Professional Documents

Culture Documents

Morning Shift 10-09-2022

Morning Shift 10-09-2022

Uploaded by

fahadullah0 ratings0% found this document useful (0 votes)

25 views2 pagesThe logbook details operations across multiple areas of a gas processing facility, noting equipment statuses, production levels, and tasks in progress. Several compressors were running across three areas. Maintenance tasks addressed included cleaning radiators, removing blinds, replacing diaphragms, and excavating for new installations.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe logbook details operations across multiple areas of a gas processing facility, noting equipment statuses, production levels, and tasks in progress. Several compressors were running across three areas. Maintenance tasks addressed included cleaning radiators, removing blinds, replacing diaphragms, and excavating for new installations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

25 views2 pagesMorning Shift 10-09-2022

Morning Shift 10-09-2022

Uploaded by

fahadullahThe logbook details operations across multiple areas of a gas processing facility, noting equipment statuses, production levels, and tasks in progress. Several compressors were running across three areas. Maintenance tasks addressed included cleaning radiators, removing blinds, replacing diaphragms, and excavating for new installations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

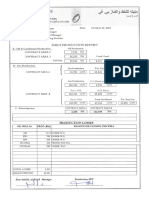

UTILITIES-III

Shift Engineer Logbook

Mirpur Mathelo

Shift: Morning Date: 10-Sept-22

Instrument securities bypassed Nil

Mechanical securities bypassed Nil

ESD Status Area-09

Feed Gas B/L Pressure, Kg/cm 2 29.7 T-901 / 902 / 940 Level, % 97.5/98/25

Fuel Gas B/L Pressure, Kg/cm 2 11.1 1n/7/14/16-17

Tube Wells in service [Total =14]

ME-1501A/ME-1502 ΔP, Kg/cm2 0.18/0.03 /19/20/27/29/31-35

E-352 ΔP, Kg/cm 2 0.50 09-FR-1 / FR2 / FR17 Flow, m3/hr. 600/470/270

NG Condensate, Fuel/Feed ml / min 50/100 Demin. Lines in Service, Ea. Cat A, Ani B

Area-06 Cation Production (A / B / C) 1800/3265/850

B-601 / 602 / 603 Load, TPH 48+51+33 = 132 Anion Production (A / B / C) reg/465/1130

Purge Gas to B- 601 /602 / 603,

2400+3500+1100=7000 Acid / Caustic Consumption, Kg -/1400

NMC/hr.

E-601 Vacuum, Kg/cm 2 -0.921 Acid / Caustic Inventory, Tons 34.45/47.4

06-XX-14A/B 9.2/9.0 Mixed Bed in Service A

B-601 / 602 Oxygen, % 2.2/2.6 Mixed Bed Production (A / B / C) 1650/500/reg

LS Prod/Vent, TPH 00/0.5 ME-952A/B pit level, % 05/40

TK-601 / MK-601 [on Rolling/Load] -/TK-601 Lime Kiln Temp. (Max) Bottom /Top, oC 650/170

Lime Kiln Buckets/ CaO Bags

TK-602 / MK-602 [on Rolling/Load] -/MK-602 20/03

Charge

Area-07 Area-08

TG-701A/B & GT-703 Load, MW 2.6+2.7+10.5 = 15.8 CWS / CWR Pressure (P1/P2),Kg/cm2 2.96/1.30

3.0/1.98 CWS / CWR Temp (T1/T2), 0C 32.6/41.3

Township Load (Max /Min), MWH

1300/0700 No. of CW Pumps in Service / Rolling ABD/-

MG-702 hot condensate / lube oil

50/48 Chlorine/Bromine Dosing (Kg) -

temperatures

E-701A/B Vacuum, Kg/cm2 -0.92/-0.95 ORP / F.Cl2, mV/ppb -

E-701A/B Hot Well Temp, oC CBD, m3/hr. / Chlorides, ppm

42/40 100/236

GT-703 Combustion Air ΔP, mm

81 Acid Inventory, Tons 24.4

WC

V-703 condensate, Lit 00 Hypo / Chlorine Inventory, Kg / Cyl. 1610/04

Area-11 Area-16

V-1103 Pressure, Kg/cm 2 3.0 pH of Waste Water [Limit: 6-9] 7.62/7.4/7.46

Conductivity of Waste Water, µs/cm

N2 Consumption, NMC 100

[Limit:2500 µs] 1823/1405/1172

Ammonia in Waste Water, ppm

N2 Inventory, NMC 7850 7/17/20

[Limit:40 ppm]

GCF

K-1501 K-1521 [JGC-4] K-1531 [JGC-6]

A B C D A B C A B C D

Speed, rpm 1100 1090 1110 1110 900 880 SB 880 925 880 880

Recycle valve opening, % 00 00 68 00 07 00 100 05 05 05 05

Suction Pressure, PSI 459 147 146

Discharge Pressure, PSI 835 483 480

15-FR-32, MMSCFD 68

24” suction valve opening, % 29.0

Steam & Power:

• TG-701A/B slip rings cleaned. Maximum temperature of 72/70°C observed during shift.

• 15-PIC-8V is 50% open.

• GT-703 radiator cleaning done, lube oil temperature decreased from 53 to 48°C. Radiator fans current is

6.8/6.4/6.5/6.4 Amp respectively.

• S/F removal from LC line near V-604 is I/P.

Off-Site:

• Clarifier makeup is on well water.

• S/F removed from 09-PSV-03.

• 08 chlorine cylinder connection required. Communicated to EQP, Please follow.

• S/F provision in 19-area for hot line cable rectification is I/P.

• Algae growth cleaned from E-800A~J both sides.

• MP-1651B discharge line rectification job is I/P. Discharge pipe removed and shifted to workshop for fabrication.

• 09-SD-82 dismantled and sent to Inst workshop for diaphragm replacement.

• Tube well no. 01N & 02 panel’s hinges are damaged, Communicated to electrical. Please pursue for rectification.

• Lights TP-800D and CP system cabin fused rods replacement communicated to electrical. Please follow.

• Tube # 03 checking against tripping is I/P. Currently racked out.

• Tube well # 36 will be remove don Monday for motor tripping fault checking / rectification. Monday Morning shift

please follow.

• M/S pursue for lime slacker body leakage rectification.

• Ferrous Sulphate dosing pumps suction strainers will be cleaned on Monday.

• Back filling on waste water line in B&S area is I/P.

• Dewatering, excavation, shoring provision on N.G line in 16-area is I/P.

• Lighting circuit connection near SWTP, backfilling of excavated trench is I/P.

• Excavation for new tube wells installation in Karachi side is I/P.

• Waste water disposal is towards E-pond.

GCF:

• EK-1501 A/B/C/D, EK-1521A/B and EK-1531A/B/C/D are in service.

• EK-1531D tripped at 0700 hrs on WG linkage sticking, auto calibration done and machine started but again

tripped at 0830 hrs. WG actuator replaced with reclaimed one and unit started at 1210 hrs.

• EK-1501C is in service to supplement FFC-GM flow.

Routine Audits:

Frequency Audit New Observations Actions

Weekly Lube oil and chemical

All inventories are OK -

inventory audit

Bi-Monthly

Monthly

Quarterly

MRM

You might also like

- We n5523521 v7 Hendrix Covered ConductorDocument55 pagesWe n5523521 v7 Hendrix Covered ConductorJ. Mauricio A. BejaranoNo ratings yet

- Evening Shift 10-09-2022Document2 pagesEvening Shift 10-09-2022fahadullahNo ratings yet

- Night Shift 10-09-2022Document2 pagesNight Shift 10-09-2022fahadullahNo ratings yet

- Night Shift 11-09-2022Document2 pagesNight Shift 11-09-2022fahadullahNo ratings yet

- Evening Shift 01-09-2022Document2 pagesEvening Shift 01-09-2022fahadullahNo ratings yet

- Morning Shift 01-09-2022Document2 pagesMorning Shift 01-09-2022fahadullahNo ratings yet

- Night Shift 01-09-2022Document2 pagesNight Shift 01-09-2022fahadullahNo ratings yet

- Rich Gas Pre Cooler - E101 A-BDocument4 pagesRich Gas Pre Cooler - E101 A-B29031978No ratings yet

- LHSS OP P-1B TGL 03 September 2023 Day-1Document1 pageLHSS OP P-1B TGL 03 September 2023 Day-1kurniapusriNo ratings yet

- I-GIO-631-104140-HD-P-302-Rev - 0 (HD OI GG)Document5 pagesI-GIO-631-104140-HD-P-302-Rev - 0 (HD OI GG)Martin DanzeNo ratings yet

- M24-Plate Heat ExcahngerDocument16 pagesM24-Plate Heat ExcahngerAlexNo ratings yet

- Laporan Mngr. Shift P-2B, 25 Agustus 2023 (Night Shift)Document1 pageLaporan Mngr. Shift P-2B, 25 Agustus 2023 (Night Shift)kurniapusriNo ratings yet

- s5113 Mm41 Plate CoolerDocument79 pagess5113 Mm41 Plate CoolerJorge AguilarNo ratings yet

- Material Stream: 6-3: ConditionsDocument6 pagesMaterial Stream: 6-3: ConditionsHerrera Jorge AgustínNo ratings yet

- Aldina Adriana - Kasus 5Document8 pagesAldina Adriana - Kasus 5Gyan PrameswaraNo ratings yet

- A100 Daily Production On 14.10.2023Document5 pagesA100 Daily Production On 14.10.2023mahmudlooking03No ratings yet

- Boiler MIURA - LX-300-16Document2 pagesBoiler MIURA - LX-300-16LuizPauloCostaNo ratings yet

- Boiler Performance - DataDocument2 pagesBoiler Performance - DataharimadhavareddyNo ratings yet

- Material Stream: 3: ConditionsDocument5 pagesMaterial Stream: 3: ConditionsHerrera Jorge AgustínNo ratings yet

- Calculation Note - Pump Rev 2Document4 pagesCalculation Note - Pump Rev 2Steve WanNo ratings yet

- Htri 105 PDFDocument1 pageHtri 105 PDFhirenpatel_62No ratings yet

- Aida Septia Rahastika - Kasus 5Document10 pagesAida Septia Rahastika - Kasus 5Gyan Prameswara100% (1)

- Environment Monitoring Monthly Report - Aug'22Document1 pageEnvironment Monitoring Monthly Report - Aug'22Mohit Kumar DasNo ratings yet

- Dual Fuel Gas/Light-Oil Burners at Two Stages: SK073506 - C - enDocument4 pagesDual Fuel Gas/Light-Oil Burners at Two Stages: SK073506 - C - ensteam mastersNo ratings yet

- E 101Document21 pagesE 101EberVelazquezChantacaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Data Sheet - 1 Att - 1-1 - Process DS For E-301 To 328ABCD Air Heaters For STV GW Loop - Modified R1 - 20160919 (Only Unit Revised)Document2 pagesData Sheet - 1 Att - 1-1 - Process DS For E-301 To 328ABCD Air Heaters For STV GW Loop - Modified R1 - 20160919 (Only Unit Revised)Avinash ShuklaNo ratings yet

- Technical Offer: Pump Description Pump ModelDocument4 pagesTechnical Offer: Pump Description Pump ModelPraveen PrajapatiNo ratings yet

- BW Liberty Gas Form CDocument8 pagesBW Liberty Gas Form Cvalter AssunçãoNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:09:04 TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:09:04 TEMA SheetWael BadriNo ratings yet

- 030-PSV-1801,1901 CASE-2 (API 520 Gas)Document2 pages030-PSV-1801,1901 CASE-2 (API 520 Gas)khushbu sharmaNo ratings yet

- Separator SizingDocument9 pagesSeparator SizingTolstoy LeoNo ratings yet

- Large Marine Diesels in Challenging Times CIMAC Circle, Marintec 2009Document26 pagesLarge Marine Diesels in Challenging Times CIMAC Circle, Marintec 2009leo_ombinkNo ratings yet

- 1 7335Document5 pages1 7335stamatsNo ratings yet

- Wascomat Flatwork Ironer Specifications IC5019 LF OC5021 R LF IC5025 R LF IC5028 R LF IC5032 R LFDocument2 pagesWascomat Flatwork Ironer Specifications IC5019 LF OC5021 R LF IC5025 R LF IC5028 R LF IC5032 R LFmairimsp2003No ratings yet

- Objective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpDocument5 pagesObjective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpAJAY1381No ratings yet

- Skikda Training CDU (Goal Content)Document26 pagesSkikda Training CDU (Goal Content)Mohamed OuichaouiNo ratings yet

- 001.17056.000028-AK008-01 1st Stage PreheaterDocument5 pages001.17056.000028-AK008-01 1st Stage PreheaterQuy RomNo ratings yet

- Motor Gasoline Specifications and Trend in IndiaDocument2 pagesMotor Gasoline Specifications and Trend in IndiavivekagNo ratings yet

- FBR Gas P 100, 150Document8 pagesFBR Gas P 100, 150Arifin ZaenalNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetWael BadriNo ratings yet

- 1 PDFDocument1 page1 PDFWael BadriNo ratings yet

- Shell & Tube Gas HEATER EXCHANGER (P-1233002) : Srge/EsupDocument3 pagesShell & Tube Gas HEATER EXCHANGER (P-1233002) : Srge/EsupRobles DreschNo ratings yet

- Data Sheet Gas Scrubber 42 InchDocument32 pagesData Sheet Gas Scrubber 42 InchWijayantoNo ratings yet

- 240-05-DTS-000 Fire Water PumpDocument19 pages240-05-DTS-000 Fire Water PumpEmran NazirNo ratings yet

- 240-05-DTS-XXX Flare StackDocument18 pages240-05-DTS-XXX Flare StackEmran NazirNo ratings yet

- 2400-05-DTS-005cooling TowerDocument19 pages2400-05-DTS-005cooling TowerEmran NazirNo ratings yet

- T3 ME Performance Record Jan TemplateDocument5 pagesT3 ME Performance Record Jan TemplateMuhd Khir RazaniNo ratings yet

- Shift End Status: Particulars Unit-3 Unit-4Document1 pageShift End Status: Particulars Unit-3 Unit-4venkateshbitraNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Shell&TubeResults 215E009Document5 pagesShell&TubeResults 215E009ganis supriadiNo ratings yet

- Room Air Conditioner: SVC MANUAL (Exploded View)Document8 pagesRoom Air Conditioner: SVC MANUAL (Exploded View)dougsanNo ratings yet

- Gi Emme300 Ts0052uk01Document24 pagesGi Emme300 Ts0052uk01mendezalirio37No ratings yet

- Erosion Velocity CalculationsDocument9 pagesErosion Velocity CalculationsMANISH GUPTANo ratings yet

- 10-102 Endurance CalculationDocument2 pages10-102 Endurance CalculationVenkat KrishnaNo ratings yet

- TS0086UK03 - DB - Rev0Document24 pagesTS0086UK03 - DB - Rev0amirokhovatNo ratings yet

- E-313 DesignDocument1 pageE-313 DesignAamir SultanNo ratings yet

- Anexo 3.2 Hoja de Datos Del Reactor 3401 DA - DBDocument16 pagesAnexo 3.2 Hoja de Datos Del Reactor 3401 DA - DBLuis ColinaNo ratings yet

- 6648 0010 5 PS SS 0001 F - Stream SummaryDocument26 pages6648 0010 5 PS SS 0001 F - Stream SummarytamasmamerNo ratings yet

- Vapor Pressures of The ElementsDocument28 pagesVapor Pressures of The ElementsYourMotherNo ratings yet

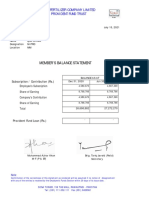

- WH Tax HBL 2020Document1 pageWH Tax HBL 2020fahadullahNo ratings yet

- Tax Year-2020 Document ListDocument20 pagesTax Year-2020 Document ListfahadullahNo ratings yet

- Provident Fund Certificate - 2020Document1 pageProvident Fund Certificate - 2020fahadullahNo ratings yet

- Evening Shift 01-09-2022Document2 pagesEvening Shift 01-09-2022fahadullahNo ratings yet

- Year 2020Document18 pagesYear 2020fahadullahNo ratings yet

- Dividend Zakat & Tax Deduction ReportsDocument4 pagesDividend Zakat & Tax Deduction ReportsfahadullahNo ratings yet

- Donation Slip-Dar Us Shifa Trust Hospital Sadiqabad (Rs 950,000)Document3 pagesDonation Slip-Dar Us Shifa Trust Hospital Sadiqabad (Rs 950,000)fahadullahNo ratings yet

- Pfcert 2021 460Document1 pagePfcert 2021 460fahadullahNo ratings yet

- Year 2016Document15 pagesYear 2016fahadullahNo ratings yet

- Telephone Directory - 2019Document7 pagesTelephone Directory - 2019fahadullahNo ratings yet

- Year 2017Document19 pagesYear 2017fahadullahNo ratings yet

- Morning Shift 01-09-2022Document2 pagesMorning Shift 01-09-2022fahadullahNo ratings yet

- Year 2015Document2 pagesYear 2015fahadullahNo ratings yet

- IG-2 Risk Assesment GCF SiteDocument19 pagesIG-2 Risk Assesment GCF SitefahadullahNo ratings yet

- Night Shift 10-09-2022Document2 pagesNight Shift 10-09-2022fahadullahNo ratings yet

- MPCL Utility EngineerDocument2 pagesMPCL Utility EngineerfahadullahNo ratings yet

- P-Iii PLR 202Document11 pagesP-Iii PLR 202fahadullahNo ratings yet

- Night Shift 01-09-2022Document2 pagesNight Shift 01-09-2022fahadullahNo ratings yet

- Evening Shift 10-09-2022Document2 pagesEvening Shift 10-09-2022fahadullahNo ratings yet

- Bill StatementDocument98 pagesBill StatementfahadullahNo ratings yet

- Night Shift 11-09-2022Document2 pagesNight Shift 11-09-2022fahadullahNo ratings yet

- Proposed Internet Bandwidth Package For TownshipDocument1 pageProposed Internet Bandwidth Package For TownshipfahadullahNo ratings yet

- Safety Audit Report 02 - 08-09-2022Document14 pagesSafety Audit Report 02 - 08-09-2022fahadullahNo ratings yet

- Chemicals StatusDocument1 pageChemicals StatusfahadullahNo ratings yet

- DuPont Methodology For Risk Assessment and Process Hazard AnalysisDocument65 pagesDuPont Methodology For Risk Assessment and Process Hazard Analysisfahadullah100% (2)

- Dunya Lahore 11 SepDocument16 pagesDunya Lahore 11 SepfahadullahNo ratings yet

- Objectives Setting Form: Metric Unit Weightage KPI ObjectiveDocument2 pagesObjectives Setting Form: Metric Unit Weightage KPI ObjectivefahadullahNo ratings yet

- Ammonia Release Mock Exercise Summary Sept 23, 2021Document11 pagesAmmonia Release Mock Exercise Summary Sept 23, 2021fahadullahNo ratings yet

- IFIF@: Ehicle Request Form & Rigging PlanDocument1 pageIFIF@: Ehicle Request Form & Rigging PlanfahadullahNo ratings yet

- Acousteel Brochure Digital FINALDocument8 pagesAcousteel Brochure Digital FINALfahadullahNo ratings yet

- S. No Name of Busniess Owner Name Admin Address Factory Office Phone Email Plant ManagerDocument1 pageS. No Name of Busniess Owner Name Admin Address Factory Office Phone Email Plant ManagerBhuvnesh ShrimaliNo ratings yet

- Nachi HydraulicDocument2 pagesNachi HydraulicDian PramadiNo ratings yet

- What Is MuscoviteDocument2 pagesWhat Is MuscoviteLyrine SarmientoNo ratings yet

- Avon Sb122 - Gas Generator Lubricating Oil SpecificationDocument9 pagesAvon Sb122 - Gas Generator Lubricating Oil Specificationpeach5No ratings yet

- DC Motor Brush Life White PaperDocument11 pagesDC Motor Brush Life White PaperHamza TaherNo ratings yet

- Coefficient of Kinetic Friction For Wax Coatings: Standard Test Method ForDocument3 pagesCoefficient of Kinetic Friction For Wax Coatings: Standard Test Method ForRajeev ChandNo ratings yet

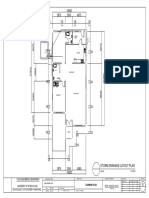

- Storm Drainage Layout Plan Allen-RafaelDocument1 pageStorm Drainage Layout Plan Allen-RafaelVios, Allen Rafael M.No ratings yet

- Assignment Non Conventional MachiningDocument5 pagesAssignment Non Conventional Machiningkapun kumar nayak100% (1)

- Seminar Report On Highway Management SystemDocument22 pagesSeminar Report On Highway Management SystemAditya ansuman RoutNo ratings yet

- Product Catalogue - Jakson PDFDocument2 pagesProduct Catalogue - Jakson PDFhiralalnhpc100% (2)

- Islanding Scheme Operation: A Project Report OnDocument24 pagesIslanding Scheme Operation: A Project Report OnSooraj Surendran SugathaNo ratings yet

- Crude Tower Simulation Using Aspen HYSYSDocument30 pagesCrude Tower Simulation Using Aspen HYSYSĐậu BắpNo ratings yet

- SIP Ni DayneDocument7 pagesSIP Ni DayneDen SamonteNo ratings yet

- Arijit Mitra: Year Course Institution CGPA/PercentageDocument1 pageArijit Mitra: Year Course Institution CGPA/PercentageArijit MitraNo ratings yet

- ApprovedmaterialslistDocument231 pagesApprovedmaterialslistkirnamaraNo ratings yet

- Economics Study Passages For ExamDocument66 pagesEconomics Study Passages For ExamPaul JonsanNo ratings yet

- A. Distillation of Essential OilDocument4 pagesA. Distillation of Essential OilUrsula BologaNo ratings yet

- Quantification of The M1 and M3 Polymorphs of Alite in OPC ClinkerDocument2 pagesQuantification of The M1 and M3 Polymorphs of Alite in OPC ClinkerDerekNo ratings yet

- 05 Fiber - Reinforced Polymers Processes and ApplicationsDocument470 pages05 Fiber - Reinforced Polymers Processes and ApplicationsarivumaniNo ratings yet

- C122S2NL - 2 - USANSI C Flex 45 RedDocument11 pagesC122S2NL - 2 - USANSI C Flex 45 RedblpovedaNo ratings yet

- European I Beam With Parallel Flange in Accordance With EN PDFDocument2 pagesEuropean I Beam With Parallel Flange in Accordance With EN PDFkaranbir123No ratings yet

- Poster Presentation Overview of SuperconductorDocument1 pagePoster Presentation Overview of SuperconductorMd. Imam UddinNo ratings yet

- Elecon Scoop Coupling Installation Maintenance ManualDocument21 pagesElecon Scoop Coupling Installation Maintenance ManualVignesh VenkatasubramanianNo ratings yet

- CV - Qa.f-038, Concrete Pour CardDocument3 pagesCV - Qa.f-038, Concrete Pour CardSandip PaulNo ratings yet

- CorrosionDocument18 pagesCorrosionmuhammadumeryaqoob16No ratings yet

- R & AC Important Questions: Iv Me, I SemDocument17 pagesR & AC Important Questions: Iv Me, I Semapi-362935264100% (1)

- Brammer Standard Catalog Cast IronDocument40 pagesBrammer Standard Catalog Cast IronFabFabFabFabNo ratings yet

- Glass Final 030406Document40 pagesGlass Final 030406Jeremiah PuaNo ratings yet

- Receiving DeliveriesDocument3 pagesReceiving DeliveriesklutgringNo ratings yet