Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

3 viewsTribology Sem Question Bank

Tribology Sem Question Bank

Uploaded by

18WJ1A03H1 kalyan pusalaThe document discusses various topics related to bearings and lubrication including defining viscosity and relating dynamic and kinematic viscosity, describing terms related to journal bearings, stating assumptions in deriving Reynold's equation, deriving Reynold's equation in two dimensions, calculating power wasted in friction for a journal bearing problem, describing boundary lubrication and its characteristics, deriving equations for linear sliding wear and bushing wear, listing requirements of good bearing materials, describing pressure feed bearings and deriving expressions for pressure distribution and load capacity for flat and non-flat circular hydrostatic pad bearings, describing different types of viscometers, explaining viscosity index and lubricant grades, deriving Petroff's equation for a lightly loaded

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Magnapunch Parts PunchDocument18 pagesMagnapunch Parts PunchAlex GonzalezNo ratings yet

- MC1 Manual Operacion Changfa 1100 195Document55 pagesMC1 Manual Operacion Changfa 1100 195miguelx69100% (2)

- Formwork and ScaffoldingDocument43 pagesFormwork and ScaffoldingAarti Vij50% (2)

- Question Bank Sliding Contact BearingsDocument2 pagesQuestion Bank Sliding Contact BearingsShree Prajapati100% (1)

- MD-III - TUT - 5 and 6Document5 pagesMD-III - TUT - 5 and 6Sushil ThakkarNo ratings yet

- Tutorials Machine DesignDocument4 pagesTutorials Machine DesignHarpinder GotraaNo ratings yet

- DMM Ii - Des QP Mid Iset IIDocument1 pageDMM Ii - Des QP Mid Iset IIM S SHARATHNo ratings yet

- Part B (15 X 2 30 Marks)Document1 pagePart B (15 X 2 30 Marks)gana999No ratings yet

- Tribology Assignment7Document2 pagesTribology Assignment7Ahmed AbdelWahed KahmisNo ratings yet

- DMM 2Document8 pagesDMM 2Robin MessiNo ratings yet

- Me 154 A06Document1 pageMe 154 A06Marriel Kayne MalateNo ratings yet

- DMM Ii - Des QP Mid Iset 1Document1 pageDMM Ii - Des QP Mid Iset 1M S SHARATHNo ratings yet

- ASSIGNMENT TribologyDocument3 pagesASSIGNMENT TribologyShabbir WahabNo ratings yet

- The Copperbelt University School of EngiDocument3 pagesThe Copperbelt University School of Engiyousef mohamedNo ratings yet

- ASSIGNMENT (Sliding Contact Bearing) PDFDocument3 pagesASSIGNMENT (Sliding Contact Bearing) PDFRakesh Kumar Shukla KEC0% (1)

- Unit 4 Bearings Important ProblemsDocument3 pagesUnit 4 Bearings Important ProblemsBrijpal PatleNo ratings yet

- Question Bank For CA-IDocument1 pageQuestion Bank For CA-ISamarth PatilNo ratings yet

- DMM-2 Question BankDocument3 pagesDMM-2 Question BankrajuNo ratings yet

- ME II Final Exam QPDocument2 pagesME II Final Exam QPsutha_me20098282No ratings yet

- BearingsDocument4 pagesBearingsvidyasagNo ratings yet

- DMM-2 3 1 Q&aDocument6 pagesDMM-2 3 1 Q&aAnand vinayNo ratings yet

- Soal#2Document1 pageSoal#2saifudin-itsNo ratings yet

- Question Bank For Machine DesignDocument3 pagesQuestion Bank For Machine DesignSachin KumbharNo ratings yet

- DMM Ii Slip Test Unit 1Document1 pageDMM Ii Slip Test Unit 1jeevankchNo ratings yet

- Design of Transmission System 2 MarksDocument3 pagesDesign of Transmission System 2 MarksMANOJ M100% (1)

- MD-II Question BankDocument3 pagesMD-II Question BankAnonymous Pfi1bgrYNo ratings yet

- Sliding Contact BearingDocument4 pagesSliding Contact BearingSp PatelNo ratings yet

- Aero EngineDocument9 pagesAero EngineVinod BalakrishnanNo ratings yet

- Attempt All Sections. If Require Any Missing Data Then Choose Suitably. Standard Design Data Book Is AllowedDocument3 pagesAttempt All Sections. If Require Any Missing Data Then Choose Suitably. Standard Design Data Book Is Allowedvk862626No ratings yet

- DMM 2Document6 pagesDMM 2Shubham MahajanNo ratings yet

- Assignment 04Document1 pageAssignment 04anurag kumarNo ratings yet

- Dme-II Mid QuestionsDocument6 pagesDme-II Mid QuestionsSree MurthyNo ratings yet

- Chapter Wise Questions Bank MD-iiDocument6 pagesChapter Wise Questions Bank MD-iiinderpreet singhNo ratings yet

- Bearings: Dr. M.SasikumarDocument40 pagesBearings: Dr. M.SasikumarHariom KumarNo ratings yet

- 1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringDocument3 pages1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringChadaram JagadishNo ratings yet

- MD2 Model QuestionsDocument2 pagesMD2 Model Questionsmanish sharmaNo ratings yet

- Questionnaire On TURBINES & COMPRESSORS:: TURBINE - GeneralDocument3 pagesQuestionnaire On TURBINES & COMPRESSORS:: TURBINE - Generalvaratharajan g rNo ratings yet

- Workcross Max X4 1000Document249 pagesWorkcross Max X4 1000geomak2000No ratings yet

- Chassis Desgin Univ 2 MarksDocument7 pagesChassis Desgin Univ 2 Markspavanrane67% (3)

- 2018sme 7 Sem Design of Mechanical Drives Summer 2018Document2 pages2018sme 7 Sem Design of Mechanical Drives Summer 2018Komal HingeNo ratings yet

- LubeCoach Volume and Frequency Recommendations PDFDocument13 pagesLubeCoach Volume and Frequency Recommendations PDFEstebanRivera100% (1)

- Design Procedure For Journal BearingsDocument4 pagesDesign Procedure For Journal BearingsSwaminathan100% (1)

- ICGT Question Bank 13ME301 InternalDocument13 pagesICGT Question Bank 13ME301 Internalవిష్ణువర్ధన్రెడ్డిNo ratings yet

- 2 Tutorial Sliding Contact BearingDocument2 pages2 Tutorial Sliding Contact BearingNirav100% (1)

- Unit III Sliding Contact BearingDocument26 pagesUnit III Sliding Contact BearingSHUBHAM GOVILNo ratings yet

- Thermal Engg Qbank 2017 FinalDocument10 pagesThermal Engg Qbank 2017 FinalBalaji DsNo ratings yet

- Machine Design - LDocument2 pagesMachine Design - LNilesh Mistry (Nilesh Sharma)No ratings yet

- Unit 1 - Force Analysis-1 - University Questions PDFDocument2 pagesUnit 1 - Force Analysis-1 - University Questions PDFArafath JazeebNo ratings yet

- Problems s7Document4 pagesProblems s7zangue billy jamesNo ratings yet

- Mechanical Machine DesignDocument25 pagesMechanical Machine DesignshahfaraazNo ratings yet

- PSI - 10 AND 15 HP LPM2A RIGHT ANGLE MANUAL (Agitator) Manual BookDocument19 pagesPSI - 10 AND 15 HP LPM2A RIGHT ANGLE MANUAL (Agitator) Manual Bookedisahputra845No ratings yet

- Design of Machine Members-II QB PDFDocument24 pagesDesign of Machine Members-II QB PDFAnonymous hUN4K5fZkeNo ratings yet

- ED7204-Integrated Mechanical Design QBDocument7 pagesED7204-Integrated Mechanical Design QBBakkiya RajNo ratings yet

- Silver Oak College of Engineering & Technology Aditya Silver Oak Institute of TechnologyDocument2 pagesSilver Oak College of Engineering & Technology Aditya Silver Oak Institute of TechnologyShree PrajapatiNo ratings yet

- At 6602 ACCD Imp Qns 2by2resultsDocument3 pagesAt 6602 ACCD Imp Qns 2by2resultsKarthickNo ratings yet

- Machine Design Ii Nme602 1Document3 pagesMachine Design Ii Nme602 1himanshujaiswal04596No ratings yet

- Dme Unit - 5 Produce by Assistant Professor G.Ganapathy (9629027354)Document13 pagesDme Unit - 5 Produce by Assistant Professor G.Ganapathy (9629027354)Anonymous tZfJJPRKsNo ratings yet

- Propulsion 2 QBDocument9 pagesPropulsion 2 QBu2b11517No ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 3.5 out of 5 stars3.5/5 (2)

- Trib OlogyDocument50 pagesTrib Ology18WJ1A03H1 kalyan pusalaNo ratings yet

- TribologyDocument23 pagesTribology18WJ1A03H1 kalyan pusalaNo ratings yet

- Basic Python Programming Unit 1Document53 pagesBasic Python Programming Unit 118WJ1A03H1 kalyan pusalaNo ratings yet

- BPP Important QuestionsDocument6 pagesBPP Important Questions18WJ1A03H1 kalyan pusalaNo ratings yet

- Algo - Lec3 - Verifying Correctness of Algorithm PDFDocument126 pagesAlgo - Lec3 - Verifying Correctness of Algorithm PDFHamza BhattiNo ratings yet

- M4 Vehicle Service ManualDocument706 pagesM4 Vehicle Service ManualManuel Gonzales80% (5)

- Fanem Baby IncubatorDocument9 pagesFanem Baby IncubatorMuhammad TanveerNo ratings yet

- GE441 Lecture5 2 PDFDocument6 pagesGE441 Lecture5 2 PDFhamza100% (1)

- Type of CoachesDocument2 pagesType of Coachesabhimanyutiwari1234No ratings yet

- H03 1051 010 PDFDocument4 pagesH03 1051 010 PDFAli AliNo ratings yet

- Terms of Reference: A Study On Skills Development & Employment in Bangladesh RMG Sector 1.0 BackgroundDocument4 pagesTerms of Reference: A Study On Skills Development & Employment in Bangladesh RMG Sector 1.0 Backgroundjaman mostofaNo ratings yet

- PRE Base Suf Unit Year C DescriptionDocument39 pagesPRE Base Suf Unit Year C DescriptionjorgeNo ratings yet

- Survey Management System-Revamped VersionDocument10 pagesSurvey Management System-Revamped VersionNeetika AgarwalNo ratings yet

- PDFDocument5 pagesPDFLesego MatojaneNo ratings yet

- USB BootLoaderDocument36 pagesUSB BootLoaderVenkatrao Potluri100% (2)

- Andrew Secure RPC ProtocolDocument10 pagesAndrew Secure RPC ProtocolanjanaNo ratings yet

- (General Knowledge) Geography of India and The World - National Highways - SSCPORTAL - in - SSC CGL, FCI, Govt ExamDocument3 pages(General Knowledge) Geography of India and The World - National Highways - SSCPORTAL - in - SSC CGL, FCI, Govt ExamRahul GargNo ratings yet

- Volumetric Feeders For Dry Solids: Model 170 SeriesDocument3 pagesVolumetric Feeders For Dry Solids: Model 170 SeriesEmerson FerreiraNo ratings yet

- IQSSLDocument4 pagesIQSSLkanilNo ratings yet

- Luminous Electra CatalogueDocument26 pagesLuminous Electra Catalogueshish0iitrNo ratings yet

- Replacing Nintendo DS Lite Touchscreen: Written By: Matt NewsomDocument13 pagesReplacing Nintendo DS Lite Touchscreen: Written By: Matt Newsomdp500No ratings yet

- Acti9 Tripping Curves & Short-Circuit Current LimitingDocument14 pagesActi9 Tripping Curves & Short-Circuit Current LimitingFred Jayson Palisoc CabansagNo ratings yet

- Diesel Completo 960Document9 pagesDiesel Completo 960oxtrolopitecuxNo ratings yet

- Etabs TutorialDocument27 pagesEtabs TutorialSyed Abdul Hannan100% (4)

- Fh64t6ht GBR EngDocument7 pagesFh64t6ht GBR EngariwibowoNo ratings yet

- Datasheet KBPC 1010Document3 pagesDatasheet KBPC 1010SalvadorPerezLuleNo ratings yet

- Matlab Based Software For Aircraft Structural Analysis and DesignDocument8 pagesMatlab Based Software For Aircraft Structural Analysis and DesignsaadNo ratings yet

- William McElcheran Paper To Bronze 2013 Digital Exhibition CatalogueDocument19 pagesWilliam McElcheran Paper To Bronze 2013 Digital Exhibition CatalogueJohn MacGregor NewmanNo ratings yet

- Evaluator Guide: Docucolor 242 / 252 / 260Document14 pagesEvaluator Guide: Docucolor 242 / 252 / 260Patricia SolisNo ratings yet

- CIE-HE Track Hydraulic Engineering (HE) en Delft ImportanteDocument238 pagesCIE-HE Track Hydraulic Engineering (HE) en Delft ImportanteDaniel SánchezNo ratings yet

- Fleximrbts Inst Fcoa QguideDocument15 pagesFleximrbts Inst Fcoa QguideasveNo ratings yet

- Chapter 3 Lab 3-5, OSPF Challenge Lab: TopologyDocument6 pagesChapter 3 Lab 3-5, OSPF Challenge Lab: TopologyJuan100% (1)

Tribology Sem Question Bank

Tribology Sem Question Bank

Uploaded by

18WJ1A03H1 kalyan pusala0 ratings0% found this document useful (0 votes)

3 views1 pageThe document discusses various topics related to bearings and lubrication including defining viscosity and relating dynamic and kinematic viscosity, describing terms related to journal bearings, stating assumptions in deriving Reynold's equation, deriving Reynold's equation in two dimensions, calculating power wasted in friction for a journal bearing problem, describing boundary lubrication and its characteristics, deriving equations for linear sliding wear and bushing wear, listing requirements of good bearing materials, describing pressure feed bearings and deriving expressions for pressure distribution and load capacity for flat and non-flat circular hydrostatic pad bearings, describing different types of viscometers, explaining viscosity index and lubricant grades, deriving Petroff's equation for a lightly loaded

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses various topics related to bearings and lubrication including defining viscosity and relating dynamic and kinematic viscosity, describing terms related to journal bearings, stating assumptions in deriving Reynold's equation, deriving Reynold's equation in two dimensions, calculating power wasted in friction for a journal bearing problem, describing boundary lubrication and its characteristics, deriving equations for linear sliding wear and bushing wear, listing requirements of good bearing materials, describing pressure feed bearings and deriving expressions for pressure distribution and load capacity for flat and non-flat circular hydrostatic pad bearings, describing different types of viscometers, explaining viscosity index and lubricant grades, deriving Petroff's equation for a lightly loaded

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

3 views1 pageTribology Sem Question Bank

Tribology Sem Question Bank

Uploaded by

18WJ1A03H1 kalyan pusalaThe document discusses various topics related to bearings and lubrication including defining viscosity and relating dynamic and kinematic viscosity, describing terms related to journal bearings, stating assumptions in deriving Reynold's equation, deriving Reynold's equation in two dimensions, calculating power wasted in friction for a journal bearing problem, describing boundary lubrication and its characteristics, deriving equations for linear sliding wear and bushing wear, listing requirements of good bearing materials, describing pressure feed bearings and deriving expressions for pressure distribution and load capacity for flat and non-flat circular hydrostatic pad bearings, describing different types of viscometers, explaining viscosity index and lubricant grades, deriving Petroff's equation for a lightly loaded

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

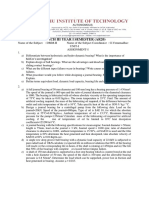

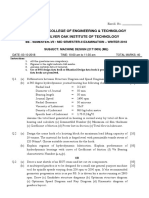

1. Define viscosity. Derive the relation between dynamic and kinematic viscosity?

2. Explain the terms related to journal bearing?

3. State the assumptions made in derivation of Reynold's equation?

4. Derive the Reynold's equation in two dimensions?

5. A 150 mm diameter shaft supporting a load of 10 kN has a speed of 1500 r.p.m. The shaft runs in a

bearing whose length is 1.5 times the shaft diameter. If the diametral clearance of the bearing is 0.15

mm and the absolute viscosity of the oil at the operating temperature is 0.011 kg/m-s, find the power

wasted in friction? A journal bearing 60 mm is diameter and 90 mm long runs at 450 r.p.m. The oil

used for hydrodynamic lubrication has absolute viscosity of 0.06 kg/ m-s. If the diametral clearance is

0.1 mm, find the safe load on the bearing?

6. What is boundary lubrication? Describe its characteristics?

7. Derive the governing equations of linear sliding wear and Bushing wear?

8. What are the general requirements of a good bearing material?

9. Describe the construction and working of pressure feed bearings with applications?

10. Derive the expression for pressure distribution and load capacity for a flat circular hydrostatic pad

bearing?

11. Derive the expression for pressure distribution and load capacity for a Non-flat circular hydrostatic pad

bearing?

12. What is a viscometer? Briefly describe the different types of viscometers with diagram?

13. What is viscosity Index? Describe the types of lubricant Grades available?

14. What are the general requirements of a good bearing material?

15. Indicating the assumptions, derive the Petroff's equation and the expression for coefficient of friction

for a lightly loaded Journal bearing?

16. Design a journal bearing for a centrifugal pump from the following data Load on the journal = 20 000

N; Speed of the journal = 900 r.p.m.; Type of oil is SAE 10, for which the absolute viscosity at 55°C =

0.017 kg/ m-s; Ambient temperature of oil 15.5°C ; Maximum bearing pressure for the pump = 1.5 N/

mm2. Calculate also mass of the lubricating oil required for artificial cooling, if rise of temperature of

oil be limited to 10'C. Heat dissipation coefficient = 1232 W/m2/C.

17. Explain the working principle and applications of hydrodynamic thrust bearing?

18. List advantages and disadvantages of gas-lubricated bearings over oil-lubricated bearings?

19. Describe the working of a splash feed lubricating system with suitable diagram?

20. Describe the working of a drip feed lubrication system with diagram?

21. Discuss the following in detail: a) Optimum film thickness in journal bearings b) Fixed tilting pads c)

Single and multiple pad bearings?

22. What are the basic functions of a lubricant?

23. List the important factors to be consider in the selection of lubrication system for given application?

You might also like

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Magnapunch Parts PunchDocument18 pagesMagnapunch Parts PunchAlex GonzalezNo ratings yet

- MC1 Manual Operacion Changfa 1100 195Document55 pagesMC1 Manual Operacion Changfa 1100 195miguelx69100% (2)

- Formwork and ScaffoldingDocument43 pagesFormwork and ScaffoldingAarti Vij50% (2)

- Question Bank Sliding Contact BearingsDocument2 pagesQuestion Bank Sliding Contact BearingsShree Prajapati100% (1)

- MD-III - TUT - 5 and 6Document5 pagesMD-III - TUT - 5 and 6Sushil ThakkarNo ratings yet

- Tutorials Machine DesignDocument4 pagesTutorials Machine DesignHarpinder GotraaNo ratings yet

- DMM Ii - Des QP Mid Iset IIDocument1 pageDMM Ii - Des QP Mid Iset IIM S SHARATHNo ratings yet

- Part B (15 X 2 30 Marks)Document1 pagePart B (15 X 2 30 Marks)gana999No ratings yet

- Tribology Assignment7Document2 pagesTribology Assignment7Ahmed AbdelWahed KahmisNo ratings yet

- DMM 2Document8 pagesDMM 2Robin MessiNo ratings yet

- Me 154 A06Document1 pageMe 154 A06Marriel Kayne MalateNo ratings yet

- DMM Ii - Des QP Mid Iset 1Document1 pageDMM Ii - Des QP Mid Iset 1M S SHARATHNo ratings yet

- ASSIGNMENT TribologyDocument3 pagesASSIGNMENT TribologyShabbir WahabNo ratings yet

- The Copperbelt University School of EngiDocument3 pagesThe Copperbelt University School of Engiyousef mohamedNo ratings yet

- ASSIGNMENT (Sliding Contact Bearing) PDFDocument3 pagesASSIGNMENT (Sliding Contact Bearing) PDFRakesh Kumar Shukla KEC0% (1)

- Unit 4 Bearings Important ProblemsDocument3 pagesUnit 4 Bearings Important ProblemsBrijpal PatleNo ratings yet

- Question Bank For CA-IDocument1 pageQuestion Bank For CA-ISamarth PatilNo ratings yet

- DMM-2 Question BankDocument3 pagesDMM-2 Question BankrajuNo ratings yet

- ME II Final Exam QPDocument2 pagesME II Final Exam QPsutha_me20098282No ratings yet

- BearingsDocument4 pagesBearingsvidyasagNo ratings yet

- DMM-2 3 1 Q&aDocument6 pagesDMM-2 3 1 Q&aAnand vinayNo ratings yet

- Soal#2Document1 pageSoal#2saifudin-itsNo ratings yet

- Question Bank For Machine DesignDocument3 pagesQuestion Bank For Machine DesignSachin KumbharNo ratings yet

- DMM Ii Slip Test Unit 1Document1 pageDMM Ii Slip Test Unit 1jeevankchNo ratings yet

- Design of Transmission System 2 MarksDocument3 pagesDesign of Transmission System 2 MarksMANOJ M100% (1)

- MD-II Question BankDocument3 pagesMD-II Question BankAnonymous Pfi1bgrYNo ratings yet

- Sliding Contact BearingDocument4 pagesSliding Contact BearingSp PatelNo ratings yet

- Aero EngineDocument9 pagesAero EngineVinod BalakrishnanNo ratings yet

- Attempt All Sections. If Require Any Missing Data Then Choose Suitably. Standard Design Data Book Is AllowedDocument3 pagesAttempt All Sections. If Require Any Missing Data Then Choose Suitably. Standard Design Data Book Is Allowedvk862626No ratings yet

- DMM 2Document6 pagesDMM 2Shubham MahajanNo ratings yet

- Assignment 04Document1 pageAssignment 04anurag kumarNo ratings yet

- Dme-II Mid QuestionsDocument6 pagesDme-II Mid QuestionsSree MurthyNo ratings yet

- Chapter Wise Questions Bank MD-iiDocument6 pagesChapter Wise Questions Bank MD-iiinderpreet singhNo ratings yet

- Bearings: Dr. M.SasikumarDocument40 pagesBearings: Dr. M.SasikumarHariom KumarNo ratings yet

- 1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringDocument3 pages1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringChadaram JagadishNo ratings yet

- MD2 Model QuestionsDocument2 pagesMD2 Model Questionsmanish sharmaNo ratings yet

- Questionnaire On TURBINES & COMPRESSORS:: TURBINE - GeneralDocument3 pagesQuestionnaire On TURBINES & COMPRESSORS:: TURBINE - Generalvaratharajan g rNo ratings yet

- Workcross Max X4 1000Document249 pagesWorkcross Max X4 1000geomak2000No ratings yet

- Chassis Desgin Univ 2 MarksDocument7 pagesChassis Desgin Univ 2 Markspavanrane67% (3)

- 2018sme 7 Sem Design of Mechanical Drives Summer 2018Document2 pages2018sme 7 Sem Design of Mechanical Drives Summer 2018Komal HingeNo ratings yet

- LubeCoach Volume and Frequency Recommendations PDFDocument13 pagesLubeCoach Volume and Frequency Recommendations PDFEstebanRivera100% (1)

- Design Procedure For Journal BearingsDocument4 pagesDesign Procedure For Journal BearingsSwaminathan100% (1)

- ICGT Question Bank 13ME301 InternalDocument13 pagesICGT Question Bank 13ME301 Internalవిష్ణువర్ధన్రెడ్డిNo ratings yet

- 2 Tutorial Sliding Contact BearingDocument2 pages2 Tutorial Sliding Contact BearingNirav100% (1)

- Unit III Sliding Contact BearingDocument26 pagesUnit III Sliding Contact BearingSHUBHAM GOVILNo ratings yet

- Thermal Engg Qbank 2017 FinalDocument10 pagesThermal Engg Qbank 2017 FinalBalaji DsNo ratings yet

- Machine Design - LDocument2 pagesMachine Design - LNilesh Mistry (Nilesh Sharma)No ratings yet

- Unit 1 - Force Analysis-1 - University Questions PDFDocument2 pagesUnit 1 - Force Analysis-1 - University Questions PDFArafath JazeebNo ratings yet

- Problems s7Document4 pagesProblems s7zangue billy jamesNo ratings yet

- Mechanical Machine DesignDocument25 pagesMechanical Machine DesignshahfaraazNo ratings yet

- PSI - 10 AND 15 HP LPM2A RIGHT ANGLE MANUAL (Agitator) Manual BookDocument19 pagesPSI - 10 AND 15 HP LPM2A RIGHT ANGLE MANUAL (Agitator) Manual Bookedisahputra845No ratings yet

- Design of Machine Members-II QB PDFDocument24 pagesDesign of Machine Members-II QB PDFAnonymous hUN4K5fZkeNo ratings yet

- ED7204-Integrated Mechanical Design QBDocument7 pagesED7204-Integrated Mechanical Design QBBakkiya RajNo ratings yet

- Silver Oak College of Engineering & Technology Aditya Silver Oak Institute of TechnologyDocument2 pagesSilver Oak College of Engineering & Technology Aditya Silver Oak Institute of TechnologyShree PrajapatiNo ratings yet

- At 6602 ACCD Imp Qns 2by2resultsDocument3 pagesAt 6602 ACCD Imp Qns 2by2resultsKarthickNo ratings yet

- Machine Design Ii Nme602 1Document3 pagesMachine Design Ii Nme602 1himanshujaiswal04596No ratings yet

- Dme Unit - 5 Produce by Assistant Professor G.Ganapathy (9629027354)Document13 pagesDme Unit - 5 Produce by Assistant Professor G.Ganapathy (9629027354)Anonymous tZfJJPRKsNo ratings yet

- Propulsion 2 QBDocument9 pagesPropulsion 2 QBu2b11517No ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 3.5 out of 5 stars3.5/5 (2)

- Trib OlogyDocument50 pagesTrib Ology18WJ1A03H1 kalyan pusalaNo ratings yet

- TribologyDocument23 pagesTribology18WJ1A03H1 kalyan pusalaNo ratings yet

- Basic Python Programming Unit 1Document53 pagesBasic Python Programming Unit 118WJ1A03H1 kalyan pusalaNo ratings yet

- BPP Important QuestionsDocument6 pagesBPP Important Questions18WJ1A03H1 kalyan pusalaNo ratings yet

- Algo - Lec3 - Verifying Correctness of Algorithm PDFDocument126 pagesAlgo - Lec3 - Verifying Correctness of Algorithm PDFHamza BhattiNo ratings yet

- M4 Vehicle Service ManualDocument706 pagesM4 Vehicle Service ManualManuel Gonzales80% (5)

- Fanem Baby IncubatorDocument9 pagesFanem Baby IncubatorMuhammad TanveerNo ratings yet

- GE441 Lecture5 2 PDFDocument6 pagesGE441 Lecture5 2 PDFhamza100% (1)

- Type of CoachesDocument2 pagesType of Coachesabhimanyutiwari1234No ratings yet

- H03 1051 010 PDFDocument4 pagesH03 1051 010 PDFAli AliNo ratings yet

- Terms of Reference: A Study On Skills Development & Employment in Bangladesh RMG Sector 1.0 BackgroundDocument4 pagesTerms of Reference: A Study On Skills Development & Employment in Bangladesh RMG Sector 1.0 Backgroundjaman mostofaNo ratings yet

- PRE Base Suf Unit Year C DescriptionDocument39 pagesPRE Base Suf Unit Year C DescriptionjorgeNo ratings yet

- Survey Management System-Revamped VersionDocument10 pagesSurvey Management System-Revamped VersionNeetika AgarwalNo ratings yet

- PDFDocument5 pagesPDFLesego MatojaneNo ratings yet

- USB BootLoaderDocument36 pagesUSB BootLoaderVenkatrao Potluri100% (2)

- Andrew Secure RPC ProtocolDocument10 pagesAndrew Secure RPC ProtocolanjanaNo ratings yet

- (General Knowledge) Geography of India and The World - National Highways - SSCPORTAL - in - SSC CGL, FCI, Govt ExamDocument3 pages(General Knowledge) Geography of India and The World - National Highways - SSCPORTAL - in - SSC CGL, FCI, Govt ExamRahul GargNo ratings yet

- Volumetric Feeders For Dry Solids: Model 170 SeriesDocument3 pagesVolumetric Feeders For Dry Solids: Model 170 SeriesEmerson FerreiraNo ratings yet

- IQSSLDocument4 pagesIQSSLkanilNo ratings yet

- Luminous Electra CatalogueDocument26 pagesLuminous Electra Catalogueshish0iitrNo ratings yet

- Replacing Nintendo DS Lite Touchscreen: Written By: Matt NewsomDocument13 pagesReplacing Nintendo DS Lite Touchscreen: Written By: Matt Newsomdp500No ratings yet

- Acti9 Tripping Curves & Short-Circuit Current LimitingDocument14 pagesActi9 Tripping Curves & Short-Circuit Current LimitingFred Jayson Palisoc CabansagNo ratings yet

- Diesel Completo 960Document9 pagesDiesel Completo 960oxtrolopitecuxNo ratings yet

- Etabs TutorialDocument27 pagesEtabs TutorialSyed Abdul Hannan100% (4)

- Fh64t6ht GBR EngDocument7 pagesFh64t6ht GBR EngariwibowoNo ratings yet

- Datasheet KBPC 1010Document3 pagesDatasheet KBPC 1010SalvadorPerezLuleNo ratings yet

- Matlab Based Software For Aircraft Structural Analysis and DesignDocument8 pagesMatlab Based Software For Aircraft Structural Analysis and DesignsaadNo ratings yet

- William McElcheran Paper To Bronze 2013 Digital Exhibition CatalogueDocument19 pagesWilliam McElcheran Paper To Bronze 2013 Digital Exhibition CatalogueJohn MacGregor NewmanNo ratings yet

- Evaluator Guide: Docucolor 242 / 252 / 260Document14 pagesEvaluator Guide: Docucolor 242 / 252 / 260Patricia SolisNo ratings yet

- CIE-HE Track Hydraulic Engineering (HE) en Delft ImportanteDocument238 pagesCIE-HE Track Hydraulic Engineering (HE) en Delft ImportanteDaniel SánchezNo ratings yet

- Fleximrbts Inst Fcoa QguideDocument15 pagesFleximrbts Inst Fcoa QguideasveNo ratings yet

- Chapter 3 Lab 3-5, OSPF Challenge Lab: TopologyDocument6 pagesChapter 3 Lab 3-5, OSPF Challenge Lab: TopologyJuan100% (1)