Professional Documents

Culture Documents

C-E Minerals: MSDS For Mulcoa 60/mulgrain 60/mulblast 60: Revision Date: 01/23/2013 Page 1 of 7

C-E Minerals: MSDS For Mulcoa 60/mulgrain 60/mulblast 60: Revision Date: 01/23/2013 Page 1 of 7

Uploaded by

Muniruddin AmranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C-E Minerals: MSDS For Mulcoa 60/mulgrain 60/mulblast 60: Revision Date: 01/23/2013 Page 1 of 7

C-E Minerals: MSDS For Mulcoa 60/mulgrain 60/mulblast 60: Revision Date: 01/23/2013 Page 1 of 7

Uploaded by

Muniruddin AmranCopyright:

Available Formats

® ®

C-E Minerals: MSDS for Mulcoa 60/Mulgrain 60/Mulblast 60

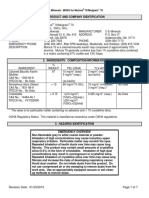

1. PRODUCT AND COMPANY IDENTIFICATION

PRODUCT NAME: Mulcoa® 60/Mulgrain® 60/Mulblast 60

FORMULA: Not Applicable - Mixture

SUPPLIER: C-E Minerals MANUFACTURER: C-E Minerals

ADDRESS: 100 Mansell Ct. E, Ste. 615 ADDRESS: P.O. Box 37

Roswell, GA 30076 Andersonville, GA 31711

PHONE: (770) 225-7923 PHONE: (229)924-4461

EMERGENCY PHONE: (229) 924-4461, After 5PM weekdays, Weekends and Holidays: (229) 815-1036

E-MAIL: sholden@ceminerals.com

DESCRIPTION: Mulcoa 60 is a calcined bauxitic kaolin clay composed of approximately 60%

alumina. Mulcoa 60 generally contains less than 1% crystalline silica combined

in a matrix containing 77% mullite and 23% Glass.

2. INGREDIENTS: COMPOSITION/INFORMATION

% LD 50/LC 50

INGREDIENT WEIGHT PEL-OSHA TLV-ACGIH ROUTE/SPECIES

Calcined Bauxitic Kaolin 77 15 mg/m3 (total) 2 mg/m3 (resp.)* No Data

(Mullite) 5 mg/m3 (resp.) (as kaolin)

CAS No.: 1302-93-8

RTECS No.: No Data (as kaolin)

Amorphous silica (Glass) < 23 80 mg/m3/% SiO2 10 mg/m3 (inhalable)* No Data

CAS No.: 7631-86-9 3 mg/m3 (resp.)*

RTECS No.: No Data

Cristobalite 0.3 ½[10 mg/m3/ 0.025 mg/m3 (resp.) No Data

CAS No.: 14464-46-1 (%SiO2+2)](resp.)

RTECS No.: VV7325000 ½[30 mg/m3/

(%SiO2+2)](total)

* The value is for particulate matter containing no asbestos and < 1% crystalline silica.

OSHA Regulatory Status: This material is classified as hazardous under OSHA regulations.

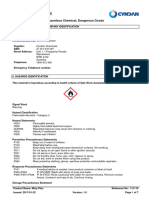

3. HAZARDS IDENTIFICATION

EMERGENCY OVERVIEW

Non-flammable grayish to white coarse granular material or

powder. Inhalation of high dust concentrations may cause

transitory upper respiratory irritation. Particulate matter may

scratch the eyes. Repeated inhalation of kaolin dusts over time

may cause lung fibrosis. This product may contain small amounts

of crystalline silica (<1%) in the form of cristobalite. . Inhalation

of high dust concentrations may result in overexposure to

crystalline silica. Repeated inhalation of crystalline silica over

time may cause lung fibrosis and increase the risks of developing

respiratory cancer. Avoid dust creation. Do not inhale dusts from

this product. Do not use compressed air or dry sweeping to

remove dusts from the work area. Use an appropriately equipped

vacuum or wet clean-up methods to remove dusts.

Revision Date: 01/23/2013 Page 1 of 7

® ®

C-E Minerals: MSDS for Mulcoa 60/Mulgrain 60/Mulblast 60

POTENTIAL HEALTH EFFECTS

EYE: Particulate matter may scratch the cornea or cause other mechanical injury to the eye.

SKIN: None anticipated.

INGESTION: Relatively non-toxic. Ingestion is not anticipated under normal working conditions.

INHALATION: Inhalation of high concentrations of dust may cause coughing and mild, transitory respiratory

irritation.

SIGNS AND SYMPTOMS: Scratching or physical damage to the eyes can cause irritation, redness, pain, tear

formation, blurred vision, and light sensitivity. Symptoms of silicosis include phlegm, coughing, characteristic

x-rays, decreased pulmonary function and decreased capacity to work.

MEDICAL CONDITIONS AGGRAVATED BY EXPOSURE: Long-term dust exposure may aggravate pre-

existing respiratory disease.

CHRONIC: Long-term inhalation of respirable kaolin dusts has caused lung fibrosis (kaolinosis) in

experimental animals and workers. In the absence of crystalline silica, it appears that kaolin causes a

relatively mild fibrosis which generally will not produce severe pulmonary disease. Kaolinosis can either be

simple or complex in nature with complex kaolinosis being associated with respiratory changes and decreased

ability of the lungs to provide oxygen.

Inhalation of high dust concentrations may result in over-exposure to respirable crystalline silica. If inhaled in

sufficient quantities over time, respirable silica can cause fibrotic disabling lung disease (silicosis) and increase

the risks of developing respiratory cancer.

TARGET ORGANS: Lungs

CARCINOGENICITY: NTP: Yes IARC: Yes (Group 1) OSHA: No

IARC and NTP classify respirable crystalline silica as a confirmed or known human carcinogen. Although

OSHA has not promulgated a specific standard for crystalline silica, materials that contain > 0.1% crystalline

silica should be treated as a confirmed carcinogen for hazard communication purposes (29 CFR 1910.1200).

4. FIRST AID MEASURES

EYE: Flush eyes with lukewarm water for 15 minutes opening and closing eyelids to ensure adequate rinsing.

If redness, irritation, pain, or tearing occurs, seek medical attention.

SKIN: Exposure not anticipated.

INHALATION: Not anticipated. If large amounts of dusts are inhaled, remove to fresh air. If breathing

problems occur, a certified professional should administer oxygen or CPR if indicated. Seek immediate

medical attention.

INGESTION: None required.

Revision Date: 01/23/2013 Page 2 of 7

® ®

C-E Minerals: MSDS for Mulcoa 60/Mulgrain 60/Mulblast 60

5. FIRE FIGHTING MEASURES

FLAMMABLE PROPERTIES

FLASH POINT: Not Applicable

FLAMMABLE LIMITS: LEL: Not Applicable UEL: Not Applicable

NFPA CLASSIFICATION:

HEALTH: 0 FLAMMABILITY: 0 INSTABILITY: 0

EXTINGUISHING MEDIA: Any. Use media appropriate for surrounding fire.

FIRE AND EXPLOSION HAZARDS: Non-flammable, non-combustible. Product will not burn.

HAZARDOUS DECOMPOSITION PRODUCTS: None known. Amorphous silica may convert to crystalline

silica at high temperatures.

FIRE FIGHTING INSTRUCTIONS: Firefighters should wear a NIOSH/MSHA approved full-facepiece self-

contained breathing apparatus (SCBA) operated in positive pressure mode and full turnout or bunker gear.

6. ACCIDENTAL RELEASE MEASURES

Isolate hazard area and deny entry to unauthorized and/or unprotected personnel. Do not walk through or

otherwise scatter spilled material. For small spills, clean with a vacuum with a filtration system sufficient to

remove and prevent recirculation of crystalline silica (a vacuum equipped with a high-efficiency particulate air

(HEPA) filter is recommended). For large spills, use a fine spray or mist to control dust creation and carefully

scoop or shovel into clean dry container for later reuse or disposal. DO NOT USE DRY SWEEPING OR

COMPRESSED AIR TO CLEAN SPILLS. Appropriate respiratory protection is essential for all clean-up

personnel. Completely remove dusts to prevent recirculation of crystalline silica into the workplace.

7. HANDLING AND STORAGE

Store in dry area in closed containers. Storage and work areas should be periodically cleaned to minimize

dust accumulation. Avoid dust inhalation and promulgation. DO NOT use compressed air or dry sweeping to

remove dust from work area. Dusts should be removed using an appropriately equipped vacuum. If an

appropriate vacuum is unavailable, only wet-clean-up methods should be used (i.e. misting). Moisture should

be added as necessary to reduce exposure to airborne respirable crystalline and fused silica dust.

Under dusty conditions, employees should wear coveralls or other suitable work clothing. Contaminated

clothing must be vacuumed before removal. DO NOT REMOVE dusts from clothing by blowing or shaking.

Practice good housekeeping. Wash thoroughly after handling. Change contaminated clothing. Do not reuse

until laundered. Do not take silica contaminated clothing home.

Comply with OSHA Hazard Communication Rule 29 CFR 1910.1200, and applicable federal, state, and local

worker or community "right-to-know" laws and regulations during storage, use, and disposal of this product.

For further information, consult the American Society for Testing and Materials (ASTM) standard practice

ASTM E 1132 Revision 99A, "Standard Practice for Health Requirements Relating to Occupational Exposure

to Crystalline Silica."

Revision Date: 01/23/2013 Page 3 of 7

® ®

C-E Minerals: MSDS for Mulcoa 60/Mulgrain 60/Mulblast 60

8. EXPOSURE CONTROLS/PERSONAL PROTECTION

RESPIRATORY: Under normal working conditions, below acceptable exposure guidelines, none is required.

Appropriate respirator selection is dependent upon the magnitude of exposure. Wear respiratory protection in

accordance with 29 CFR Part 134.

SKIN: None required.

EYES: Safety-glasses with side shields or goggles to prevent dust and particles from entering the eye.

ENGINEERING CONTROLS: Local exhaust ventilation and collection systems must be designed and

maintained to prevent the accumulation and recirculation of free silica dust into the workplace.

OTHER: Where there is a potential exposure to free silica (cristobalite), the following warnings should be

readily visible and posted near entrances or accessways to work areas: WARNING! FREE SILICA WORK

AREA. Unauthorized persons keep out. The following warning should be posted within the work area where

potential exposure may occur: WARNING! FREE SILICA WORK AREA. Avoid Breathing Dust. May Cause

Delayed Lung Injury (silicosis). (NIOSH Criteria Document, Occupational Exposure to Crystalline Silica, pg. 5,

1974.)

Medical surveillance program in accordance with "Criteria for a Recommended Standard... Occupational

Exposure to Crystalline Silica," NIOSH, pp.: 2-4, 1974.

9. PHYSICAL AND CHEMICAL PROPERTIES

APPEARANCE: White to grayish in color

ODOR: Odorless

SOLUBILITY IN WATER: Insoluble

SPECIFIC GRAVITY (H2O = 1): 2.8

MELTING POINT: + 3000 F (+1094C)

pH (10% slurry): 6.5-8

% VOLATILE 0

TYPES: Size ranges from Kiln Run (approx. 1/2”) to 325 Mesh

Powder

10. STABILITY AND REACTIVITY

STABILITY: Stable

REACTIVITY/INCOMPATIBILITY: Kaolin is a relatively inert substance. Silicon dioxide is incompatible with

strong oxidizers (i.e.: fluorine, oxygen difluoride, and chlorine trifluoride).

DECOMPOSITION PRODUCTS: Amorphous silica may convert to cristobalite at high temperature.

HAZARDOUS POLYMERIZATION: Will not occur.

Revision Date: 01/23/2013 Page 4 of 7

® ®

C-E Minerals: MSDS for Mulcoa 60/Mulgrain 60/Mulblast 60

11. TOXICOLOGICAL INFORMATION

EYE: Particulate matter may cause physical injury to the eye.

SKIN: Skin irritation is not anticipated.

INHALATION: May cause minor transient respiratory irritation.

INGESTION: Kaolin dusts will absorb water if ingested. If water intake is sufficient, kaolin will tend to have a

laxative effect. When water intake is not sufficient, intestinal obstruction may occur.

CHRONIC: While crystalline silica exposure appears to enhance the severity of kaolinosis, data indicates that

kaolin has the ability to induce a fibrogenic response in the absence of crystalline silica. Kaolin

pneumoconiosis is characterized by roentgenograms which exhibit small irregular shadows and large

capacities.

CHRONIC (continued):

Silicosis is a progressive fibrotic pneumoconiosis which greatly decreases the ability of the lungs to provide

oxygen (decreased pulmonary capacity). The extent and severity of lung injury depends on a variety of factors

including particle size, percentage of silica, natural resistance, dust concentration and length of exposure. The

damaged lungs will become increasingly less able to provide the body with oxygen causing tiredness,

shortness of breath, decreased capacity to work, and can result in death by cardiac failure or by the destruction

of lung tissue. Persons who develop silicosis have greatly increased risks of developing tuberculosis and

workers who are exposed to crystalline silica and smoke have increased risks of lung damage. silicosis may

progress in the absence of continued exposure.

SUBCHRONIC: No Data

OTHER: Silica particles < 10 μm are considered respirable; however, particles retained in the lungs are

generally much smaller.

12. ECOLOGICAL INFORMATION

Mulcoa 60 is an inert material. It does not contain ozone depleting substances and is not expected to exert an

ecotoxic effect or bioconcentrate in the food chain.

13. DISPOSAL CONSIDERATIONS

Dispose of according to applicable federal, state, and local regulations.

14. TRANSPORT INFORMATION

U.S. Department of Transportation (DOT): Not Classified.

Revision Date: 01/23/2013 Page 5 of 7

® ®

C-E Minerals: MSDS for Mulcoa 60/Mulgrain 60/Mulblast 60

15. REGULATORY INFORMATION

CANADIAN WHMIS: D2A, D2B

EPCRA Section 302 (EHSs): This product does not contain ingredients subject to reporting requirements of 40

CFR Part 355, Appendices A and B (Extremely Hazardous Substances).

CERCLA, Section 304: This product does not contain ingredients subject to state and local reporting under

Section 304 of SARA Title III as listed in 40 CFR Part 302, Table 302.4

SARA 313 REPORTING REQUIREMENTS: This product does not contain ingredients subject to the reporting

requirements of Section 313 SARA, and Section 6607 of the Pollution Prevention Act:

SARA HAZARD CATEGORY: This product has been reviewed according to the EPA Hazard Categories

promulgated under Sections 311 and 312 of the Superfund Amendment and Reauthorization Act of 1986

(SARA Title III) and by definition meets the requirements of the following category:

Chronic Health Hazard

CALIFORNIA Proposition 65: This product contains crystalline silica, an ingredient known to the State of

California to cause cancer.

TSCA (Toxic Substances Control Act): All ingredients contained in this product are on the TSCA inventory.

16. OTHER INFORMATION

Revision Date: 5/7/98 added Calif. Proposition 65 information and TSCA information.

10/3/00 reissued with no changes

8/27/01 updated new area code for manufacturing facility.

8/15/03 health and safety review and update.

7/13//06 health and safety review and update.

11/17/09 health and safety review and update.

American Conference of Governmental Industrial Hygienists

KEY: Chemical Abstracts Service

Ceiling Limit

ACGIH: Department of Transportation

CAS: International Agency for Research on Cancer

(C): Mine Safety and Health Administration

DOT: National Fire Protection Association

IARC: National Institute for Occupational Safety and Health

MSHA: National Toxicology Program

NFPA: Occupational Safety and Health Administration

NIOSH: Permissible Exposure Limit

NTP: Superfund Amendment and Reauthorization Act

OSHA: Threshold Limit Value

PEL:

SARA:

TLV:

Revision Date: 01/23/2013 Page 6 of 7

® ®

C-E Minerals: MSDS for Mulcoa 60/Mulgrain 60/Mulblast 60

DISCLAIMER

Although reasonable care has been taken in the

preparation of the information contained herein,

C-E Minerals extends no warranties, makes no

representation and assumes no responsibility as to

the accuracy of suitability of such information for

application to purchaser’s intended purposes or for

consequences of its use.

Revision Date: 01/23/2013 Page 7 of 7

You might also like

- Coconut Shells Ash As A Substitute For Graphite 1Document30 pagesCoconut Shells Ash As A Substitute For Graphite 1King Gabriel Wayne Lontoc100% (2)

- Process-Kiln-Refractory ManualDocument97 pagesProcess-Kiln-Refractory ManualDurga Prasad100% (4)

- C-E Minerals: MSDS For Mulcoa 70/mulgrain 70: Revision Date: 01/23/2013 Page 1 of 7Document7 pagesC-E Minerals: MSDS For Mulcoa 70/mulgrain 70: Revision Date: 01/23/2013 Page 1 of 7Muniruddin AmranNo ratings yet

- Material Safety Data Sheet: Silica FumeDocument3 pagesMaterial Safety Data Sheet: Silica FumeHemlata LodhaNo ratings yet

- Material Safety Data Sheet: Silica FumeDocument3 pagesMaterial Safety Data Sheet: Silica FumeEzequiel BeitiaNo ratings yet

- Geoscience Testing Laboratory: Material Safety Data SheetDocument4 pagesGeoscience Testing Laboratory: Material Safety Data SheetAnonymous G6ceYCzwtNo ratings yet

- Crystalline Silica SDSDocument9 pagesCrystalline Silica SDSJustin ChongNo ratings yet

- Msds Silica XXX MeshDocument9 pagesMsds Silica XXX MeshJorge CamargoNo ratings yet

- Msds Gma GarnetDocument4 pagesMsds Gma GarnetAbah AmaniNo ratings yet

- Rapid Set Repair MaterialDocument7 pagesRapid Set Repair Materialsam damsNo ratings yet

- 5889 Kruzite 70 - (Usa)Document7 pages5889 Kruzite 70 - (Usa)Hugo RomeroNo ratings yet

- Cooper Industries - Chico A Sealing CompoundDocument6 pagesCooper Industries - Chico A Sealing Compoundjaredf@jfelectric.com100% (3)

- Carbolite - Todas Las Mallas FDS PDFDocument3 pagesCarbolite - Todas Las Mallas FDS PDFwilmerNo ratings yet

- Gyprock-Plaster-Based Cements AdhesivesDocument7 pagesGyprock-Plaster-Based Cements AdhesivesJonoNo ratings yet

- Absorbent - Oil Dri Sweeping CompoundDocument6 pagesAbsorbent - Oil Dri Sweeping CompoundArihsoy Derahs Leafar HerreraNo ratings yet

- Fire Barrier 135 Msds PDFDocument8 pagesFire Barrier 135 Msds PDFE Hammam El MissiryNo ratings yet

- HM 106 108Document8 pagesHM 106 108albaraha albarahaNo ratings yet

- Material Safety Data Sheet X-CIDE 207: 1. Chemical Product and Company IdentificationDocument7 pagesMaterial Safety Data Sheet X-CIDE 207: 1. Chemical Product and Company IdentificationLuis Gomez JimenezNo ratings yet

- Flyash Msds KenzoDocument5 pagesFlyash Msds KenzoErianto XuNo ratings yet

- SDS LIddell CoalDocument6 pagesSDS LIddell CoalIvan OsipovNo ratings yet

- Material Safety Data Sheet: Maryland Refractories CompanyDocument5 pagesMaterial Safety Data Sheet: Maryland Refractories CompanyChayon MondalNo ratings yet

- Silica Sand MSDSDocument4 pagesSilica Sand MSDSAchmad Syariful HidayatNo ratings yet

- Silica Sand MSDS PDFDocument4 pagesSilica Sand MSDS PDFFadelNo ratings yet

- Radar Open Plan Acoustical Panels SDS 811433Document10 pagesRadar Open Plan Acoustical Panels SDS 811433Qasim JummaniNo ratings yet

- MSDS - Tuff-Krete HD - Part DDocument6 pagesMSDS - Tuff-Krete HD - Part DAl GuinitaranNo ratings yet

- Sds Limestone-F-PulverizedDocument6 pagesSds Limestone-F-PulverizedAzuan MABKNo ratings yet

- Safety Data Sheet: LimestoneDocument7 pagesSafety Data Sheet: LimestoneGloria HurianNo ratings yet

- MSDS Actchem-UsaDocument5 pagesMSDS Actchem-UsaAdrian ChannelNo ratings yet

- SDS NeoSlurry Systems 5 Gal 08.19.151Document7 pagesSDS NeoSlurry Systems 5 Gal 08.19.151ferdy110276No ratings yet

- Vulkem SealantDocument8 pagesVulkem SealantsachinoakNo ratings yet

- Holcimnz Sds EcoplanetDocument6 pagesHolcimnz Sds Ecoplanetmartinezryan725No ratings yet

- SulfuricacidDocument9 pagesSulfuricacidqavictoriacareNo ratings yet

- Pt. Atlantic Intraco - Safety Data Sheet: Calcium Oxide - CaoDocument5 pagesPt. Atlantic Intraco - Safety Data Sheet: Calcium Oxide - CaoAreIf Cron BmxStreetNo ratings yet

- CSR - Base Coat and Adhesive - SDS - 20.11.2019Document7 pagesCSR - Base Coat and Adhesive - SDS - 20.11.2019jr-nts ntsNo ratings yet

- Safety Data Sheet: SandstoneDocument8 pagesSafety Data Sheet: SandstoneharNo ratings yet

- Arena para Gato MSDSDocument6 pagesArena para Gato MSDSAlexander Franco CastrillonNo ratings yet

- Silica Flour MSDSDocument7 pagesSilica Flour MSDSizzybjNo ratings yet

- Foster 30 65 SDSDocument7 pagesFoster 30 65 SDSsheetalnathNo ratings yet

- CMC (Sodium Carboxymethyl Cellulose)Document6 pagesCMC (Sodium Carboxymethyl Cellulose)Sanggari MogarajaNo ratings yet

- Msds-016 Conbextra GP - Sds11813 - enDocument5 pagesMsds-016 Conbextra GP - Sds11813 - enjoker batmanNo ratings yet

- MSDS SuperTemp1900insulatingcementDocument5 pagesMSDS SuperTemp1900insulatingcementGustavo FigueroaNo ratings yet

- Arena para Gato 2 MSDSDocument4 pagesArena para Gato 2 MSDSAlexander Franco CastrillonNo ratings yet

- Kyanite - 35 48 100 - 09 25 14Document6 pagesKyanite - 35 48 100 - 09 25 14Cheyenne KruseNo ratings yet

- General Purpose Cement - 0Document8 pagesGeneral Purpose Cement - 0H GNo ratings yet

- Usg Sheetrock Durabond Setting Type Joint Compounds Sds en 61000030006Document8 pagesUsg Sheetrock Durabond Setting Type Joint Compounds Sds en 61000030006bo cephusNo ratings yet

- MBS Auto Refinish - SDS - EnglishDocument5 pagesMBS Auto Refinish - SDS - EnglishFulan Bin FulanNo ratings yet

- MSDS AAC Hebel Blocks - 2002Document4 pagesMSDS AAC Hebel Blocks - 2002aditarian .pNo ratings yet

- 1101 Audrey Blackman Portelan Pasta 1250kgDocument3 pages1101 Audrey Blackman Portelan Pasta 1250kgmiha bNo ratings yet

- Safety Data Sheet Loctite Super Glue Liquid: 1 Identification of The Substance/Preparation and Company/UndertakingDocument4 pagesSafety Data Sheet Loctite Super Glue Liquid: 1 Identification of The Substance/Preparation and Company/UndertakingqualityfreekNo ratings yet

- Plasterboard Non Hazardous - Jan22Document6 pagesPlasterboard Non Hazardous - Jan22sivaramNo ratings yet

- Correct Material Safety Data SheetDocument7 pagesCorrect Material Safety Data SheetSami KhanNo ratings yet

- Coke Msds (Opal)Document6 pagesCoke Msds (Opal)Viral PatelNo ratings yet

- Cebex 100 MSDSDocument4 pagesCebex 100 MSDSprashant mankarNo ratings yet

- Moly Plus-SDSDocument7 pagesMoly Plus-SDSaldyyp736No ratings yet

- 423 GHS Carpet ShampooDocument7 pages423 GHS Carpet ShampoorezaNo ratings yet

- Material Safety Data Sheet: (Granite)Document4 pagesMaterial Safety Data Sheet: (Granite)paNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument8 pagesSafety Data Sheet: 1. Identificationyavy83No ratings yet

- Msds-Oreas (Nram)Document7 pagesMsds-Oreas (Nram)Heber Diaz ChavezNo ratings yet

- Identification: Infosafe No.: LPSIZ Issued Date: 30/03/2015 Issued By: Sibelco Australia LimitedDocument7 pagesIdentification: Infosafe No.: LPSIZ Issued Date: 30/03/2015 Issued By: Sibelco Australia Limitedsentient.bean8226No ratings yet

- Msds Oreas (Rada)Document10 pagesMsds Oreas (Rada)Heber Diaz ChavezNo ratings yet

- Silkolene Pro RG2-SDSDocument6 pagesSilkolene Pro RG2-SDSrexNo ratings yet

- Ezflob 09Document2 pagesEzflob 09Muniruddin AmranNo ratings yet

- Ezfloa 10Document2 pagesEzfloa 10Muniruddin AmranNo ratings yet

- Deluxcote BinderDocument2 pagesDeluxcote BinderMuniruddin AmranNo ratings yet

- C-E Minerals: MSDS For Mulcoa 70/mulgrain 70: Revision Date: 01/23/2013 Page 1 of 7Document7 pagesC-E Minerals: MSDS For Mulcoa 70/mulgrain 70: Revision Date: 01/23/2013 Page 1 of 7Muniruddin AmranNo ratings yet

- Alfabetos de Minerales Nepouita-LizarditaDocument152 pagesAlfabetos de Minerales Nepouita-LizarditaJorge PirelaNo ratings yet

- KaolinDocument13 pagesKaolinFadjar AditiyaNo ratings yet

- Sedimentation Behavior of A Fine Kaolinite in The Presence of Fresh Fe ElectrolyteDocument7 pagesSedimentation Behavior of A Fine Kaolinite in The Presence of Fresh Fe ElectrolytedongngoNo ratings yet

- Nano Material EsDocument156 pagesNano Material EsAreitos DelgadoNo ratings yet

- Microstructural Characteristics, Properties, Synthesis and Applications of MulliteDocument17 pagesMicrostructural Characteristics, Properties, Synthesis and Applications of MulliterenatubunituNo ratings yet

- Practical Charts To Identify The Predominant ClayDocument6 pagesPractical Charts To Identify The Predominant ClayJuan Diego GiraldoNo ratings yet

- China Clay & Bauxite Mining in OrissaDocument19 pagesChina Clay & Bauxite Mining in OrissaHimansu S M100% (1)

- PDF The Foundation Engineering Handbook 2Nd Edition Manjriker Gunaratne Editor Ebook Full ChapterDocument53 pagesPDF The Foundation Engineering Handbook 2Nd Edition Manjriker Gunaratne Editor Ebook Full Chapterlinda.thompson854100% (1)

- Applications of Using Nano Material in Concrete - A ReviewDocument7 pagesApplications of Using Nano Material in Concrete - A ReviewJohn GiannakopoulosNo ratings yet

- Synthesis and Characterisation of Zeolite A For Adsorption Refrigeration ApplicationDocument9 pagesSynthesis and Characterisation of Zeolite A For Adsorption Refrigeration ApplicationAna QuintanaNo ratings yet

- Lecture Notes BricksDocument8 pagesLecture Notes BricksMurtaza KolsawalaNo ratings yet

- Seminar Swelling SoilsDocument43 pagesSeminar Swelling Soilssharath1199No ratings yet

- Accessing The Chemical Properties of Clay Deposits in Ekiti StateDocument41 pagesAccessing The Chemical Properties of Clay Deposits in Ekiti StateJayla CroninNo ratings yet

- Cerro CoronaDocument17 pagesCerro CoronaJaime Mercado BenavidesNo ratings yet

- Exploration For China Clay in and Around Mangalapuram, Thiruvananthapuram District, Kerala A Prabhakumar and Sughada Pradeep Directorate of Mining and GeologyDocument9 pagesExploration For China Clay in and Around Mangalapuram, Thiruvananthapuram District, Kerala A Prabhakumar and Sughada Pradeep Directorate of Mining and GeologyS.Alec Knowle100% (3)

- Ashapura Group PresentationDocument18 pagesAshapura Group Presentationkaspal123No ratings yet

- CN101774595B - Process For Enhanced Reduction and Bleaching of Kaolin by Using Thiocarbamide - Google PatentsDocument4 pagesCN101774595B - Process For Enhanced Reduction and Bleaching of Kaolin by Using Thiocarbamide - Google Patentsbkpadhi815No ratings yet

- Awt 10 PDFDocument17 pagesAwt 10 PDFBhupesh MulikNo ratings yet

- (1995 - Konta) Clay and Man PDFDocument61 pages(1995 - Konta) Clay and Man PDFDavid MartinsNo ratings yet

- The Situation and Mining Prospect of Kaolinitic Clays in RomaniaDocument25 pagesThe Situation and Mining Prospect of Kaolinitic Clays in RomaniaD CNo ratings yet

- Shale: Devanarayanan EM I.Msc Applied GeologyDocument20 pagesShale: Devanarayanan EM I.Msc Applied GeologyDq DevanNo ratings yet

- Preparation of Cationic Surfactant Modified Kaolin For Enhanced Adsorption of Hexavalent Chromium From Aqueous SolutionDocument8 pagesPreparation of Cationic Surfactant Modified Kaolin For Enhanced Adsorption of Hexavalent Chromium From Aqueous SolutionSaddam HusienNo ratings yet

- Synthesis and Characterization of Zeolite A by HydDocument8 pagesSynthesis and Characterization of Zeolite A by HydSayyied Al KareemNo ratings yet

- 1 Synthesis and Characterization of 13X Zeolite From Low-GradeDocument5 pages1 Synthesis and Characterization of 13X Zeolite From Low-GradeAmir SetiadiNo ratings yet

- Review of Related Literature For Geopolymer CobcreteDocument6 pagesReview of Related Literature For Geopolymer CobcreteAldrich Francis Ortiz PeñaflorNo ratings yet

- Metakaolin From Kaolinite PDFDocument14 pagesMetakaolin From Kaolinite PDFMartha Carolina Gomez MartinezNo ratings yet

- Mineral Resources and Sustainable DevelopmentDocument6 pagesMineral Resources and Sustainable DevelopmentKeneth CandidoNo ratings yet

- The Effect of Curing On The Properties of Metakaolin and Fly Ash-Based Geopolymer PasteDocument7 pagesThe Effect of Curing On The Properties of Metakaolin and Fly Ash-Based Geopolymer PasteMuhammad Riaz AhmadNo ratings yet