Professional Documents

Culture Documents

Size Reduction Table 29.1

Size Reduction Table 29.1

Uploaded by

Ivan Thaddeaus SantoniaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Size Reduction Table 29.1

Size Reduction Table 29.1

Uploaded by

Ivan Thaddeaus SantoniaCopyright:

Available Formats

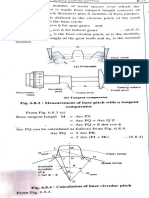

964 OPERATIONS INVOLVING PARTICULATE SOLIDS

the product, sPiv.- By Eq. (28.1), sp/vp = 6(ifl,DP, from which it follows that

p K,

(29.8)

;;= JD:,

where K, is a constant that depends on the type of machine and on the material

being crushed. This is equivalent to a solution of Eq. (29.7) with n = 1.5 and a

feed of infinite size. To use Eq. (29.8), a work index W, is defined as the gross

energy requirement in kilowatthours per ton (2000 lb) of feed needed to reduce a

very large feed to such a size that 80 percent of the product passes a 100-}lm

screen. This definition leads to a relation between K, and W,. If DP is in millimeters,

p in kilowatts, and min tons per hour,

K, = j100 x 10- 3 W, = 0.31621¥, (29.9)

If 80 percent of the feed passes a mesh size of Dpa millimeters and 80 percent

of the product a mesh of DP, millimeters, it follows from Eqs. (29.8) and (29.9) that

~- ~)

ti; = 0.31621¥, ( yDp, (29.10)

yDpa

The work index includes the friction in the crusher, and the power given by Eq.

(29.10) is gross power.

Table 29.1 gives typical work indexes for some common minerals. These data

do not vary greatly among different machines of the same general type and apply

TABLE 29.1

Work indexes for dry crusbingt or wet grinding~

Material Specific gravity Work index, W;

Bauxite 2.20 8.78

Cement clinker 3.15 13.45

Cement raw material 2.67 10.51

Clay 2.51 6.30

Coal 1.4 13.00

Coke 1.31 15.13

Granite 2.66 15.13

Gravel 2.66 16.06

Gypsum rock 2.69 6.73

Iron ore (hematite) 3.53 12.84

Limestone 2.66 12.74

Phosphate rock 2.74 9.92

Quartz 2.65 13.57

Shale 2.63 15.87

Slate 2.57 14.30

Trap rock 2.87 19.32

t For dry grinding, multiply by!.

t From Allis-Chalmers, Solids Processing Equipment Div., Appleton,

Wisconsin, by permission.

You might also like

- Kenics Static Mixer TechnologyDocument12 pagesKenics Static Mixer Technologyfoad arabyNo ratings yet

- Catalogo Motores Brook Crompton 2008Document74 pagesCatalogo Motores Brook Crompton 2008DELMAR QUIROGA CALDERONNo ratings yet

- Molienda y Milling MachinresDocument7 pagesMolienda y Milling MachinresAlexander UFNo ratings yet

- Synthesis of Metal Organic FrameworksDocument37 pagesSynthesis of Metal Organic Frameworksmoonwolf178No ratings yet

- SCFM Vs ACFM Conversion Guide PDFDocument16 pagesSCFM Vs ACFM Conversion Guide PDFasteriskinNo ratings yet

- Smith Et al-1958-AIChE Journal PDFDocument3 pagesSmith Et al-1958-AIChE Journal PDFAlastairNo ratings yet

- A Compendium of Ground Modification TechniquesDocument371 pagesA Compendium of Ground Modification Techniquesminhhuan0101No ratings yet

- Map Gems RohanDocument5 pagesMap Gems RohanThoriq Nasrul FattahNo ratings yet

- Data Set of World Phosphate Mines, Deposits, and Occurrences-Part A. Geologic DataDocument352 pagesData Set of World Phosphate Mines, Deposits, and Occurrences-Part A. Geologic DatasahjNo ratings yet

- Full 66817Document8 pagesFull 66817EvaPuspitaSariNo ratings yet

- Coll OidsDocument77 pagesColl OidsIrham Hikmawan RamadhanNo ratings yet

- Powder Technology: Aca Jovanovi Ć, Milada Pezo, Lato Pezo, Ljubinko Levi ĆDocument9 pagesPowder Technology: Aca Jovanovi Ć, Milada Pezo, Lato Pezo, Ljubinko Levi ĆEdison GarciaNo ratings yet

- PCMO - Module-II Size Reduction Equipment PDFDocument66 pagesPCMO - Module-II Size Reduction Equipment PDFrefarmita24No ratings yet

- Chapter - Ii Synthesis Methods of NanoparticlesDocument20 pagesChapter - Ii Synthesis Methods of NanoparticlesEswara SaiNo ratings yet

- Chapter - Ii Synthesis Methods of NanoparticlesDocument20 pagesChapter - Ii Synthesis Methods of Nanoparticlesjkc collegeNo ratings yet

- Mathcad - 2Document4 pagesMathcad - 2Desejo SozinandoNo ratings yet

- TP - The Compact Precisione0208Document20 pagesTP - The Compact Precisione0208Pradip GuptaNo ratings yet

- Winch Drum Capacity CalculationsDocument2 pagesWinch Drum Capacity CalculationsDwi ArifNo ratings yet

- PlateDocument3 pagesPlateAdnan RanaNo ratings yet

- Mass Transfer CoefficientDocument7 pagesMass Transfer CoefficientkolkeNo ratings yet

- PMPa006 A Comparison of Extenders in Semi-Gloss Emulsion Paints June 2009Document2 pagesPMPa006 A Comparison of Extenders in Semi-Gloss Emulsion Paints June 2009Dian Pires100% (2)

- Ramdas Osborne Ortt 1980 PDFDocument10 pagesRamdas Osborne Ortt 1980 PDFSebastian PinzonNo ratings yet

- 2015-Tackling Difficult Mixing ProblemsDocument8 pages2015-Tackling Difficult Mixing Problemsjuan sepulvedaNo ratings yet

- Pumps and Compressors: Week 7Document20 pagesPumps and Compressors: Week 7ednsmnNo ratings yet

- Air Gas RatioDocument2 pagesAir Gas RatioArjun Singh0% (1)

- Centrifugal Pump CurvesDocument2 pagesCentrifugal Pump CurvesasdNo ratings yet

- Superfine Grinding TechniquesDocument34 pagesSuperfine Grinding TechniquesKazemizNo ratings yet

- 2007 Dias, Efficient Cooling of Fermentation Vats in Ethanol Production - Part 1Document8 pages2007 Dias, Efficient Cooling of Fermentation Vats in Ethanol Production - Part 1roger_shNo ratings yet

- Brochure SMBDocument24 pagesBrochure SMBfelipeNo ratings yet

- New Microsoft PowerPoint PresentationDocument19 pagesNew Microsoft PowerPoint PresentationYaSsin Saad100% (1)

- Pbe - 200810-Conveying Line Elbows Provide Maintenance-Free OperationDocument4 pagesPbe - 200810-Conveying Line Elbows Provide Maintenance-Free Operation설동하No ratings yet

- Pump Power CalculatorDocument2 pagesPump Power CalculatorArpit ShahNo ratings yet

- Bulk Density PDFDocument15 pagesBulk Density PDFrudi rockerNo ratings yet

- Stress Intensifiyer in Tanks 01Document22 pagesStress Intensifiyer in Tanks 01gechaves1No ratings yet

- Formula Basic Hydraulic Formulas Pressure, Force and Horsepower RelationshipsDocument5 pagesFormula Basic Hydraulic Formulas Pressure, Force and Horsepower Relationshipsshashidhar h vNo ratings yet

- Controlling Ejector Performance: BY C. G. Blatchley Schutte & KoertingDocument9 pagesControlling Ejector Performance: BY C. G. Blatchley Schutte & KoertingCan YıldırımNo ratings yet

- Aleaciones de Aluminio Astm b928b928mDocument10 pagesAleaciones de Aluminio Astm b928b928mHaniel FcNo ratings yet

- Critical Analysis of Zwietering Correlation For Solids Suspension in Stirred TanksDocument10 pagesCritical Analysis of Zwietering Correlation For Solids Suspension in Stirred TanksVerónica ArévaloNo ratings yet

- p493 02 PDFDocument7 pagesp493 02 PDFmuzideweixiaoNo ratings yet

- Brook Motor Data SheetDocument2 pagesBrook Motor Data SheetVidhyananthan RamasamyNo ratings yet

- 4500MB Parr Stirred Reactors and Pressure Vessels Catalog v15 Literature 2Document178 pages4500MB Parr Stirred Reactors and Pressure Vessels Catalog v15 Literature 2asdasdNo ratings yet

- Inquiry - Sitemap - E-Mail: Dispersing, Suspending, Emulsifying & Homogenizing Technik For Liquid and PasteDocument5 pagesInquiry - Sitemap - E-Mail: Dispersing, Suspending, Emulsifying & Homogenizing Technik For Liquid and PasteCik MinnNo ratings yet

- 5560 English PDFDocument11 pages5560 English PDFdonya100% (1)

- CasoEstudio PervaporaciónDocument17 pagesCasoEstudio PervaporaciónValentina SánchezNo ratings yet

- Vacuum Systems PDFDocument12 pagesVacuum Systems PDFSnigdha YadavNo ratings yet

- Effect of Impeller Design On The Flow Pattern and Mixing in Stirred Tanks PDFDocument21 pagesEffect of Impeller Design On The Flow Pattern and Mixing in Stirred Tanks PDFEricEspinozaAcostaNo ratings yet

- Txy Diagram For Ethanol/Water at 760Mmhg: Model, Bubble Point Model, Dew Point Data, Bubble Point Data, Dew PointDocument3 pagesTxy Diagram For Ethanol/Water at 760Mmhg: Model, Bubble Point Model, Dew Point Data, Bubble Point Data, Dew PointjunomarsNo ratings yet

- Vertical Colloid Mill - China Sun and Moon Food Machinery CoDocument2 pagesVertical Colloid Mill - China Sun and Moon Food Machinery Coasit_mNo ratings yet

- Document'S Code Attachment 10.3 Revision 0: ClientDocument4 pagesDocument'S Code Attachment 10.3 Revision 0: ClientrfriosEP100% (1)

- Stok PreparationDocument5 pagesStok PreparationtisaNo ratings yet

- DIN-En-1822 Mez Klasifikace enDocument1 pageDIN-En-1822 Mez Klasifikace enGabrielNo ratings yet

- 2013 Lect6 FORCES ON PIPE BENDSDocument39 pages2013 Lect6 FORCES ON PIPE BENDSBagus PrakasaNo ratings yet

- Gear Pump Design SheetDocument3 pagesGear Pump Design Sheetdeion29No ratings yet

- 722222-CD-000-PIP-MTO-001 - Piping, Fitting, Flange, Gasket, Bolt - Nut - RA (Aboveground)Document16 pages722222-CD-000-PIP-MTO-001 - Piping, Fitting, Flange, Gasket, Bolt - Nut - RA (Aboveground)rianafrian2611No ratings yet

- 225 H Engg DataDocument8 pages225 H Engg DataPravin BoteNo ratings yet

- Properties of Pipes, Tubes, and ScreensDocument1 pageProperties of Pipes, Tubes, and ScreensDarrenGCGNo ratings yet

- Base Tangent LengthDocument1 pageBase Tangent LengthKalpesh BawankarNo ratings yet

- Falling Film Evaporator-MEng-ThesisDocument206 pagesFalling Film Evaporator-MEng-ThesisElza Febrianty AngrainiNo ratings yet

- Datasheet For Hopper (D-3103)Document1 pageDatasheet For Hopper (D-3103)Joe GrosirNo ratings yet

- Butterfly Valves: Uses, Types, Working, Advantages, Symbols: Skip To ContentDocument9 pagesButterfly Valves: Uses, Types, Working, Advantages, Symbols: Skip To ContentVinay SharmaNo ratings yet

- Abdullah Naser Al-Mmotiry (1,2,3)Document9 pagesAbdullah Naser Al-Mmotiry (1,2,3)nzb1234No ratings yet

- L04 - Pile DesignDocument22 pagesL04 - Pile DesignKhairul NayanNo ratings yet

- Fe (L5B) 3ched Santonia IjtfDocument2 pagesFe (L5B) 3ched Santonia IjtfIvan Thaddeaus SantoniaNo ratings yet

- 3D Santonia IJTF SetF - Part4Document1 page3D Santonia IJTF SetF - Part4Ivan Thaddeaus SantoniaNo ratings yet

- 04 - View Factor HandoutDocument1 page04 - View Factor HandoutIvan Thaddeaus SantoniaNo ratings yet

- Laudato Si: Ivan Thaddeaus Santonia 1-29Document3 pagesLaudato Si: Ivan Thaddeaus Santonia 1-29Ivan Thaddeaus SantoniaNo ratings yet

- Brick For LicenceDocument8 pagesBrick For LicenceAbinashNo ratings yet

- Stormwater Management Devices: Design Guidelines Manual: Second Edition, May 2003Document250 pagesStormwater Management Devices: Design Guidelines Manual: Second Edition, May 2003louise9347No ratings yet

- MGB - Hazard Information PDFDocument74 pagesMGB - Hazard Information PDFKyla MatiasNo ratings yet

- 3.-Investigating Anisotropy in Shear Strength of Clayey SoilsDocument5 pages3.-Investigating Anisotropy in Shear Strength of Clayey SoilsRamiro ChairezNo ratings yet

- Assignment On Soil PollutionDocument18 pagesAssignment On Soil PollutionImran Hussain100% (1)

- Water Hyacinth Fiber Stripping MachineDocument2 pagesWater Hyacinth Fiber Stripping MachineRonald Melvin Rodriguez Rosas100% (1)

- KS3 Chemistry Rocks Presentation Classroom 1Document15 pagesKS3 Chemistry Rocks Presentation Classroom 1Bushra QaiserNo ratings yet

- A Detailed Lesson Plan in Science III (Composition of Soil)Document3 pagesA Detailed Lesson Plan in Science III (Composition of Soil)Joby Ganda100% (1)

- 3.1 Pile GroupDocument42 pages3.1 Pile GroupRadifan HalifNo ratings yet

- Water Retention Curve Is The Relationship Between The Moisture CharacteristicDocument31 pagesWater Retention Curve Is The Relationship Between The Moisture CharacteristicasprillaNo ratings yet

- Cone Penetration Testing-IIDocument45 pagesCone Penetration Testing-IIRobert PrinceNo ratings yet

- Bio FertilizersDocument16 pagesBio Fertilizersnet_setNo ratings yet

- 01 HofstraDocument5 pages01 HofstraHEBERT JHON RAFAEL AGUILARNo ratings yet

- Md. Yousuf Gazi, Lecturer, Department of Geology, University of Dhaka (Yousuf - Geo@du - Ac.bd)Document20 pagesMd. Yousuf Gazi, Lecturer, Department of Geology, University of Dhaka (Yousuf - Geo@du - Ac.bd)ehabNo ratings yet

- Replay FW 1819Document17 pagesReplay FW 1819infoNo ratings yet

- RWH PresentationDocument17 pagesRWH PresentationFaisal AshrafNo ratings yet

- Rungta College of Engineering and TechnologDocument8 pagesRungta College of Engineering and TechnologBhavika GyakwadNo ratings yet

- Garter Squish A4Document2 pagesGarter Squish A4moldodeeaNo ratings yet

- Akasia HibridDocument24 pagesAkasia HibridAida HusnaNo ratings yet

- 2 Clay MineralogyDocument26 pages2 Clay MineralogyShah Alam100% (1)

- Hydrology - Subsurface FlowDocument27 pagesHydrology - Subsurface FlowMark B. BarrogaNo ratings yet

- Contoh Perhitungan Uji HidrometerDocument16 pagesContoh Perhitungan Uji HidrometerMIKCHAEL WADHANTONo ratings yet

- Skempton - A Contribution To The Settlement Analysis of Foundations On ClayDocument11 pagesSkempton - A Contribution To The Settlement Analysis of Foundations On ClayrodrigoNo ratings yet

- BS 1377-5Document40 pagesBS 1377-5Omar Imad SrajNo ratings yet

- Soil Suitability TarlacDocument16 pagesSoil Suitability TarlacDino Siopongco100% (1)

- 4 Soil Color DEQ SepticDocument27 pages4 Soil Color DEQ SepticAshutosh Sharma100% (1)

- Aqua Module - Week3&4Document32 pagesAqua Module - Week3&4Rheinald Baldo100% (1)