Professional Documents

Culture Documents

12) Vulkan Vulastik-L 2800, 2801, 2810, 2811, 2830, 2831 en

12) Vulkan Vulastik-L 2800, 2801, 2810, 2811, 2830, 2831 en

Uploaded by

Ashish JhaCopyright:

Available Formats

You might also like

- Wartsila 38.part1Document296 pagesWartsila 38.part1Flo MarineNo ratings yet

- Final Review of EC, IEE & EIA Regulation 2021 (LAW DEPARTMENT AMENDMENT)Document18 pagesFinal Review of EC, IEE & EIA Regulation 2021 (LAW DEPARTMENT AMENDMENT)munaizza100% (1)

- 6N18 (A) L-V: Thank You For Purchasing YANMAR ProductDocument494 pages6N18 (A) L-V: Thank You For Purchasing YANMAR ProductNicanor Aliaga100% (3)

- CVS Jets Instruction ManualDocument91 pagesCVS Jets Instruction ManualAndrey100% (3)

- Pci 389Document2 pagesPci 389ZitaPNo ratings yet

- Maintenance: and Operating Manual For Gearbox Type ZF WDocument104 pagesMaintenance: and Operating Manual For Gearbox Type ZF WTansu Mavunacı100% (1)

- InstallationManual Azipull RRM000341953 54Document3 pagesInstallationManual Azipull RRM000341953 54Maricel Hincu0% (1)

- Coastal Engineering Manual: Overview And Coastal HydrodynamicsFrom EverandCoastal Engineering Manual: Overview And Coastal HydrodynamicsNo ratings yet

- Chris Marine Surface Grinder Type CPLDocument22 pagesChris Marine Surface Grinder Type CPLSamer Saliba100% (1)

- Ingersoll Rand RR150rv5C DocumentationDocument23 pagesIngersoll Rand RR150rv5C DocumentationSergei KurpishNo ratings yet

- M32Document146 pagesM32Vicente R Edano Jr75% (4)

- Big End Bore MeasurementDocument1 pageBig End Bore MeasurementmohamedNo ratings yet

- RT 137A2 Issue2Document7 pagesRT 137A2 Issue2G_ARVALIS8470No ratings yet

- VULKAN RATO-S CouplingDocument33 pagesVULKAN RATO-S CouplingMischa CHO100% (1)

- Tools SW280 PDFDocument8 pagesTools SW280 PDFRonald Bienemi Paez100% (2)

- H2 RudderDocument19 pagesH2 RudderVinay Kumar Neelam100% (1)

- V222TI Operation & Maintenance ManualDocument294 pagesV222TI Operation & Maintenance ManualLisandroNo ratings yet

- Data & Specifications: 3299N030 4-Stroke EnginesDocument9 pagesData & Specifications: 3299N030 4-Stroke EnginesShadi MuhammedNo ratings yet

- Manual OC 5.0 EB - 1201-1250 - v0416sDocument88 pagesManual OC 5.0 EB - 1201-1250 - v0416sdessireNo ratings yet

- Manual EVK SealDocument18 pagesManual EVK Sealpanamajack26No ratings yet

- Rta 15Document7 pagesRta 15George DomusciuNo ratings yet

- 701Document35 pages701tmtt44100% (2)

- Iston With Undulated Piston Crown: Lmbo QFKD Fkpqor'qflkDocument2 pagesIston With Undulated Piston Crown: Lmbo QFKD Fkpqor'qflkRonald Bienemi Paez100% (2)

- HATLAPA Air CompressorsDocument239 pagesHATLAPA Air CompressorsSiavash YektaNo ratings yet

- 2 Maintenance BDocument324 pages2 Maintenance BPranav Shekhar100% (1)

- Wartsila Spare PartsDocument1 pageWartsila Spare PartsMaan MohammedNo ratings yet

- 1 ManualDocument441 pages1 ManualMaksym KovalchukNo ratings yet

- Parts 22490Document196 pagesParts 22490Ronald Bienemi PaezNo ratings yet

- Daihatsu DL 22Document10 pagesDaihatsu DL 22prakash buddhdev100% (1)

- Engine Operating Instructions Type VM32Document418 pagesEngine Operating Instructions Type VM32Tamer Elsayed100% (6)

- 12165-70 C25 - 33L9AY - Tier2 Operating ManualDocument385 pages12165-70 C25 - 33L9AY - Tier2 Operating ManualkodrysNo ratings yet

- MAN L32/40 Working InstructionsDocument511 pagesMAN L32/40 Working Instructionsalanwangark100% (1)

- Honing StonesDocument1 pageHoning Stonesiskricaman7No ratings yet

- BookDocument28 pagesBookFebrian Wardoyo100% (1)

- W8L20 - Safety Spare Parts RecommendationDocument8 pagesW8L20 - Safety Spare Parts RecommendationTuan Linh VoNo ratings yet

- Rta 70Document6 pagesRta 70George Domusciu100% (1)

- Maintenance Schedule DK-20 DaihatsuDocument1 pageMaintenance Schedule DK-20 Daihatsuamasrur100% (1)

- Crankpin Calibration ReportDocument1 pageCrankpin Calibration ReportDoss LawrenceNo ratings yet

- Imo Pump Ace PDFDocument4 pagesImo Pump Ace PDFpetrakou aglaia100% (1)

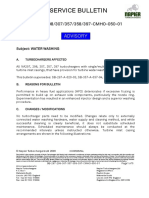

- Napier TC Water Cleaning Procedure SB - 297 - 298 - 307 - 357 - 358 - 397 - CMHO - 050 - 01Document5 pagesNapier TC Water Cleaning Procedure SB - 297 - 298 - 307 - 357 - 358 - 397 - CMHO - 050 - 01jomari saliganNo ratings yet

- Jets Products GW TKDocument1 pageJets Products GW TKВладимир БNo ratings yet

- Om Wingd Rt-Flex50dfDocument610 pagesOm Wingd Rt-Flex50dfПавел ГалущенкоNo ratings yet

- Operating Instruction: Modification Instructions For Anti Polishing Ring in Cylinder LinerDocument6 pagesOperating Instruction: Modification Instructions For Anti Polishing Ring in Cylinder LinerRonald Bienemi PaezNo ratings yet

- Maintenance Manual ZAL40S Int UseDocument313 pagesMaintenance Manual ZAL40S Int UseRocknRollerNo ratings yet

- M25 Maintenance Schedule PDFDocument3 pagesM25 Maintenance Schedule PDFMYO WINNo ratings yet

- WS S20 Exhaust Valve Seat Bore TB00-2703-10Document6 pagesWS S20 Exhaust Valve Seat Bore TB00-2703-10DP100% (2)

- W46 Adjustment of Fuel Valve Opening Pressure 4616Q006 - 01gbDocument2 pagesW46 Adjustment of Fuel Valve Opening Pressure 4616Q006 - 01gbDP100% (1)

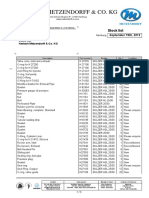

- Herbert Metzendorff & Co. KGDocument3 pagesHerbert Metzendorff & Co. KGbeu catalin0% (2)

- White Metal Bearing Shell: Ident No.: 0742027-9Document10 pagesWhite Metal Bearing Shell: Ident No.: 0742027-9Şansal DikmenerNo ratings yet

- Cylinder Liner W32Document1 pageCylinder Liner W32Poma100% (1)

- S 46 MCCDocument240 pagesS 46 MCCJageNo ratings yet

- Service Letter SL2020-698/KAMO: CPR Piston Ring PackDocument4 pagesService Letter SL2020-698/KAMO: CPR Piston Ring PackPrinceSadhotraNo ratings yet

- sn280 06Document1 pagesn280 06Ronald Bienemi PaezNo ratings yet

- Big End Bearing BoreDocument1 pageBig End Bearing BorePoma100% (2)

- IPI Aker Yards 728 W9L20 A1Document172 pagesIPI Aker Yards 728 W9L20 A1Andrei Krivda100% (1)

- L35MC 01Document804 pagesL35MC 01cengiz kutukcu100% (2)

- Service Information M20Document72 pagesService Information M20Alexander100% (1)

- Manual L W26Document436 pagesManual L W26Taufan Arif100% (1)

- MAN Marine Diesel Engine - enDocument1,566 pagesMAN Marine Diesel Engine - enYacine GhanemiNo ratings yet

- COUPLING (PTOMMEE) VULASTIK L 845kW 955 RPMDocument10 pagesCOUPLING (PTOMMEE) VULASTIK L 845kW 955 RPMtm5u2r100% (1)

- C5946Document25 pagesC5946liliam ariza100% (1)

- SafetyDocument1 pageSafetyAshish JhaNo ratings yet

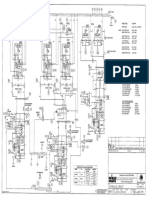

- Hydraulic Circuit of Favell FavcoDocument2 pagesHydraulic Circuit of Favell FavcoAshish JhaNo ratings yet

- Flowline Gumbo ManualDocument80 pagesFlowline Gumbo ManualAshish JhaNo ratings yet

- By Krzysztof Szymanski at 5:13 PM, Sep 24, 2009Document7 pagesBy Krzysztof Szymanski at 5:13 PM, Sep 24, 2009Ashish JhaNo ratings yet

- I MV021 Xe 0003036 - 04Document1 pageI MV021 Xe 0003036 - 04Ashish JhaNo ratings yet

- Hydrowa Piston AccumulatorDocument2 pagesHydrowa Piston AccumulatorAshish JhaNo ratings yet

- D231000604-Operation and Maintenance ManualDocument456 pagesD231000604-Operation and Maintenance ManualAshish JhaNo ratings yet

- SSGD Draworks Operation Manual - S0100827-OPM-800Document68 pagesSSGD Draworks Operation Manual - S0100827-OPM-800Ashish Jha100% (1)

- Wartsila 32 Maintenance - ScheduleDocument14 pagesWartsila 32 Maintenance - ScheduleAshish JhaNo ratings yet

- 302 EMD Parts Manual 1 - Part3 - 1630037002852Document117 pages302 EMD Parts Manual 1 - Part3 - 1630037002852Ashish JhaNo ratings yet

- 302 EMD Parts Manual 1 - Part2 - 1630037002851Document117 pages302 EMD Parts Manual 1 - Part2 - 1630037002851Ashish JhaNo ratings yet

- ROSOVDocument26 pagesROSOVambrishNo ratings yet

- Er320lr PDFDocument2 pagesEr320lr PDFsiva8000No ratings yet

- Climaeco: Intelligent Hvac Solutions With Abb I-Bus® KNXDocument16 pagesClimaeco: Intelligent Hvac Solutions With Abb I-Bus® KNXAyoub DjemaciNo ratings yet

- Numerical Simulation of Nanofluid Turbulent Flow in A Double Pipe Heat Exchanger Equipped With Circular FinsDocument13 pagesNumerical Simulation of Nanofluid Turbulent Flow in A Double Pipe Heat Exchanger Equipped With Circular FinsnabeelNo ratings yet

- Cooperative A UsDocument6 pagesCooperative A UscjethmalaniNo ratings yet

- 950H, 962H and IT62H Wheel Loader Hydraulic System: Command Control SteeringDocument2 pages950H, 962H and IT62H Wheel Loader Hydraulic System: Command Control SteeringTeofilo Paredes CosmeNo ratings yet

- Universe Series Catalogu - TSURUMI PUMPDocument11 pagesUniverse Series Catalogu - TSURUMI PUMPpapathsheilaNo ratings yet

- Training Couses CatalogueDocument99 pagesTraining Couses CatalogueZ Babar KhanNo ratings yet

- Cambridge International AS & A Level: BUSINESS 9609/32Document4 pagesCambridge International AS & A Level: BUSINESS 9609/32OSHADA AKALANKA 11-BNo ratings yet

- Jet Fuel ProductionDocument101 pagesJet Fuel Productionshezistic pRoNo ratings yet

- Applied Energy: Jasim M. Mahdi, Emmanuel C. NsoforDocument12 pagesApplied Energy: Jasim M. Mahdi, Emmanuel C. Nsoforanil_stephenNo ratings yet

- Mathematics of Karate Techniques Dynamics & Kinematics of KarateDocument3 pagesMathematics of Karate Techniques Dynamics & Kinematics of KarateiirNo ratings yet

- AD-170 HR Parts 450415Document20 pagesAD-170 HR Parts 450415naokito AkemiNo ratings yet

- Bosch Guide To Flow Wrapping enDocument30 pagesBosch Guide To Flow Wrapping engherla_bogdanNo ratings yet

- Instructional Module: Republic of The Philippines Nueva Vizcaya State University Bambang, Nueva VizcayaDocument10 pagesInstructional Module: Republic of The Philippines Nueva Vizcaya State University Bambang, Nueva VizcayaKosjeNo ratings yet

- Subramanian Karunanithi,: Curriculum VitaeDocument5 pagesSubramanian Karunanithi,: Curriculum VitaePazhamalairajan KaliyaperumalNo ratings yet

- Region VII-Eastern VisayasDocument4 pagesRegion VII-Eastern VisayasBlazelCarvajalGrimaresNo ratings yet

- 25 M Fast Supply Vessel Swe v1Document2 pages25 M Fast Supply Vessel Swe v1Sebastian RentschNo ratings yet

- Site Assesment Pump ReportDocument1 pageSite Assesment Pump ReportThebe HanyaneNo ratings yet

- Experimental Thermal and Fluid Science: A.L. Neckel, M. GodinhoDocument10 pagesExperimental Thermal and Fluid Science: A.L. Neckel, M. GodinhoPett PeeveNo ratings yet

- Part Test # 2 NSEJS BatchDocument8 pagesPart Test # 2 NSEJS BatchRA• PLAYZNo ratings yet

- FM Unit I Two MarksDocument5 pagesFM Unit I Two MarksKomalaselvan VNo ratings yet

- Technical Manual Index: Cj610 Turbojet and CF700 TURBOFANDocument7 pagesTechnical Manual Index: Cj610 Turbojet and CF700 TURBOFANVenus khanNo ratings yet

- 10 1016-j Ijplas 2008 03 009Document52 pages10 1016-j Ijplas 2008 03 009sali8439443No ratings yet

- ST 330 81 1981 Chevrolet Light Duty Truck 10 To 30 Service Manual PDFDocument1,157 pagesST 330 81 1981 Chevrolet Light Duty Truck 10 To 30 Service Manual PDFrev8100% (3)

- Lester ElectricalDocument5 pagesLester ElectricalIsai WaldoNo ratings yet

- Unit 3 Grade 9 Sept 09Document28 pagesUnit 3 Grade 9 Sept 09girmaamanNo ratings yet

- 1Neher-McGrath Paper PDFDocument12 pages1Neher-McGrath Paper PDFmordelon468No ratings yet

- Furnace & Ovens WP (Original)Document38 pagesFurnace & Ovens WP (Original)Mumahmmad Rizwan RNo ratings yet

12) Vulkan Vulastik-L 2800, 2801, 2810, 2811, 2830, 2831 en

12) Vulkan Vulastik-L 2800, 2801, 2810, 2811, 2830, 2831 en

Uploaded by

Ashish JhaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

12) Vulkan Vulastik-L 2800, 2801, 2810, 2811, 2830, 2831 en

12) Vulkan Vulastik-L 2800, 2801, 2810, 2811, 2830, 2831 en

Uploaded by

Ashish JhaCopyright:

Available Formats

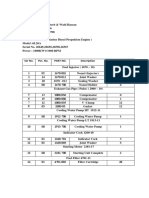

Commission XXX

Drawing no. XXX

Installation and Operating Instruction for VULKAN

VULASTIK-L couplings

Series 2800, 2801, 2810, 2811, 2830, 2831

Table of contents:

1 General safety instructions............................................................................................................................... 2

1.1 Symbol for industrial safety.......................................................................................................................2

1.2 Attention remark........................................................................................................................................2

1.3 Safety Regulations ....................................................................................................................................2

2 Generalities ...................................................................................................................................................... 2

3 Technical Data ................................................................................................................................................. 2

4 Series and executions ...................................................................................................................................... 3

4.1 Series 2800 and 2801 ...............................................................................................................................3

4.2 Series 2810 and 2811 ...............................................................................................................................4

4.3 Series 2830 and 2831 ...............................................................................................................................5

5 Torsional limit device........................................................................................................................................ 6

6 Assembly of the coupling ................................................................................................................................. 6

6.1 Assembly of bell-housing applications, series 2800 a. 2801 ....................................................................6

6.2 Assembly of free-standing applications ....................................................................................................6

6.2.1 Assembly of series 2810, sizes 1410-1910...........................................................................................6

6.2.2 Assembly of series 2810 u. 2811, sizes 2210-4310..............................................................................7

6.2.3 Assembly of series 2830 a. 2831 ..........................................................................................................7

7 Couplings with hubs for an oil-pressure unit .................................................................................................... 8

7.1 Mounting of the hub ..................................................................................................................................8

7.2 Disassembly of the hub.............................................................................................................................8

8 Alignment of the coupling ................................................................................................................................. 9

9 Commissioning and Safety Regulations ........................................................................................................ 10

10 Replacement of the VULASTIK-L elements................................................................................................... 10

10.1 Replacement of the element in bell-housing applications, series 2800 a. 2801.....................................10

10.2 Replacement of the element in free-standing applications .....................................................................10

10.2.1 Replacement of the element, series 2810, sizes 1410-1910 ..........................................................10

10.2.2 Replacement of the element, series 2810 a. 2811, sizes 2210-4310 .............................................11

10.2.3 Replacement of the element, series 2830 a. 2831 ..........................................................................11

11 Guarantee ...................................................................................................................................................... 11

12 Maintenance................................................................................................................................................... 11

VULKAN Kupplungs- und Getriebebau

B. Hackforth GmbH & Co. KG

Postfach 200462, 44634 Herne / Germany

Heerstraße 66, 44653 Herne / Germany

Tel. ++49-2325/922-0

Fax ++49-2325/71110

E-Mail: info.vkg@vulkan24.com

http://www.vulkan24.com

Titel Installation and Operating Instruction Theme Vulastik-L 2800,-01,-10,-11,-30,-31

Responsibility Authoring Checked and released Document E&W Vulastik-L 2800, 2801, 2810,

2811, 2830, 2831 englisch-

11.01.2006 11.01.2006 Version:: 003

TB 20 H. Brenienek T. Schoppe Page: 1/11

1 General safety instructions

1.1 Symbol for industrial safety

This symbol is added to all passages of this documentation concerning industrial

safety and including a risk to people's life and limb. Please follow these instructions

and handle with the utmost caution in these situations. Hand over all industrial safety

instructions to other users as well.

1.2 Attention remark

This "Attention!" remark is added to passages in this documentation which

should be specially noted in order to stick to the guidelines, regulations,

instructions and correct flow of work and to prevent any damages or de-

struction of the coupling.

1.3 Safety Regulations

A coupling shield has to be provided, according to the accident prevention regulations. According to EN 292,

part 1 „Safety of Machines“, a shield against mechanical movements of machine parts (protection against acci-

dental contact) is permissible, if a „usage according to the regulations“ is guaranteed during all working con-

ditions. At the same time a good ventilation of the coupling has to be ensured (use of perforated plates). If the

possibility of exceeding the permissible speed of the coupling, nkmax, cannot be excluded completely, e. g. in

case of an incident or because of a failure of the over-speed-trip in the system, the coupling shield has to be so

designed that possible coupling fragments cannot escape to the surrounding environment. For coupling appli-

cations in fast ships (Dynamically Supported Craft), the safety regulations of publication A373 of IMO (Inter-

national Maritime Organisation) are valid. Dependant on the construction, these machine arrangements contain

components with a high rotating energy. When the coupling runs outside of a casing, an external protecting

device has to be provided to keep off possible coupling fragments in any case.

2 Generalities

The highly-flexible VULASTIK-L coupling is a torsionally flexible rubber coupling compensating radial, axial and

angular displacements of the connected machines.

The torque transmission is guaranteed by the ring-shaped rubber elements which are loaded with turning thrust.

The VULASTIK-L coupling series 2800 is especially suitable for the installation in gearbox bell housings or ge-

nerator bell housings.

The coupling should be protected against the permanent effect of oil and against the radiation of heat.

The VULASTIK-L element is designed for use at ambient temperatures between -45° C up to +90° C (silicone

elements from –45° up to +120°C).

To reach a long service life, a sufficient ventilation cross section should be guaranteed. This especially refers to

bell housing installations.

Basically, the connection surfaces of the coupling and the finish bores are preserved by Tectyl. Prior to instal-

lation of the coupling, these surfaces should be cleaned with conventional solvents.

Pay attention to wear protective clothes (gloves, safety glasses etc.) while working with solvents.

When the cleaned surfaces are completely dry, they must be greased slightly.

To guarantee faultless function and optimum use of the highly-flexible VULASTIK-L coupling, certain installation

instructions have to be observed. First of all this means to tighten all screwed connections participating in the

transmission of the torque with a torque spanner. The permissible tightening torques for the corresponding ma-

terial quality are given by the manufacturers of the screws and are not allowed to be exceeded. The tightening

torques for the fastening screws of the flexible elements (7) are given in the respective general drawing of the

coupling.

3 Technical Data

For the valid technical data please look into the actual product information from catalogues or Internet-pages.

Titel Installation and Operating Instruction Theme Vulastik-L 2800,-01,-10,-11,-30,-31

Responsibility Authoring Checked and released Document E&W Vulastik-L 2800, 2801, 2810,

2811, 2830, 2831 englisch-

11.01.2006 11.01.2006 Version:: 003

TB 20 H. Brenienek T. Schoppe Page: 2/11

4 Series and executions

VULASTIK-L couplings can be supplied in the following executions:

4.1 Series 2800 and 2801

• for connection of a SAE-flywheel with a shaft

• element replacement with displacement of the connected units

• series 2800 without torsional limit device

• series 2801 like 2800, however, with torsional limit device

figure 1 figure 2

2800 2801

figure 3

2800 dual

Titel Installation and Operating Instruction Theme Vulastik-L 2800,-01,-10,-11,-30,-31

Responsibility Authoring Checked and released Document E&W Vulastik-L 2800, 2801, 2810,

2811, 2830, 2831 englisch-

11.01.2006 11.01.2006 Version:: 003

TB 20 H. Brenienek T. Schoppe Page: 3/11

4.2 Series 2810 and 2811

• for connection of a SAE-flywheel with a shaft

• element replacement without displacement of the connected units

• series 2810 without torsional limit device

• series 2811 like 2810, however, with torsional limit device

figure 4 figure 5 figure 6

2810 (sizes 14 – 19) 2810 (sizes 22-43) 2811

figure 7 figure 8

2810 dual 2811 dual

Titel Installation and Operating Instruction Theme Vulastik-L 2800,-01,-10,-11,-30,-31

Responsibility Authoring Checked and released Document E&W Vulastik-L 2800, 2801, 2810,

2811, 2830, 2831 englisch-

11.01.2006 11.01.2006 Version:: 003

TB 20 H. Brenienek T. Schoppe Page: 4/11

4.3 Series 2830 and 2831

• for connection of two shafts

• element replacement without displacement of the connected units

• series 2830 without torsional limit device

• series 2831 like 2830, however, with torsional limit device

figure 9 figure 10

2830 2831

figure 11 figure 12

2830 dual 2831 dual

Titel Installation and Operating Instruction Theme Vulastik-L 2800,-01,-10,-11,-30,-31

Responsibility Authoring Checked and released Document E&W Vulastik-L 2800, 2801, 2810,

2811, 2830, 2831 englisch-

11.01.2006 11.01.2006 Version:: 003

TB 20 H. Brenienek T. Schoppe Page: 5/11

5 Torsional limit device

The VULASTK-L coupling series 2801, 2811, 2831 is delivered with

a torsional limit device. This torsional limit device allows emergency

operation up to 25% of the engine nominal torque.

During emergency operation the system has to run under conditions

that no hammering should occur between the emergency-run cams.

The elements should be replaced as soon as possible.

After a break of the VULASTIK-L element and installation of a tor-

sional limit device it is required to replace the element as well as the

cam ring, the limit ring and the fastening screws.

With respect to the assembly of the torsional limit

device, special attention should be paid that the cams are stag-

gered by 90° towards each other. figure 13

6 Assembly of the coupling

During transportation, please pay attention to a sufficient carrying force of the lifting devices. Only use

approved transportation elements. Fix the transportation elements thoroughly.

While lifting the flexible element, pay attention not to damage the flexible element and the add-

on pieces.

The VULASTIK-L coupling is dispatched by VULKAN in the assembled condition (executions with oil-fitted hubs

in the preassembled condition).

6.1 Assembly of bell-housing applications, series 2800 a. 2801

Sequence of operations (please refer to figure 1, figure 2, figure 3):

• Remove the housing (1) from the coupling and attach it to the engine flywheel using suitable

connection elements and the washers noted in the drawing.

The tightening torque required for the chosen screw quality is to be kept.

Series 2801: Place the limit ring (8) between housing (1) and engine flywheel.

• Release the connecting elements (7) and pull the flexible element (6) – for dual couplings (5, 6) –

from the hub.

Series 2801: Remove the cam ring (9) as well.

• Push the hub (4) onto the shaft end using a method meeting a modern engineering practice.

The assembly of the hub with oil-pressure unit is described separately.

• Screw up the flexible element (6) – for dual couplings (5, 6) – with the hub (4) using the connecting

elements (7). The tightening torque required for the chosen screw quality is given on the drawing.

Series 2801: Place the cam ring (9) against the flexible element (6) on the face.

• Join engine and machine and attach them to the engine housing using suitable connecting

elements, so that the element toothing (6) is in alignment with the toothing gaps of the housing (1).

• Concerning series 2801: In addition, please pay attention that the cams are stag-

gered by 90° towards each other (please refer to paragraph 5 „Torsional limit device“).

6.2 Assembly of free-standing applications

6.2.1 Assembly of series 2810, sizes 1410-1910

Sequence of operations (please refer to figure 4):

• Remove housing (1) and spacer ring (12) from the coupling.

• Release the connecting elements (7) and pull the flexible element (6) and – if required – the spacer

ring (19) from the hub.

• Push the hub (4) onto the shaft end using a method meeting modern engineering practice.

Deposit the housing (1) on the hub (4).

Titel Installation and Operating Instruction Theme Vulastik-L 2800,-01,-10,-11,-30,-31

Responsibility Authoring Checked and released Document E&W Vulastik-L 2800, 2801, 2810,

2811, 2830, 2831 englisch-

11.01.2006 11.01.2006 Version:: 003

TB 20 H. Brenienek T. Schoppe Page: 6/11

The alignment of the system and the alignment control are described separately.

The assembly of the hub with oi-pressure unit is described separately.

• Insert the flexible element (6) and spacer ring (19) between hub (4) and engine flywheel and screw

up these parts with the hub (4) using the connecting elements (7). The tightening torque required for

the chosen screw quality is given on the drawing.

• Take the housing (1) and the spacer ring (12) from the hub (4) and fix them to the engine flywheel

using appropriate connecting elements and the washers noted in the drawing.

The tightening torque required for the chosen screw quality is to be kept.

6.2.2 Assembly of series 2810 u. 2811, sizes 2210-4310

Sequence of operations (please refer to figure 5 figure 6, figure 7, figure 8):

• Remove the housing (1) from the coupling.

Series 2811: Remove the limit ring (8) as well.

• Release the connecting elements (7) and pull the flexible element (6) – for dual coupling (5, 6) –

from the hub.

Series 2811: Remove the cam ring (19) as well.

• Push the hub (4) onto the shaft end using a method meeting modern engineering practice.

Deposit the housing (1) – with respect to series 2811 the limit ring (8) as well – on the hub (4).

The alignment of the system and the alignment control are described separately.

The assembly of the hub with oil-pressure unit is described separately.

• Insert the flexible element (6) – for dual couplings (5, 6) - between hub (4) and engine flywheel and

screw up these parts with the hub (4) using the connecting elements (7). The tightening torque

required for the chosen screw quality is given on the drawing.

Series 2811: Place the cam ring (19) between hub (4) and flexible element (6).

• Take the housing (1) from the hub (4) and fix these parts to the engine flywheel using appropriate

connecting elements and the washers noted in the drawing.

The tightening torque required for the chosen screw quality is to be kept.

• Concerning series 2811: Place the limit ring (8) against the housing (1) on the face.

In addition, please pay attention that the cams are displaced by 90° towards each other (please

refer to paragraph 5 „Torsional limit device“).

6.2.3 Assembly of series 2830 a. 2831

Sequence of operations (please refer to figure 9, figure 10, figure 11, figure 12):

• Release connecting elements (15, 16, 17).

• Remove the housing (1) from the coupling.

Series 2831: Remove the limit ring (8) as well.

• Release connecting elements (7) and pull the flexible element (6) – for dual couplings (5, 6) – from

the hub.

Series 2831: Remove the cam ring (19) as well.

• Push the hub (4) onto the shaft end using a method meeting modern engineering practice.

Deposit the housing (1) – with respect to series 2831 the limit ring (8) as well – on the hub (4).

The assembly of the hub with oil-pressure unit is described separately.

• Release the connecting elements (14) and separate the plate flange (12) from the hub (13).

• Push the hub (13) onto the shaft end using a method meeting modern engineering practice.

The alignment of the system and the alignment control are described separately.

The assembly of the hub with oil-pressure unit is described separately.

• Assemble the plate flange (12) to the hub (13) using the connecting elements (14).

• Insert the flexible element (6) – for dual couplings (5, 6) - between hub (4) and plate flange (12) and

screw it up with the hub (4) using the connecting elements (7) and with the plate flange (12) using

the connecting elements (15, 16, 17). The tightening torque required for the chosen screw quality is

given on the drawing.

Series 2831: Place the cam ring (19) between hub (4) and flexible element (6).

• Take the housing (1) from the hub (4) and fix them to the engine flywheel using appropriate connec-

ting elements and the washers noted on the drawing.

The tightening torque required for the chosen screw quality is to be kept.

Titel Installation and Operating Instruction Theme Vulastik-L 2800,-01,-10,-11,-30,-31

Responsibility Authoring Checked and released Document E&W Vulastik-L 2800, 2801, 2810,

2811, 2830, 2831 englisch-

11.01.2006 11.01.2006 Version:: 003

TB 20 H. Brenienek T. Schoppe Page: 7/11

• Concerning series 2831: Place the limit ring (8) against the housing (1) on the face.

In addition, please pay attention that the cams are displaced by 90° towards each other (please

refer to paragraph 5 „Torsional limit device“).

7 Couplings with hubs for an oil-pressure unit

7.1 Mounting of the hub

Before the assembly it is required to check the interfaces from the

cone surfaces and the oil keyways with respect to edges. The

fitting can be controlled by applying a thin layer of blue grease and

by pressing the parts together.

Then clean and dry the cone surface.

In order to determine the push-up distance, the hub must be

pushed onto the shaft.

Do not assemble the parts firmly. The push-up distance is calcu-

lated from the point where the conical surfaces are closely con-

tiguous without exerting any pressure.

In order to determine the reference dimension, the edge of the

hub and the hydraulic nut are used.

In order to determine the reference dimension, the edge of the hub and the hydraulic nut are used.

Before the installation, the cone surface is coated with SAE-10 oil (viscosity approx. 20 cSt at 50°C).

After having attached the hydraulic nut, the hydraulic supply can be connected. The push-up dimension inclu-

ding tolerance is marked on the front surface of the hub.

After the connection to the hydraulic supply, pressure is given on connection A in order to push-up the hub and

on connection B in order to expand the hub.

The hub should be positioned without any interruption. The push-up pressure (connection A) for

the hydraulic nut depends on the hub’s diameter of the part to be pressed on.

After having pressed the part in the correct position, the expanding pressure has to be reduced slowly, whereas

the push-up pressure has to be kept in order to get the oil distributed (approx. 30 minutes).

The push-up pressure has to be maintained all the time, while the expanding pressure is redu-

cing, so that the part will keep its position.

A waiting time of 24 hours is required before the oil-pressure unit can be loaded with the full nominal speed of

the engine.

This is necessary to ensure that the oil has completely dropped off from the mounted hub.

Oil under high pressure can cause injuries. While working with high-pressure oil systems, take care for

an adequate protection equipment. High-pressure oil should not come in contact with the skin.

After the hub has been installed, the alignment control can be carried out:

7.2 Disassembly of the hub

The hydraulic nut is installed same as for the assembly and put under pressure. The nut thread has to be com-

pletely screwed on the shaft journal.

The mounted parts are under high pressure and can cause injuries when pulling them off. The hy-

draulic nut serves as stop to hold the part to be disassembled. For the disassembly, the hub has to be ex-

panded, i. e. oil-pressure has to be given on connection B.

The hub releases abruptly from the shaft journal by oil-pressure on connection B and simultaneous reduction of

the oil-pressure at connection A.

Titel Installation and Operating Instruction Theme Vulastik-L 2800,-01,-10,-11,-30,-31

Responsibility Authoring Checked and released Document E&W Vulastik-L 2800, 2801, 2810,

2811, 2830, 2831 englisch-

11.01.2006 11.01.2006 Version:: 003

TB 20 H. Brenienek T. Schoppe Page: 8/11

The part to be removed releases suddenly, if the oil-pressure at connection A is reduced down to zero.

Therefore pay attention to the correct assembly of the hydraulic nut.

In case that the hub does not release, the disassembly process has to be repeated with the following changes:

• increase the oil-pressure at connection B

• let the hub remain under pressure for an hour

• heat the hub

• use a disassembly device

8 Alignment of the coupling

Before starting the coupling assembly, the drive system has to be aligned. Only couplings in free-standing appli-

cation must be aligned. The more exact the system is aligned, the more reserves are given for the coupling to

compensate displacements during operation.

For the alignment of the system the following alignment tolerances are to be kept.

radial alignment axial angular

tolerance alignment tolerance alignment tolerance

∆Kr= ∆Ka= ∆Kw=

size 14 – 19: ±1 ± 0.05

± 0,1 [mm] [mm] [°]

size 22 – 34:

± 0,2 [mm]

size 40 – 43:

± 0,35 [mm]

The permissible gap X resulting from the angle

is to be calculated from the angle tolerances

∆Kw and the reference diameter D:

D

X= ⋅ tan( ∆K ) w

2

The alignement tolerances must be suitable for the warmed up application

under running conditions.

After the coupling has been installed into the system according to the installation and operating instruction de-

livered with the coupling, we recommend to check the alignment by measuring with a dial gauge over one revo-

lution in order to determine the radial and angular deviations.

With respect to series 2800, 2801, 2810,

2811 a machined surface at the flywheel or

at the flywheel housing serves as reference

surface.

Titel Installation and Operating Instruction Theme Vulastik-L 2800,-01,-10,-11,-30,-31

Responsibility Authoring Checked and released Document E&W Vulastik-L 2800, 2801, 2810,

2811, 2830, 2831 englisch-

11.01.2006 11.01.2006 Version:: 003

TB 20 H. Brenienek T. Schoppe Page: 9/11

Concerning series 2830, 2831 it is mea-

sured from hub to hub (please refer to the

figure).

9 Commissioning and Safety Regulations

After completion of the assembly, the drive system is ready for operation, as far as the coupling is concerned.

We would like to point out that before first operation you have to make sure that all installation

aid devices have been removed from the VULASTIK-L coupling.

10 Replacement of the VULASTIK-L elements

In case of a replacement of the elements, only original VULKAN elements with coordinated

technical data, approved by the classification societies, must be used!

10.1 Replacement of the element in bell-housing applications, series 2800 a. 2801

The VULASTIK-L element can be exchanged by displacing the units.

Sequence of operations (please refer to figure 1, figure 2, figure 3):

• Release the screwed connection of the system components and separate the units

• Release connecting elements (7).

• Pull the flexible element (6) – for dual couplings (5, 6) – from the hub (4).

Series 2801: Remove the cam ring (9) as well.

• Installation of a new element in the reversed order (please refer to chapter 6.1 Assembly of bell-

housing applications, series 2800 a. 2801)

10.2 Replacement of the element in free-standing applications

The VULASTIK-L element can be replaced without having to displace the units.

10.2.1 Replacement of the element, series 2810, sizes 1410-1910

Sequence of operations (please refer to figure 4):

• Release connecting elements (7).

• Release the connecting elements to the engine flywheel.

Remove housing (1) and spacer ring (12) from the flywheel and deposit them on the hub (4).

• Press the element (6) from the flywheel.

• Remove the spacer ring (19).

• Remove the element (6).

• Release connecting elements (11) and remove the intermediate ring (10) from the element (6) and

attach it to the new element.

• Installation of the new element in the reversed order (please refer to chapter 6.2.1 Assembly of

series 2810, sizes 1410-1910)

Titel Installation and Operating Instruction Theme Vulastik-L 2800,-01,-10,-11,-30,-31

Responsibility Authoring Checked and released Document E&W Vulastik-L 2800, 2801, 2810,

2811, 2830, 2831 englisch-

11.01.2006 11.01.2006 Version:: 003

TB 20 H. Brenienek T. Schoppe Page: 10/11

10.2.2 Replacement of the element, series 2810 a. 2811, sizes 2210-4310

Sequence of operations (please refer to figure 5 figure 6, figure 7, figure 8):

• Release connecting elements (7).

• Release the connecting elements to the engine flywheel.

Remove housing (1) and spacer ring (12) from the flywheel and desposit them on the hub (4).

Series 2811: additionally deposit the limit ring (8).

• Press the element (6) – for dual couplings (5, 6) – towards the flywheel and remove it.

Series 2811: Remove the cam ring (19) as well.

• Release the connecting elements (11) as well and remove the intermediate ring (10) from the ele-

ment and fix it to the new element. This is not applicable for dual couplings of series 2830.

Concerning dual couplings of series 2831: Release connecting elements (18) and remove the

spacer ring (10) from the element (5). and fix it to the new element.

• Installation of the new element in the reversed order (please refer to chapter 6.2.2 Assembly of

series 2810 u. 2811, sizes 2210-4310)

10.2.3 Replacement of the element, series 2830 a. 2831

Sequence of operations (please refer to figure 9, figure 10, figure 11, figure 12):

• Release connecting elements (7).

• Release connecting elements (15, 16, 17) .

Remove the housing (1) from the plate flange (12) and deposit it on the hub.

Series 2831: additionally deposit the limit ring (8).

• Press the element (6) – for dual couplings (5, 6) – towards the plate flange (12) and remove it.

Series 2831: additionally remove the cam ring (19).

• Release connecting elements (11) and remove the intermediate ring (10) from the element (6) and

attach it to the new element. This is not applicable for series 2830.

Concerning dual couplings of series 2831: Release connecting elements (18) and remove the

spacer ring (10) from the element (5) and attach it to the new element.

• Installation of the new element in the reversed order (please refer to chapter 6.2.3 Assembly of

series 2830 a. 2831)

11 Guarantee

On behalf of the international approval bodies, we wish to state the following for classified couplings:

The torsional vibration behaviour of the driving system has been checked and approved by the classification

society. The expected and satisfactory behaviour is guaranteed only, provided that all components comply to

the values, the torsional vibration calculation is based upon. With respect to the coupling, this means to exactly

keep to the dynamic stiffness and damping. In case of a replacement of the elements, only original VULKAN

elements with coordinated technical data, approved by the classification societies, must be used!

12 Maintenance

Under normal circumstances, the highly-flexible VULASTIK-L coupling does not require maintenance. In many

cases, however, the highly-flexible VULASTIK-L coupling is an indicator for malfunctions in the system. In case

of unusual events, e. g. propeller contact, misfiring operation, short circuit, faulty synchronization or emergency

shutdown, we recommend a check of the flexible element.

In addition, an annual check of the flexible part and for free-standing applications a alignment control should be

carried out.

If cracks should be found during the visual inspection at the VULASTIK-L element, the element has to be re-

moved.

The element should be replaced after approx. 15000 operating hours or 10 years resp.

Titel Installation and Operating Instruction Theme Vulastik-L 2800,-01,-10,-11,-30,-31

Responsibility Authoring Checked and released Document E&W Vulastik-L 2800, 2801, 2810,

2811, 2830, 2831 englisch-

11.01.2006 11.01.2006 Version:: 003

TB 20 H. Brenienek T. Schoppe Page: 11/11

You might also like

- Wartsila 38.part1Document296 pagesWartsila 38.part1Flo MarineNo ratings yet

- Final Review of EC, IEE & EIA Regulation 2021 (LAW DEPARTMENT AMENDMENT)Document18 pagesFinal Review of EC, IEE & EIA Regulation 2021 (LAW DEPARTMENT AMENDMENT)munaizza100% (1)

- 6N18 (A) L-V: Thank You For Purchasing YANMAR ProductDocument494 pages6N18 (A) L-V: Thank You For Purchasing YANMAR ProductNicanor Aliaga100% (3)

- CVS Jets Instruction ManualDocument91 pagesCVS Jets Instruction ManualAndrey100% (3)

- Pci 389Document2 pagesPci 389ZitaPNo ratings yet

- Maintenance: and Operating Manual For Gearbox Type ZF WDocument104 pagesMaintenance: and Operating Manual For Gearbox Type ZF WTansu Mavunacı100% (1)

- InstallationManual Azipull RRM000341953 54Document3 pagesInstallationManual Azipull RRM000341953 54Maricel Hincu0% (1)

- Coastal Engineering Manual: Overview And Coastal HydrodynamicsFrom EverandCoastal Engineering Manual: Overview And Coastal HydrodynamicsNo ratings yet

- Chris Marine Surface Grinder Type CPLDocument22 pagesChris Marine Surface Grinder Type CPLSamer Saliba100% (1)

- Ingersoll Rand RR150rv5C DocumentationDocument23 pagesIngersoll Rand RR150rv5C DocumentationSergei KurpishNo ratings yet

- M32Document146 pagesM32Vicente R Edano Jr75% (4)

- Big End Bore MeasurementDocument1 pageBig End Bore MeasurementmohamedNo ratings yet

- RT 137A2 Issue2Document7 pagesRT 137A2 Issue2G_ARVALIS8470No ratings yet

- VULKAN RATO-S CouplingDocument33 pagesVULKAN RATO-S CouplingMischa CHO100% (1)

- Tools SW280 PDFDocument8 pagesTools SW280 PDFRonald Bienemi Paez100% (2)

- H2 RudderDocument19 pagesH2 RudderVinay Kumar Neelam100% (1)

- V222TI Operation & Maintenance ManualDocument294 pagesV222TI Operation & Maintenance ManualLisandroNo ratings yet

- Data & Specifications: 3299N030 4-Stroke EnginesDocument9 pagesData & Specifications: 3299N030 4-Stroke EnginesShadi MuhammedNo ratings yet

- Manual OC 5.0 EB - 1201-1250 - v0416sDocument88 pagesManual OC 5.0 EB - 1201-1250 - v0416sdessireNo ratings yet

- Manual EVK SealDocument18 pagesManual EVK Sealpanamajack26No ratings yet

- Rta 15Document7 pagesRta 15George DomusciuNo ratings yet

- 701Document35 pages701tmtt44100% (2)

- Iston With Undulated Piston Crown: Lmbo QFKD Fkpqor'qflkDocument2 pagesIston With Undulated Piston Crown: Lmbo QFKD Fkpqor'qflkRonald Bienemi Paez100% (2)

- HATLAPA Air CompressorsDocument239 pagesHATLAPA Air CompressorsSiavash YektaNo ratings yet

- 2 Maintenance BDocument324 pages2 Maintenance BPranav Shekhar100% (1)

- Wartsila Spare PartsDocument1 pageWartsila Spare PartsMaan MohammedNo ratings yet

- 1 ManualDocument441 pages1 ManualMaksym KovalchukNo ratings yet

- Parts 22490Document196 pagesParts 22490Ronald Bienemi PaezNo ratings yet

- Daihatsu DL 22Document10 pagesDaihatsu DL 22prakash buddhdev100% (1)

- Engine Operating Instructions Type VM32Document418 pagesEngine Operating Instructions Type VM32Tamer Elsayed100% (6)

- 12165-70 C25 - 33L9AY - Tier2 Operating ManualDocument385 pages12165-70 C25 - 33L9AY - Tier2 Operating ManualkodrysNo ratings yet

- MAN L32/40 Working InstructionsDocument511 pagesMAN L32/40 Working Instructionsalanwangark100% (1)

- Honing StonesDocument1 pageHoning Stonesiskricaman7No ratings yet

- BookDocument28 pagesBookFebrian Wardoyo100% (1)

- W8L20 - Safety Spare Parts RecommendationDocument8 pagesW8L20 - Safety Spare Parts RecommendationTuan Linh VoNo ratings yet

- Rta 70Document6 pagesRta 70George Domusciu100% (1)

- Maintenance Schedule DK-20 DaihatsuDocument1 pageMaintenance Schedule DK-20 Daihatsuamasrur100% (1)

- Crankpin Calibration ReportDocument1 pageCrankpin Calibration ReportDoss LawrenceNo ratings yet

- Imo Pump Ace PDFDocument4 pagesImo Pump Ace PDFpetrakou aglaia100% (1)

- Napier TC Water Cleaning Procedure SB - 297 - 298 - 307 - 357 - 358 - 397 - CMHO - 050 - 01Document5 pagesNapier TC Water Cleaning Procedure SB - 297 - 298 - 307 - 357 - 358 - 397 - CMHO - 050 - 01jomari saliganNo ratings yet

- Jets Products GW TKDocument1 pageJets Products GW TKВладимир БNo ratings yet

- Om Wingd Rt-Flex50dfDocument610 pagesOm Wingd Rt-Flex50dfПавел ГалущенкоNo ratings yet

- Operating Instruction: Modification Instructions For Anti Polishing Ring in Cylinder LinerDocument6 pagesOperating Instruction: Modification Instructions For Anti Polishing Ring in Cylinder LinerRonald Bienemi PaezNo ratings yet

- Maintenance Manual ZAL40S Int UseDocument313 pagesMaintenance Manual ZAL40S Int UseRocknRollerNo ratings yet

- M25 Maintenance Schedule PDFDocument3 pagesM25 Maintenance Schedule PDFMYO WINNo ratings yet

- WS S20 Exhaust Valve Seat Bore TB00-2703-10Document6 pagesWS S20 Exhaust Valve Seat Bore TB00-2703-10DP100% (2)

- W46 Adjustment of Fuel Valve Opening Pressure 4616Q006 - 01gbDocument2 pagesW46 Adjustment of Fuel Valve Opening Pressure 4616Q006 - 01gbDP100% (1)

- Herbert Metzendorff & Co. KGDocument3 pagesHerbert Metzendorff & Co. KGbeu catalin0% (2)

- White Metal Bearing Shell: Ident No.: 0742027-9Document10 pagesWhite Metal Bearing Shell: Ident No.: 0742027-9Şansal DikmenerNo ratings yet

- Cylinder Liner W32Document1 pageCylinder Liner W32Poma100% (1)

- S 46 MCCDocument240 pagesS 46 MCCJageNo ratings yet

- Service Letter SL2020-698/KAMO: CPR Piston Ring PackDocument4 pagesService Letter SL2020-698/KAMO: CPR Piston Ring PackPrinceSadhotraNo ratings yet

- sn280 06Document1 pagesn280 06Ronald Bienemi PaezNo ratings yet

- Big End Bearing BoreDocument1 pageBig End Bearing BorePoma100% (2)

- IPI Aker Yards 728 W9L20 A1Document172 pagesIPI Aker Yards 728 W9L20 A1Andrei Krivda100% (1)

- L35MC 01Document804 pagesL35MC 01cengiz kutukcu100% (2)

- Service Information M20Document72 pagesService Information M20Alexander100% (1)

- Manual L W26Document436 pagesManual L W26Taufan Arif100% (1)

- MAN Marine Diesel Engine - enDocument1,566 pagesMAN Marine Diesel Engine - enYacine GhanemiNo ratings yet

- COUPLING (PTOMMEE) VULASTIK L 845kW 955 RPMDocument10 pagesCOUPLING (PTOMMEE) VULASTIK L 845kW 955 RPMtm5u2r100% (1)

- C5946Document25 pagesC5946liliam ariza100% (1)

- SafetyDocument1 pageSafetyAshish JhaNo ratings yet

- Hydraulic Circuit of Favell FavcoDocument2 pagesHydraulic Circuit of Favell FavcoAshish JhaNo ratings yet

- Flowline Gumbo ManualDocument80 pagesFlowline Gumbo ManualAshish JhaNo ratings yet

- By Krzysztof Szymanski at 5:13 PM, Sep 24, 2009Document7 pagesBy Krzysztof Szymanski at 5:13 PM, Sep 24, 2009Ashish JhaNo ratings yet

- I MV021 Xe 0003036 - 04Document1 pageI MV021 Xe 0003036 - 04Ashish JhaNo ratings yet

- Hydrowa Piston AccumulatorDocument2 pagesHydrowa Piston AccumulatorAshish JhaNo ratings yet

- D231000604-Operation and Maintenance ManualDocument456 pagesD231000604-Operation and Maintenance ManualAshish JhaNo ratings yet

- SSGD Draworks Operation Manual - S0100827-OPM-800Document68 pagesSSGD Draworks Operation Manual - S0100827-OPM-800Ashish Jha100% (1)

- Wartsila 32 Maintenance - ScheduleDocument14 pagesWartsila 32 Maintenance - ScheduleAshish JhaNo ratings yet

- 302 EMD Parts Manual 1 - Part3 - 1630037002852Document117 pages302 EMD Parts Manual 1 - Part3 - 1630037002852Ashish JhaNo ratings yet

- 302 EMD Parts Manual 1 - Part2 - 1630037002851Document117 pages302 EMD Parts Manual 1 - Part2 - 1630037002851Ashish JhaNo ratings yet

- ROSOVDocument26 pagesROSOVambrishNo ratings yet

- Er320lr PDFDocument2 pagesEr320lr PDFsiva8000No ratings yet

- Climaeco: Intelligent Hvac Solutions With Abb I-Bus® KNXDocument16 pagesClimaeco: Intelligent Hvac Solutions With Abb I-Bus® KNXAyoub DjemaciNo ratings yet

- Numerical Simulation of Nanofluid Turbulent Flow in A Double Pipe Heat Exchanger Equipped With Circular FinsDocument13 pagesNumerical Simulation of Nanofluid Turbulent Flow in A Double Pipe Heat Exchanger Equipped With Circular FinsnabeelNo ratings yet

- Cooperative A UsDocument6 pagesCooperative A UscjethmalaniNo ratings yet

- 950H, 962H and IT62H Wheel Loader Hydraulic System: Command Control SteeringDocument2 pages950H, 962H and IT62H Wheel Loader Hydraulic System: Command Control SteeringTeofilo Paredes CosmeNo ratings yet

- Universe Series Catalogu - TSURUMI PUMPDocument11 pagesUniverse Series Catalogu - TSURUMI PUMPpapathsheilaNo ratings yet

- Training Couses CatalogueDocument99 pagesTraining Couses CatalogueZ Babar KhanNo ratings yet

- Cambridge International AS & A Level: BUSINESS 9609/32Document4 pagesCambridge International AS & A Level: BUSINESS 9609/32OSHADA AKALANKA 11-BNo ratings yet

- Jet Fuel ProductionDocument101 pagesJet Fuel Productionshezistic pRoNo ratings yet

- Applied Energy: Jasim M. Mahdi, Emmanuel C. NsoforDocument12 pagesApplied Energy: Jasim M. Mahdi, Emmanuel C. Nsoforanil_stephenNo ratings yet

- Mathematics of Karate Techniques Dynamics & Kinematics of KarateDocument3 pagesMathematics of Karate Techniques Dynamics & Kinematics of KarateiirNo ratings yet

- AD-170 HR Parts 450415Document20 pagesAD-170 HR Parts 450415naokito AkemiNo ratings yet

- Bosch Guide To Flow Wrapping enDocument30 pagesBosch Guide To Flow Wrapping engherla_bogdanNo ratings yet

- Instructional Module: Republic of The Philippines Nueva Vizcaya State University Bambang, Nueva VizcayaDocument10 pagesInstructional Module: Republic of The Philippines Nueva Vizcaya State University Bambang, Nueva VizcayaKosjeNo ratings yet

- Subramanian Karunanithi,: Curriculum VitaeDocument5 pagesSubramanian Karunanithi,: Curriculum VitaePazhamalairajan KaliyaperumalNo ratings yet

- Region VII-Eastern VisayasDocument4 pagesRegion VII-Eastern VisayasBlazelCarvajalGrimaresNo ratings yet

- 25 M Fast Supply Vessel Swe v1Document2 pages25 M Fast Supply Vessel Swe v1Sebastian RentschNo ratings yet

- Site Assesment Pump ReportDocument1 pageSite Assesment Pump ReportThebe HanyaneNo ratings yet

- Experimental Thermal and Fluid Science: A.L. Neckel, M. GodinhoDocument10 pagesExperimental Thermal and Fluid Science: A.L. Neckel, M. GodinhoPett PeeveNo ratings yet

- Part Test # 2 NSEJS BatchDocument8 pagesPart Test # 2 NSEJS BatchRA• PLAYZNo ratings yet

- FM Unit I Two MarksDocument5 pagesFM Unit I Two MarksKomalaselvan VNo ratings yet

- Technical Manual Index: Cj610 Turbojet and CF700 TURBOFANDocument7 pagesTechnical Manual Index: Cj610 Turbojet and CF700 TURBOFANVenus khanNo ratings yet

- 10 1016-j Ijplas 2008 03 009Document52 pages10 1016-j Ijplas 2008 03 009sali8439443No ratings yet

- ST 330 81 1981 Chevrolet Light Duty Truck 10 To 30 Service Manual PDFDocument1,157 pagesST 330 81 1981 Chevrolet Light Duty Truck 10 To 30 Service Manual PDFrev8100% (3)

- Lester ElectricalDocument5 pagesLester ElectricalIsai WaldoNo ratings yet

- Unit 3 Grade 9 Sept 09Document28 pagesUnit 3 Grade 9 Sept 09girmaamanNo ratings yet

- 1Neher-McGrath Paper PDFDocument12 pages1Neher-McGrath Paper PDFmordelon468No ratings yet

- Furnace & Ovens WP (Original)Document38 pagesFurnace & Ovens WP (Original)Mumahmmad Rizwan RNo ratings yet