Professional Documents

Culture Documents

Night Shift 01-09-2022

Night Shift 01-09-2022

Uploaded by

fahadullah0 ratings0% found this document useful (0 votes)

13 views2 pages1) Key plant units were operating normally with no instrument or mechanical bypasses.

2) Production rates for various units like cation, anion and mixed bed were reported.

3) GCF units K-1501A/B/D, K-1521A/B and K-1531A/C/D were in service while K-1531B tripped due to a waste gate issue.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) Key plant units were operating normally with no instrument or mechanical bypasses.

2) Production rates for various units like cation, anion and mixed bed were reported.

3) GCF units K-1501A/B/D, K-1521A/B and K-1531A/C/D were in service while K-1531B tripped due to a waste gate issue.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

13 views2 pagesNight Shift 01-09-2022

Night Shift 01-09-2022

Uploaded by

fahadullah1) Key plant units were operating normally with no instrument or mechanical bypasses.

2) Production rates for various units like cation, anion and mixed bed were reported.

3) GCF units K-1501A/B/D, K-1521A/B and K-1531A/C/D were in service while K-1531B tripped due to a waste gate issue.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

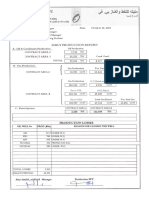

UTILITIES-III

Shift Engineer Logbook

Mirpur Mathelo

Shift: Night Date:01-Sept-22

Instrument securities bypassed Nil

Mechanical securities bypassed Nil

ESD Status Area-09

Feed Gas B/L Pressure, Kg/cm 2 30.0 T-901 / 902 / 940 Level, % 98/98.8/30

Fuel Gas B/L Pressure, Kg/cm 2 10.1 1/7/16-20/27/29-

Tube Wells in service [Total =15]

ME-1501A/ME-1502 ΔP, Kg/cm2 0.21/0.03 34/36

E-352 ΔP, Kg/cm 2 0.45 09-FR-1 / FR2 / FR17 Flow, m3/hr. 650/475/270

NG Condensate, Fuel/Feed ml / min 50/100 Demin. Lines in Service, Ea. B

Area-06 Cation Production (A / B / C) 740/4450/2190

B-601 / 602 / 603 Load, TPH 45+52+33 = 130 Anion Production (A / B / C) 590/2700/1540

Purge Gas to B- 601 /602 / 603,

2300+3400+1000=6700 Acid / Caustic Consumption, Kg -/-

NMC/hr.

E-601 Vacuum, Kg/cm2 -0.918 Acid / Caustic Inventory, Tons 27.63/63.8

06-XX-14A/B 10.1/9.3 Mixed Bed in Service B

B-601 / 602 Oxygen, % 3.2/2.7 Mixed Bed Production (A / B / C) 680/9480/2490

LS Prod/Vent, TPH 00/00 ME-952A/B pit level, % 20/25

TK-601 / MK-601 [on Rolling/Load] -/TK-601 Lime Kiln Temp. (Max) Bottom /Top, oC 746/225

Lime Kiln Buckets/ CaO Bags

TK-602 / MK-602 [on Rolling/Load] -/MK-602 07/02

Charge

Area-07 Area-08

TG-701A/B & GT-703 Load, MW 2.4+2.3+9.6 = 14.3 CWS / CWR Pressure (P1/P2),Kg/cm2 2.96/1.30

2.52/2.00 CWS / CWR Temp (T1/T2), 0C 32.9/41.6

Township Load (Max /Min), MWH

2300/0500 No. of CW Pumps in Service / Rolling ABD/-

MG-702 hot condensate / lube oil

50/47 Chlorine/Bromine Dosing (Kg) 60/30

temperatures

E-701A/B Vacuum, Kg/cm2 -0.95/-0.96 ORP / F.Cl2, mV/ppb 757/432

E-701A/B Hot Well Temp, oC CBD, m3/hr. / Chlorides, ppm

41/39 150/234

GT-703 Combustion Air ΔP, mm

84 Acid Inventory, Tons 26.8

WC

V-703 condensate, Lit 00 Hypo / Chlorine Inventory, Kg / Cyl. 1490/04

Area-11 Area-16

V-1103 Pressure, Kg/cm 2 3.0 pH of Waste Water [Limit: 6-9] 7.88/8.20/6.10

Conductivity of Waste Water, µs/cm

N2 Consumption, NMC 700

[Limit:2500 µs] 1136/1739/2454

Ammonia in Waste Water, ppm

N2 Inventory, NMC 10700 13/36/34

[Limit:40 ppm]

GCF

K-1501 K-1521 [JGC-4] K-1531 [JGC-6]

A B C D A B C A B C D

Speed, rpm 1115 1100 SB 1110 900 895 SB 915 UM 900 880

Recycle valve opening, % 00 00 100 00 05 00 100 05 100 00 15

Suction Pressure, PSI 450 164 164

Discharge Pressure, PSI 822 480 478

15-FR-32, MMSCFD 52.5

24” suction valve opening, % 26.5

Steam & Power:

• TG-701A/B slip rings cleaned. Maximum temperature of 62/60°C observed during shift.

• 15-PIC-8 remained close.

• TK-601 oil sample sent at 0400 hrs, moisture reported <200 ppm. Oil centrifuge remained in service.

• B-601 air preheater sealing air hose clamp tightening required.

Off-Site:

• Clarifier makeup is on well water.

• Potable water plant op. cabin tube lights rectification required.

• 09 bromine pump suction/discharge tube leakage rectification required.

• ME-921 recycle valve diaphragm leakage rectification required.

• ME-920 top lights rectification required.

• P-920A pump gland leakage rectification required.

• M/S follow for S-950C inlet line leakage rectification.

• Waste water disposal is towards C-pound due to E-pond high level.

GCF:

• EK-1501 A/B/D, EK-1521A/B and EK-1531A/C/D are in service.

• EK-1531B old waste gate reinstalled, waste gate module jigs cleaned and engine cylinders inspected. Unit started

at 1200 hrs, it tripped at 0220 hrs on engine low speed due to waste gate sticking. Further jobs will be carried out

in M/S, however, engine can be started as per requirement.

Routine Audits:

Frequency Audit New Observations Actions

Weekly

Bi-Monthly

Monthly

Quarterly

AUB

You might also like

- 1.1.7 Practice - Chemical Reactions and The Mole (Practice)Document6 pages1.1.7 Practice - Chemical Reactions and The Mole (Practice)asdffNo ratings yet

- Chemistry Nmat ReviewerDocument8 pagesChemistry Nmat ReviewerAlec Jasper U. Villamayor100% (7)

- Internship Presentation: Seven Star Sugar Mills Sangl A HillDocument26 pagesInternship Presentation: Seven Star Sugar Mills Sangl A HillDrsaabNo ratings yet

- Evening Shift 01-09-2022Document2 pagesEvening Shift 01-09-2022fahadullahNo ratings yet

- Morning Shift 01-09-2022Document2 pagesMorning Shift 01-09-2022fahadullahNo ratings yet

- Night Shift 10-09-2022Document2 pagesNight Shift 10-09-2022fahadullahNo ratings yet

- Night Shift 11-09-2022Document2 pagesNight Shift 11-09-2022fahadullahNo ratings yet

- Evening Shift 10-09-2022Document2 pagesEvening Shift 10-09-2022fahadullahNo ratings yet

- Morning Shift 10-09-2022Document2 pagesMorning Shift 10-09-2022fahadullahNo ratings yet

- Rich Gas Pre Cooler - E101 A-BDocument4 pagesRich Gas Pre Cooler - E101 A-B29031978No ratings yet

- I-GIO-631-104140-HD-P-302-Rev - 0 (HD OI GG)Document5 pagesI-GIO-631-104140-HD-P-302-Rev - 0 (HD OI GG)Martin DanzeNo ratings yet

- M24-Plate Heat ExcahngerDocument16 pagesM24-Plate Heat ExcahngerAlexNo ratings yet

- LHSS OP P-1B TGL 03 September 2023 Day-1Document1 pageLHSS OP P-1B TGL 03 September 2023 Day-1kurniapusriNo ratings yet

- Material Stream: 6-3: ConditionsDocument6 pagesMaterial Stream: 6-3: ConditionsHerrera Jorge AgustínNo ratings yet

- s5113 Mm41 Plate CoolerDocument79 pagess5113 Mm41 Plate CoolerJorge AguilarNo ratings yet

- Aldina Adriana - Kasus 5Document8 pagesAldina Adriana - Kasus 5Gyan PrameswaraNo ratings yet

- Material Stream: 3: ConditionsDocument5 pagesMaterial Stream: 3: ConditionsHerrera Jorge AgustínNo ratings yet

- Boiler MIURA - LX-300-16Document2 pagesBoiler MIURA - LX-300-16LuizPauloCostaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Htri 105 PDFDocument1 pageHtri 105 PDFhirenpatel_62No ratings yet

- Boiler Performance - DataDocument2 pagesBoiler Performance - DataharimadhavareddyNo ratings yet

- BW Liberty Gas Form CDocument8 pagesBW Liberty Gas Form Cvalter AssunçãoNo ratings yet

- Laporan Mngr. Shift P-2B, 25 Agustus 2023 (Night Shift)Document1 pageLaporan Mngr. Shift P-2B, 25 Agustus 2023 (Night Shift)kurniapusriNo ratings yet

- Aida Septia Rahastika - Kasus 5Document10 pagesAida Septia Rahastika - Kasus 5Gyan Prameswara100% (1)

- Separator SizingDocument9 pagesSeparator SizingTolstoy LeoNo ratings yet

- Objective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpDocument5 pagesObjective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpAJAY1381No ratings yet

- A100 Daily Production On 14.10.2023Document5 pagesA100 Daily Production On 14.10.2023mahmudlooking03No ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:09:04 TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:09:04 TEMA SheetWael BadriNo ratings yet

- E 101Document21 pagesE 101EberVelazquezChantacaNo ratings yet

- Calculation Note - Pump Rev 2Document4 pagesCalculation Note - Pump Rev 2Steve WanNo ratings yet

- Room Air Conditioner: SVC MANUAL (Exploded View)Document8 pagesRoom Air Conditioner: SVC MANUAL (Exploded View)dougsanNo ratings yet

- Shell&TubeResults 215E009Document5 pagesShell&TubeResults 215E009ganis supriadiNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Data Sheet - 1 Att - 1-1 - Process DS For E-301 To 328ABCD Air Heaters For STV GW Loop - Modified R1 - 20160919 (Only Unit Revised)Document2 pagesData Sheet - 1 Att - 1-1 - Process DS For E-301 To 328ABCD Air Heaters For STV GW Loop - Modified R1 - 20160919 (Only Unit Revised)Avinash ShuklaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V8.8Document3 pagesAspen Exchanger Design and Rating Shell & Tube V8.8Camila Florencia ScarlatoNo ratings yet

- Technical Offer: Pump Description Pump ModelDocument4 pagesTechnical Offer: Pump Description Pump ModelPraveen PrajapatiNo ratings yet

- 2400-05-DTS-005cooling TowerDocument19 pages2400-05-DTS-005cooling TowerEmran NazirNo ratings yet

- 240-05-DTS-000 Fire Water PumpDocument19 pages240-05-DTS-000 Fire Water PumpEmran NazirNo ratings yet

- 240-05-DTS-XXX Flare StackDocument18 pages240-05-DTS-XXX Flare StackEmran NazirNo ratings yet

- Data Sheet Gas Scrubber 42 InchDocument32 pagesData Sheet Gas Scrubber 42 InchWijayantoNo ratings yet

- Anexo 3.2 Hoja de Datos Del Reactor 3401 DA - DBDocument16 pagesAnexo 3.2 Hoja de Datos Del Reactor 3401 DA - DBLuis ColinaNo ratings yet

- Environment Monitoring Monthly Report - Aug'22Document1 pageEnvironment Monitoring Monthly Report - Aug'22Mohit Kumar DasNo ratings yet

- Shell & Tube Gas HEATER EXCHANGER (P-1233002) : Srge/EsupDocument3 pagesShell & Tube Gas HEATER EXCHANGER (P-1233002) : Srge/EsupRobles DreschNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetWael BadriNo ratings yet

- 1 PDFDocument1 page1 PDFWael BadriNo ratings yet

- Ficha Tecnica Inverter Mini SplitDocument1 pageFicha Tecnica Inverter Mini SplitpabloabelgilsotoNo ratings yet

- Ceiling & Floor Type Air Conditioner: Service ManualDocument43 pagesCeiling & Floor Type Air Conditioner: Service ManualCesar Calderon GrNo ratings yet

- Steam Heater E-002Document2 pagesSteam Heater E-002vidyaNo ratings yet

- Heat Exchanger Rating Data Sheet SI Units: C:/Users/Berta/Desktop/Intercambiador E-101.htriDocument1 pageHeat Exchanger Rating Data Sheet SI Units: C:/Users/Berta/Desktop/Intercambiador E-101.htriEduardoNo ratings yet

- PDM-P-CS-002 - HP Prod SeparatorDocument6 pagesPDM-P-CS-002 - HP Prod Separatorfirman adiyantoNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9Document1 pageAspen Exchanger Design and Rating Shell & Tube V9Maira Alejandra GuzmánNo ratings yet

- 6648 0010 5 PS SS 0001 F - Stream SummaryDocument26 pages6648 0010 5 PS SS 0001 F - Stream SummarytamasmamerNo ratings yet

- File: C:/Users/carre/Downloads/E-104 OK - EDR Printed: 27/08/2020 at 17:37:22Document14 pagesFile: C:/Users/carre/Downloads/E-104 OK - EDR Printed: 27/08/2020 at 17:37:22Camila Florencia ScarlatoNo ratings yet

- Pump: P-101: Aspen Technology Inc. Aspen HYSYS Version 10 Page 1 of 5Document5 pagesPump: P-101: Aspen Technology Inc. Aspen HYSYS Version 10 Page 1 of 5amaterasu31416No ratings yet

- T3 ME Performance Record Jan TemplateDocument5 pagesT3 ME Performance Record Jan TemplateMuhd Khir RazaniNo ratings yet

- Dual Fuel Gas/Light-Oil Burners at Two Stages: SK073506 - C - enDocument4 pagesDual Fuel Gas/Light-Oil Burners at Two Stages: SK073506 - C - ensteam mastersNo ratings yet

- 1 7335Document5 pages1 7335stamatsNo ratings yet

- FBR Gas P 100, 150Document8 pagesFBR Gas P 100, 150Arifin ZaenalNo ratings yet

- E-313 DesignDocument1 pageE-313 DesignAamir SultanNo ratings yet

- Erosion Velocity CalculationsDocument9 pagesErosion Velocity CalculationsMANISH GUPTANo ratings yet

- Boiler AccesoriesDocument127 pagesBoiler Accesoriesramnath008100% (1)

- KG2-3G - Baseload Performance - W-Part Load Data - Rev01Document21 pagesKG2-3G - Baseload Performance - W-Part Load Data - Rev01joellopezzNo ratings yet

- WH Tax HBL 2020Document1 pageWH Tax HBL 2020fahadullahNo ratings yet

- Tax Year-2020 Document ListDocument20 pagesTax Year-2020 Document ListfahadullahNo ratings yet

- Provident Fund Certificate - 2020Document1 pageProvident Fund Certificate - 2020fahadullahNo ratings yet

- Evening Shift 10-09-2022Document2 pagesEvening Shift 10-09-2022fahadullahNo ratings yet

- Year 2020Document18 pagesYear 2020fahadullahNo ratings yet

- Dividend Zakat & Tax Deduction ReportsDocument4 pagesDividend Zakat & Tax Deduction ReportsfahadullahNo ratings yet

- Donation Slip-Dar Us Shifa Trust Hospital Sadiqabad (Rs 950,000)Document3 pagesDonation Slip-Dar Us Shifa Trust Hospital Sadiqabad (Rs 950,000)fahadullahNo ratings yet

- Pfcert 2021 460Document1 pagePfcert 2021 460fahadullahNo ratings yet

- Year 2016Document15 pagesYear 2016fahadullahNo ratings yet

- Telephone Directory - 2019Document7 pagesTelephone Directory - 2019fahadullahNo ratings yet

- Year 2017Document19 pagesYear 2017fahadullahNo ratings yet

- Evening Shift 01-09-2022Document2 pagesEvening Shift 01-09-2022fahadullahNo ratings yet

- Year 2015Document2 pagesYear 2015fahadullahNo ratings yet

- IG-2 Risk Assesment GCF SiteDocument19 pagesIG-2 Risk Assesment GCF SitefahadullahNo ratings yet

- Morning Shift 10-09-2022Document2 pagesMorning Shift 10-09-2022fahadullahNo ratings yet

- MPCL Utility EngineerDocument2 pagesMPCL Utility EngineerfahadullahNo ratings yet

- P-Iii PLR 202Document11 pagesP-Iii PLR 202fahadullahNo ratings yet

- Morning Shift 01-09-2022Document2 pagesMorning Shift 01-09-2022fahadullahNo ratings yet

- Night Shift 10-09-2022Document2 pagesNight Shift 10-09-2022fahadullahNo ratings yet

- Bill StatementDocument98 pagesBill StatementfahadullahNo ratings yet

- Night Shift 11-09-2022Document2 pagesNight Shift 11-09-2022fahadullahNo ratings yet

- Proposed Internet Bandwidth Package For TownshipDocument1 pageProposed Internet Bandwidth Package For TownshipfahadullahNo ratings yet

- Safety Audit Report 02 - 08-09-2022Document14 pagesSafety Audit Report 02 - 08-09-2022fahadullahNo ratings yet

- Chemicals StatusDocument1 pageChemicals StatusfahadullahNo ratings yet

- DuPont Methodology For Risk Assessment and Process Hazard AnalysisDocument65 pagesDuPont Methodology For Risk Assessment and Process Hazard Analysisfahadullah100% (2)

- Dunya Lahore 11 SepDocument16 pagesDunya Lahore 11 SepfahadullahNo ratings yet

- Objectives Setting Form: Metric Unit Weightage KPI ObjectiveDocument2 pagesObjectives Setting Form: Metric Unit Weightage KPI ObjectivefahadullahNo ratings yet

- Ammonia Release Mock Exercise Summary Sept 23, 2021Document11 pagesAmmonia Release Mock Exercise Summary Sept 23, 2021fahadullahNo ratings yet

- IFIF@: Ehicle Request Form & Rigging PlanDocument1 pageIFIF@: Ehicle Request Form & Rigging PlanfahadullahNo ratings yet

- Acousteel Brochure Digital FINALDocument8 pagesAcousteel Brochure Digital FINALfahadullahNo ratings yet

- Gibbs Free Energy Gibbs Free Energy: DG DH - TdsDocument8 pagesGibbs Free Energy Gibbs Free Energy: DG DH - TdsEmmanuel HoangNo ratings yet

- Philippine Tables of Controlled Chemicals Re: PDEADocument1 pagePhilippine Tables of Controlled Chemicals Re: PDEARomel PobleteNo ratings yet

- Test2 SolutionDocument10 pagesTest2 SolutionHua KhienNo ratings yet

- Skripsi Full UnilaDocument695 pagesSkripsi Full UnilaMaya PuspitasariNo ratings yet

- Critical Coalescence Concentration of Inorganic Salt Solutions PDFDocument6 pagesCritical Coalescence Concentration of Inorganic Salt Solutions PDFJose Luis Barrientos RiosNo ratings yet

- Half Facepiece Respirators 7500 Series, Ultimate ReusableDocument3 pagesHalf Facepiece Respirators 7500 Series, Ultimate ReusableRuby Valladolid GarcíaNo ratings yet

- Electro FlashcardsDocument6 pagesElectro FlashcardsVanCancioNo ratings yet

- 1057 - Determination of HG in Used Engine Oil PDFDocument3 pages1057 - Determination of HG in Used Engine Oil PDFYudhistira Bin ZufriNo ratings yet

- The Dissolution of Microcrystalline Cellulose in Sodium Hydroxide-Urea Aqueous SolutionsDocument10 pagesThe Dissolution of Microcrystalline Cellulose in Sodium Hydroxide-Urea Aqueous SolutionsCassiano PiresNo ratings yet

- Kemresis S15Document1 pageKemresis S15hamedmustafa093No ratings yet

- Enzyme Simulation - Amylase A - SPREADSHEETDocument5 pagesEnzyme Simulation - Amylase A - SPREADSHEETs1085088No ratings yet

- Sikalastic®-726 Balcony One Shot: Product Data SheetDocument4 pagesSikalastic®-726 Balcony One Shot: Product Data Sheetcphammond83No ratings yet

- Cambridge International General Certificate of Secondary EducationDocument16 pagesCambridge International General Certificate of Secondary EducationTshegofatso SaliNo ratings yet

- Degradation of Ascorbic Acid in Ethanolic Solutions - Comments - J. Agric. Food Chem., 2013, 61 (10), PP 2580-2582 PDFDocument3 pagesDegradation of Ascorbic Acid in Ethanolic Solutions - Comments - J. Agric. Food Chem., 2013, 61 (10), PP 2580-2582 PDFnonameNo ratings yet

- Corrosion Prevention by Use of InhibitorsDocument19 pagesCorrosion Prevention by Use of InhibitorsSai PradeepNo ratings yet

- Lab.7 عقاقير ثانيDocument9 pagesLab.7 عقاقير ثانيهاني عقيل حسين جوادNo ratings yet

- Functional Groups: Naming of EstersDocument6 pagesFunctional Groups: Naming of EsterspappadakunduNo ratings yet

- Chem31.1 ATQ8 Santos PDFDocument3 pagesChem31.1 ATQ8 Santos PDFClaire Santos100% (1)

- BatteryDocument1 pageBatteryonaar232No ratings yet

- IPI UV Inks PL 2000 - IngDocument3 pagesIPI UV Inks PL 2000 - IngPallino 26No ratings yet

- Infineum Ilsa Gf-6 API SP e JasoDocument28 pagesInfineum Ilsa Gf-6 API SP e JasoDanielNo ratings yet

- TD Bio 211 2023-2024Document9 pagesTD Bio 211 2023-2024Remadji vieriNo ratings yet

- P Block NotesDocument51 pagesP Block Notessureshstipl sureshNo ratings yet

- Iso 4624-2016Document18 pagesIso 4624-2016Edgmar Bassi FioriNo ratings yet

- Chemistry Extraction of Essential OilsDocument23 pagesChemistry Extraction of Essential OilsLIVE GAMERNo ratings yet

- WCH11 - 01 - Que - 20190110 (3), EdexcelDocument24 pagesWCH11 - 01 - Que - 20190110 (3), EdexcelAbdoNo ratings yet

- AlkaloidsDocument13 pagesAlkaloidsGanesh.S NairNo ratings yet