Professional Documents

Culture Documents

SKS 30 Arkm 27 SBR 1712

SKS 30 Arkm 27 SBR 1712

Uploaded by

Manav PandyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SKS 30 Arkm 27 SBR 1712

SKS 30 Arkm 27 SBR 1712

Uploaded by

Manav PandyaCopyright:

Available Formats

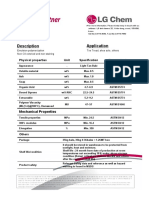

SKS-30 ARKM-27 / SBR-1712

Styrene-Butadiene Rubber

Specifications

Styrene-butadiene rubber SKS-30 ARKM-27 (SBR-1712) is a styrene and butadiene copolymer obtained by

emulsification method with the use of mixture of rosin and fatty acids soaps. The rubber is filled with extender

DAE-type oil for synthetic rubbers.

• REACH registered.

• Application: widely used in tire and industrial rubber industries.

Rubber should not contain any foreign impurities and must meet the following requirements:

• Appearance: briquettes (bales)

• Weight: 30.0+/-1.0 kg

• Colour: from light-brown to dark-brown

The product must meet the following quality parameters:

Parameter Standard Test Method

Mooney viscosity ML 1+4 (100°C)* 47-57 ASTM D 1646 (para. 7.2.2)

Viscosity spread within a batch, units, max* 6

Volatile matter content, %, max (1 hour)* 0.6 ASTM D 5668 (method C)

Ash content, %, max* 0.6 ASTM D 5667 (part A)

Bound styrene content, %* 22-25 ASTM D 5775

Antioxidant content, %:

– VS-1 or* 0.3-0.7 Method of supplier

– Agidol-2* 0.8-1.5 Method of supplier

Oil (DAE) content, %* 26-29 ASTM D 5774

Organic acids content, %* 4.0-5.6 ASTM D 5774

Organic acids soaps content, %, max* 0.3 ASTM D 5774

Rheometric Properties Standard Test Method

МL, dNm** 1.6-3.6 ASTM D 5289

MH, dNm** 12.6-16.5 ASTM D 5289

ts1, min** 3.5-6.5 ASTM D 5289

t’50,min** 6.5-10.5 ASTM D 5289

t’90,min** 15.0-18.5 ASTM D 5289

* - specified in the certificate of quality.

** - non-rejectable.

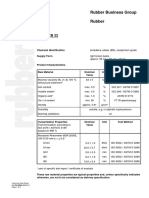

Preparation of rubber mixes is carried out in accordance with ASTMD 3185 recipe 1А, mixing – according to method A. Mixing mills are

prepared according to ASTM D 3182. Rheometric properties are determined according to ASTM D 5289 using an MDR 2000 rheometer (flow

meter). Wait time for rubber mix before testing is 2-6 hours.

Rubber mix recipe and measurement conditions:

Rubber mix recipe in parts by weight: Standard

Rubber 100.00

Zinc oxide 3.00

IRB 7 (N330) carbon black 50.00

Sulphur 1.75

Stearic acid 1.00

TBBS (N-tert-Butyl-2-benzothiazolesulfenamide) 1.00

Rheometer MDR 2000, measurement conditions: Standard

o

Temperature, С 160

Duration, min 30

Oscillation amplitude, deg. +/-0.5

Oscillation frequency, Hz 1.7

Packaging: Rubber briquettes (bales) are packaged in marked PE film (thickness of 0.05 +/- 0.01 mm,

melting temperature of 108-112оС), then – in plastic box pallets of 450kg or in plywood

containers of 1,080kg, or metal containers of 1,260kg.

Transportation: Rubber is transported by all types of transport in covered transporting means in

accordance to all rules of cargo’s transportation standing at transport of this form.

Storage: At a temperature not exceeding 30оС, in dry place free from direct sunlight.

Guaranteed Shelf Life: 1 (one) year from the manufacture date. After the expiration of the guaranteed shelf life,

the rubber can be used for its intended purpose after confirmation of its conformity to

the requirements of this product specification

You might also like

- Sge 6 TDSDocument2 pagesSge 6 TDSI Love MusicNo ratings yet

- Resina HidrocarburicaDocument1 pageResina HidrocarburicaManuel OsorioNo ratings yet

- TJPC 1502Document2 pagesTJPC 1502mohamad mostafaviNo ratings yet

- LG SBR1502 - TDSDocument1 pageLG SBR1502 - TDSYASHICA VAITTIANATHANNo ratings yet

- Specification of High Speed DieselDocument1 pageSpecification of High Speed DieselCHARAN AjmeeraNo ratings yet

- (Light Neutral) : Technical Data SheetDocument1 page(Light Neutral) : Technical Data SheetSameh RadwanNo ratings yet

- Luprene LG411: Technical Data SheetDocument2 pagesLuprene LG411: Technical Data Sheetrajeshji_000No ratings yet

- Buna CB 29Document2 pagesBuna CB 29TmacNo ratings yet

- 290 SodiumhydroxideflakeDocument1 page290 Sodiumhydroxideflakepaez lamaNo ratings yet

- Technical Datasheet LITEN FB 75 - EngDocument2 pagesTechnical Datasheet LITEN FB 75 - EngTo RaNo ratings yet

- Gac RC Eco Sorb 4x8: Granular Activated CarbonDocument12 pagesGac RC Eco Sorb 4x8: Granular Activated CarbonKamatchi Nathan100% (1)

- Результаты испытаний по методике ASTM D-6210-07Document4 pagesРезультаты испытаний по методике ASTM D-6210-07Mohamed SalemNo ratings yet

- Garlock Blue Gard 3000 Data SheetDocument1 pageGarlock Blue Gard 3000 Data SheetMatheus TorresNo ratings yet

- Buna CB 10 Rubber SpecificationsDocument2 pagesBuna CB 10 Rubber SpecificationsTmacNo ratings yet

- Mobil Diesel Oil B20 Marketing SpecDocument3 pagesMobil Diesel Oil B20 Marketing SpecsatriasinagaNo ratings yet

- Buna CB 22Document2 pagesBuna CB 22Tmac100% (1)

- Jotamastic 80 Aluminium - TDSDocument6 pagesJotamastic 80 Aluminium - TDSTeknik produksi wikonNo ratings yet

- UNIT II-CharacterizationDocument12 pagesUNIT II-CharacterizationSampanna AwareNo ratings yet

- TJPC 1507Document1 pageTJPC 1507mohamad mostafaviNo ratings yet

- TPC 7240Document1 pageTPC 7240babarancho56No ratings yet

- T 90 Ep2 S: Motor Vehicle Transmission OilDocument1 pageT 90 Ep2 S: Motor Vehicle Transmission Oilrobertjob34No ratings yet

- Polyolefin Copolymer Halogen Free Cable Insulation Compound: KI-LSHF-3401-ISDocument2 pagesPolyolefin Copolymer Halogen Free Cable Insulation Compound: KI-LSHF-3401-ISAMARENDRA SINo ratings yet

- Corrosiveness To Copper From Petroleum Products by Copper Strip TestDocument10 pagesCorrosiveness To Copper From Petroleum Products by Copper Strip TestLuigi MazzuccoNo ratings yet

- SN80Document1 pageSN80Abdul kadirNo ratings yet

- (AdvanSix) (TDS) Aegis H135ZPDocument3 pages(AdvanSix) (TDS) Aegis H135ZPMarcos KodairaNo ratings yet

- KF 70-TDSDocument1 pageKF 70-TDSKhoa HuynhNo ratings yet

- Corrosiveness To Copper From Petroleum Products by Copper Strip TestDocument10 pagesCorrosiveness To Copper From Petroleum Products by Copper Strip TestmuhannadNo ratings yet

- Ki LSHF 3401 IsDocument2 pagesKi LSHF 3401 IsjamilNo ratings yet

- 50-01 Test ReportDocument1 page50-01 Test ReportjanakaNo ratings yet

- Bitoner Resin C9 BP-120 TDSDocument2 pagesBitoner Resin C9 BP-120 TDSdamiendamNo ratings yet

- Product Data: Turbinol XDocument2 pagesProduct Data: Turbinol XdedyhidNo ratings yet

- Technical Datasheet LITEN BB 85 F - EngDocument2 pagesTechnical Datasheet LITEN BB 85 F - EngTo RaNo ratings yet

- PTFE HY29 HoerbigerDocument1 pagePTFE HY29 HoerbigerТатьяна ВасильеваNo ratings yet

- Product Specification - Apcoshield Py905sg Grey Ral 7016 20kgDocument1 pageProduct Specification - Apcoshield Py905sg Grey Ral 7016 20kgVenkatraman Subramaniam100% (1)

- MbtsDocument3 pagesMbtsBharat ChatrathNo ratings yet

- Technical Datasheet LH0075: 1) Product DescriptionDocument1 pageTechnical Datasheet LH0075: 1) Product DescriptionjavadmohammadiNo ratings yet

- Enersyn RC-S RangeDocument2 pagesEnersyn RC-S RangecarmaNo ratings yet

- Corrosiveness To Copper From Petroleum Products by Copper Strip TestDocument10 pagesCorrosiveness To Copper From Petroleum Products by Copper Strip TesteliiiiiiNo ratings yet

- Rubber TestingDocument4 pagesRubber TestingSharma ShailenNo ratings yet

- Datasheet Turbo Oil 2197Document2 pagesDatasheet Turbo Oil 2197loopkkNo ratings yet

- TDS 525 Jotamastic 87 GF Euk GBDocument5 pagesTDS 525 Jotamastic 87 GF Euk GBhidayatNo ratings yet

- Product TDS-1475Document1 pageProduct TDS-1475Company EcoplastNo ratings yet

- D 329 - 99 - Rdmyos1sruq - PDFDocument3 pagesD 329 - 99 - Rdmyos1sruq - PDFgravity castNo ratings yet

- ASTM D 130-10 - Corrosiveness To Copper From Petroleum Products by Copper Strip TestDocument9 pagesASTM D 130-10 - Corrosiveness To Copper From Petroleum Products by Copper Strip TestAnak Ayam100% (1)

- BNO Thermo Oil-32 (Mineral Based) : Product Data SheetDocument2 pagesBNO Thermo Oil-32 (Mineral Based) : Product Data SheetAyon HossenNo ratings yet

- HO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)Document2 pagesHO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)azimchemNo ratings yet

- SABIC Cycolac MG47FDocument3 pagesSABIC Cycolac MG47FChu ChuNo ratings yet

- 03 Blending PowerpointDocument70 pages03 Blending PowerpointNinhHoàngHải100% (4)

- Jotamastic 80 Technical Data SheetDocument6 pagesJotamastic 80 Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Nte Inen 935 10Document12 pagesNte Inen 935 10Gustavo FalconiNo ratings yet

- LEXAN FST3403tDocument3 pagesLEXAN FST3403tJose Ramon Florez OrdizNo ratings yet

- Aircol HC 7, HC 10Document2 pagesAircol HC 7, HC 10Vladislav TrempoletsNo ratings yet

- SuperS InhibitedTransformerOil SpecDocument2 pagesSuperS InhibitedTransformerOil Spechhahn01No ratings yet

- Unigear s3 Industrial Gear Oil SeriesDocument2 pagesUnigear s3 Industrial Gear Oil SeriesAnya J PamungkasNo ratings yet

- Highly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesFrom EverandHighly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesNo ratings yet

- Industrial Inorganic PigmentsFrom EverandIndustrial Inorganic PigmentsGunter BuxbaumRating: 5 out of 5 stars5/5 (1)

- Mechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingFrom EverandMechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingNo ratings yet

- Fuel System (018-016) : SpecificationsDocument2 pagesFuel System (018-016) : SpecificationsRasoolKhadibiNo ratings yet

- Abaqus Beam ModelingDocument14 pagesAbaqus Beam Modelingkiran129No ratings yet

- DENSO SeaShield HDPE OutercoverDocument1 pageDENSO SeaShield HDPE OutercoverJorge QuintanaNo ratings yet

- Lab ManualDocument34 pagesLab ManualSamuelPannierselvamShirleyNo ratings yet

- MiVoice Business NCR - Tech Update - R8.0 Iss 1Document60 pagesMiVoice Business NCR - Tech Update - R8.0 Iss 1Guillaume HochainNo ratings yet

- Transformer DetailsDocument3 pagesTransformer DetailsbinodeNo ratings yet

- S S H L: Mall-Cale Ydrodynamics in AkesDocument42 pagesS S H L: Mall-Cale Ydrodynamics in Akesbrian790No ratings yet

- O Ring Stretch & Fill & SqueezeDocument9 pagesO Ring Stretch & Fill & SqueezeGaurav MahajanNo ratings yet

- A General Solution For The Stress Around Internally Pressurized Circular Hole in Symmetric LaminatesDocument5 pagesA General Solution For The Stress Around Internally Pressurized Circular Hole in Symmetric LaminatesIoan-Lucian StanNo ratings yet

- PXE Lot or PXE LiteDocument10 pagesPXE Lot or PXE Lite1E : Empowering IT Efficiency100% (1)

- Ajax EliteDocument2 pagesAjax Elitegangruka75% (4)

- WincroDocument20 pagesWincromdavies20No ratings yet

- Cast Designer FolderDocument2 pagesCast Designer Foldergui_nf6618No ratings yet

- Install GuideDocument2 pagesInstall GuideffdfNo ratings yet

- NBTI Schroder NotesDocument47 pagesNBTI Schroder NotesRizwan AliNo ratings yet

- Fundamentals in Cavity PreprationDocument42 pagesFundamentals in Cavity PreprationNamrataNo ratings yet

- Fores GroupDocument5 pagesFores GrouppnaronaNo ratings yet

- Itc Prospectus & Syllabus 2018Document8 pagesItc Prospectus & Syllabus 2018Naresh LalwaniNo ratings yet

- CNC Job 2Document12 pagesCNC Job 2AnshorNo ratings yet

- Aerated Concrete Production Using Various Raw MaterialsDocument5 pagesAerated Concrete Production Using Various Raw Materialskinley dorjee100% (1)

- RAYCHEM - EPKT Terminations: Termination Systems For Polymeric and MIND Paper Insulated Cables From 7.2kV Up To 36kVDocument1 pageRAYCHEM - EPKT Terminations: Termination Systems For Polymeric and MIND Paper Insulated Cables From 7.2kV Up To 36kVStephen BridgesNo ratings yet

- Dae (Vecc)Document1 pageDae (Vecc)ashidh666No ratings yet

- Ds SOLIDserver DDI EN 190204 PDFDocument6 pagesDs SOLIDserver DDI EN 190204 PDFGhanshyam YadavaNo ratings yet

- JC Gasket CranfoilDocument2 pagesJC Gasket CranfoilMachineryengNo ratings yet

- Thermosolar Catalogue PDFDocument28 pagesThermosolar Catalogue PDFbagastcNo ratings yet

- Online ChattingDocument24 pagesOnline ChattingAmruthaprashanthNo ratings yet

- 08 09 CT2 ScribdDocument116 pages08 09 CT2 Scribdratninp9368100% (1)

- Manpower & Equipment Deployment Rev 0Document345 pagesManpower & Equipment Deployment Rev 0syedahmad3950% (2)

- Data Ontap 8.1.1Document128 pagesData Ontap 8.1.1mikkyphpNo ratings yet

- Excel Efficiency TipsDocument80 pagesExcel Efficiency Tipspinku_malhotra007100% (4)