligations

1.30m 1.30m 1.80m Brogan Group drawing constitutes Design Risk assessment in accordance with Regulation 11 of CDM Regulations 2007.

Refer to relevant Guides Codes and HSE publications for guidance of elimination of general risk in use of temporary works

and good practice. Wherever possible risk is designed out of this proposal

Erection

Scaffold erected in accordance with SG4:15

1.30m 1.30m 1.80m

Temporary Handrails have been omitted for clarity

Drawing to be read in conjunction with Method statement and Risk Assessment

TG4:11

D1

6.4 TEST PROCEDURES

Hilti M16 HKD

Table of proof test sample M16 Ringbolt

anchor

tie

Total ties number of

on the job proof test

Butt

D3

0 - 60 3

D1

tube

ELEVATION PLAN @ CANTILEVER AREA 61 - 100

101 - 120

121 - 140

5

7

Tie tube

141 - 160 8 through ring

161 - 180 9

181 - 200 10 TIE DETAIL

C13 200 - 220 11 PROOF TEST TO 7.60kN

221 - 240 12 PRELIMINARY TEST LOAD TO 12.20kN

PERMANENT STRUCTURE

D2

50mm Min. 50mm Min.

1200mm 1200mm 1200mm

150mm Max. 150mm Max.

1.00m

1.00m

1.00m

1200 1200 1200

HKD-M16

Maximum

1.00m

2.40

UNIT BEAM

CR2 1.00m

HKD-M16

LACING & BRACING DETAIL

1.00m

STANDARD 3.9m BOARD

TRANSOM SUPPORT DETAIL

+ 100mm Tollerance in accordance with TG20 Table 8

1.00m 1.30m

1.00m 1.30m

WFD1

1.00m 1.30m

HKD-M16

WORKING

C1 1.30m

DRAWING

D3

1.30m

CW-5* D1

1.30m

SCAFFOLDING PLAN

REV. AMENDMENTS BY DATE

SECTION C @ CANTILEVER AREA BRO G A N

GROUP

1303 GROSVENOR TOWER BUSINESS TOWER

TECOM DUBAI

UNITED ARAB EMIRATES

www.brogangroup.com

Title:

ACCESS SCAFFOLDING

USING CUPLOCK SYSTEM

SCAFFOLDING PLAN LAYOUT & CANTILEVER SECTION AREA

Customer:

Design Based Hazards actively eliminated where possible in

AL TATWEER CONTRACTING LLC

the Design Process. Where Hazards cannot be eliminated, this

symbol on the drawing with an attached note means: Depot: Scale:

1. Design Based Hazards Exists within this proposal NTS

2. Action is required by the person supervising the

work to manage the design Hazards during construction Prepd By: Date: Drg. No:

In accordance with Brogan Group Procedures the PERSON SUPERVISING DS 30-OCT-2017

the construction MUST CONTACT the Design Office, BEFORE

WORK COMMENCES, for CLARIFICATION of the Identified Hazards Approved By: Pages: BG-DWG-2017-0171-R1

--- 01 OF 02

You might also like

- Aashto HB-17 Division Ii Sec 22Document6 pagesAashto HB-17 Division Ii Sec 22sofiane mokhtariNo ratings yet

- Section 034900 Glass Fiber Reinforced Concrete (EI 2017-04-02)Document13 pagesSection 034900 Glass Fiber Reinforced Concrete (EI 2017-04-02)Nagarjuna MuthineniNo ratings yet

- G+12 Design Basis ReportDocument38 pagesG+12 Design Basis ReportvinujohnpanickerNo ratings yet

- BG-DWG-2017-0171-R0 AL TATWEER CONTRACTING 30-OCT-2017-Layout1Document1 pageBG-DWG-2017-0171-R0 AL TATWEER CONTRACTING 30-OCT-2017-Layout1DanielNo ratings yet

- NCMA Annotated D&C ManualDocument306 pagesNCMA Annotated D&C ManualestanilorenteNo ratings yet

- DVC Collaborating Plate Installation ProcedureDocument17 pagesDVC Collaborating Plate Installation ProcedureScribdTranslationsNo ratings yet

- 720097-8310-SP-0003 (En) - 1.0 - Specification For GroutingDocument9 pages720097-8310-SP-0003 (En) - 1.0 - Specification For Groutingjohn.woosey48No ratings yet

- Ethane Furnace Erection SequenceDocument5 pagesEthane Furnace Erection SequenceAleem QureshiNo ratings yet

- The Ashenheim Residence - Structural Package - 061623Document45 pagesThe Ashenheim Residence - Structural Package - 061623LSF StructuresNo ratings yet

- Section 031100 FormworkDocument10 pagesSection 031100 Formwork刘盘石No ratings yet

- WMS-Cable Tray & TrunkingDocument3 pagesWMS-Cable Tray & TrunkingLeoj Saliw-an PalaoagNo ratings yet

- Annexure 24-As-Built RequirementsDocument17 pagesAnnexure 24-As-Built RequirementsTayyab KhanNo ratings yet

- Setc - WRKS - RS - 264 - Hyd - DRW - Sag - 2265 - E00 - en - Final 240109Document6 pagesSetc - WRKS - RS - 264 - Hyd - DRW - Sag - 2265 - E00 - en - Final 240109Sanjay SwamiNo ratings yet

- TS For 33kv Transmission LineDocument19 pagesTS For 33kv Transmission LineRamaKrishna ANo ratings yet

- JFD Paint Schedules DivingDocument16 pagesJFD Paint Schedules DivingakashmalayiNo ratings yet

- Arch Girder - Repair Calculation SheetDocument74 pagesArch Girder - Repair Calculation Sheetmohamed ellithyNo ratings yet

- High 5 PQDocument175 pagesHigh 5 PQsyed hadiNo ratings yet

- Technical Requirement For Pre-Engineered Building Works: M/S Design SanyojakaDocument4 pagesTechnical Requirement For Pre-Engineered Building Works: M/S Design SanyojakaHARSHADNo ratings yet

- RFIs To Date - 120823Document5 pagesRFIs To Date - 120823Amogh SwamyNo ratings yet

- Calculation NoteDocument51 pagesCalculation NoteALBERTNo ratings yet

- Release Note Gen 2023 v1.1Document11 pagesRelease Note Gen 2023 v1.1Aleksiey PellicciaNo ratings yet

- E-Construct: Design Basis ReportDocument16 pagesE-Construct: Design Basis ReportAdNo ratings yet

- TMS 402 - Chapter 1Document4 pagesTMS 402 - Chapter 1Alina ShresthaNo ratings yet

- Drying and Cooling Plant ReportDocument47 pagesDrying and Cooling Plant ReportMonsur AlamNo ratings yet

- Bac5583 Process For Potting InsertsDocument54 pagesBac5583 Process For Potting InsertsdkirNo ratings yet

- DBR of 2PX8 Table 30D 0.5 NGL Ground Mount MMSDocument8 pagesDBR of 2PX8 Table 30D 0.5 NGL Ground Mount MMSSalauddinAnsariNo ratings yet

- E-Construct: Design Basis ReportDocument16 pagesE-Construct: Design Basis ReportKuldeepLalwaniNo ratings yet

- Det 1020 PDFDocument1 pageDet 1020 PDFLaurence SarmientoNo ratings yet

- Detailed Structural Analysis and Design: NSEC SS Outdoor Lighting PostDocument19 pagesDetailed Structural Analysis and Design: NSEC SS Outdoor Lighting PostArchilles P. Adverderada100% (1)

- Moti SS 421Document22 pagesMoti SS 421jennifergiannouNo ratings yet

- Material Approval & Specification Comparison SheetDocument3 pagesMaterial Approval & Specification Comparison Sheetfrancisbautista100% (1)

- D1D2-MAR-A-0348 Rev.00Document54 pagesD1D2-MAR-A-0348 Rev.00francisbautistaNo ratings yet

- SKEB-ED-MS-003 (Method Statement For Reinforcement Work, 08.09.2021)Document174 pagesSKEB-ED-MS-003 (Method Statement For Reinforcement Work, 08.09.2021)Tira LakNo ratings yet

- SS RailingDocument27 pagesSS RailingPrasad kapureNo ratings yet

- Detailed Structural Analysis and Design: MAEC SS Outdoor Lighting PostDocument19 pagesDetailed Structural Analysis and Design: MAEC SS Outdoor Lighting PostArchilles P. AdverderadaNo ratings yet

- Design Long Hand Flanged Beam PDFDocument66 pagesDesign Long Hand Flanged Beam PDFMauricio Bustamante HuaquipaNo ratings yet

- BS 8110 ETAbsDocument63 pagesBS 8110 ETAbsnabnaj100% (1)

- Design Calculation of UMW INDUSTRIES WAREHOUSE R00Document28 pagesDesign Calculation of UMW INDUSTRIES WAREHOUSE R00Việt QuốcNo ratings yet

- Comm BLDG ReportDocument40 pagesComm BLDG Reportsafsf100% (1)

- D-Bottom Bracket Anchor DesignDocument8 pagesD-Bottom Bracket Anchor Designmayeshayesh83No ratings yet

- Supplier Data Requirements - Furnace RefractoriesDocument6 pagesSupplier Data Requirements - Furnace RefractoriesAleem QureshiNo ratings yet

- General Notes: Submittal For ApprovalDocument6 pagesGeneral Notes: Submittal For ApprovalMyo AungNo ratings yet

- Roof Level: QiblaDocument1 pageRoof Level: QiblaMostafaHeshmatNo ratings yet

- Milliken Carpets To Be Used: S.N. Shade Design Size Category TextureDocument17 pagesMilliken Carpets To Be Used: S.N. Shade Design Size Category TexturePoshan GautamNo ratings yet

- Bound Brook 300 - Structural PackageDocument25 pagesBound Brook 300 - Structural PackageGuillermo Romero HuertasNo ratings yet

- Comments Replies 31-10-2021Document2 pagesComments Replies 31-10-2021tauqeer544gmailcomNo ratings yet

- Material Approval: For CONTRACTOR-Target Engineering Construction Co. Received by AECOM (Received Stamp)Document46 pagesMaterial Approval: For CONTRACTOR-Target Engineering Construction Co. Received by AECOM (Received Stamp)francisbautistaNo ratings yet

- Larsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreDocument1 pageLarsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreOuseppachan AmbookenNo ratings yet

- Sezad Structural GuidelinesDocument36 pagesSezad Structural GuidelinesFateh QuadriNo ratings yet

- 2-General Layout Key Plan_DS2Document1 page2-General Layout Key Plan_DS2Ahmad BelalNo ratings yet

- 5 Why's Analysis Worksheet: Date: 21-Dec-20 Area: DMB 14+320 & 15+094Document1 page5 Why's Analysis Worksheet: Date: 21-Dec-20 Area: DMB 14+320 & 15+094NickNo ratings yet

- CDB2 CCMi Malabar Gold D015Document20 pagesCDB2 CCMi Malabar Gold D015BAVITH KAMMANA MEETHALNo ratings yet

- Civil - Structural DBRDocument20 pagesCivil - Structural DBRUmesh MaheshwariNo ratings yet

- Tender - Civil Works Panel Technical SpecificationDocument52 pagesTender - Civil Works Panel Technical Specificationmxolisi zumaNo ratings yet

- Burj Dubai - The Residences Emaar PropertiesDocument4 pagesBurj Dubai - The Residences Emaar PropertiesAhmedNo ratings yet

- CNCI (C) - 03 - Implementing Standards Through InstallationDocument14 pagesCNCI (C) - 03 - Implementing Standards Through InstallationDjDiggoNorderNo ratings yet

- General Arrangement LegendDocument7 pagesGeneral Arrangement LegendAtiq Ur RehmanNo ratings yet

- 03 230000 4200000011 Ido Civ DRG 013203 - 01Document1 page03 230000 4200000011 Ido Civ DRG 013203 - 01Anuar ChinNo ratings yet

- E-Wall Bracket Above DL DoorDocument9 pagesE-Wall Bracket Above DL DoorMohammed AyeshNo ratings yet

- 4 Process - Analysis - Practice - Problem - SolutionsDocument7 pages4 Process - Analysis - Practice - Problem - SolutionsHEMANT KUMARNo ratings yet

- Motivational SpeakersDocument7 pagesMotivational Speakersapi-549322745No ratings yet

- Practice Test CDocument64 pagesPractice Test CAneri100% (1)

- Staad Pro Stainless Steel ReportDocument29 pagesStaad Pro Stainless Steel ReportRaviteja Girijala100% (1)

- Decision Trees - 2022Document49 pagesDecision Trees - 2022Soubhav ChamanNo ratings yet

- MENTOR FEEDBACK FORM March 2022Document2 pagesMENTOR FEEDBACK FORM March 2022Darius NixNo ratings yet

- Financial Behavior of Millenial Genration On Investment DecisionDocument8 pagesFinancial Behavior of Millenial Genration On Investment DecisionYuslia Nandha Anasta SariNo ratings yet

- AnalysisofUnder reamedPilesSubjectedtoDifferentTypesofLoadinClayeySoil 1 8 PDFDocument9 pagesAnalysisofUnder reamedPilesSubjectedtoDifferentTypesofLoadinClayeySoil 1 8 PDFAkhilesh Kumar SinghNo ratings yet

- Why Nokia FailedDocument4 pagesWhy Nokia FailedNational Star Montessori SchoolNo ratings yet

- Impacts of Economic, Cultural, Social, Individual and Environmental Factors On Demands For Cinema: Case Study of TehranDocument15 pagesImpacts of Economic, Cultural, Social, Individual and Environmental Factors On Demands For Cinema: Case Study of Tehran14-Fy arts Div A Nikhil SharmaNo ratings yet

- Sam Report 12Document18 pagesSam Report 12Sabab ZamanNo ratings yet

- Z370 AORUS Gaming 3: User's ManualDocument48 pagesZ370 AORUS Gaming 3: User's ManualAtrocitus RedNo ratings yet

- UTAMU Procurement and Disposal of Assets Policy 2017Document46 pagesUTAMU Procurement and Disposal of Assets Policy 2017Abdulai WakoNo ratings yet

- Salleh2021 Article TheEmergenceOfVeryLargeContainDocument21 pagesSalleh2021 Article TheEmergenceOfVeryLargeContainSajid KhanNo ratings yet

- Cl400e VDocument2 pagesCl400e VCá ThuNo ratings yet

- Population Control Measures in India Explained PointwiseDocument8 pagesPopulation Control Measures in India Explained PointwiseGAUTAM NATHNo ratings yet

- Quick Start PF70Document18 pagesQuick Start PF70selvan_rsk761No ratings yet

- Ready To Use 101 Powerful Excel VBA Code Just Copy - Paste - Run (For Functional Users) (Anil Nahar) (Z-Library)Document152 pagesReady To Use 101 Powerful Excel VBA Code Just Copy - Paste - Run (For Functional Users) (Anil Nahar) (Z-Library)rahulNo ratings yet

- Kahn's Light: The Measurable and The Unmeasurable of The Bangladesh National Assembly BuildingDocument14 pagesKahn's Light: The Measurable and The Unmeasurable of The Bangladesh National Assembly BuildingbilibiliNo ratings yet

- Personality DevelopmentDocument28 pagesPersonality Developmentmaverick-riouNo ratings yet

- Mispa I2 User ManualDocument43 pagesMispa I2 User ManualJosef GrapesNo ratings yet

- 214.039 Operation of Sieve Shaker2012Document3 pages214.039 Operation of Sieve Shaker2012Pradeep KumarNo ratings yet

- PVC-O PipesDocument40 pagesPVC-O PipesMichaelNo ratings yet

- F520Document2 pagesF520Marcos AldrovandiNo ratings yet

- Chapter 5 - Welding Joint Design and Welding SymbolsDocument43 pagesChapter 5 - Welding Joint Design and Welding Symbolsyves suarezNo ratings yet

- Friction ChartDocument4 pagesFriction ChartSupawat RangsiwongNo ratings yet

- Foundation Design ProjectDocument31 pagesFoundation Design ProjectChoco Late100% (1)

- Once There Were Wolves - AnalysisDocument5 pagesOnce There Were Wolves - AnalysisДаниела ИсаевичNo ratings yet

- Physics Project of Class 11 IscDocument1 pagePhysics Project of Class 11 Iscpratima patelNo ratings yet

- QuestionsDocument20 pagesQuestionsmaheshNo ratings yet