Professional Documents

Culture Documents

Evening Shift 01-09-2022

Evening Shift 01-09-2022

Uploaded by

fahadullah0 ratings0% found this document useful (0 votes)

26 views2 pages- The shift log details operations across multiple areas including steam & power, off-site, and gas conditioning facilities (GCF). Key points include turbines, pumps, and compressors being in service, minor repairs and maintenance activities, and air/gas/effluent monitoring results within normal ranges. Equipment issues included stuck waste gate feedback on a GCF compressor requiring further attention. Routine audits were noted to be on schedule.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document- The shift log details operations across multiple areas including steam & power, off-site, and gas conditioning facilities (GCF). Key points include turbines, pumps, and compressors being in service, minor repairs and maintenance activities, and air/gas/effluent monitoring results within normal ranges. Equipment issues included stuck waste gate feedback on a GCF compressor requiring further attention. Routine audits were noted to be on schedule.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

26 views2 pagesEvening Shift 01-09-2022

Evening Shift 01-09-2022

Uploaded by

fahadullah- The shift log details operations across multiple areas including steam & power, off-site, and gas conditioning facilities (GCF). Key points include turbines, pumps, and compressors being in service, minor repairs and maintenance activities, and air/gas/effluent monitoring results within normal ranges. Equipment issues included stuck waste gate feedback on a GCF compressor requiring further attention. Routine audits were noted to be on schedule.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

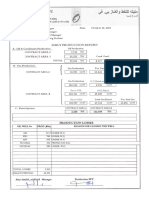

UTILITIES-III

Shift Engineer Logbook

Mirpur Mathelo

Shift: Evening Date:01-Sept-22

Instrument securities bypassed Nil

Mechanical securities bypassed Nil

ESD Status Area-09

Feed Gas B/L Pressure, Kg/cm 2 30.0 T-901 / 902 / 940 Level, % 97/98.8/20

Fuel Gas B/L Pressure, Kg/cm 2 10.2 1/7/16-20/27/29-

Tube Wells in service [Total =15]

ME-1501A/ME-1502 ΔP, Kg/cm2 0.21/0.03 34/36

E-352 ΔP, Kg/cm 2 0.45 09-FR-1 / FR2 / FR17 Flow, m3/hr. 650/475/270

NG Condensate, Fuel/Feed ml / min 50/100 Demin. Lines in Service, Ea. B

Area-06 Cation Production (A / B / C) 550/3950/2000

B-601 / 602 / 603 Load, TPH 47+50+33 = 130 Anion Production (A / B / C) 400/2200/1350

Purge Gas to B- 601 /602 / 603,

2400+3400+1200=7000 Acid / Caustic Consumption, Kg -/-

NMC/hr.

E-601 Vacuum, Kg/cm2 -0.919 Acid / Caustic Inventory, Tons 27.63/63.8

06-XX-14A/B 9.5/9.4 Mixed Bed in Service B

B-601 / 602 Oxygen, % 2.5/2.5 Mixed Bed Production (A / B / C) 680/8200/2150

LS Prod/Vent, TPH 00/00 ME-952A/B pit level, % 30/30

TK-601 / MK-601 [on Rolling/Load] -/TK-601 Lime Kiln Temp. (Max) Bottom /Top, oC 760/220

Lime Kiln Buckets/ CaO Bags

TK-602 / MK-602 [on Rolling/Load] -/MK-602 04/02

Charge

Area-07 Area-08

TG-701A/B & GT-703 Load, MW 2.3+2.3+10.5 = 15.1 CWS / CWR Pressure (P1/P2),Kg/cm2 2.96/1.30

2.9/2.71 CWS / CWR Temp (T1/T2), 0C 33.0/41.6

Township Load (Max /Min), MWH

1500/1700 No. of CW Pumps in Service / Rolling ABD/-

MG-702 hot condensate / lube oil

50/48 Chlorine/Bromine Dosing (Kg) 60/30

temperatures

E-701A/B Vacuum, Kg/cm2 -0.94/-0.95 ORP / F.Cl2, mV/ppb 780/653

E-701A/B Hot Well Temp, oC CBD, m3/hr. / Chlorides, ppm

41/40 150/234

GT-703 Combustion Air ΔP, mm

83 Acid Inventory, Tons 28.6

WC

V-703 condensate, Lit 00 Hypo / Chlorine Inventory, Kg / Cyl. 1590/04

Area-11 Area-16

V-1103 Pressure, Kg/cm 2 3.2 pH of Waste Water [Limit: 6-9] 8.12/7.2/7.15

Conductivity of Waste Water, µs/cm

N2 Consumption, NMC 150

[Limit:2500 µs] -/1279/1246

Ammonia in Waste Water, ppm

N2 Inventory, NMC 11400 21/18/20

[Limit:40 ppm]

GCF

K-1501 K-1521 [JGC-4] K-1531 [JGC-6]

A B C D A B C A B C D

Speed, rpm 1115 1100 SB 1110 900 895 SB 915 UM 900 880

Recycle valve opening, % 00 00 100 00 05 00 100 05 100 00 15

Suction Pressure, PSI 450 164 164

Discharge Pressure, PSI 815 480 478

15-FR-32, MMSCFD 52.5

24” suction valve opening, % 26.5

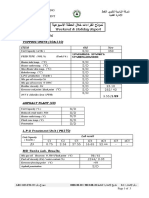

Steam & Power:

• TG-701A/B slip rings cleaned. Maximum temperature of 63/64°C observed during shift.

• 15-PIC-8 remained closed.

• TK-601 oil centrifuge replaced with one from ammonia unit and taken in service. N/S please send oil sample at

0400 hrs.

• 07-HPA-104A (MP-701A running indication alarm) switch replaced with reclaimed one, pump test run done and is

OK.

• MP-601C winding 01 temp (out of 03) Connections tightening from marshalling cabinet checked and observed

normal. Temperature in shift remained normal.

• TG-701A container 02 fused light fixtures replaced while 3rd fused tube light replaced but again fused. Its fixture is

faulty and will be checked tomorrow.

• B-601/2/3 flue gases samples results,

CO2 O2 CO NOx

B-601 7.53 4.27 <5 208

B-602 7.53 4.16 <5 208

B-603 2.85 14.38 <5 168

• B-601/2 BLP lighting circuit rectification remained in progress.

• S/F erection at B-601 SH platform for lighting circuit remained in progress.

• Thickness monitoring of LC line near V-602 and MP-605A/B remained in progress.

• S/F erection at LS utility point near TP-601A remained in progress

• Insulation provision of TK-601 hydraulic valve and 06-SD-49B remained in progress.

Off-Site:

• Clarifier makeup is on well water.

• V-941 inlet nozzles cleaning done, plastic piece observed in one nozzle. Degassifier normalized at 1855 hrs.

• 09 System cabinet exhaust fan dismantled to workshop against abnormal sound.

• Lime slacker motor to gearbox coupling tightening of bolts done and now OK.

• MP-921A power cable checking and rectification in / outside of chemical hall and in SS-2 remained I/P.

• Dewatering of excavated area of waste water line near B&S remained in progress.

• Lime stone trolley received unloaded as sample results were OK.

• E-800I/J stairs platform repairing job remained in progress.

• S/F adjustment on 09-PSV-3 is in progress. M/S please follow for PSV removal.

• Water transferred from D-pond to E-pond stopped due to high level in E-pond.

• S-950C inlet line checked by equipment. M/S please follow for its leakage rectification.

• Waste water disposal is towards C-pound.

GCF:

• EK-1501 A/B/D, EK-1521A/B and EK-1531A/B/C are in service.

• EK-1531B waste gate actuator replaced and machine and machine taken in service but again tripped on waste

gate linkage sticking feedback. (ALM 324 FB). Communicated to Inst & Mach area engineers.

Routine Audits:

Frequency Audit New Observations Actions

Weekly

Bi-Monthly

Monthly

Quarterly

MRM

You might also like

- Npi Vs FerronickelDocument4 pagesNpi Vs Ferronickelarkent98100% (1)

- Enzyme AssaysDocument3 pagesEnzyme AssaysAudreySlitNo ratings yet

- MSTC e BulletinDocument11 pagesMSTC e BulletinTrilok33% (3)

- FillerDocument9 pagesFillerTaj AnwarNo ratings yet

- Stainless Steel Grades 2008 01 PDFDocument2 pagesStainless Steel Grades 2008 01 PDFRahul LavandNo ratings yet

- Nature of Material EngineeringDocument40 pagesNature of Material EngineeringLee Francis Baluyot100% (2)

- Morning Shift 01-09-2022Document2 pagesMorning Shift 01-09-2022fahadullahNo ratings yet

- Evening Shift 10-09-2022Document2 pagesEvening Shift 10-09-2022fahadullahNo ratings yet

- Night Shift 01-09-2022Document2 pagesNight Shift 01-09-2022fahadullahNo ratings yet

- Night Shift 10-09-2022Document2 pagesNight Shift 10-09-2022fahadullahNo ratings yet

- Night Shift 11-09-2022Document2 pagesNight Shift 11-09-2022fahadullahNo ratings yet

- Morning Shift 10-09-2022Document2 pagesMorning Shift 10-09-2022fahadullahNo ratings yet

- Rich Gas Pre Cooler - E101 A-BDocument4 pagesRich Gas Pre Cooler - E101 A-B29031978No ratings yet

- LHSS OP P-1B TGL 03 September 2023 Day-1Document1 pageLHSS OP P-1B TGL 03 September 2023 Day-1kurniapusriNo ratings yet

- I-GIO-631-104140-HD-P-302-Rev - 0 (HD OI GG)Document5 pagesI-GIO-631-104140-HD-P-302-Rev - 0 (HD OI GG)Martin DanzeNo ratings yet

- M24-Plate Heat ExcahngerDocument16 pagesM24-Plate Heat ExcahngerAlexNo ratings yet

- Laporan Mngr. Shift P-2B, 25 Agustus 2023 (Night Shift)Document1 pageLaporan Mngr. Shift P-2B, 25 Agustus 2023 (Night Shift)kurniapusriNo ratings yet

- Boiler MIURA - LX-300-16Document2 pagesBoiler MIURA - LX-300-16LuizPauloCostaNo ratings yet

- s5113 Mm41 Plate CoolerDocument79 pagess5113 Mm41 Plate CoolerJorge AguilarNo ratings yet

- Boiler Performance - DataDocument2 pagesBoiler Performance - DataharimadhavareddyNo ratings yet

- Aldina Adriana - Kasus 5Document8 pagesAldina Adriana - Kasus 5Gyan PrameswaraNo ratings yet

- Calculation Note - Pump Rev 2Document4 pagesCalculation Note - Pump Rev 2Steve WanNo ratings yet

- Htri 105 PDFDocument1 pageHtri 105 PDFhirenpatel_62No ratings yet

- Separator SizingDocument9 pagesSeparator SizingTolstoy LeoNo ratings yet

- Data Sheet - 1 Att - 1-1 - Process DS For E-301 To 328ABCD Air Heaters For STV GW Loop - Modified R1 - 20160919 (Only Unit Revised)Document2 pagesData Sheet - 1 Att - 1-1 - Process DS For E-301 To 328ABCD Air Heaters For STV GW Loop - Modified R1 - 20160919 (Only Unit Revised)Avinash ShuklaNo ratings yet

- Material Stream: 6-3: ConditionsDocument6 pagesMaterial Stream: 6-3: ConditionsHerrera Jorge AgustínNo ratings yet

- Aida Septia Rahastika - Kasus 5Document10 pagesAida Septia Rahastika - Kasus 5Gyan Prameswara100% (1)

- Objective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpDocument5 pagesObjective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpAJAY1381No ratings yet

- 1 7335Document5 pages1 7335stamatsNo ratings yet

- Material Stream: 3: ConditionsDocument5 pagesMaterial Stream: 3: ConditionsHerrera Jorge AgustínNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Shell & Tube Gas HEATER EXCHANGER (P-1233002) : Srge/EsupDocument3 pagesShell & Tube Gas HEATER EXCHANGER (P-1233002) : Srge/EsupRobles DreschNo ratings yet

- BW Liberty Gas Form CDocument8 pagesBW Liberty Gas Form Cvalter AssunçãoNo ratings yet

- Technical Offer: Pump Description Pump ModelDocument4 pagesTechnical Offer: Pump Description Pump ModelPraveen PrajapatiNo ratings yet

- A100 Daily Production On 14.10.2023Document5 pagesA100 Daily Production On 14.10.2023mahmudlooking03No ratings yet

- Environment Monitoring Monthly Report - Aug'22Document1 pageEnvironment Monitoring Monthly Report - Aug'22Mohit Kumar DasNo ratings yet

- Room Air Conditioner: SVC MANUAL (Exploded View)Document8 pagesRoom Air Conditioner: SVC MANUAL (Exploded View)dougsanNo ratings yet

- Anexo 3.2 Hoja de Datos Del Reactor 3401 DA - DBDocument16 pagesAnexo 3.2 Hoja de Datos Del Reactor 3401 DA - DBLuis ColinaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:09:04 TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:09:04 TEMA SheetWael BadriNo ratings yet

- Large Marine Diesels in Challenging Times CIMAC Circle, Marintec 2009Document26 pagesLarge Marine Diesels in Challenging Times CIMAC Circle, Marintec 2009leo_ombinkNo ratings yet

- Shift End Status: Particulars Unit-3 Unit-4Document1 pageShift End Status: Particulars Unit-3 Unit-4venkateshbitraNo ratings yet

- E 101Document21 pagesE 101EberVelazquezChantacaNo ratings yet

- FBR Gas P 100, 150Document8 pagesFBR Gas P 100, 150Arifin ZaenalNo ratings yet

- 030-PSV-1801,1901 CASE-2 (API 520 Gas)Document2 pages030-PSV-1801,1901 CASE-2 (API 520 Gas)khushbu sharmaNo ratings yet

- Dual Fuel Gas/Light-Oil Burners at Two Stages: SK073506 - C - enDocument4 pagesDual Fuel Gas/Light-Oil Burners at Two Stages: SK073506 - C - ensteam mastersNo ratings yet

- Wascomat Flatwork Ironer Specifications IC5019 LF OC5021 R LF IC5025 R LF IC5028 R LF IC5032 R LFDocument2 pagesWascomat Flatwork Ironer Specifications IC5019 LF OC5021 R LF IC5025 R LF IC5028 R LF IC5032 R LFmairimsp2003No ratings yet

- Shell&TubeResults 215E009Document5 pagesShell&TubeResults 215E009ganis supriadiNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Date:06/02/2016 Weekend & Holiday Report: TOPPING UNITS (10&110) Item Old NewDocument3 pagesDate:06/02/2016 Weekend & Holiday Report: TOPPING UNITS (10&110) Item Old NewrawadNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9Document1 pageAspen Exchanger Design and Rating Shell & Tube V9Maira Alejandra GuzmánNo ratings yet

- 1 PDFDocument1 page1 PDFWael BadriNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetWael BadriNo ratings yet

- Gi Emme300 Ts0052uk01Document24 pagesGi Emme300 Ts0052uk01mendezalirio37No ratings yet

- 6648 0010 5 PS SS 0001 F - Stream SummaryDocument26 pages6648 0010 5 PS SS 0001 F - Stream SummarytamasmamerNo ratings yet

- Ficha Tecnica Inverter Mini SplitDocument1 pageFicha Tecnica Inverter Mini SplitpabloabelgilsotoNo ratings yet

- Riello RS/MDocument36 pagesRiello RS/MfharishputraNo ratings yet

- Major Equipment List Cilacap LNG TerminalDocument2 pagesMajor Equipment List Cilacap LNG Terminalwong_949618676No ratings yet

- Pump: P-101: Aspen Technology Inc. Aspen HYSYS Version 10 Page 1 of 5Document5 pagesPump: P-101: Aspen Technology Inc. Aspen HYSYS Version 10 Page 1 of 5amaterasu31416No ratings yet

- 2400-05-DTS-005cooling TowerDocument19 pages2400-05-DTS-005cooling TowerEmran NazirNo ratings yet

- 240-05-DTS-000 Fire Water PumpDocument19 pages240-05-DTS-000 Fire Water PumpEmran NazirNo ratings yet

- 240-05-DTS-XXX Flare StackDocument18 pages240-05-DTS-XXX Flare StackEmran NazirNo ratings yet

- Data Sheet Gas Scrubber 42 InchDocument32 pagesData Sheet Gas Scrubber 42 InchWijayantoNo ratings yet

- Cold Test Report 4Document1 pageCold Test Report 4Venkitesh PGNo ratings yet

- Ceiling & Floor Type Air Conditioner: Service ManualDocument43 pagesCeiling & Floor Type Air Conditioner: Service ManualCesar Calderon GrNo ratings yet

- Boiler AccesoriesDocument127 pagesBoiler Accesoriesramnath008100% (1)

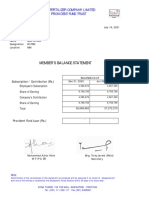

- WH Tax HBL 2020Document1 pageWH Tax HBL 2020fahadullahNo ratings yet

- Tax Year-2020 Document ListDocument20 pagesTax Year-2020 Document ListfahadullahNo ratings yet

- Provident Fund Certificate - 2020Document1 pageProvident Fund Certificate - 2020fahadullahNo ratings yet

- Evening Shift 10-09-2022Document2 pagesEvening Shift 10-09-2022fahadullahNo ratings yet

- Year 2020Document18 pagesYear 2020fahadullahNo ratings yet

- Dividend Zakat & Tax Deduction ReportsDocument4 pagesDividend Zakat & Tax Deduction ReportsfahadullahNo ratings yet

- Donation Slip-Dar Us Shifa Trust Hospital Sadiqabad (Rs 950,000)Document3 pagesDonation Slip-Dar Us Shifa Trust Hospital Sadiqabad (Rs 950,000)fahadullahNo ratings yet

- Pfcert 2021 460Document1 pagePfcert 2021 460fahadullahNo ratings yet

- Year 2016Document15 pagesYear 2016fahadullahNo ratings yet

- Telephone Directory - 2019Document7 pagesTelephone Directory - 2019fahadullahNo ratings yet

- Year 2017Document19 pagesYear 2017fahadullahNo ratings yet

- Morning Shift 01-09-2022Document2 pagesMorning Shift 01-09-2022fahadullahNo ratings yet

- Year 2015Document2 pagesYear 2015fahadullahNo ratings yet

- IG-2 Risk Assesment GCF SiteDocument19 pagesIG-2 Risk Assesment GCF SitefahadullahNo ratings yet

- Morning Shift 10-09-2022Document2 pagesMorning Shift 10-09-2022fahadullahNo ratings yet

- MPCL Utility EngineerDocument2 pagesMPCL Utility EngineerfahadullahNo ratings yet

- P-Iii PLR 202Document11 pagesP-Iii PLR 202fahadullahNo ratings yet

- Night Shift 01-09-2022Document2 pagesNight Shift 01-09-2022fahadullahNo ratings yet

- Night Shift 10-09-2022Document2 pagesNight Shift 10-09-2022fahadullahNo ratings yet

- Bill StatementDocument98 pagesBill StatementfahadullahNo ratings yet

- Night Shift 11-09-2022Document2 pagesNight Shift 11-09-2022fahadullahNo ratings yet

- Proposed Internet Bandwidth Package For TownshipDocument1 pageProposed Internet Bandwidth Package For TownshipfahadullahNo ratings yet

- Safety Audit Report 02 - 08-09-2022Document14 pagesSafety Audit Report 02 - 08-09-2022fahadullahNo ratings yet

- Chemicals StatusDocument1 pageChemicals StatusfahadullahNo ratings yet

- DuPont Methodology For Risk Assessment and Process Hazard AnalysisDocument65 pagesDuPont Methodology For Risk Assessment and Process Hazard Analysisfahadullah100% (2)

- Dunya Lahore 11 SepDocument16 pagesDunya Lahore 11 SepfahadullahNo ratings yet

- Objectives Setting Form: Metric Unit Weightage KPI ObjectiveDocument2 pagesObjectives Setting Form: Metric Unit Weightage KPI ObjectivefahadullahNo ratings yet

- Ammonia Release Mock Exercise Summary Sept 23, 2021Document11 pagesAmmonia Release Mock Exercise Summary Sept 23, 2021fahadullahNo ratings yet

- IFIF@: Ehicle Request Form & Rigging PlanDocument1 pageIFIF@: Ehicle Request Form & Rigging PlanfahadullahNo ratings yet

- Acousteel Brochure Digital FINALDocument8 pagesAcousteel Brochure Digital FINALfahadullahNo ratings yet

- Aisi 1018 Carbon Steel (Uns g10180)Document4 pagesAisi 1018 Carbon Steel (Uns g10180)Ángeles Campaña OlmosNo ratings yet

- Methods To Preserve SpecimensDocument25 pagesMethods To Preserve SpecimensKaranja Gitau100% (6)

- Vanhook 1980Document53 pagesVanhook 1980Reyner ParreirasNo ratings yet

- 01 Alchol, Phenol and Ether Theory Final EDocument19 pages01 Alchol, Phenol and Ether Theory Final Eummer farooqNo ratings yet

- Mepc.2-Circ.22 (E)Document86 pagesMepc.2-Circ.22 (E)tomislav_darlic100% (1)

- Physical Properties and Identification of Acid-Base Properties of Representative Organic Compounds Using Simple Solubility TestsDocument6 pagesPhysical Properties and Identification of Acid-Base Properties of Representative Organic Compounds Using Simple Solubility TestsMatthew SA100% (1)

- Covalent BondingDocument52 pagesCovalent BondingTanvir MatharuNo ratings yet

- 32 Urea Fact SheetDocument3 pages32 Urea Fact SheetYadeta RegasaNo ratings yet

- Ch08 3 Descriptive Group 3 PDFDocument17 pagesCh08 3 Descriptive Group 3 PDFBRUNO RAMOS DE LIMANo ratings yet

- Important Topic Inorganic ChemistryDocument19 pagesImportant Topic Inorganic ChemistrydasabitathaNo ratings yet

- Preparation and Textile Application of Poly Methyl Methacrylate Co Methacrylic Acid N Octadecane and N Eicosane MicrocapsulesDocument13 pagesPreparation and Textile Application of Poly Methyl Methacrylate Co Methacrylic Acid N Octadecane and N Eicosane MicrocapsulesFelipe Vázquez DávilaNo ratings yet

- Soalan DDocument8 pagesSoalan DSyi VeenaNo ratings yet

- Tech Topic Reduced Shrinkage in Molding Compound ApplicationsDocument2 pagesTech Topic Reduced Shrinkage in Molding Compound ApplicationsAhmed ZamanNo ratings yet

- Friedel Crafts ReactionsDocument6 pagesFriedel Crafts ReactionsjanmanchiNo ratings yet

- Development of Natural Bio-Plantation Waste As Pulp For Paper MakingDocument6 pagesDevelopment of Natural Bio-Plantation Waste As Pulp For Paper MakingIngrid ContrerasNo ratings yet

- Food AdditivesDocument91 pagesFood AdditivesWidia AprilianiNo ratings yet

- Xuper 2109Document2 pagesXuper 2109Brian HernandezNo ratings yet

- Shalimar Aluminium PaintDocument2 pagesShalimar Aluminium PaintDeepak Tantuway100% (1)

- Nadcap 2020Document4 pagesNadcap 2020amirkhakzad498No ratings yet

- Conductomeric TitrationDocument12 pagesConductomeric TitrationKoio KumarNo ratings yet

- F334 JAN 10 - MS (New Spec)Document13 pagesF334 JAN 10 - MS (New Spec)ExamStuffNo ratings yet

- TDS Alkyd-Styrenated Resin-55 X ENDocument2 pagesTDS Alkyd-Styrenated Resin-55 X ENprincekamutikanjoreNo ratings yet

- STERISAFE Pro Disinfection Robot 1711Document8 pagesSTERISAFE Pro Disinfection Robot 1711Bach PhamNo ratings yet

- Intracanal Medicaments and IrrigantsDocument85 pagesIntracanal Medicaments and IrrigantsAmit Abbey100% (1)