Professional Documents

Culture Documents

SES 400kW

SES 400kW

Uploaded by

Jafar ShojaCopyright:

Available Formats

You might also like

- JMS 616 GS-N.L: Technical SpecificationDocument4 pagesJMS 616 GS-N.L: Technical SpecificationMohammad SarjoghiNo ratings yet

- Jen Bacher Gas EngineDocument4 pagesJen Bacher Gas Enginedannymay9575% (4)

- Rolls Royce Gas Engine of 5.255 MWDocument1 pageRolls Royce Gas Engine of 5.255 MWRashid Mahmood0% (1)

- Ge Jenbacher - Jgs 616dsDocument4 pagesGe Jenbacher - Jgs 616dsabdulkidwai2009No ratings yet

- Cat C32-1100 en PDFDocument1 pageCat C32-1100 en PDFOsanebi Chukwudi LuckyNo ratings yet

- Kompendium PDFDocument142 pagesKompendium PDFsiladharmaNo ratings yet

- CE365 Hydro, HW 1 SolutionDocument6 pagesCE365 Hydro, HW 1 SolutionbrayanNo ratings yet

- JMS 620 GS-N.L: Technical SpecificationDocument4 pagesJMS 620 GS-N.L: Technical SpecificationjoellopezzNo ratings yet

- JMS 208 GS-B.L: Jenbacher Gas EnginesDocument4 pagesJMS 208 GS-B.L: Jenbacher Gas EnginesSunil WadekarNo ratings yet

- Ficha Motor Gas Natural Jenbacher JMS 612 GSNL PDFDocument4 pagesFicha Motor Gas Natural Jenbacher JMS 612 GSNL PDFJuan Jose RuedaNo ratings yet

- JMS 320 GS-B.L: Jenbacher Gas EnginesDocument4 pagesJMS 320 GS-B.L: Jenbacher Gas EnginesSergioNo ratings yet

- JMS-320 GS NL (1065kw)Document4 pagesJMS-320 GS NL (1065kw)Dexterous EngineeringNo ratings yet

- JMS 416 GS-N.LDocument4 pagesJMS 416 GS-N.Lemamul613No ratings yet

- Janbacher 312 MergedDocument10 pagesJanbacher 312 MergedБогдан СендецькийNo ratings yet

- JMS 612 GS-N.L: Jenbacher Gas EnginesDocument4 pagesJMS 612 GS-N.L: Jenbacher Gas EngineshadNo ratings yet

- J 312Document4 pagesJ 312shahzad 28390% (1)

- JMS 420 GS-N.L: Technical SpecificationDocument4 pagesJMS 420 GS-N.L: Technical SpecificationАлександр ПедашNo ratings yet

- J 616Document4 pagesJ 616UsAmaImtiAz0% (1)

- Mtu 20V4000 DS4000: Diesel Generator SetDocument15 pagesMtu 20V4000 DS4000: Diesel Generator SetSlick72No ratings yet

- Diesel Engine D 2842 LE21x Technical Data PreliminaryDocument3 pagesDiesel Engine D 2842 LE21x Technical Data PreliminaryAung MhNo ratings yet

- Technical Specification: JMS 620 GS-N.LDocument3 pagesTechnical Specification: JMS 620 GS-N.LHoseinKhodadadyNo ratings yet

- Motordatenblatt MAN D2842LE201Document5 pagesMotordatenblatt MAN D2842LE201jonia1371No ratings yet

- 01 TS Cento 530 MAN NG C LB 50Hz S ENDocument2 pages01 TS Cento 530 MAN NG C LB 50Hz S ENDennis RamsumairNo ratings yet

- 2G Avus1000aDocument3 pages2G Avus1000ahamadaNo ratings yet

- 20V4000 L33 FN Technical Data SheetDocument2 pages20V4000 L33 FN Technical Data SheetB-ENERGY INVESTMENTNo ratings yet

- Technical Data 50 HZ: TCG 2016 V08 C, Bio Gas 55/45%, 500 NoxDocument1 pageTechnical Data 50 HZ: TCG 2016 V08 C, Bio Gas 55/45%, 500 NoxVladimir VoronovNo ratings yet

- PG Spec 16V4000DS2250 2160kVA 3B FC 50HzDocument5 pagesPG Spec 16V4000DS2250 2160kVA 3B FC 50HzMahmudur RahmanNo ratings yet

- Technical Data D2842LE301 1999 07 13Document2 pagesTechnical Data D2842LE301 1999 07 13scrollock0428No ratings yet

- Riello Rls Ts0040uk03 Rev2Document32 pagesRiello Rls Ts0040uk03 Rev2Mantenimiento PuntoFlexNo ratings yet

- MAN Energy SolutionsDocument4 pagesMAN Energy SolutionsRudiNo ratings yet

- PG Spec 20V4000DS3300 3130kVA 3F NOx 50HzDocument5 pagesPG Spec 20V4000DS3300 3130kVA 3F NOx 50HzkoosofehNo ratings yet

- MTU 16V4000 DS2500: Diesel Generator SetDocument6 pagesMTU 16V4000 DS2500: Diesel Generator Setmohsen_cumminsNo ratings yet

- Technische Daten D 2876 LE 20x-EngDocument3 pagesTechnische Daten D 2876 LE 20x-EngFahad MohammedNo ratings yet

- DS 825 PDFDocument6 pagesDS 825 PDFvuongNo ratings yet

- PG Spec 16V2000DS1250 800kVA 3A FC 50HzDocument5 pagesPG Spec 16V2000DS1250 800kVA 3A FC 50HzLucas PereiraNo ratings yet

- Ts0031uk01 Riello 40 FDocument16 pagesTs0031uk01 Riello 40 Fcorsini999No ratings yet

- PG Spec 16V4000DS2500 2360kVA 3F NEA 50HzDocument5 pagesPG Spec 16V4000DS2500 2360kVA 3F NEA 50HzYousefNo ratings yet

- Jpflorez - Caterpillar - Gas Genset CG170-12 1200 KweDocument1 pageJpflorez - Caterpillar - Gas Genset CG170-12 1200 Kweeduardo santosNo ratings yet

- Part A: Diesel Engine D 2842 LE403 Technical DataDocument4 pagesPart A: Diesel Engine D 2842 LE403 Technical DataardelNo ratings yet

- Technical - Info MTU 20V4000L62Document7 pagesTechnical - Info MTU 20V4000L62Marvin Tejerina Garfias100% (1)

- TSS DM1909 04 GS Epg 9463839Document3 pagesTSS DM1909 04 GS Epg 9463839mnezamiNo ratings yet

- Jpflorez Cat-2000 NatGas EngineDocument1 pageJpflorez Cat-2000 NatGas Engineeduardo santosNo ratings yet

- Asm1760 S16r-Pta-C 1280KWDocument7 pagesAsm1760 S16r-Pta-C 1280KWMinhThanh AdminNo ratings yet

- 20191119-3 - JGS 620 Technical Description and Calculation - enDocument8 pages20191119-3 - JGS 620 Technical Description and Calculation - enjonathan arboledaNo ratings yet

- Riello Rls M MX Ts0064uk03 Rev1Document32 pagesRiello Rls M MX Ts0064uk03 Rev1weweqweqwNo ratings yet

- 114 KW GeneratorDocument2 pages114 KW GeneratorKardin RadinkaNo ratings yet

- 3516 - Technical Spec SheetDocument3 pages3516 - Technical Spec Sheetadewunmi olufemiNo ratings yet

- Stratos MGM 160 Biogas: CogenerationDocument11 pagesStratos MGM 160 Biogas: CogenerationGeorge PircalabuNo ratings yet

- CAT C13 400kW SubmittalDocument42 pagesCAT C13 400kW SubmittalAli AlshazlyNo ratings yet

- 3516 - Technical Spec SheetDocument3 pages3516 - Technical Spec SheetAdewunmi OlufemiNo ratings yet

- 3.6 Data Sheet CTE 34 L8 ED Freezer 1Document1 page3.6 Data Sheet CTE 34 L8 ED Freezer 1Le Ngoc AnhNo ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Handbook of Electrical Engineering: For Practitioners in the Oil, Gas and Petrochemical IndustryFrom EverandHandbook of Electrical Engineering: For Practitioners in the Oil, Gas and Petrochemical IndustryNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- 7423-mwmtcg2032v16 50hzDocument17 pages7423-mwmtcg2032v16 50hzJafar ShojaNo ratings yet

- Gas Genset - SMUDocument1 pageGas Genset - SMUJafar ShojaNo ratings yet

- 0802 MAN Gas Engines AdjustmentsDocument2 pages0802 MAN Gas Engines AdjustmentsJafar ShojaNo ratings yet

- SlabDocument1 pageSlabJafar ShojaNo ratings yet

- Stepper Motor: With GPL Planetary GearDocument2 pagesStepper Motor: With GPL Planetary GearJafar ShojaNo ratings yet

- Ticket 1040133553Document1 pageTicket 1040133553Jafar ShojaNo ratings yet

- Psychrometric ChartDocument39 pagesPsychrometric ChartSalley BukhariNo ratings yet

- Vorticity and CirculationDocument5 pagesVorticity and CirculationChandana KarumanchiNo ratings yet

- Colligative Properties of Solution (3rd Week)Document41 pagesColligative Properties of Solution (3rd Week)SomeThingNo ratings yet

- Forced VibrationsDocument17 pagesForced Vibrationssuhas110No ratings yet

- AN27701 Hall Effect IC Application Guide PDFDocument44 pagesAN27701 Hall Effect IC Application Guide PDFjonataapolinarioNo ratings yet

- Calibration of ThermocoupleDocument22 pagesCalibration of ThermocoupleMuhammad Fahad100% (1)

- Pipe Flow AdditionalDocument11 pagesPipe Flow AdditionalKefene GurmessaNo ratings yet

- Workshop 5: Analyzing DC Circuits Solutions: in OutDocument12 pagesWorkshop 5: Analyzing DC Circuits Solutions: in OutvichuNo ratings yet

- AL1676Document15 pagesAL1676nareshNo ratings yet

- Ohmic HeatingDocument66 pagesOhmic HeatingNitesh Yadav100% (5)

- Electrostatics: Charge and Coulomb's LawDocument26 pagesElectrostatics: Charge and Coulomb's Lawashok pradhan0% (1)

- For Quadrant DC Motor ControlDocument43 pagesFor Quadrant DC Motor ControlDarshanRupani100% (1)

- Coil Selection FormatDocument6 pagesCoil Selection FormatTanveer AzizNo ratings yet

- Ap3015 ADocument11 pagesAp3015 ANguyen HuanNo ratings yet

- Single Axis Solar Tracker Using Servo MotorDocument9 pagesSingle Axis Solar Tracker Using Servo Motorjaan ka birthdayNo ratings yet

- Calculation of Smoke Movement in Building in Case of Fire: Takayuki Matsushita, Hiroshi Fukai, and Toshio TeraiDocument10 pagesCalculation of Smoke Movement in Building in Case of Fire: Takayuki Matsushita, Hiroshi Fukai, and Toshio Teraiefmartin21No ratings yet

- Low Voltage & Automotive Circuit ProtectionDocument7 pagesLow Voltage & Automotive Circuit ProtectionTim schroderNo ratings yet

- Physics Investigatory ProjectDocument11 pagesPhysics Investigatory ProjectKishore Kumar Robinho50% (2)

- TSM 101Document15 pagesTSM 101thiemncNo ratings yet

- Torque Worksheet: Class Set - Do Not Write On This Paper - Return To Teacher at End On Period!!Document4 pagesTorque Worksheet: Class Set - Do Not Write On This Paper - Return To Teacher at End On Period!!Arlyn Pong Pling PioNo ratings yet

- MPPT ReportDocument66 pagesMPPT ReportPavan Kumar100% (1)

- Density Altitude ChartDocument1 pageDensity Altitude Chartkiran tasneemNo ratings yet

- ST2009DHI: High Voltage Fast-Switching NPN Power TransistorDocument7 pagesST2009DHI: High Voltage Fast-Switching NPN Power TransistorMiloud ChouguiNo ratings yet

- NGR Sizing and Selection As Per IEEEDocument47 pagesNGR Sizing and Selection As Per IEEEutshab.ghosh2023No ratings yet

- Density, Relative Density, or API Gravity of Crude Petroleum and Liquid Petroleum Products by Hydrometer MethodDocument8 pagesDensity, Relative Density, or API Gravity of Crude Petroleum and Liquid Petroleum Products by Hydrometer MethodAbidin SyakirinNo ratings yet

- 09 - 1 (Hydraulic Fracturing-Treatment Design)Document31 pages09 - 1 (Hydraulic Fracturing-Treatment Design)Fanata YudhaNo ratings yet

- Ch4 Power System Slide07Document89 pagesCh4 Power System Slide07hafiz azman100% (2)

- 10 EIM Q2M1 TLE10 - EIM - Q2 - Mod1 - Wk1-5 - Elec-Meter-Connection-and-Grounding - v3Document35 pages10 EIM Q2M1 TLE10 - EIM - Q2 - Mod1 - Wk1-5 - Elec-Meter-Connection-and-Grounding - v3Lady Christianne BucsitNo ratings yet

SES 400kW

SES 400kW

Uploaded by

Jafar ShojaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SES 400kW

SES 400kW

Uploaded by

Jafar ShojaCopyright:

Available Formats

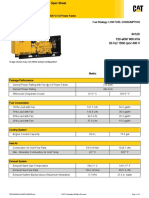

Technical Data Sheet

COGEN Compact Module SES - HPC 400 N - V12

Engine data version 02.2011

Basic Data Heat exchanger unit

Fuel Natural gas Jacket water heat output kW 236

Minimum heating value Hu kWh/m³ 10,0 Intercooler HT heat output kW 55

Methane number Mz ≥ 80 Intercooler LT heat output kW 16

Heating water system temperature °C 70 / 90 Exhaust heat

kW 222

CHP coefficient 0,79 (cooling up to 120°C)

Primary energy factor fp EnEV 2007 0,73 Total thermal power output via plate heat

kW 513

Frequency Hz 50 exchanger

Nominal voltage Un V 400 Heating water temp. inlet °C 70

Speed min-1 1.500 Heating water temp. outlet °C 90

Intercooler version °C 50

Electrical nominal power at cosφ=1 kW 405 Design and operation

Thermal power utile * kW 513

Maintenance interval oh 1.250

Fuel power input kW 1.045

Efficiency electrical % 38,8 Lubricant oil content engine min./max. l 40/90

Efficiency thermal % 49,1 Generator efficiency cosφ=1, 400V % 96,4

Efficiency total % 87,9 Generator current nominal cosφ=1, 400V A 584

Lean operation Radiation heat module kW 61

After-treatment of exhaust gases

and oxicat Intake air mass flow kg/h 16.566

Pollutant emissions TA-Luft 2002 Outlet air mass flow kg/h 14.516

(dry exhaust gas with 5% O2) Combustion air mass flow

kg/h 2.050

Formaldehyde ***** mg/Nm³ < 60 at 25°C and 1013 mbar

NOx measured as NO2 mg/Nm³ < 500 Intake air temp. ISO 3046 min/max °C 10 / 25

CO mg/Nm³ < 300 Exhaust mass flow wet kg/h 2.126

Exhaust volume flow, dry 0% O2

Nm³/h 1.698

Engine (0°C, 1013 mbar)

Engine Type MAN E 2842 LE 322 Permissible exhaust gas back pressure

mbar 5

Combustion type Gas engine downstream of module for piping

Operating principle 4-stroke Airbone noise (sound power level) Module ** dB(A) 106

Cylinder No./ configuration V 12 Sound level reduction with standard sound-

Displacement l 21,9 absorbing hood (average frequency range of dB 28

Engine power according ISO 3046/1 kW mech 420 500 Hz - 4000 Hz)

Specific fuel consumption MJ/kWh 8,96 Exhaust noise (sound pressure level) damped

with primary exhaust silencer dB(A) 70

Generator at 10 m distance ***

Type of Generator Leroy Somer 47.2 L9 C6/4

Apparent power kVA 600 Connections and interfaces

Voltage V 400 Gas inlet Rp 2"

Stator connection Y Exhaust gas outlet (flange) DN250/PN10

Ambient temperature max. °C 40 Condensate drain R 1"

Protection class IP23 Heating water inlet/outlet (flange) DN65/PN10

Radio interference class acc. VDE 0875 N Intercooling system LT inlet/outlet (flange) DN40/PN10

Heating class H Flanges conform to DIN EN 1092-1

Generator weight kg 1.331 Module dimensions and weight

Length mm 3.725

Width mm 1.740

Height mm 2.750

Operating weight approx. kg 5.500

* Possibility of increasing thermal power by using a calorific value waste-gas heat exchanger.

** Measurement of noise in free field, tolerance ± 1,0 dB(A)

*** Measurement of noise in free field, tolerance ± 2,5 dB(A)

***** Special-Oxi-Cat (Formaldehyde, H2CO < 40 mg/Nm³) causes additional charge.

Tolerance for preceding heat output ±7% and energy input +5%.

All further data are valid for grid parallel operation. Derating through adjustment of reactive power factor cosφ by energy supplier possible.

Features of our scope of supply are only warranted, when SES expressly stated the warranty. Power and efficiencies according ISO 3046/1

and DIN 6271, at 25°C air temperature, 100 kPa air pressure (at 100 m above see level), 30% rel. humidity, methane number ≥ 80, as well as

cosφ = 1. As fuel natural gas according German DVGW Worksheet G260, category 2, group L is valid. Furthermore following documents are

valid: MAN Operating Materials and Operating Instructions for MAN Industrial Gas Engines in latest edition. These documents are available

on request. A gas flow pressure before module of 40 - 80 mbar is necessary. A temperature of gas mixer outlet of 10 °C to 30 °C has to be

ensured. Data for other operating conditions or gas qualities on request.

Subject to technical modifications. E. & OE. V 11/2012 © SES Energiesysteme GmbH

You might also like

- JMS 616 GS-N.L: Technical SpecificationDocument4 pagesJMS 616 GS-N.L: Technical SpecificationMohammad SarjoghiNo ratings yet

- Jen Bacher Gas EngineDocument4 pagesJen Bacher Gas Enginedannymay9575% (4)

- Rolls Royce Gas Engine of 5.255 MWDocument1 pageRolls Royce Gas Engine of 5.255 MWRashid Mahmood0% (1)

- Ge Jenbacher - Jgs 616dsDocument4 pagesGe Jenbacher - Jgs 616dsabdulkidwai2009No ratings yet

- Cat C32-1100 en PDFDocument1 pageCat C32-1100 en PDFOsanebi Chukwudi LuckyNo ratings yet

- Kompendium PDFDocument142 pagesKompendium PDFsiladharmaNo ratings yet

- CE365 Hydro, HW 1 SolutionDocument6 pagesCE365 Hydro, HW 1 SolutionbrayanNo ratings yet

- JMS 620 GS-N.L: Technical SpecificationDocument4 pagesJMS 620 GS-N.L: Technical SpecificationjoellopezzNo ratings yet

- JMS 208 GS-B.L: Jenbacher Gas EnginesDocument4 pagesJMS 208 GS-B.L: Jenbacher Gas EnginesSunil WadekarNo ratings yet

- Ficha Motor Gas Natural Jenbacher JMS 612 GSNL PDFDocument4 pagesFicha Motor Gas Natural Jenbacher JMS 612 GSNL PDFJuan Jose RuedaNo ratings yet

- JMS 320 GS-B.L: Jenbacher Gas EnginesDocument4 pagesJMS 320 GS-B.L: Jenbacher Gas EnginesSergioNo ratings yet

- JMS-320 GS NL (1065kw)Document4 pagesJMS-320 GS NL (1065kw)Dexterous EngineeringNo ratings yet

- JMS 416 GS-N.LDocument4 pagesJMS 416 GS-N.Lemamul613No ratings yet

- Janbacher 312 MergedDocument10 pagesJanbacher 312 MergedБогдан СендецькийNo ratings yet

- JMS 612 GS-N.L: Jenbacher Gas EnginesDocument4 pagesJMS 612 GS-N.L: Jenbacher Gas EngineshadNo ratings yet

- J 312Document4 pagesJ 312shahzad 28390% (1)

- JMS 420 GS-N.L: Technical SpecificationDocument4 pagesJMS 420 GS-N.L: Technical SpecificationАлександр ПедашNo ratings yet

- J 616Document4 pagesJ 616UsAmaImtiAz0% (1)

- Mtu 20V4000 DS4000: Diesel Generator SetDocument15 pagesMtu 20V4000 DS4000: Diesel Generator SetSlick72No ratings yet

- Diesel Engine D 2842 LE21x Technical Data PreliminaryDocument3 pagesDiesel Engine D 2842 LE21x Technical Data PreliminaryAung MhNo ratings yet

- Technical Specification: JMS 620 GS-N.LDocument3 pagesTechnical Specification: JMS 620 GS-N.LHoseinKhodadadyNo ratings yet

- Motordatenblatt MAN D2842LE201Document5 pagesMotordatenblatt MAN D2842LE201jonia1371No ratings yet

- 01 TS Cento 530 MAN NG C LB 50Hz S ENDocument2 pages01 TS Cento 530 MAN NG C LB 50Hz S ENDennis RamsumairNo ratings yet

- 2G Avus1000aDocument3 pages2G Avus1000ahamadaNo ratings yet

- 20V4000 L33 FN Technical Data SheetDocument2 pages20V4000 L33 FN Technical Data SheetB-ENERGY INVESTMENTNo ratings yet

- Technical Data 50 HZ: TCG 2016 V08 C, Bio Gas 55/45%, 500 NoxDocument1 pageTechnical Data 50 HZ: TCG 2016 V08 C, Bio Gas 55/45%, 500 NoxVladimir VoronovNo ratings yet

- PG Spec 16V4000DS2250 2160kVA 3B FC 50HzDocument5 pagesPG Spec 16V4000DS2250 2160kVA 3B FC 50HzMahmudur RahmanNo ratings yet

- Technical Data D2842LE301 1999 07 13Document2 pagesTechnical Data D2842LE301 1999 07 13scrollock0428No ratings yet

- Riello Rls Ts0040uk03 Rev2Document32 pagesRiello Rls Ts0040uk03 Rev2Mantenimiento PuntoFlexNo ratings yet

- MAN Energy SolutionsDocument4 pagesMAN Energy SolutionsRudiNo ratings yet

- PG Spec 20V4000DS3300 3130kVA 3F NOx 50HzDocument5 pagesPG Spec 20V4000DS3300 3130kVA 3F NOx 50HzkoosofehNo ratings yet

- MTU 16V4000 DS2500: Diesel Generator SetDocument6 pagesMTU 16V4000 DS2500: Diesel Generator Setmohsen_cumminsNo ratings yet

- Technische Daten D 2876 LE 20x-EngDocument3 pagesTechnische Daten D 2876 LE 20x-EngFahad MohammedNo ratings yet

- DS 825 PDFDocument6 pagesDS 825 PDFvuongNo ratings yet

- PG Spec 16V2000DS1250 800kVA 3A FC 50HzDocument5 pagesPG Spec 16V2000DS1250 800kVA 3A FC 50HzLucas PereiraNo ratings yet

- Ts0031uk01 Riello 40 FDocument16 pagesTs0031uk01 Riello 40 Fcorsini999No ratings yet

- PG Spec 16V4000DS2500 2360kVA 3F NEA 50HzDocument5 pagesPG Spec 16V4000DS2500 2360kVA 3F NEA 50HzYousefNo ratings yet

- Jpflorez - Caterpillar - Gas Genset CG170-12 1200 KweDocument1 pageJpflorez - Caterpillar - Gas Genset CG170-12 1200 Kweeduardo santosNo ratings yet

- Part A: Diesel Engine D 2842 LE403 Technical DataDocument4 pagesPart A: Diesel Engine D 2842 LE403 Technical DataardelNo ratings yet

- Technical - Info MTU 20V4000L62Document7 pagesTechnical - Info MTU 20V4000L62Marvin Tejerina Garfias100% (1)

- TSS DM1909 04 GS Epg 9463839Document3 pagesTSS DM1909 04 GS Epg 9463839mnezamiNo ratings yet

- Jpflorez Cat-2000 NatGas EngineDocument1 pageJpflorez Cat-2000 NatGas Engineeduardo santosNo ratings yet

- Asm1760 S16r-Pta-C 1280KWDocument7 pagesAsm1760 S16r-Pta-C 1280KWMinhThanh AdminNo ratings yet

- 20191119-3 - JGS 620 Technical Description and Calculation - enDocument8 pages20191119-3 - JGS 620 Technical Description and Calculation - enjonathan arboledaNo ratings yet

- Riello Rls M MX Ts0064uk03 Rev1Document32 pagesRiello Rls M MX Ts0064uk03 Rev1weweqweqwNo ratings yet

- 114 KW GeneratorDocument2 pages114 KW GeneratorKardin RadinkaNo ratings yet

- 3516 - Technical Spec SheetDocument3 pages3516 - Technical Spec Sheetadewunmi olufemiNo ratings yet

- Stratos MGM 160 Biogas: CogenerationDocument11 pagesStratos MGM 160 Biogas: CogenerationGeorge PircalabuNo ratings yet

- CAT C13 400kW SubmittalDocument42 pagesCAT C13 400kW SubmittalAli AlshazlyNo ratings yet

- 3516 - Technical Spec SheetDocument3 pages3516 - Technical Spec SheetAdewunmi OlufemiNo ratings yet

- 3.6 Data Sheet CTE 34 L8 ED Freezer 1Document1 page3.6 Data Sheet CTE 34 L8 ED Freezer 1Le Ngoc AnhNo ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Handbook of Electrical Engineering: For Practitioners in the Oil, Gas and Petrochemical IndustryFrom EverandHandbook of Electrical Engineering: For Practitioners in the Oil, Gas and Petrochemical IndustryNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- 7423-mwmtcg2032v16 50hzDocument17 pages7423-mwmtcg2032v16 50hzJafar ShojaNo ratings yet

- Gas Genset - SMUDocument1 pageGas Genset - SMUJafar ShojaNo ratings yet

- 0802 MAN Gas Engines AdjustmentsDocument2 pages0802 MAN Gas Engines AdjustmentsJafar ShojaNo ratings yet

- SlabDocument1 pageSlabJafar ShojaNo ratings yet

- Stepper Motor: With GPL Planetary GearDocument2 pagesStepper Motor: With GPL Planetary GearJafar ShojaNo ratings yet

- Ticket 1040133553Document1 pageTicket 1040133553Jafar ShojaNo ratings yet

- Psychrometric ChartDocument39 pagesPsychrometric ChartSalley BukhariNo ratings yet

- Vorticity and CirculationDocument5 pagesVorticity and CirculationChandana KarumanchiNo ratings yet

- Colligative Properties of Solution (3rd Week)Document41 pagesColligative Properties of Solution (3rd Week)SomeThingNo ratings yet

- Forced VibrationsDocument17 pagesForced Vibrationssuhas110No ratings yet

- AN27701 Hall Effect IC Application Guide PDFDocument44 pagesAN27701 Hall Effect IC Application Guide PDFjonataapolinarioNo ratings yet

- Calibration of ThermocoupleDocument22 pagesCalibration of ThermocoupleMuhammad Fahad100% (1)

- Pipe Flow AdditionalDocument11 pagesPipe Flow AdditionalKefene GurmessaNo ratings yet

- Workshop 5: Analyzing DC Circuits Solutions: in OutDocument12 pagesWorkshop 5: Analyzing DC Circuits Solutions: in OutvichuNo ratings yet

- AL1676Document15 pagesAL1676nareshNo ratings yet

- Ohmic HeatingDocument66 pagesOhmic HeatingNitesh Yadav100% (5)

- Electrostatics: Charge and Coulomb's LawDocument26 pagesElectrostatics: Charge and Coulomb's Lawashok pradhan0% (1)

- For Quadrant DC Motor ControlDocument43 pagesFor Quadrant DC Motor ControlDarshanRupani100% (1)

- Coil Selection FormatDocument6 pagesCoil Selection FormatTanveer AzizNo ratings yet

- Ap3015 ADocument11 pagesAp3015 ANguyen HuanNo ratings yet

- Single Axis Solar Tracker Using Servo MotorDocument9 pagesSingle Axis Solar Tracker Using Servo Motorjaan ka birthdayNo ratings yet

- Calculation of Smoke Movement in Building in Case of Fire: Takayuki Matsushita, Hiroshi Fukai, and Toshio TeraiDocument10 pagesCalculation of Smoke Movement in Building in Case of Fire: Takayuki Matsushita, Hiroshi Fukai, and Toshio Teraiefmartin21No ratings yet

- Low Voltage & Automotive Circuit ProtectionDocument7 pagesLow Voltage & Automotive Circuit ProtectionTim schroderNo ratings yet

- Physics Investigatory ProjectDocument11 pagesPhysics Investigatory ProjectKishore Kumar Robinho50% (2)

- TSM 101Document15 pagesTSM 101thiemncNo ratings yet

- Torque Worksheet: Class Set - Do Not Write On This Paper - Return To Teacher at End On Period!!Document4 pagesTorque Worksheet: Class Set - Do Not Write On This Paper - Return To Teacher at End On Period!!Arlyn Pong Pling PioNo ratings yet

- MPPT ReportDocument66 pagesMPPT ReportPavan Kumar100% (1)

- Density Altitude ChartDocument1 pageDensity Altitude Chartkiran tasneemNo ratings yet

- ST2009DHI: High Voltage Fast-Switching NPN Power TransistorDocument7 pagesST2009DHI: High Voltage Fast-Switching NPN Power TransistorMiloud ChouguiNo ratings yet

- NGR Sizing and Selection As Per IEEEDocument47 pagesNGR Sizing and Selection As Per IEEEutshab.ghosh2023No ratings yet

- Density, Relative Density, or API Gravity of Crude Petroleum and Liquid Petroleum Products by Hydrometer MethodDocument8 pagesDensity, Relative Density, or API Gravity of Crude Petroleum and Liquid Petroleum Products by Hydrometer MethodAbidin SyakirinNo ratings yet

- 09 - 1 (Hydraulic Fracturing-Treatment Design)Document31 pages09 - 1 (Hydraulic Fracturing-Treatment Design)Fanata YudhaNo ratings yet

- Ch4 Power System Slide07Document89 pagesCh4 Power System Slide07hafiz azman100% (2)

- 10 EIM Q2M1 TLE10 - EIM - Q2 - Mod1 - Wk1-5 - Elec-Meter-Connection-and-Grounding - v3Document35 pages10 EIM Q2M1 TLE10 - EIM - Q2 - Mod1 - Wk1-5 - Elec-Meter-Connection-and-Grounding - v3Lady Christianne BucsitNo ratings yet