Professional Documents

Culture Documents

Performance of Large Storage Tank in Bhuj Earthquake

Performance of Large Storage Tank in Bhuj Earthquake

Uploaded by

CEG BangladeshOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance of Large Storage Tank in Bhuj Earthquake

Performance of Large Storage Tank in Bhuj Earthquake

Uploaded by

CEG BangladeshCopyright:

Available Formats

PERFORMANCE OF LARGE STORAGE TANK IN BHUJ EARTHQUAKE

K.R. Datye M.G. Khare

Consulting Engineer Larsen and Toubro Ltd., ECC Division

Vile Parle, Mumbai, India – 400 057 Chennai, India – 600 089

ABSTRACT

The 2001 Bhuj earthquake of magnitude 7.7 caused a widespread damage in the state of Gujarat, India. This paper presents a case

study of phosphoric acid storage tank weighing 100,000 kN and measuring 30 m in diameter built for a fertilizer plant in Kandla,

Gujarat. The post earthquake performance assessment was carried out by exhuming the nearby piles and non-destructive testing of

piles. The storage tanks supported on piles, installed in a ground treated with stone columns, showed no failure and have performed

well during the earthquake. The design philosophy used to resist axial and lateral loads is explained.

PROJECT BACKGROUND

Fuel oil storage tank N

A large fertilizer plant was built by the Indian Farmers

Fertilizer Cooperative Ltd. (IFFCO) at Kandla in the western Phosphoric acid storage tanks

state of Gujarat, India. The phase I was built from 1970-1972.

It included the NPK plant (main plant), phosphoric acid tanks,

ammonia tanks, water tanks, storage heaps, steel conveyor

galleries, workshops, pipe racks and other service structures. *

A

Except for the main plant, all other structures were founded on

stone column/sand drain treated ground. For the major heaps *

(product), piles were used with due consideration to negative

drag. Phase II was built from 1976 to 1980, to double the

plant capacity. For Phase I, pseudo static analysis was carried

out, whereas for phase II, dynamic analysis was also carried A

out for soil-pile-superstructure interaction. a) Plan

The project included various critical structures such as Phosphoric acid storage tank

ammonia, main NPK plant supporting heavy machines,

phosphoric acid storage tanks, and adjoining RCC conveyer Bund

galleries. The site profile near the phosphoric acid storage

tanks is shown in Fig. 1. The 2001 Bhuj earthquake prompted 2

the IFFCO authorities to undertake a detailed study of the 1 2.5 Kandla Creek

possible damage to foundation and rehabilitation measures 1 2

required to ensure the plant safety in the future. The first 1

author was responsible for the original design of foundation b) Cross section through A-A

system used for all the structures within the IFFCO plant when

it was built and therefore was entrusted the task of post * Tank exclusively on

earthquake analysis of its performance. This paper deals with stone columns

the soil profile, design philosophy adopted for foundation and

its post earthquake performance through specific reference to Fig. 1 Site lay out of IFFCO plant

the large phosphoric acid storage tank.

Paper No. 3.29 1

SOIL INVESTIGATION DESIGN ISSUES

The IFFCO site is situated on a low-lying area gradually The phosphoric acid storage tank with design vertical load of

sloping towards the Kandla creek. The ground where the large 150,000 kN had to be built with stringent performance

storage tanks and other critical structures would be built was criterion. Apart from the large vertical load, the foundation

submerged under Kandla creek with a mean tidal level of 2 m. had to be designed to resist the lateral load due to soil

The mobilization of drill rigs for the soil investigation in movement in the event of earthquake.

shallow water was not possible. Therefore, the submerged

areas were investigated using a lightweight dynamic probe

having the same geometry of the SPT sampling tube. The

probing, using a hammer weighing 18 kg along with the Shear strength (kPa)

disturbed sampling was carried out using small boats. The +4

Fill 0 20 40 6 8

disturbed samples were used to estimate the soil index ±0

properties. A more elaborate soil investigation including SPT, - 1.2 Grey silt Undistrubed

vane shear test, and undisturbed sampling was carried out Remoulded

where the drill rigs could be mobilized. The site specific

correlations thus developed were used for structures located in

Blue fine sand

areas where a detailed investigation could not be carried out.

with silt or clay

This decision was based on the experience from the previous

soil explorations in the Kandla creek where the correlations

have been found to be valid owing to the consistent

geomorphology of the creek. - 10.2

Blue fine sand

SOIL PROFILE with silt and clay

- 15

A typical soil profile based on visual classification and sieve - 16 Sandy silt with blue fines

analysis carried out in site laboratory is shown in Fig. 2. The Blue fine cemented sand

top 4 m consist of well compacted fill of silty clayey sand (SM - 18.5

- SC). The fill is underlain by 10 m of sandy silt. The silt is Hard overconsolidated reddish brown

followed by 6 m of clay and silt mixed with fine sand. The clay

field vane shear tests conducted on silty and clayey sand

layers showed the shear strength values in the range of 5 to 70

kPa. Although the clay fraction in these layers (between 1.5 to Fig. 2 Soil profile at IFFCO plant

15 m depth) is less, the soil is plastic due to high activity of

clay. At few locations, the liquidity index of more than one

was observed. These layers are susceptible to cyclic mobility During earthquakes, low density fine sand with little silt

due to the presence of silt. This behavior was confirmed content can liquefy but clay even of low shear strength does

during the pile driving when the piles showed a penetration of not liquefy but is subject to cyclic mobility and may thus

up to 4-5 m under a single stroke of the hammer. In addition, result in very large displacement. In the present case, the soft

the vane shear test results show that soil has low shear soil between 1.5 to 16 m depth was likely to develop cyclic

strength. Therefore, for design parameters, the interpretation mobility. In such event, the foundation would be subjected to

of soil characteristics was done by examining vane shear tests, large lateral displacement. In such situations, it is important to

index properties and liquidity index in particular. The clay predict the maximum ground motion anticipated based on the

and silt layer is followed by 2 m of cemented sand and hard soil profile (Kanai, 1966, Idriss and Seed, 1968). Tajimi

clay with SPT values higher than 50. The hard clay was (1977) reported the maximum ground displacement for

chosen as the bearing layer for supporting the storage tank. different soil conditions as given in Table 1.

The bearing capacity was estimated by conducting a static

cone penetration test on top of hard clay. A special tool was Based on Table 1 a maximum ground displacement of 150

fabricated since the hard layer could not be reached by mm that corresponds to the 10 m thick soil of soft consistency

conventional static cone penetration (SCPT) tools. The was anticipated for the present case. However it is not clear

ultimate bearing capacity was estimated to be 20000 kPa using whether the anticipated displacement values correspond to

static cone penetration test and the cavity expansion theory short-term event (during earthquake) or to the long-term

proposed by Vesic (1972). residual deformations. For the design purpose, it was assumed

that the load corresponding to lateral soil displacement would

remain for design life. This would result in the large lateral

load on the foundation in the event of earthquake.

Paper No. 3.29 2

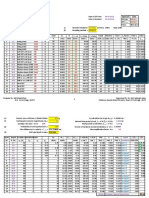

Table 1. Anticipated maximum ground displacement and soil

conditions (after Tajimi, 1977) Axial Capacity

The design axial capacity of piles was achieved by driving the

Soil Conditions

piles into hard clay stratum. After the required set was

Soil Soil SPT value H (m) Ug (cm) achieved the driving was continued till piles were penetrated

consistency type further one pile diameter using ‘Oslo’ type shoe pin inserted at

10 1 the pile tip as shown in Fig. 4. The piles were driven to impart

Sandy 30>N>20 an estimated compressive force of 2450 kN (250 tons) into

Firm 20 1.5

Clayey 20>N>5 hard clay. The hard clay was preconsolidated under this

30 2

10 3 compressive force. The increase in the soil strength as a result

Sandy 20>N>5 of preconsolidation was hypothesized based on the following,

Intermediate 20 7

Clayey 5>N>2

30 10

a) The hard clay would undergo hydraulic fracturing under

10 15

Sandy 5>N the high stresses induced by the pile driving and result in

Soft 20 25

Clayey 1>N the cavity expansion around the pile tip. This would

30 35

result in to a network of cracks in the radial and other

directions. The excess pore water pressure would

Where dissipate within few days due to formation of cracks and

H = thickness of soil layer, soil would regain its shear strength.

N = penetration blow count,

b) The clay stratum, which experiences a large compressive

Ug = maximum ground displacement. force (estimated to be 2450 kN) during pile driving, is

likely to undergo a very small settlement under the design

Therefore, the foundation had to satisfy the following, load of 780 kN for which each pile was designed.

a) settlement criterion under the vertical load of structure

plus the dragload on account of fill The long-term pile settlement was restricted as the pile was

b) resistance to large lateral forces resulting from soil preloaded by overdriving beyond the design capacity. This

movement in the event of earthquake. hypothesis was verified by the settlements observed in pile

load tests as shown in Fig. 5. The settlement of 5 mm was

A raker pile system is generally used when the structure is measured at 1300 kN (which is 1.5 times the design load).

subjected to large lateral loads. A raker pile system installed The settlement increased to 6 mm at the end of 48 hours from

in a thick soft soil would be subjected to large interactive the time of the peak load application, which was, much less

forces when the ground shifts due to earthquake of large than the allowable settlement of 12 mm. A substantial

intensity. However, due to uncertainty involved in anticipated component of the recorded settlement can be attributed to the

ground movement the raker pile option was dropped during elastic compression of the pile material. Therefore, it is

the Phase II of the project. A foundation system was devised evident that the low magnitude of the settlement is a result of

to take the vertical loads and minimize the lateral loads on preconsolidation of the hard clay stratum. Also the observed

account of soil movement as explained in the following pile settlement in load test carried out at the end of 7 and 30

sections. The vertical load from the storage tank was days were practically same.

transferred to the hard clay stratum through a system of short

columns and raft supported on driven precast concrete piles as The piles were provided with spiral reinforcement in pile head

shown in Fig. 3. The large diameter bored cast in situ piles and tip to withstand high driving stresses. The confining

have brittle structural response due to lack of flexibility and effect of spiral reinforcement also prevents cracks if pile

ductility when subjected to horizontal movement. The precast undergoes a combination of axial and flexural stresses.

concrete piles of 400 mm size were adopted to carry the axial

load.

The precast piles were designed as flexible vertical members

to withstand the large lateral deformations that may occur

during earthquake.

Paper No. 3.29 3

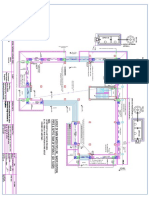

12550 mm

14500 mm

16000 mm

17500 mm

19000 mm

20500 mm

400 mm square stub piles at 3352 mm c/c

400 mm square stub piles at 1518 mm c/c

750 mm φ stone columns at 1990 mm c/c

750 mm φ stone columns at 2147 mm c/c

600 mm

400 mm Octagonal bearing piles at 1800 mm c/c

350 mm

Main raft

Annular raft

Short columns supporting the storage tank

Fig. 3 Foundation system for phosphoric acid storage tank

Load (kN)

0 250 500 750 1000 1250 1500

0

D 1

Spiral 2

Settlement (mm)..

reinforcement

3

Cast iron shoe 4

Set level

5

1D

6 48 Hrs

Hardened steel point

(introduced during casting)

7

Fig.4 Details of pile toe

Fig. 5. Results of pile load test

Paper No. 3.29 4

Lateral Capacity behaving with hinges both at top and at bottom and was free to

move so that any relative movement between pile and raft

The lateral capacity was achieved using three types of would not result in stresses in pile.

foundation systems as described in the following section.

Piles connected to Diaphragm Wall. The diaphragm walls

Piles Installed in Improved Ground. If the foundation is were used in places where a wall of sufficient face area could

designed to provide ductility, a large amount of energy can be be constructed to mobilize the required passive resistance.

absorbed during the period of a very strong earthquake The pile caps were connected to the diaphragm walls, which

(Penzien, 1970). Energy absorption or work capacity is a were designed to transfer the base shear to the surrounding

more meaningful measure of earthquake capacity of most soil through passive resistance. In this case, the displacement

structures than the strength alone (Blume, 1960, and Housner, required to mobilize the passive resistance was much less than

1956). If there is no ductility and if there is no alternate stress the anticipated ground movement of 150 mm.

path, the structure collapses under continued earthquake

demands of similar or greater amount. On the other hand,

ductility and reserve inelastic energy capacity and /or alternate Raker Piles. Raker piles were used for some structures (which

or stronger stress paths may be available and may save the were away from the creek) to take the lateral loads arising

structure (Blume, 1970). The large diameter piles cannot from the ground movement during the first phase of the plant.

provide such ductility when the surrounding clay medium The raker piles were designed for interaction forces resulting

moves during the earthquake. In such situations a small from pseudo static analysis of superstructure and foundation.

diameter piles would have an advantage over the large No specific estimate of interaction forces between soil and pile

diameter piles as far as flexural stresses are concerned. In this was done. However, the subsequent assessment of piles with

view, the system of following components was adopted for respect to lateral forces during phase II showed that if the piles

foundation and as shown in Fig.3, were to be subjected compressive loads higher than the base

capacity, it would result in yielding of pile into the bearing

a) 400 mm octagonal precast concrete piles to support the layer without causing axial stresses larger than the design

storage tank structural strength of the pile. The piles were designed for a

b) an annular raft supported on 400 mm square stub piles large margin in respect to the structural strength compared to

(of short length) to resist the lateral loads due to ground the ultimate bearing capacity. The piles experiencing the

movement tensile forces (as a result of horizontal movement) were not

c) isolation of annular raft from the piles supporting the critical for design. However due to uncertainties involved in

storage tank. this method of analysis and lesser reserve capacity with

d) ground improvement of the soil using 750 mm diameter respect to lateral resistance, the option of raker piles was

stone columns to restrict the soil movement dropped during phase II. In the phase II, vertical piles

surrounding the piles supporting the main storage tank, installed in improved ground were used extensively.

during the event of an earthquake

The stone columns improved the surrounding ground, which POST EARTHQUAKE PERFORMANCE

would also act as drainage channels for quick dissipation of

excess pore pressures, which may develop during the The settlements of all critical structures were monitored over

earthquake. The stone columns also result in the better the period of 25 years as a part of routine plant maintenance,

interaction between the laterally displaced soil and piles and no significant relative settlement was observed. However,

supporting the annular raft. Stone columns being a stiff there was a concern regarding the safety of foundation and the

element would prevent collapse of soil structure liable to superstructures after the Bhuj, 2001 earthquake. The post

liquefy. The stone columns also contribute to the shear earthquake performance check was carried out which included

strength of the soil mass and thereby reduce the displacement the exhuming of 4 m of top soil around piles in the area close

of the top layer, relative to the bearing stratum. The improved to the phosphoric acid storage tanks and non-destructive

soil in the annulus enhances the lateral capacity of the stub testing of piles. The main load bearing piles of phosphoric

piles. The annular raft supported on short piles was designed acid storage tanks were not accessible for the inspection.

to take the most of the lateral load, which may result from the However, the piles supporting the phosphoric acid storage

soil displacement. The annular raft and the main raft tank were installed in the improved ground and there were no

supporting the storage tank were at the same elevation but signs of cyclic mobility observed around these tanks after the

separated by a flexible bituminous material to prevent any earthquake. Hence, it was evident that the piles would not

vertical load transfer by shear to the main raft. The storage have suffered any damage during the earthquake. Therefore,

tank was placed above short columns fixed on the main raft. the post earthquake inspection was carried out on piles where

A hinged connection was used between the top of main piles the diaphragm wall and raker piles were used to resist the

and the raft as a result of which, no bending moment would be lateral loads.

created at the pile top. As a consequence, the pile was

Paper No. 3.29 5

In all six piles were exposed by excavating the top soil since REFERENCES

the piles are subjected to the maximum flexural stresses near

pile head when there is any substantial lateral soil movement. Blume, J.A. [1960]. “Structural Dynamics in Earthquake

The visual inspection of piles showed no sign of cracks and Resistant Design”. Transaction ASCE, 125, 1088-1139.

corrosion over 20-25 years of operation in saline environment.

In addition to visual inspection, integrity tests were carried out Blume, J.A. [1970]. “Design of Earthquake-Resistant Poured-

on these piles to check the damage at deeper level. All piles in-Place Concrete Structures”. Chapter 18 in Earthquake

were found to have acceptable integrity. The pile concrete Engineering Edited by R.L. Wiegel, Prentice Hall, Englewood

was found to be of satisfactory to excellent quality. The raker Cliffs, N.J., USA, pp 449-474.

piles have performed well, although the piles were designed

based on pseudo static analysis with an element of uncertainty Housner, G. W. [1956]. “Limit Design of Structures to Resist

regarding anticipated ground movement and the reserve Earthquakes”. Proc. of the First World Conference on

capacity of pile. Earthquake Engineering, Berkley, CA, USA, 5.1-5.13.

Idriss, I.M. and Seed, H.B. [1968]. “Seismic Response of

CONCLUSIONS Horizontal Soil Layers”. Journal of Soil Mechanics and

Foundation Engineering, ASCE, vol.94, no. SM 4, pp. 1003-

Long flexible piles driven in hard clay performed well even in 1031.

earthquake of magnitude 7.7. The soil improved with stone

columns provided better interaction between displaced soil Kanai, K. [1966]. “Improved Empirical Formula for the

and piles supporting the annular raft. A system of annular raft Characteristics of Strong Earthquake Motions”. Proc.

supported on short piles driven in an improved ground was Japanese Earthquake Engineering Symposium, Tokyo, Japan,

successful in taking the substantial amount of lateral load, pp. 1-4.

keeping the main piles supporting the tank free from undue

shear stresses. The entire foundation system was found to be Penzien, J. [1970]. “Soil-Pile Foundation Interaction”.

intact in the post earthquake investigation at the site. The Chapter 14 in Earthquake Engineering (Edited by Weigel,

foundation system using piles installed in the improved R.L. et al.), Prentice Hall, Englewood Cliffs, N.J., USA, pp

ground and the piles connected to diaphragm wall have an 349-381.

edge over the raker pile system as a substantial lateral

resistance can be mobilized at a relatively small horizontal Tajimi, H. [1977]. "Seismic effects on piles, state-of-the-art.

deformation and consequently gives a reserve capacity to the report No. 2." Proc. Int. Conf. Soil Mechanics Foundation and

foundation. Engineering, Specialty Session 10, pp 15–27.

Vesic, A.S. [1972]. “Expansion of cavities in infinite soil

ACKNOWLEDGEMENT mass”. Journal of Soil Mechanics and Foundation Division,

ASCE, vol., 98, No. SM3, pp. 265-290.

The major contribution made by Late Dr. S. D. Bondre,

Structural Consultant and partner of the first author, in

development of design concepts used in foundation system is

gratefully acknowledged. The literature relevant to this paper

was provided by Mr. Jay M. Joshi a post-graduate student

working on this topic and guided by Prof. Mhaiskar, Sardar

Patel College of Engineering, Mumbai.

Paper No. 3.29 6

You might also like

- PVD Design ReportDocument61 pagesPVD Design ReportCEG BangladeshNo ratings yet

- EIA Report-Dhaka Metro RailDocument350 pagesEIA Report-Dhaka Metro RailCEG BangladeshNo ratings yet

- 8SEAGC1985 Deep Caisson Foundations For OUB Centre Singapore, 1985Document6 pages8SEAGC1985 Deep Caisson Foundations For OUB Centre Singapore, 1985freezefreezeNo ratings yet

- Qadri Group PDFDocument19 pagesQadri Group PDFAhmed NiazNo ratings yet

- Black Cotton SoilDocument4 pagesBlack Cotton Soilibson045001256100% (2)

- Chimney Foundation On Drilled PiersDocument6 pagesChimney Foundation On Drilled Piersdipeshbarua55No ratings yet

- Dock & Harbour EngineeringDocument12 pagesDock & Harbour EngineeringHRCNo ratings yet

- Effect of Soil-Cement Reinforcement Panels in Seismic Ground Improvement of SoftDocument4 pagesEffect of Soil-Cement Reinforcement Panels in Seismic Ground Improvement of Softskdumka1997No ratings yet

- Bearing Capacity of Reinforced Pond Ash: Joyanta Maity, Bikash Chandra ChattopadhyayDocument4 pagesBearing Capacity of Reinforced Pond Ash: Joyanta Maity, Bikash Chandra ChattopadhyayerpublicationNo ratings yet

- A Case Study of Piling Project and Testing in PolandDocument4 pagesA Case Study of Piling Project and Testing in PolandAsif AhmedNo ratings yet

- Comparative Cost Analysis of Pile Foundation-HBRP PublicationDocument9 pagesComparative Cost Analysis of Pile Foundation-HBRP PublicationRaj-Kanishk SharmaNo ratings yet

- Effectiveness of Sand Column As A Ground Improvement TechniqueDocument5 pagesEffectiveness of Sand Column As A Ground Improvement TechniqueMuhammad IrfanNo ratings yet

- An Analysis On Bearing Capacity Variations of Expansions Soils Blended With Groundnut Shell AshDocument6 pagesAn Analysis On Bearing Capacity Variations of Expansions Soils Blended With Groundnut Shell AshVivek SenNo ratings yet

- Applicability of GI Techniques in Fly Ahs - Key Note Lecture - DR V R RajuDocument10 pagesApplicability of GI Techniques in Fly Ahs - Key Note Lecture - DR V R RajuSridevi SundaramNo ratings yet

- Piles Through Soft Clay For A Metro ProjectDocument9 pagesPiles Through Soft Clay For A Metro ProjectBinSayeedNo ratings yet

- Design of 20 M Deep Excavation With Permanent AnchoredDocument10 pagesDesign of 20 M Deep Excavation With Permanent Anchoredadiccto87No ratings yet

- Effect of Compaction Delay On Metakaolin Stabilized Lateritic Soil For Highway ConstructionDocument8 pagesEffect of Compaction Delay On Metakaolin Stabilized Lateritic Soil For Highway ConstructionGARBA Ahmad AliNo ratings yet

- 9ARC1991 Large Settlements of The Kansai International Airport Island, ThailandDocument4 pages9ARC1991 Large Settlements of The Kansai International Airport Island, ThailandfreezefreezeNo ratings yet

- Engelhardt 1975Document9 pagesEngelhardt 1975jorge.jimenezNo ratings yet

- Compaction PilesDocument11 pagesCompaction PilesJuhili SawantNo ratings yet

- Volume Change Behavior of Clayey Soil-Fly Ash Mixtures: B. A. Mir and A. SridharanDocument12 pagesVolume Change Behavior of Clayey Soil-Fly Ash Mixtures: B. A. Mir and A. SridharanYugandhar DamallaNo ratings yet

- Soil Investigationin Land ReclamationDocument27 pagesSoil Investigationin Land ReclamationSarah HaiderNo ratings yet

- A Case History of Coastal Land Reclamation ProjectDocument12 pagesA Case History of Coastal Land Reclamation ProjectAmir Asyraf SuhailiNo ratings yet

- 2004 Granular Pile Anchor Foundation (GPAF) System For Improving The Engineering Behavior of Expansive Clay BedsDocument9 pages2004 Granular Pile Anchor Foundation (GPAF) System For Improving The Engineering Behavior of Expansive Clay BedsS R Kumar KonathalaNo ratings yet

- AAES32021451Document8 pagesAAES32021451dulguun97nNo ratings yet

- Sandilands-ANZ2019 Building On Soft Ground A Case Study in Tauranga, New Zealand Rev01Document6 pagesSandilands-ANZ2019 Building On Soft Ground A Case Study in Tauranga, New Zealand Rev01danNo ratings yet

- Behaviour of Undrained Cohesion in Fly Ash Stabilized Lateritic SoilDocument5 pagesBehaviour of Undrained Cohesion in Fly Ash Stabilized Lateritic SoilInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Optimal Foundation Solution For Storage Terminal in MangaloreDocument4 pagesOptimal Foundation Solution For Storage Terminal in MangalorelingamkumarNo ratings yet

- Presentation of GeomaterialDocument87 pagesPresentation of GeomaterialbertaNo ratings yet

- Settlement Behaviour of Deep Engineered FillDocument10 pagesSettlement Behaviour of Deep Engineered FillDanny LamNo ratings yet

- Stabilization of Expansive Soil by Lime and Fly Ash : (Received: Jan. 28,2002) AbstractDocument5 pagesStabilization of Expansive Soil by Lime and Fly Ash : (Received: Jan. 28,2002) AbstractРадо МицевNo ratings yet

- Literature ReviewDocument7 pagesLiterature Reviewhareesh vinodNo ratings yet

- The Engineering Properties of Coral Limestone Used As Sub Base in Dar-Bagamoyo Road ProjectDocument15 pagesThe Engineering Properties of Coral Limestone Used As Sub Base in Dar-Bagamoyo Road ProjectGerald MaregesiNo ratings yet

- Water PDFDocument6 pagesWater PDFMary Grace BautistaNo ratings yet

- Slurry Trench Stability AnalysisDocument7 pagesSlurry Trench Stability AnalysisAparna CkNo ratings yet

- Ground Improvement Using The Vibro-Replacement Technique: March 2007Document13 pagesGround Improvement Using The Vibro-Replacement Technique: March 2007Tsalis SalsabilaNo ratings yet

- Ground Improvement Using The Vibro Stone Column TechniqueDocument12 pagesGround Improvement Using The Vibro Stone Column TechniqueIvan ArapovNo ratings yet

- Ground Improvement Using The Vibro-Replacement Technique: March 2007Document13 pagesGround Improvement Using The Vibro-Replacement Technique: March 2007Javiera MoralesNo ratings yet

- Compaction in Loose SoilDocument4 pagesCompaction in Loose SoilBefekNo ratings yet

- Sand Column: International Research Journal of Engineering and Technology (IRJET)Document9 pagesSand Column: International Research Journal of Engineering and Technology (IRJET)Dhanya Kumar 4PA19EC003No ratings yet

- An Investigation16Document19 pagesAn Investigation16badisnoveNo ratings yet

- Experimental Study of Silty Clay StabilizationDocument6 pagesExperimental Study of Silty Clay StabilizationTanveer KhanNo ratings yet

- Stabilization of Cinder Gravel With Clay and CementDocument73 pagesStabilization of Cinder Gravel With Clay and Cementufomib5155100% (4)

- Paper Malbase Final ACMSDocument8 pagesPaper Malbase Final ACMSirfannshaikh11No ratings yet

- Application of Geobrugg Rockfall Barrier - The Malaysian ExperienceDocument4 pagesApplication of Geobrugg Rockfall Barrier - The Malaysian ExperienceSze Mian KuehNo ratings yet

- International Society For Soil Mechanics and Geotechnical EngineeringDocument6 pagesInternational Society For Soil Mechanics and Geotechnical EngineeringmaizansofiaNo ratings yet

- Journal Embankment PileDocument6 pagesJournal Embankment PileFaRhan AzamNo ratings yet

- Soil Dynamics and Earthquake Engineering: Hamidreza Bolouri Bazaz, Ali Akhtarpour, Abbas KaramodinDocument10 pagesSoil Dynamics and Earthquake Engineering: Hamidreza Bolouri Bazaz, Ali Akhtarpour, Abbas KaramodinJuan Nicolas Montiel SalgadoNo ratings yet

- The Effect of Saba Banana (Musa Acuminata X Balbisiana) Peel Ash and Lime On The Stability of Expansive SoilDocument21 pagesThe Effect of Saba Banana (Musa Acuminata X Balbisiana) Peel Ash and Lime On The Stability of Expansive SoilKimberly Joy TulinNo ratings yet

- Comparative Cost Analysis of Pile Foundation With Soil Improvemnet of A Reclaimed AreaDocument10 pagesComparative Cost Analysis of Pile Foundation With Soil Improvemnet of A Reclaimed AreaZhenhe SongNo ratings yet

- Compressive Pile Load Test On CFA Piles & On A Driven Timber PileDocument4 pagesCompressive Pile Load Test On CFA Piles & On A Driven Timber PilepatybagNo ratings yet

- Keynote - Lecture - Finn&Wu (FLAC) PDFDocument15 pagesKeynote - Lecture - Finn&Wu (FLAC) PDFRelu MititeluNo ratings yet

- Journal of Building Engineering: Sumit Kumar, Sekhar Chandra Dutta TDocument13 pagesJournal of Building Engineering: Sumit Kumar, Sekhar Chandra Dutta Tkundan kumarNo ratings yet

- Curing of Lime SamplesDocument14 pagesCuring of Lime SamplesFahim MarwatNo ratings yet

- Halcrow TechnoteDocument17 pagesHalcrow TechnoteJimmy ThomasNo ratings yet

- Comparative Cost Analysis of Pile Foundation With Soil Improvemnet of A Reclaimed AreaDocument10 pagesComparative Cost Analysis of Pile Foundation With Soil Improvemnet of A Reclaimed AreasaifurNo ratings yet

- A Study of Pile Foundation To Enhance Soil Bearing Capacity For The StructureDocument12 pagesA Study of Pile Foundation To Enhance Soil Bearing Capacity For The StructurearjunNo ratings yet

- Geotechnical Investigation Report FinalDocument34 pagesGeotechnical Investigation Report FinalNatalia ShkurinaNo ratings yet

- Improvement Effect of Vacuum Consolidation and Prefabricated Vertical Drain in Peat GroundDocument10 pagesImprovement Effect of Vacuum Consolidation and Prefabricated Vertical Drain in Peat GroundMark MengNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionFrom EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionNo ratings yet

- How To Use Soil Stabilization In Road ConstructionFrom EverandHow To Use Soil Stabilization In Road ConstructionRating: 4 out of 5 stars4/5 (1)

- All Proceedings-4iref 2022 BangladeshDocument206 pagesAll Proceedings-4iref 2022 BangladeshCEG BangladeshNo ratings yet

- Part B - Proceedings Articles Theme 1 - Civil Engg, Environment and Archetecture - FinalDocument784 pagesPart B - Proceedings Articles Theme 1 - Civil Engg, Environment and Archetecture - FinalCEG BangladeshNo ratings yet

- Part D - Proceedings Articles Theme 3 - Chemical, Food, Petroleum and Mining - FinalDocument276 pagesPart D - Proceedings Articles Theme 3 - Chemical, Food, Petroleum and Mining - FinalCEG BangladeshNo ratings yet

- Part A - Proceedings - Cover Page, Messages, Plenary Sessions and Program ScheduleDocument46 pagesPart A - Proceedings - Cover Page, Messages, Plenary Sessions and Program ScheduleCEG BangladeshNo ratings yet

- Part E - Proceedings Articles Theme 4 - Mechanical, Manufactuirng and Industrial Engineering - FinalDocument196 pagesPart E - Proceedings Articles Theme 4 - Mechanical, Manufactuirng and Industrial Engineering - FinalCEG BangladeshNo ratings yet

- Stability Analysis of Embankments On Soft Ground-LowDocument17 pagesStability Analysis of Embankments On Soft Ground-LowCEG BangladeshNo ratings yet

- MS Project-Rajeev SharmaDocument185 pagesMS Project-Rajeev SharmaCEG BangladeshNo ratings yet

- 17 12th SEAGC 1996 Malaysia v1 290Document598 pages17 12th SEAGC 1996 Malaysia v1 290CEG BangladeshNo ratings yet

- Lateral Response of Contiguous Pile Wall Subjected To Staged Excavation - Physical and Numerical InvestigationsDocument10 pagesLateral Response of Contiguous Pile Wall Subjected To Staged Excavation - Physical and Numerical InvestigationsCEG BangladeshNo ratings yet

- Deep Excavation Supported by Diaphragm Wall - A Case StudyDocument11 pagesDeep Excavation Supported by Diaphragm Wall - A Case StudyCEG BangladeshNo ratings yet

- Part C - Proceedings Articles Theme 2 - Computer Science, Electrical and Electronics - FinalDocument171 pagesPart C - Proceedings Articles Theme 2 - Computer Science, Electrical and Electronics - FinalCEG BangladeshNo ratings yet

- Liquefaction AnalysisDocument4 pagesLiquefaction AnalysisCEG BangladeshNo ratings yet

- Design and Construction of Bored Tunnels For Mumbai Metro Line 3Document14 pagesDesign and Construction of Bored Tunnels For Mumbai Metro Line 3CEG BangladeshNo ratings yet

- CONSULTANCY SERVICES FOR "FEASIBILITY STUDY AND DETAILED DESIGN (ROAD,BRIDGES & CULVERTS) FOR PROPOSED ROAD EIDMONEY TO CHOWFALDANDI BRIDGE APPROACH (APPROXIMATE LENGTH 18.00 KM TO 25.00 KM)" EXTENDED UPTO COX'S BAZAR (REVISED LENGTH 36.900 KM) UNDER COX'S BAZAR ROAD DIVISION (0+000 CHAINAGE AT COX'S BAZAR)Document70 pagesCONSULTANCY SERVICES FOR "FEASIBILITY STUDY AND DETAILED DESIGN (ROAD,BRIDGES & CULVERTS) FOR PROPOSED ROAD EIDMONEY TO CHOWFALDANDI BRIDGE APPROACH (APPROXIMATE LENGTH 18.00 KM TO 25.00 KM)" EXTENDED UPTO COX'S BAZAR (REVISED LENGTH 36.900 KM) UNDER COX'S BAZAR ROAD DIVISION (0+000 CHAINAGE AT COX'S BAZAR)CEG Bangladesh100% (1)

- Effect of Spatial Variability of Soft Clays On Geotechnical Design of Braced Excavations - A Case Study of Formosa ExcavationDocument12 pagesEffect of Spatial Variability of Soft Clays On Geotechnical Design of Braced Excavations - A Case Study of Formosa ExcavationCEG Bangladesh100% (2)

- Design Consultant For The :ork Under The Project Construction of Lebukhali-Rampur-Mirzagonj Link RoadDocument5 pagesDesign Consultant For The :ork Under The Project Construction of Lebukhali-Rampur-Mirzagonj Link RoadCEG Bangladesh100% (1)

- Comparison of Subgrade Reaction and FEM For D Wall DesignDocument7 pagesComparison of Subgrade Reaction and FEM For D Wall DesignCEG BangladeshNo ratings yet

- Design and Construction of Diaphragm Walls Embedded in Rock For A Metro ProjectDocument27 pagesDesign and Construction of Diaphragm Walls Embedded in Rock For A Metro ProjectCEG BangladeshNo ratings yet

- Geotechnical Challenges in Design and Construction of Tunnels For Mumbai Metro Line 3Document10 pagesGeotechnical Challenges in Design and Construction of Tunnels For Mumbai Metro Line 3CEG BangladeshNo ratings yet

- Energy Modeling & Daylight DesignDocument12 pagesEnergy Modeling & Daylight DesignCEG BangladeshNo ratings yet

- Ground Improvement Techniques and ApplicationsDocument94 pagesGround Improvement Techniques and ApplicationsCEG BangladeshNo ratings yet

- Applications of Finite Element Method in Geotechnical EngineeringDocument47 pagesApplications of Finite Element Method in Geotechnical EngineeringCEG BangladeshNo ratings yet

- Option-01 - Ground Floor Plan-Detailed DrawingsDocument1 pageOption-01 - Ground Floor Plan-Detailed DrawingsCEG BangladeshNo ratings yet

- ASTM D421 GranulometríaDocument2 pagesASTM D421 GranulometríaDaniel Villagomez SilvaNo ratings yet

- Tunnel-Rocscience Africa 2022 ConferenceDocument15 pagesTunnel-Rocscience Africa 2022 ConferenceCEG BangladeshNo ratings yet

- Feasibility Study Report and Resettlement PlanDocument100 pagesFeasibility Study Report and Resettlement PlanCEG BangladeshNo ratings yet

- Sustainability Professionals Resume DirectoryDocument67 pagesSustainability Professionals Resume DirectoryCEG BangladeshNo ratings yet

- Option-05 - Ground Floor Plan-Detailed DrawingsDocument1 pageOption-05 - Ground Floor Plan-Detailed DrawingsCEG BangladeshNo ratings yet

- Ikigai (Passion)Document10 pagesIkigai (Passion)Siti KhoirunnisaNo ratings yet

- The Importance of Play in Early Childhood Development: MontguideDocument4 pagesThe Importance of Play in Early Childhood Development: MontguideI Gusti komang ApriadiNo ratings yet

- Capitalization Rules LPDocument6 pagesCapitalization Rules LPCarlynArgentinaPaitanCarduzaNo ratings yet

- Master Opp GaveDocument112 pagesMaster Opp GaveFirda FitriaNo ratings yet

- Overpower Complete ChecklistDocument147 pagesOverpower Complete Checklistanimefan26bNo ratings yet

- A Comparison of AASHTO Bridge Load Rating MethodsDocument103 pagesA Comparison of AASHTO Bridge Load Rating MethodsVietanh Phung100% (1)

- English Code Phonics Book 2Document51 pagesEnglish Code Phonics Book 2Jezabel Escobar100% (1)

- The Uzbek-American Expedition in BukharaDocument5 pagesThe Uzbek-American Expedition in Bukharahcarn2016No ratings yet

- ME 308 Machine Elements Ii: Spring Design - 1Document66 pagesME 308 Machine Elements Ii: Spring Design - 1xxxNo ratings yet

- Chapter 9Document22 pagesChapter 9aneeqa sikanderNo ratings yet

- Task 2 Writing Task Yasneidy ContrerasDocument3 pagesTask 2 Writing Task Yasneidy ContrerasDaniela santanderNo ratings yet

- 12 Questions To Help You Make Sense of Economic EvaluationsDocument6 pages12 Questions To Help You Make Sense of Economic EvaluationsHaNo ratings yet

- Pengaruh Harga Dan Lokasi Terhadap Keputusan Pembelian Rumah Pada Cv. Interhouse DesignDocument6 pagesPengaruh Harga Dan Lokasi Terhadap Keputusan Pembelian Rumah Pada Cv. Interhouse DesignAbu RijalNo ratings yet

- R20 MECH SyllabusDocument264 pagesR20 MECH SyllabusSujitha SunilNo ratings yet

- 4 Gauss Forward Formula2Document10 pages4 Gauss Forward Formula2Saiful IslamNo ratings yet

- Diesel Ignition TemperatureDocument2 pagesDiesel Ignition Temperaturewahaha06No ratings yet

- Andrew Zago, Awkward Position, 2010Document15 pagesAndrew Zago, Awkward Position, 2010Davide Tommaso FerrandoNo ratings yet

- 23-0296 - Purchase To Pay Specialist - EnglishDocument1 page23-0296 - Purchase To Pay Specialist - EnglishSamson OnanubiNo ratings yet

- Frank ISC Mathematics Model Test Paper 20Document3 pagesFrank ISC Mathematics Model Test Paper 20Rohan Chakraborty100% (3)

- Vocational Training ReportDocument32 pagesVocational Training ReportManish KujurNo ratings yet

- Anna University:: Chennai - 600 025: EXAMINATION HALL TICKET (212614114305)Document2 pagesAnna University:: Chennai - 600 025: EXAMINATION HALL TICKET (212614114305)Kranthy JcNo ratings yet

- La Escalera de Wittgenstein, David LehmanDocument6 pagesLa Escalera de Wittgenstein, David Lehmanwilbert_tapia_1No ratings yet

- Concept Mapping: Group 5Document10 pagesConcept Mapping: Group 5John Rey MontemorNo ratings yet

- Karuppuchamy OriginalDocument3 pagesKaruppuchamy Originalkaruppuchamy becivilNo ratings yet

- Collaborative Assessment ToolDocument20 pagesCollaborative Assessment ToolTungwape MiriamNo ratings yet

- Science 10 TosDocument5 pagesScience 10 TosMenard Licuanan RosalesNo ratings yet

- STAB22 Section 8.2 and Chapter 8 Exer-CisesDocument10 pagesSTAB22 Section 8.2 and Chapter 8 Exer-CisesCinzanoNo ratings yet

- Non-Tin Catalysts For Alkoxy Silane Polymers: Silicone Chemis TryDocument8 pagesNon-Tin Catalysts For Alkoxy Silane Polymers: Silicone Chemis TryŞafakNo ratings yet

- Test of Performance StrategiesDocument4 pagesTest of Performance StrategiesmaytevaosNo ratings yet