Professional Documents

Culture Documents

Omv Lo SR2 XMSLC ZD K

Omv Lo SR2 XMSLC ZD K

Uploaded by

Asad AhmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Omv Lo SR2 XMSLC ZD K

Omv Lo SR2 XMSLC ZD K

Uploaded by

Asad AhmedCopyright:

Available Formats

1 Repair instructions/occurring faults

Dräger Medizintechnik

D

Defect/error/fault Described in:

Paint damage on front panel unit See "Paint damage on front panel unit" on page 2

Leaks in airway system See "Leaks in the airway system" on page 3

Error message: «Xef28»Pressure See "Error: «Xef28»Pressure meas. inop.«Xaa»" on

meas. inop.«Xaa» page 4

Errors in use of DC module See "Errors in use of the DC module option" on

option page 5

Errors in representation of CO2 See "Errors in representation of CO2 data" on page

data 6

Error message 13.99.130 See "Error message 13.99.130 in conjunction with

other error messages" on page 7

Causes of error in O2 calibration See "Errors in O2 calibration and O2 measurement"

on page 8

Noise in ventilation See "Noise during ventilation" on page 9

Observe DIN 34 protection mark. Copyright reserved.

GBR5664500Hxx.fm 04.09.00

5664.500 Evita 4 06.00 Repair Instructions Page 1

2 Paint damage on front panel unit

Dräger Medizintechnik

D

On the Evita 4 and Evita 2 dura paint damage arising from manufacturing faults may occur on

the front panel unit (control panel or front panel). The adhesion of the paint primer is faulty on

some units (around 100), so the paint comes off easily.

Local repair of the faulty paintwork is advisable only as a temporary measure while new units

are on order, because the new coating will also come off again.

When ordering components for the Evita 4 the serial number of the control panel must be

quoted. The serial number is located on the back of the control panel. The new component is

then delivered with the quoted serial number.

The component exchange is handled as a complaint claim.

Observe DIN 34 protection mark. Copyright reserved.

GBR5664500Hxx.fm 04.09.00

5664.500 Evita 4 06.00 Repair Instructions Page 2

3 Leaks in the airway system

Dräger Medizintechnik

D

If leaks in the airway system are detected in leak testing in the course of the unit check, we

recommend the following troubleshooting procedure:

1. Check for mechanical damage:

Visual inspection of the hoses, tube connectors and the cuvette for damage or visible

leakage.

2. Error source: crater of expiratory valve, PEEP valve:

Seal off outlet of expiratory valve to flow sensor and repeat test. If the measured value is

then OK, there is a leak in the crater of the expiratory valve or the actuation pressure of

the PEEP is too low. The expiratory valve should be replaced as necessary, and the

PEEP valve calibrated. Remove the seal.

3. Error source: expiratory valve:

Seal socket of expiratory block with a rubber plug and restart leak test. The time until

the measured value is obtained is now substantially longer (approx. 10 seconds). If the

leak remains, the defect is on the expiration side of the airway system (patient section,

pressure measurement block, tube for flush flow). Remove the seal and plug the tube

system in with no humidifier.

4. Error source: leaking tube system:

Disconnect tube from inspiratory socket and seal tube. Start leak test. The time until the

measured value is obtained is approx. 20 seconds. If the leak remains, the defect is in

the tube system (tubes, cuvette, tube connector). A humidifier must not be integrated in

the tube system.

5. Error source: inspiratory block:

Connect expiratory and inspiratory socket with a short tube and start leak test. If the

leak remains, it is in the inspiratory block.

6. Error source: O2 amplifier:

Unscrew O2 amplifier on right-hand side of inspiratory block. Take out O2 sensor, close

off opening for O2 sensor with a rubber plug and restart leak test. If the measured value

is now OK, there is a leak due to damage or dirt contamination of the seal between the

O2 amplifier and the inspiratory block.

7. Error source: 100 mbar valve D3.3 and seals:

Unscrew inspiratory block and check for missing or damaged seals. If no seals

appeared faulty, seal off top side of 100 mbar valve D3.3 air-tight using adhesive tape.

Refit inspiratory block and start leak test. If the measured value is now OK, there is a

leak in the 100 mbar valve.

8. Error source: airway sensors and calibration valves:

Observe DIN 34 protection mark. Copyright reserved.

Leaks may occur in the area of the pneumatic valve Y3.1, the airway sensors S6.1 and

S6.2, and the calibration valves Y6.1 and Y6.2. When replacing the calibration valves,

check that the seals are fitted.

GBR5664500Hxx.fm 04.09.00

5664.500 Evita 4 06.00 Repair Instructions Page 3

4 Error: «Xef28»Pressure meas. inop.«Xaa»

Dräger Medizintechnik

D

If the operation «Xef28»Pressure meas. inop.«Xaa» occurs during operation:

Unit setting: IPPV without AutoFlow; breathing frequency = 0.5 min-1, PEEP = 5 mbar;

Pmax = 60 mbar.

Start internal service mode.

Evita 4: «Xef28»Configuration«Xaa» --> «Xef28»Basic settings«Xaa» --> «Xef28»Service dia-

gnosis«Xaa»

Evita 2 dura: «Xef28»Config./Calibrate«Xaa» --> «Xef28»Ventilation«Xaa»

Then enter the access code «Xef28»4655«Xaa». The data for the airway sensors are mapped

under the «Xef28»Pneumatic«Xaa» and «Xef28»Sensors«Xaa» menu items.

In relation to the selected ventilation parameters the following error messages may occur, but

can be ignored: «Xef28»Fail to cycle«Xaa» and «Xef28»Airway pressure too low«Xaa»

The voltage values for the sensors displayed in internal service mode should be

approx. 1.74 V at ambient pressure [Cal V].

The voltage rises by approx. 40 mV per mbar.

The following airway pressure sensor data may indicate defects:

1. If the voltage values [V] for [insp] and [exp] differ widely,

--> sensors defective, water in expiratory valve.

2. If the voltage values [Cal V] for [insp] and [exp] differ widely,

--> calibration valves defective.

Observe DIN 34 protection mark. Copyright reserved.

GBR5664500Hxx.fm 04.09.00

5664.500 Evita 4 06.00 Repair Instructions Page 4

5 Errors in use of the DC module option

Dräger Medizintechnik

D

In installation and operation of the DC module option, a variety of errors can occur. The follo-

wing section outlines a number of error characteristics:

1. When the unit is switched on the audible power failure alarm sounds, even though

mains power is connected. The unit is not operational.

--> Connector k of DC module is faulty or not plugged in.

2. The DC module exhibits no function when the mains voltage fails. The audible power

failure alarm sounds.

--> Connector h not plugged into DC module or rechargeable batteries defective.

3. When the unit is switched on the warning: «Xef28»Int. battery...«Xaa» appears even

though the mains power is connected.

--> Connector g (FASTON) not swapped over in installation or faulty.

4. No mains power or battery symbols are shown on the display. No alarm is delivered in

operation with the internal or external rechargeable battery. The power failure is only

signalled, by the audible power failure alarm, when the internal battery has discharged.

--> DC module option not activated (code '4811')

g h

Fig. 1: DC module connector

Observe DIN 34 protection mark. Copyright reserved.

GBR5664500Hxx.fm 04.09.00

5664.500 Evita 4 06.00 Repair Instructions Page 5

6 Errors in representation of CO2 data

Dräger Medizintechnik

D

The CO2 data are represented as curves and numbers on the display of the Evita 4/2dura.

No display of CO2 data:

Neither the number values nor the curve are shown. The «Xef28»CO2«Xaa» option is not

offered under the «Xef28»Alarm limits«Xaa» -> «Xef28»Monitoring«Xaa» menu item--> CO2

monitoring must be activated (service code «Xef28»6795«Xaa» ) or the CO2 sensor was not

detected when the Evita 4/2 dura was switched on.

Breaks in curve; CO2 value always zero; CO2 calibration not possible:

Frequently this means there is a defect in the Power Supply PCB --> Replace the Power Sup-

ply PCB.

Even though the sensor is connected the message «Xef28»CO2 sensor?«Xaa» sporadically

appears:

The CO2 sensor is not detected when CO2 measurement is active and the curve or value

representation temporarily fails --> Cable between Signal Processor PCB and sensor socket

on Evita 4/2dura defective.

Observe DIN 34 protection mark. Copyright reserved.

GBR5664500Hxx.fm 04.09.00

5664.500 Evita 4 06.00 Repair Instructions Page 6

7

Dräger Medizintechnik

Error message 13.99.130 in conjunction with other error messa-

ges

D

Error message 13.99.130 indicates triggering of the watchdog on the CPU PCB. The normal

program sequence could not be executed without error.

Error message 13.99.130 in MEDIBUS mode at the COM1 port:

When a monitor is connected to the COM1 port on the CPU PCB, there have been isolated

reports of the functioning of the Evita 4/2 dura and being affected and occurrence of error

message 13.99.130.

--> In these isolated cases one remedy is to operate the monitor on one of the ports of

the Communication PCB (option).

Error message 13.99.130 together with other errors:

If error messages other than error message 13.99.130, such as 02.71.016, 02.12.001 or

10.99.112, have occurred simultaneously, there is probably a problem with the +15V voltage

supply. This may be caused by sticking mixer cartridges in the pneumatic unit or defects in

the power pack. Short-term mains power failure to units without DC modules may also result

in this error combination.

Observe DIN 34 protection mark. Copyright reserved.

GBR5664500Hxx.fm 04.09.00

5664.500 Evita 4 06.00 Repair Instructions Page 7

8

Dräger Medizintechnik

Errors in O2 calibration and O2 measurement

D

Alarm signal: «Xef28»O2 meas. inop.«Xaa»:

The O2 sensor is measuring a value above 106% (upper limit exceeded) or below 15%

(lower limit not reached).

− O2 sensor is defective

− O2 sensor is not calibrated

− O2 sensor did not get 100% O2 during calibration, so the unit may (internally) measure

more than 100% O2.

--> reducer R3.1 clogged; diaphragm assembly in Y3.3 tilted; reducer R1.3 clogged.

− Pressure was applied to O2 sensor during calibration. This results in a concentration >

100% referred to ambient pressure. Consequently the O2 display may be below 21%.

--> Valve Y3.2 does not open.

Incorrect values in O2 measurement:

− Incorrect gas concentration due to defects in the cartridges or the HPSV Controller

PCB.

− Incorrect measurement data due to defective O2 sensors, tilted diaphragm assemblies

in Y3.3 or defective Pneumatics PCB.

Observe DIN 34 protection mark. Copyright reserved.

GBR5664500Hxx.fm 04.09.00

5664.500 Evita 4 06.00 Repair Instructions Page 8

9 Noise during ventilation

Dräger Medizintechnik

D

During the inspiration and expiration phases noise may be emitted by the Evita 4/2 dura,

especially in neonatal mode. The following causes of noise have been observed:

1. Noise disturbance from the patient section resulting from flapping diaphragm, damage

to the crater, dirty lip seals to the patient section or uncalibrated PEEP valve

--> Replace cover of patient section with a new one with a 6mm rim;

clean lip seal; calibrate PEEP valve.

2. Noise disturbance from mixer and slight leakage

--> Check mixer

Observe DIN 34 protection mark. Copyright reserved.

GBR5664500Hxx.fm 04.09.00

5664.500 Evita 4 06.00 Repair Instructions Page 9

You might also like

- Method Statement - Fabrication and Installation of Prefabricated Coodo 64Document15 pagesMethod Statement - Fabrication and Installation of Prefabricated Coodo 64arunNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- F2cfe613 Fjbfe613Document518 pagesF2cfe613 Fjbfe613jvega_534120100% (3)

- ServiceManual Cryo5 CompleteDocument50 pagesServiceManual Cryo5 Completemaluc100% (1)

- FILTREX ANIKA OM-32 DACXT - IngDocument29 pagesFILTREX ANIKA OM-32 DACXT - IngSady KanettiNo ratings yet

- Battenfeld Plus 350 Instruction-Manual 119816-100Document100 pagesBattenfeld Plus 350 Instruction-Manual 119816-100Giovani Cristi100% (1)

- Turnip28 V16a Core RulesDocument73 pagesTurnip28 V16a Core RulesСлавік БачинськийNo ratings yet

- Coating Supply Machine PDFDocument26 pagesCoating Supply Machine PDFDeniMestiWidianto100% (1)

- Inst - OP TD V3.05 Rev.1 PDFDocument57 pagesInst - OP TD V3.05 Rev.1 PDFshri_palaniNo ratings yet

- Manuale M 260 LX - Ti017g0003 - enDocument52 pagesManuale M 260 LX - Ti017g0003 - enJose Angel Basanta HernandezNo ratings yet

- Is My Machine OK?: A Field Guide to Assessing Process MachineryFrom EverandIs My Machine OK?: A Field Guide to Assessing Process MachineryNo ratings yet

- 5503 TroubleDocument69 pages5503 Troublesalgueroti100% (1)

- Engine Failure Cause PDFDocument5 pagesEngine Failure Cause PDFRohmanNo ratings yet

- Engine Failure Cause PDFDocument5 pagesEngine Failure Cause PDFRohmanNo ratings yet

- CR 30-X 2nd CR 30-Xm - Chapter 03.3 - TroubleshootingDocument17 pagesCR 30-X 2nd CR 30-Xm - Chapter 03.3 - TroubleshootingCRC BioservNo ratings yet

- M2424a service-YESDocument428 pagesM2424a service-YESystloveNo ratings yet

- Trouble Shooting GuideDocument33 pagesTrouble Shooting GuideBader SadeqaNo ratings yet

- 103M5088DDocument17 pages103M5088DRabah AmidiNo ratings yet

- Lawnboy Mower ManualDocument20 pagesLawnboy Mower ManualbowcoastieNo ratings yet

- A Conceptual Framework For System Fault ToleranceDocument44 pagesA Conceptual Framework For System Fault ToleranceAlexandreNo ratings yet

- Service Bulletin Trucks: Electric Fuel Pump, Fault TracingDocument10 pagesService Bulletin Trucks: Electric Fuel Pump, Fault Tracingedge_575No ratings yet

- UtasTech Claim ReportDocument2 pagesUtasTech Claim ReportGalilea GalileaNo ratings yet

- Zeppelin - Rotary Valve - dx5 160-2,6 HCDocument27 pagesZeppelin - Rotary Valve - dx5 160-2,6 HCThanh Xuan100% (1)

- Design Clause in Engineering Insurance ContractDocument6 pagesDesign Clause in Engineering Insurance Contract6640443100% (2)

- Mapa Ge Medical Tonoport VDocument38 pagesMapa Ge Medical Tonoport VWilson CepedaNo ratings yet

- Low Compression, Fault TracingDocument8 pagesLow Compression, Fault TracingIzz Bahar100% (2)

- 1.trilogy 100 Ventilator Information and User Guide For Qualified Health Professionals v6Document21 pages1.trilogy 100 Ventilator Information and User Guide For Qualified Health Professionals v6Mohammed NaeemNo ratings yet

- BiotrendDocument50 pagesBiotrendrobertNo ratings yet

- Types of Technical ReportsDocument88 pagesTypes of Technical ReportsMNo ratings yet

- An Analysis of Common Causes of Major Losses in The Onshore Oil, Gas Petrochemical IndustriesDocument12 pagesAn Analysis of Common Causes of Major Losses in The Onshore Oil, Gas Petrochemical IndustriesVahid TaghdiriNo ratings yet

- Troubleshooting Mecanico PDFDocument39 pagesTroubleshooting Mecanico PDFIvan Peralta RodriguezNo ratings yet

- TRT Ba DH25S DH65S TC 001 en PDFDocument16 pagesTRT Ba DH25S DH65S TC 001 en PDFAbilash SubramanianNo ratings yet

- MC 10125662 9999Document3 pagesMC 10125662 9999djdimagomelNo ratings yet

- Global 8D Training Report Example: Created by Visteon Europe STA DepartmentDocument3 pagesGlobal 8D Training Report Example: Created by Visteon Europe STA DepartmentSudhaNo ratings yet

- WorkCentre 123 128 133 Service ManualDocument1,176 pagesWorkCentre 123 128 133 Service Manualconnectingeurope8479100% (3)

- Installation and Operating Manual: T Turbo Coupling With Constant FillDocument154 pagesInstallation and Operating Manual: T Turbo Coupling With Constant Fillpk cfctkNo ratings yet

- Sinumerik 840C Simodrive 611-D: Diagnostics Guide 09.2001 EditionDocument260 pagesSinumerik 840C Simodrive 611-D: Diagnostics Guide 09.2001 EditionІван ГалNo ratings yet

- (PRESURIZACIÓN) 3003 Instalation InstructionDocument24 pages(PRESURIZACIÓN) 3003 Instalation InstructionJORGE ALOR RODRIGUEZNo ratings yet

- Z200 Trouble Shooting Guide, MechanicalDocument17 pagesZ200 Trouble Shooting Guide, MechanicalBader SadeqaNo ratings yet

- Work Centre M118 Service ManualDocument564 pagesWork Centre M118 Service ManualNordkonungNo ratings yet

- XEROX Work Centre M118 Service ManualDocument564 pagesXEROX Work Centre M118 Service ManualPreduta Monica100% (1)

- MY21 Sienna Dashcam (DIO) IssBDocument10 pagesMY21 Sienna Dashcam (DIO) IssBerviNo ratings yet

- English: 7425MUM009 Rev00 - GBDocument17 pagesEnglish: 7425MUM009 Rev00 - GBMaciekLembrykNo ratings yet

- Y-Strainer: Mounting and Installation ManualDocument20 pagesY-Strainer: Mounting and Installation ManualJhonathan RodriguezNo ratings yet

- DialogAd SM Chapter 5-4-2002Document9 pagesDialogAd SM Chapter 5-4-2002enricolamNo ratings yet

- FMEADocument3 pagesFMEAyadiNo ratings yet

- Failure Investigation Report On Different ComponenDocument6 pagesFailure Investigation Report On Different Componenadilahmed147639No ratings yet

- JD 624h Loader Tc62h Operator Sec WatDocument20 pagesJD 624h Loader Tc62h Operator Sec Watalbert100% (55)

- MC 10186819 0001Document2 pagesMC 10186819 0001scarab scarabNo ratings yet

- Workcentre 7220/7225 Service Documentation: November 9, 2012 Ecat VersionDocument1,017 pagesWorkcentre 7220/7225 Service Documentation: November 9, 2012 Ecat VersionDoicho AndonovNo ratings yet

- PART I Rotating Equipment - BookletDocument36 pagesPART I Rotating Equipment - BookletFarhan Hyder SyedNo ratings yet

- Operator MaintenenceDocument9 pagesOperator MaintenenceJhonAlexRiveroNo ratings yet

- DFMEADocument7 pagesDFMEAhitenNo ratings yet

- Technical Note 3511A Xg0D: Basic Manual: Workshop Repair Manual 341Document109 pagesTechnical Note 3511A Xg0D: Basic Manual: Workshop Repair Manual 341Nikola Jevdjic JevdzaNo ratings yet

- Guidelines for Siting and Layout of FacilitiesFrom EverandGuidelines for Siting and Layout of FacilitiesNo ratings yet

- Medical Coatings and Deposition TechnologiesFrom EverandMedical Coatings and Deposition TechnologiesDavid GlockerNo ratings yet

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Clinical and Laboratory Manual of Dental Implant AbutmentsFrom EverandClinical and Laboratory Manual of Dental Implant AbutmentsRating: 3 out of 5 stars3/5 (2)

- A Comprehensive Guide On WhatApp Customer SupportDocument55 pagesA Comprehensive Guide On WhatApp Customer SupportAsad AhmedNo ratings yet

- AD824Document16 pagesAD824Asad AhmedNo ratings yet

- Atmel 6438 32 Bit ARM926 Embedded Microprocessor S-2585389Document1,227 pagesAtmel 6438 32 Bit ARM926 Embedded Microprocessor S-2585389Asad AhmedNo ratings yet

- Silo - Tips - Cardiostart Defibrillator MonitorDocument92 pagesSilo - Tips - Cardiostart Defibrillator MonitorAsad AhmedNo ratings yet

- TicketDocument2 pagesTicketAsad AhmedNo ratings yet

- 108Document1 page108Asad AhmedNo ratings yet

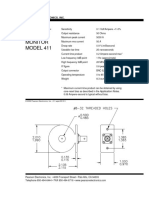

- Pearson Current Monitor MODEL 411Document1 pagePearson Current Monitor MODEL 411Asad AhmedNo ratings yet

- 07 31 2020 15.02.26Document1 page07 31 2020 15.02.26Asad AhmedNo ratings yet

- Invoice 03Document1 pageInvoice 03Asad AhmedNo ratings yet

- 0bfac16f-3bd2-4759-bbe9-0daa6cdd1956Document2 pages0bfac16f-3bd2-4759-bbe9-0daa6cdd1956Asad AhmedNo ratings yet

- SN54LV4053A, SN74LV4053A Triple 2-Channel Analog Multiplexers/DemultiplexersDocument33 pagesSN54LV4053A, SN74LV4053A Triple 2-Channel Analog Multiplexers/DemultiplexersAsad AhmedNo ratings yet

- ContinueDocument2 pagesContinueAsad AhmedNo ratings yet

- Pressure SensorDocument4 pagesPressure SensorAsad AhmedNo ratings yet

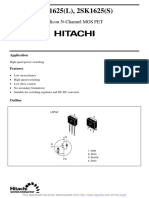

- 740 3 005230 2SK1625Document6 pages740 3 005230 2SK1625Asad AhmedNo ratings yet

- Microchip Arm926ej S Microcontroller 64 KB 10 Bit TfbgaDocument50 pagesMicrochip Arm926ej S Microcontroller 64 KB 10 Bit TfbgaAsad AhmedNo ratings yet

- Ecx 10 N 20Document4 pagesEcx 10 N 20Asad AhmedNo ratings yet

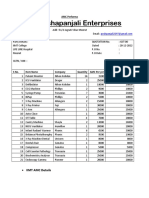

- IIMT AMC QutationDocument1 pageIIMT AMC QutationAsad AhmedNo ratings yet

- Vishay Sfernice: FeaturesDocument5 pagesVishay Sfernice: FeaturesAsad AhmedNo ratings yet

- DC-DC Converter YD12 Series Technical Specification V1.0Document6 pagesDC-DC Converter YD12 Series Technical Specification V1.0Asad AhmedNo ratings yet

- Lab 9101aDocument2 pagesLab 9101aAsad AhmedNo ratings yet

- 1987 Samsung SFET Data BookDocument446 pages1987 Samsung SFET Data BookAsad AhmedNo ratings yet

- Noninvasive Blood Pressure (NIBP) Measurement by Oscillometric PrincipleDocument6 pagesNoninvasive Blood Pressure (NIBP) Measurement by Oscillometric PrincipleAsad AhmedNo ratings yet

- CI20T120P: Features OutlineDocument4 pagesCI20T120P: Features OutlineAsad AhmedNo ratings yet

- DSA00164356Document14 pagesDSA00164356Asad AhmedNo ratings yet

- Order Details PDFDocument3 pagesOrder Details PDFAsad AhmedNo ratings yet

- Red Light Violation Detection SystemDocument2 pagesRed Light Violation Detection SystemAsad AhmedNo ratings yet

- DatasheetDocument12 pagesDatasheetAsad AhmedNo ratings yet

- Infineon IHW30N120R5 DataSheet v02 - 03 ENDocument15 pagesInfineon IHW30N120R5 DataSheet v02 - 03 ENAsad AhmedNo ratings yet

- Earth As A SphereDocument96 pagesEarth As A SphereMarlina MohamedNo ratings yet

- Climate DLLDocument2 pagesClimate DLLlucky may100% (1)

- Iteco-010901-B (0.6 - 1KV TFR-CV Spec)Document9 pagesIteco-010901-B (0.6 - 1KV TFR-CV Spec)Kyaw ThihaNo ratings yet

- Avlon Silent PilerDocument1 pageAvlon Silent PilerDushyantha JayawardenaNo ratings yet

- Total Final Weight of Job KGDocument38 pagesTotal Final Weight of Job KGx30patelNo ratings yet

- Solvent Extraction of Aluminium in The Presence of Cobalt, Nickel and Magnesium From Sulphate Solutions by Cyanex 272Document8 pagesSolvent Extraction of Aluminium in The Presence of Cobalt, Nickel and Magnesium From Sulphate Solutions by Cyanex 272Leda HidalgoNo ratings yet

- Zilog Z8000 Reference ManualDocument299 pagesZilog Z8000 Reference ManualNathalie VillemaireNo ratings yet

- Laplace TransformsDocument22 pagesLaplace TransformsAustin JamesNo ratings yet

- Sketchup Ur Space Dec 2013Document40 pagesSketchup Ur Space Dec 2013EryAjaDeh100% (1)

- Joints in Steel Construction - Simple Connections - Part 02 PDFDocument4 pagesJoints in Steel Construction - Simple Connections - Part 02 PDFkakem61No ratings yet

- Signing Document in CM - SECP vs. Innovative Investment Bank (CO No. 46 of 2010)Document3 pagesSigning Document in CM - SECP vs. Innovative Investment Bank (CO No. 46 of 2010)Azhar RanaNo ratings yet

- Cortana Tutorial: Raphael Mudge, Strategic Cyber LLCDocument61 pagesCortana Tutorial: Raphael Mudge, Strategic Cyber LLCcastillo_leoNo ratings yet

- Kayla Malik Resume February 2017Document2 pagesKayla Malik Resume February 2017api-340785737No ratings yet

- Stock in Transit (GR - IR Regrouping - Reclassification) - SAP BlogsDocument7 pagesStock in Transit (GR - IR Regrouping - Reclassification) - SAP BlogsusamaNo ratings yet

- 2000girls tcm77-254006Document92 pages2000girls tcm77-254006ВладиславNo ratings yet

- Lección 7 - Who - Why-Because (WH Questions)Document3 pagesLección 7 - Who - Why-Because (WH Questions)V QuintNo ratings yet

- InfosyspdfDocument30 pagesInfosyspdfBrinda BMNo ratings yet

- CC103 Engineering Surveying 1 Chapter 2Document15 pagesCC103 Engineering Surveying 1 Chapter 2Xendra AqeylaaNo ratings yet

- ChawlaDocument449 pagesChawlarajamannar322No ratings yet

- Gallbladder Mucocele A ReviewDocument6 pagesGallbladder Mucocele A ReviewThaís ChouinNo ratings yet

- Protective Coating PhilosophyDocument10 pagesProtective Coating PhilosophyAleem QureshiNo ratings yet

- TareekhePakistan 2ndDocument141 pagesTareekhePakistan 2ndAHMAD RAZANo ratings yet

- Additional Course Costs For UK and EU Students 2020-2021Document67 pagesAdditional Course Costs For UK and EU Students 2020-2021dsnNo ratings yet

- Notes Ed-124Document33 pagesNotes Ed-124Mary Cristine GaboteroNo ratings yet

- Pembumian 110705103913 Phpapp02Document33 pagesPembumian 110705103913 Phpapp02Noor Syazwani Md SharifNo ratings yet

- Assessing The Nature of Soil AcidityDocument8 pagesAssessing The Nature of Soil AcidityPartha DebRoyNo ratings yet

- Darwin EvolutionDocument43 pagesDarwin EvolutionJohn michael SumagaysayNo ratings yet

- Political Activism in Nursing Final PresentationDocument30 pagesPolitical Activism in Nursing Final PresentationDip Ayan MNo ratings yet