Professional Documents

Culture Documents

Night Shift 10-09-2022

Night Shift 10-09-2022

Uploaded by

fahadullah0 ratings0% found this document useful (0 votes)

13 views2 pagesThe logbook details operations across multiple areas of a gas processing facility for the night shift of September 10th, including steam and power systems, off-site systems, gas compressor facilities, routine audits, and notes on various process parameters and equipment status. Equipment pressures, temperatures, production rates, and inventory levels are reported. Issues addressed include high delta P readings on specific lines and condensate observed in filters requiring draining.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe logbook details operations across multiple areas of a gas processing facility for the night shift of September 10th, including steam and power systems, off-site systems, gas compressor facilities, routine audits, and notes on various process parameters and equipment status. Equipment pressures, temperatures, production rates, and inventory levels are reported. Issues addressed include high delta P readings on specific lines and condensate observed in filters requiring draining.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

13 views2 pagesNight Shift 10-09-2022

Night Shift 10-09-2022

Uploaded by

fahadullahThe logbook details operations across multiple areas of a gas processing facility for the night shift of September 10th, including steam and power systems, off-site systems, gas compressor facilities, routine audits, and notes on various process parameters and equipment status. Equipment pressures, temperatures, production rates, and inventory levels are reported. Issues addressed include high delta P readings on specific lines and condensate observed in filters requiring draining.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

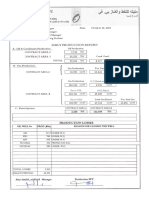

UTILITIES-III

Shift Engineer Logbook

Mirpur Mathelo

Shift: Night Date: 10-Sept-22

Instrument securities bypassed Nil

Mechanical securities bypassed Nil

ESD Status Area-09

Feed Gas B/L Pressure, Kg/cm 2 30.2 T-901 / 902 / 940 Level, % 98/98/25

Fuel Gas B/L Pressure, Kg/cm 2 10.2 1N/7/14/16-

Tube Wells in service [Total =16]

ME-1501A/ME-1502 ΔP, Kg/cm2 0.19/0.03 20/27/29-35

E-352 ΔP, Kg/cm 2 0.80 09-FR-1 / FR2 / FR17 Flow, m3/hr. 710/470/270

NG Condensate, Fuel/Feed ml / min 50/100 Demin. Lines in Service, Ea. B

Area-06 Cation Production (A / B / C) 2435/4425/1000

B-601 / 602 / 603 Load, TPH 49+50+33 = 132 Anion Production (A / B / C) 635/1625/1280

Purge Gas to B- 601 /602 / 603,

2200+3600+1100=6900 Acid / Caustic Consumption, Kg -/-

NMC/hr.

E-601 Vacuum, Kg/cm 2 -0.920 Acid / Caustic Inventory, Tons 34.85/46.80

06-XX-14A/B 9.3/9.3 Mixed Bed in Service A

B-601 / 602 Oxygen, % 2.3/2.5 Mixed Bed Production (A / B / C) 4575/900/Fresh

LS Prod/Vent, TPH 00/01 ME-952A/B pit level, % 10/10

TK-601 / MK-601 [on Rolling/Load] -/TK-601 Lime Kiln Temp. (Max) Bottom /Top, oC 653/237

Lime Kiln Buckets/ CaO Bags

TK-602 / MK-602 [on Rolling/Load] -/MK-602 08/02

Charge

Area-07 Area-08

TG-701A/B & GT-703 Load, MW 2.2+2.4+9.6 = 14.2 CWS / CWR Pressure (P1/P2),Kg/cm2 2.96/1.30

2.62 / 2.06 CWS / CWR Temp (T1/T2), 0C 33.0/41.7

Township Load (Max /Min), MWH

2300 / 0500 No. of CW Pumps in Service / Rolling ABD/-

MG-702 hot condensate / lube oil

50/46 Chlorine/Bromine Dosing (Kg) 60/30

temperatures

E-701A/B Vacuum, Kg/cm2 -0.95/-0.95 ORP / F.Cl2, mV/ppb 596/337

E-701A/B Hot Well Temp, oC CBD, m3/hr. / Chlorides, ppm

41/40 100/236

GT-703 Combustion Air ΔP, mm

84 Acid Inventory, Tons 234

WC

V-703 condensate, Lit 00 Hypo / Chlorine Inventory, Kg / Cyl. 1510/04

Area-11 Area-16

V-1103 Pressure, Kg/cm 2 3.0 pH of Waste Water [Limit: 6-9] 8.38/7.30/7.90

Conductivity of Waste Water, µs/cm

N2 Consumption, NMC 50

[Limit:2500 µs] 1291/1192/1555

Ammonia in Waste Water, ppm

N2 Inventory, NMC 7700 10/11/18

[Limit:40 ppm]

GCF

K-1501 K-1521 [JGC-4] K-1531 [JGC-6]

A B C D A B C A B C D

Speed, rpm 1100 1100 1115 1110 900 880 SB 880 880 880 880

Recycle valve opening, % 00 00 67 00 07 00 100 05 07 07 05

Suction Pressure, PSI 455 140 140

Discharge Pressure, PSI 846 484 483

15-FR-32, MMSCFD 68.5

24” suction valve opening, % 29.0

Steam & Power:

• TG-701A/B slip rings cleaned. Maximum temperature of 56/57°C observed during shift.

• 15-PIC-8V is 25% open.

• E-352 ∆P increased from 0.5 to 0.8 Kg/cm2. 06-PR-45 pressure maintained at 5.55 Kg/cm2. 15 area valves set point

increased from 6.35 to 6.62 Kg/cm2. ME-1501A ∆P and condensate checked, ∆P is 0.19 Kg/cm2, condensate level

observed in filter, it drained. ME-1501A drain valve is slightly opened, no condensate observed since then. V-352

drain also checked, no condensate observed. Monday M/S follow for E-352 tubes cleaning.

Off-Site:

• Clarifier makeup is on well water.

• Waste water disposal is towards E-pond.

GCF:

• EK-1501 A/B/C/D, EK-1521A/B and EK-1531A/B/C/D are in service.

Routine Audits:

Frequency Audit New Observations Actions

Weekly Steam losses Notification initiated

Bi-Monthly

Monthly

Quarterly

AUB

You might also like

- Biland Sa-250: Technical SpecificationsDocument4 pagesBiland Sa-250: Technical SpecificationsNofriagara Davit HarnawanNo ratings yet

- NAVAJO Electrical SystemDocument133 pagesNAVAJO Electrical SystemJoao Correia100% (1)

- Night Shift 11-09-2022Document2 pagesNight Shift 11-09-2022fahadullahNo ratings yet

- Evening Shift 10-09-2022Document2 pagesEvening Shift 10-09-2022fahadullahNo ratings yet

- Evening Shift 01-09-2022Document2 pagesEvening Shift 01-09-2022fahadullahNo ratings yet

- Morning Shift 10-09-2022Document2 pagesMorning Shift 10-09-2022fahadullahNo ratings yet

- Night Shift 01-09-2022Document2 pagesNight Shift 01-09-2022fahadullahNo ratings yet

- Morning Shift 01-09-2022Document2 pagesMorning Shift 01-09-2022fahadullahNo ratings yet

- Rich Gas Pre Cooler - E101 A-BDocument4 pagesRich Gas Pre Cooler - E101 A-B29031978No ratings yet

- I-GIO-631-104140-HD-P-302-Rev - 0 (HD OI GG)Document5 pagesI-GIO-631-104140-HD-P-302-Rev - 0 (HD OI GG)Martin DanzeNo ratings yet

- M24-Plate Heat ExcahngerDocument16 pagesM24-Plate Heat ExcahngerAlexNo ratings yet

- LHSS OP P-1B TGL 03 September 2023 Day-1Document1 pageLHSS OP P-1B TGL 03 September 2023 Day-1kurniapusriNo ratings yet

- s5113 Mm41 Plate CoolerDocument79 pagess5113 Mm41 Plate CoolerJorge AguilarNo ratings yet

- A100 Daily Production On 14.10.2023Document5 pagesA100 Daily Production On 14.10.2023mahmudlooking03No ratings yet

- Laporan Mngr. Shift P-2B, 25 Agustus 2023 (Night Shift)Document1 pageLaporan Mngr. Shift P-2B, 25 Agustus 2023 (Night Shift)kurniapusriNo ratings yet

- Material Stream: 3: ConditionsDocument5 pagesMaterial Stream: 3: ConditionsHerrera Jorge AgustínNo ratings yet

- Material Stream: 6-3: ConditionsDocument6 pagesMaterial Stream: 6-3: ConditionsHerrera Jorge AgustínNo ratings yet

- Boiler MIURA - LX-300-16Document2 pagesBoiler MIURA - LX-300-16LuizPauloCostaNo ratings yet

- Aldina Adriana - Kasus 5Document8 pagesAldina Adriana - Kasus 5Gyan PrameswaraNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Environment Monitoring Monthly Report - Aug'22Document1 pageEnvironment Monitoring Monthly Report - Aug'22Mohit Kumar DasNo ratings yet

- Htri 105 PDFDocument1 pageHtri 105 PDFhirenpatel_62No ratings yet

- Aida Septia Rahastika - Kasus 5Document10 pagesAida Septia Rahastika - Kasus 5Gyan Prameswara100% (1)

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:09:04 TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:09:04 TEMA SheetWael BadriNo ratings yet

- BW Liberty Gas Form CDocument8 pagesBW Liberty Gas Form Cvalter AssunçãoNo ratings yet

- E 101Document21 pagesE 101EberVelazquezChantacaNo ratings yet

- Data Sheet - 1 Att - 1-1 - Process DS For E-301 To 328ABCD Air Heaters For STV GW Loop - Modified R1 - 20160919 (Only Unit Revised)Document2 pagesData Sheet - 1 Att - 1-1 - Process DS For E-301 To 328ABCD Air Heaters For STV GW Loop - Modified R1 - 20160919 (Only Unit Revised)Avinash ShuklaNo ratings yet

- Boiler Performance - DataDocument2 pagesBoiler Performance - DataharimadhavareddyNo ratings yet

- Technical Offer: Pump Description Pump ModelDocument4 pagesTechnical Offer: Pump Description Pump ModelPraveen PrajapatiNo ratings yet

- Calculation Note - Pump Rev 2Document4 pagesCalculation Note - Pump Rev 2Steve WanNo ratings yet

- Objective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpDocument5 pagesObjective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpAJAY1381No ratings yet

- Pour Card 121 Cube Test Report (28 Days)Document1 pagePour Card 121 Cube Test Report (28 Days)Dhananjay SinghNo ratings yet

- Separator SizingDocument9 pagesSeparator SizingTolstoy LeoNo ratings yet

- 030-PSV-1801,1901 CASE-2 (API 520 Gas)Document2 pages030-PSV-1801,1901 CASE-2 (API 520 Gas)khushbu sharmaNo ratings yet

- Dual Fuel Gas/Light-Oil Burners at Two Stages: SK073506 - C - enDocument4 pagesDual Fuel Gas/Light-Oil Burners at Two Stages: SK073506 - C - ensteam mastersNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- 1 PDFDocument1 page1 PDFWael BadriNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetWael BadriNo ratings yet

- 6648 0010 5 PS SS 0001 F - Stream SummaryDocument26 pages6648 0010 5 PS SS 0001 F - Stream SummarytamasmamerNo ratings yet

- Shell&TubeResults 215E009Document5 pagesShell&TubeResults 215E009ganis supriadiNo ratings yet

- Room Air Conditioner: SVC MANUAL (Exploded View)Document8 pagesRoom Air Conditioner: SVC MANUAL (Exploded View)dougsanNo ratings yet

- Shell & Tube Gas HEATER EXCHANGER (P-1233002) : Srge/EsupDocument3 pagesShell & Tube Gas HEATER EXCHANGER (P-1233002) : Srge/EsupRobles DreschNo ratings yet

- Large Marine Diesels in Challenging Times CIMAC Circle, Marintec 2009Document26 pagesLarge Marine Diesels in Challenging Times CIMAC Circle, Marintec 2009leo_ombinkNo ratings yet

- Shift End Status: Particulars Unit-3 Unit-4Document1 pageShift End Status: Particulars Unit-3 Unit-4venkateshbitraNo ratings yet

- Skikda Training CDU (Goal Content)Document26 pagesSkikda Training CDU (Goal Content)Mohamed OuichaouiNo ratings yet

- RLS - M MX - Ts0064uk02Document24 pagesRLS - M MX - Ts0064uk02RaduNo ratings yet

- Boiler AccesoriesDocument127 pagesBoiler Accesoriesramnath008100% (1)

- 2400-05-DTS-005cooling TowerDocument19 pages2400-05-DTS-005cooling TowerEmran NazirNo ratings yet

- 240-05-DTS-000 Fire Water PumpDocument19 pages240-05-DTS-000 Fire Water PumpEmran NazirNo ratings yet

- Data Sheet Gas Scrubber 42 InchDocument32 pagesData Sheet Gas Scrubber 42 InchWijayantoNo ratings yet

- 240-05-DTS-XXX Flare StackDocument18 pages240-05-DTS-XXX Flare StackEmran NazirNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V8.8Document3 pagesAspen Exchanger Design and Rating Shell & Tube V8.8Camila Florencia ScarlatoNo ratings yet

- File: C:/Users/carre/Downloads/E-104 OK - EDR Printed: 27/08/2020 at 17:37:22Document14 pagesFile: C:/Users/carre/Downloads/E-104 OK - EDR Printed: 27/08/2020 at 17:37:22Camila Florencia ScarlatoNo ratings yet

- 1 7335Document5 pages1 7335stamatsNo ratings yet

- BBS-10-W8-DS-011 - C - Glycol Surge Drum DS PDFDocument2 pagesBBS-10-W8-DS-011 - C - Glycol Surge Drum DS PDFAdianto RahmanNo ratings yet

- E-313 DesignDocument1 pageE-313 DesignAamir SultanNo ratings yet

- 10-102 Endurance CalculationDocument2 pages10-102 Endurance CalculationVenkat KrishnaNo ratings yet

- TS0086UK03 - DB - Rev0Document24 pagesTS0086UK03 - DB - Rev0amirokhovatNo ratings yet

- Wascomat Flatwork Ironer Specifications IC5019 LF OC5021 R LF IC5025 R LF IC5028 R LF IC5032 R LFDocument2 pagesWascomat Flatwork Ironer Specifications IC5019 LF OC5021 R LF IC5025 R LF IC5028 R LF IC5032 R LFmairimsp2003No ratings yet

- Gi Emme300 Ts0052uk01Document24 pagesGi Emme300 Ts0052uk01mendezalirio37No ratings yet

- 20191119-3 - JGS 620 Technical Description and Calculation - enDocument8 pages20191119-3 - JGS 620 Technical Description and Calculation - enjonathan arboledaNo ratings yet

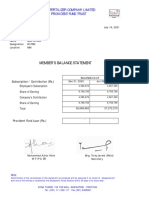

- WH Tax HBL 2020Document1 pageWH Tax HBL 2020fahadullahNo ratings yet

- Tax Year-2020 Document ListDocument20 pagesTax Year-2020 Document ListfahadullahNo ratings yet

- Donation Slip-Dar Us Shifa Trust Hospital Sadiqabad (Rs 950,000)Document3 pagesDonation Slip-Dar Us Shifa Trust Hospital Sadiqabad (Rs 950,000)fahadullahNo ratings yet

- Provident Fund Certificate - 2020Document1 pageProvident Fund Certificate - 2020fahadullahNo ratings yet

- Year 2016Document15 pagesYear 2016fahadullahNo ratings yet

- Pfcert 2021 460Document1 pagePfcert 2021 460fahadullahNo ratings yet

- Telephone Directory - 2019Document7 pagesTelephone Directory - 2019fahadullahNo ratings yet

- Year 2020Document18 pagesYear 2020fahadullahNo ratings yet

- Year 2017Document19 pagesYear 2017fahadullahNo ratings yet

- Dividend Zakat & Tax Deduction ReportsDocument4 pagesDividend Zakat & Tax Deduction ReportsfahadullahNo ratings yet

- Evening Shift 10-09-2022Document2 pagesEvening Shift 10-09-2022fahadullahNo ratings yet

- MPCL Utility EngineerDocument2 pagesMPCL Utility EngineerfahadullahNo ratings yet

- IG-2 Risk Assesment GCF SiteDocument19 pagesIG-2 Risk Assesment GCF SitefahadullahNo ratings yet

- Year 2015Document2 pagesYear 2015fahadullahNo ratings yet

- Proposed Internet Bandwidth Package For TownshipDocument1 pageProposed Internet Bandwidth Package For TownshipfahadullahNo ratings yet

- Morning Shift 10-09-2022Document2 pagesMorning Shift 10-09-2022fahadullahNo ratings yet

- P-Iii PLR 202Document11 pagesP-Iii PLR 202fahadullahNo ratings yet

- Morning Shift 01-09-2022Document2 pagesMorning Shift 01-09-2022fahadullahNo ratings yet

- Night Shift 01-09-2022Document2 pagesNight Shift 01-09-2022fahadullahNo ratings yet

- Evening Shift 01-09-2022Document2 pagesEvening Shift 01-09-2022fahadullahNo ratings yet

- Chemicals StatusDocument1 pageChemicals StatusfahadullahNo ratings yet

- Safety Audit Report 02 - 08-09-2022Document14 pagesSafety Audit Report 02 - 08-09-2022fahadullahNo ratings yet

- Dunya Lahore 11 SepDocument16 pagesDunya Lahore 11 SepfahadullahNo ratings yet

- Bill StatementDocument98 pagesBill StatementfahadullahNo ratings yet

- DuPont Methodology For Risk Assessment and Process Hazard AnalysisDocument65 pagesDuPont Methodology For Risk Assessment and Process Hazard Analysisfahadullah100% (1)

- Ammonia Release Mock Exercise Summary Sept 23, 2021Document11 pagesAmmonia Release Mock Exercise Summary Sept 23, 2021fahadullahNo ratings yet

- Night Shift 11-09-2022Document2 pagesNight Shift 11-09-2022fahadullahNo ratings yet

- Objectives Setting Form: Metric Unit Weightage KPI ObjectiveDocument2 pagesObjectives Setting Form: Metric Unit Weightage KPI ObjectivefahadullahNo ratings yet

- IFIF@: Ehicle Request Form & Rigging PlanDocument1 pageIFIF@: Ehicle Request Form & Rigging PlanfahadullahNo ratings yet

- Acousteel Brochure Digital FINALDocument8 pagesAcousteel Brochure Digital FINALfahadullahNo ratings yet

- MCQs - EAM - Unit 5Document10 pagesMCQs - EAM - Unit 5Sayee DeshpandeNo ratings yet

- Topic 4 EcologyDocument1 pageTopic 4 EcologymatthewNo ratings yet

- IB Chemistry - Unit 6 - Chemical Kinetics Study GuideDocument6 pagesIB Chemistry - Unit 6 - Chemical Kinetics Study GuideHamzah JoharNo ratings yet

- Communities - Trophic Structure 2Document19 pagesCommunities - Trophic Structure 2waranya kasemchittNo ratings yet

- 03 Crude Unit DesignDocument88 pages03 Crude Unit DesignVĂN ĐOÀN HUYNo ratings yet

- Eaton Security Series 1000 Magnetic Contacts Datasheet enDocument1 pageEaton Security Series 1000 Magnetic Contacts Datasheet encolombarolli.nclNo ratings yet

- Napier TC training - v2Document9 pagesNapier TC training - v2artemio CardosoNo ratings yet

- Dossier Final Induction MotorsDocument149 pagesDossier Final Induction MotorsElectrifying GuyNo ratings yet

- Unit9 Eng School BKDocument306 pagesUnit9 Eng School BKKarthiNo ratings yet

- Techno-Economic Arid India ApvDocument15 pagesTechno-Economic Arid India ApvAstitva kumarNo ratings yet

- Control Engineering Practice: Michael Erhard, Hans StrauchDocument14 pagesControl Engineering Practice: Michael Erhard, Hans StrauchSka dooshNo ratings yet

- Space Vector Control of A Three-Phase Rectifier Using PLECSDocument5 pagesSpace Vector Control of A Three-Phase Rectifier Using PLECSNguyễn Đình VănNo ratings yet

- Data Sheet US - S6D630AM0101 KM201575Document5 pagesData Sheet US - S6D630AM0101 KM201575VĩnhNo ratings yet

- EI Integrity Bolted JointsDocument54 pagesEI Integrity Bolted JointsStephen LeighNo ratings yet

- TM 55-1520-210-23-3Document762 pagesTM 55-1520-210-23-3deniz taylanNo ratings yet

- Service and Repair Manual: GS - 3384 GS - 3390 GS - 4390 GS - 5390Document213 pagesService and Repair Manual: GS - 3384 GS - 3390 GS - 4390 GS - 5390Juan CortezNo ratings yet

- Science 9 Q4 Week 4Document4 pagesScience 9 Q4 Week 4Joemarie Brette Hart SisonNo ratings yet

- HD9 Sheet Chassis Euro3 4x4 GBDocument4 pagesHD9 Sheet Chassis Euro3 4x4 GBErsa RahmandaNo ratings yet

- Panasonic SC Ak960 Manual de UsuarioDocument28 pagesPanasonic SC Ak960 Manual de UsuarioJorgeNo ratings yet

- Coca-Cola Bottling in Rajasthan, India: Tragedy of The CommonsDocument16 pagesCoca-Cola Bottling in Rajasthan, India: Tragedy of The Commonsmuhammad harisNo ratings yet

- Lab 8Document10 pagesLab 8Mohamad HaziqNo ratings yet

- Digital Pressure Switch For Energy-Saving Control Ejector: ZK2-ZSV####-ADocument56 pagesDigital Pressure Switch For Energy-Saving Control Ejector: ZK2-ZSV####-AOtavio CarvalhoNo ratings yet

- CPRI Feb Submitted-1Document5 pagesCPRI Feb Submitted-1YOHANES HANDREANNo ratings yet

- HK-100 KSMBDocument20 pagesHK-100 KSMBMimih NunungNo ratings yet

- PAPER CIGRE Drying of Power Transformers in The Field Applying The LFH Technology in Combination With Oil Reclamation 2006Document8 pagesPAPER CIGRE Drying of Power Transformers in The Field Applying The LFH Technology in Combination With Oil Reclamation 2006Alonso Lioneth100% (1)

- After 4000 RH & 2000 RH After 1000 RHDocument2 pagesAfter 4000 RH & 2000 RH After 1000 RHadeel ghouseNo ratings yet

- Hydraulic - Graphic Symbols Pumps Motors Cylinders and EquipmentDocument1 pageHydraulic - Graphic Symbols Pumps Motors Cylinders and EquipmentM. AguiarNo ratings yet

- To Determine The V Curve of A Synchronous MotorDocument3 pagesTo Determine The V Curve of A Synchronous MotorAthay khanNo ratings yet