Professional Documents

Culture Documents

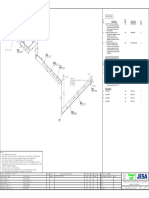

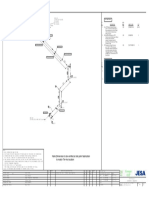

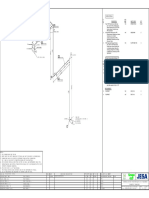

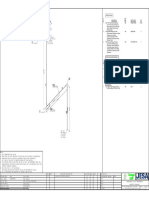

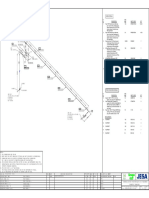

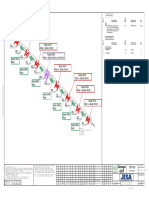

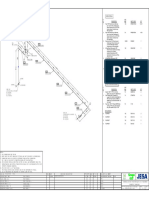

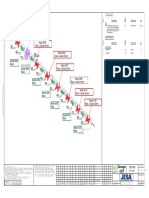

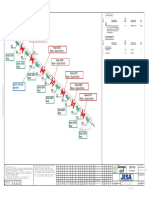

To Match Tie-Ins Location: 3 Support

To Match Tie-Ins Location: 3 Support

Uploaded by

ABDERRAZZAKCopyright:

Available Formats

You might also like

- Characteristic Curves KWP - KSBDocument224 pagesCharacteristic Curves KWP - KSBDaniel MilosevskiNo ratings yet

- 0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionDocument1 page0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- 0 10/24/2022 A.N Y.S K.M 10/24/2022 Issued For ConstructionDocument1 page0 10/24/2022 A.N Y.S K.M 10/24/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- Ilovepdf MergedDocument3 pagesIlovepdf MergedABDERRAZZAKNo ratings yet

- To Match Tie-Ins Location: See SHT 200-PB-13F-219-BK1 SHT 1 F4 G5 B6Document1 pageTo Match Tie-Ins Location: See SHT 200-PB-13F-219-BK1 SHT 1 F4 G5 B6ABDERRAZZAKNo ratings yet

- 0127 R8B 07 WP 311 01Document1 page0127 R8B 07 WP 311 01ABDERRAZZAKNo ratings yet

- To Match Tie-Ins LocationDocument1 pageTo Match Tie-Ins LocationABDERRAZZAKNo ratings yet

- To Match Tie-Ins LocationDocument1 pageTo Match Tie-Ins LocationABDERRAZZAKNo ratings yet

- 0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionDocument1 page0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- 300 WW 14T2 1 009 Bk1.shaDocument1 page300 WW 14T2 1 009 Bk1.shaABDERRAZZAKNo ratings yet

- 0 10/25/22 A.N Y.S K.B 10/25/22 Issued For ConstructionDocument1 page0 10/25/22 A.N Y.S K.B 10/25/22 Issued For ConstructionABDERRAZZAKNo ratings yet

- 0127 R8B 03 WP 311 01Document1 page0127 R8B 03 WP 311 01ABDERRAZZAKNo ratings yet

- To Match Tie-Ins LocationDocument1 pageTo Match Tie-Ins LocationABDERRAZZAKNo ratings yet

- 0127 R8B 06 WP 311 01Document1 page0127 R8B 06 WP 311 01ABDERRAZZAKNo ratings yet

- 0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionDocument1 page0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- 0127 R8B 04 WP 311 01Document1 page0127 R8B 04 WP 311 01ABDERRAZZAKNo ratings yet

- 0127 R8B 05 WP 311 01Document1 page0127 R8B 05 WP 311 01ABDERRAZZAKNo ratings yet

- Perspective Diagram Pentray Perspective 1: Jose Miguel BorjaDocument1 pagePerspective Diagram Pentray Perspective 1: Jose Miguel Borjajohn Patrick valinoNo ratings yet

- Notes: Roof: Concrete Roof Tiles On TrussesDocument1 pageNotes: Roof: Concrete Roof Tiles On TrussesanzaniNo ratings yet

- Pump Foundation Design PDFDocument18 pagesPump Foundation Design PDFArchana ArchuNo ratings yet

- FPSOInterface Engineering 09Document43 pagesFPSOInterface Engineering 09Ronnie Paul100% (1)

- Manual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkDocument33 pagesManual, Owner'S Drum-Export 1/1: Suffix Language Page Remarkchad tanNo ratings yet

- Selec Chart Concrete enDocument1 pageSelec Chart Concrete enRubal ShawNo ratings yet

- Transfame SDN BHD Paint Matrix Provision of Hook Up & Commissioning (Huc) Works For Murphy'S FacilitiesDocument2 pagesTransfame SDN BHD Paint Matrix Provision of Hook Up & Commissioning (Huc) Works For Murphy'S FacilitiesSupport RFZ2 EngineeringNo ratings yet

- Expansion Joint - Internal Corner: Solid Wall AT-mineral WoolDocument1 pageExpansion Joint - Internal Corner: Solid Wall AT-mineral WoolWadi Gabor100% (1)

- Sp3 MB A WPF Det - Typ 007 (Roof)Document1 pageSp3 MB A WPF Det - Typ 007 (Roof)Renaldo BunaidiNo ratings yet

- Equipment Schematic - For P5 DualDocument4 pagesEquipment Schematic - For P5 DualrahulNo ratings yet

- Precast T-Wall Alt 1Document2 pagesPrecast T-Wall Alt 1Kinantoko FauzanNo ratings yet

- Paf-Mdf Control 02Document33 pagesPaf-Mdf Control 02thanh sang đinhNo ratings yet

- MFL68723109 IndoDocument33 pagesMFL68723109 Indoarcercoa1No ratings yet

- GT1015Document1 pageGT1015Basten M H SilitongaNo ratings yet

- 66 Ihd 0003 ADocument1 page66 Ihd 0003 AMbalekelwa MpembeNo ratings yet

- MFL67284329劤틔 - hun-09-09 10Document33 pagesMFL67284329劤틔 - hun-09-09 10gyorfizsuzsi1986No ratings yet

- Paf-Mdf Control 01Document33 pagesPaf-Mdf Control 01thanh sang đinhNo ratings yet

- Gambar Listrik CilacapDocument10 pagesGambar Listrik CilacapDanang RizkiNo ratings yet

- Manual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkDocument81 pagesManual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkGuillermo SilvaNo ratings yet

- Manual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkDocument33 pagesManual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkVaniNo ratings yet

- Manual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkDocument33 pagesManual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkAndrei BogdanNo ratings yet

- 69 - IDN - 142 (Revised)Document5 pages69 - IDN - 142 (Revised)visheshssrivastavaNo ratings yet

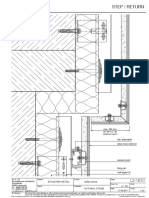

- Step / Return: Standard Detail - Airtec Stone Natural StoneDocument1 pageStep / Return: Standard Detail - Airtec Stone Natural StoneWadi GaborNo ratings yet

- WPS MatrixDocument4 pagesWPS MatrixHarshaVeeragandham50% (2)

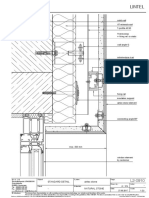

- L2 0910 PDFDocument1 pageL2 0910 PDFWadi GaborNo ratings yet

- Regular-Density Panel For Cost-Efficiency and Reliability: Commercial Roof FiberboardDocument2 pagesRegular-Density Panel For Cost-Efficiency and Reliability: Commercial Roof FiberboardNikola BoskovicNo ratings yet

- A2-Floor Plan, ElevationsDocument1 pageA2-Floor Plan, ElevationsRonnel John CruzNo ratings yet

- RV WU1348 Eldoret Mtungi Road - DesignDocument6 pagesRV WU1348 Eldoret Mtungi Road - DesignIKO NETWORKNo ratings yet

- 62.Tủ Điện MP-P-B2B-FAFDocument11 pages62.Tủ Điện MP-P-B2B-FAFthanh sang đinhNo ratings yet

- Thermacor Preinsulated PipesDocument6 pagesThermacor Preinsulated PipesBernard SolisNo ratings yet

- 63.Tủ Điện MP-P-B2C-FAFDocument11 pages63.Tủ Điện MP-P-B2C-FAFthanh sang đinhNo ratings yet

- PUDLO TJD GPUS 013 Slab Pipe Penetration DetailDocument1 pagePUDLO TJD GPUS 013 Slab Pipe Penetration DetailJosip MedvedNo ratings yet

- Ip 54 Ahf PDFDocument2 pagesIp 54 Ahf PDFvalay salesNo ratings yet

- Manual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkDocument33 pagesManual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkcrnimajstorNo ratings yet

- GC11 Pipe Thickness CalcDocument1 pageGC11 Pipe Thickness CalcsrinivasanNo ratings yet

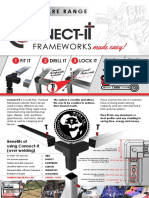

- Made Easy!: 25Mm Square RangeDocument2 pagesMade Easy!: 25Mm Square RangeTonyNo ratings yet

- 10.Tủ Điện DB-B-MDFDocument7 pages10.Tủ Điện DB-B-MDFthanh sang đinhNo ratings yet

- Manual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkDocument33 pagesManual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkriyadhplyNo ratings yet

- Pipe Thru Wall & Slab Detail Exhaust Air Louver Detail Door Upstand at RoofDocument1 pagePipe Thru Wall & Slab Detail Exhaust Air Louver Detail Door Upstand at RoofAdel KhalilNo ratings yet

- Grating Black Start Plan at T/G El (+) 0.300 (3 Nos) Grating Black Start Plan at T/G El (+) 0.100 (2 Nos)Document1 pageGrating Black Start Plan at T/G El (+) 0.300 (3 Nos) Grating Black Start Plan at T/G El (+) 0.100 (2 Nos)sivagnanamNo ratings yet

- 32 Gfc-P2c3-Tu02-Crp-Dr-Btn-73106-01-ADocument1 page32 Gfc-P2c3-Tu02-Crp-Dr-Btn-73106-01-ASUBHASH KUMARNo ratings yet

- FC Double Operable W - Muntins & Transom & Sidelits - Brick-to-Brick Installation Details 1Document2 pagesFC Double Operable W - Muntins & Transom & Sidelits - Brick-to-Brick Installation Details 1Payal YadavNo ratings yet

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- Rep 01Document1 pageRep 01ABDERRAZZAKNo ratings yet

- 0127 R8B 06 WP 311 01Document1 page0127 R8B 06 WP 311 01ABDERRAZZAKNo ratings yet

- Rep02 R01Document1 pageRep02 R01ABDERRAZZAKNo ratings yet

- Aspiration R01Document1 pageAspiration R01ABDERRAZZAKNo ratings yet

- Passerelle PAT150Document1 pagePasserelle PAT150ABDERRAZZAKNo ratings yet

- Plan ImplantationDocument1 pagePlan ImplantationABDERRAZZAKNo ratings yet

- IMPLANTATION Layout1Document1 pageIMPLANTATION Layout1ABDERRAZZAKNo ratings yet

- Aspiration R02Document1 pageAspiration R02ABDERRAZZAKNo ratings yet

- Support SecondaireDocument1 pageSupport SecondaireABDERRAZZAKNo ratings yet

- 0127 R8B 05 WP 311 01Document1 page0127 R8B 05 WP 311 01ABDERRAZZAKNo ratings yet

- 0127 R8B 03 WP 311 01Document1 page0127 R8B 03 WP 311 01ABDERRAZZAKNo ratings yet

- 0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionDocument1 page0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- 0127 R8B 07 WP 311 01Document1 page0127 R8B 07 WP 311 01ABDERRAZZAKNo ratings yet

- 0 10/25/22 A.N Y.S K.B 10/25/22 Issued For ConstructionDocument1 page0 10/25/22 A.N Y.S K.B 10/25/22 Issued For ConstructionABDERRAZZAKNo ratings yet

- 0127 R8B 04 WP 311 01Document1 page0127 R8B 04 WP 311 01ABDERRAZZAKNo ratings yet

- 0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionDocument1 page0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- 0 10/24/2022 A.N Y.S K.M 10/24/2022 Issued For ConstructionDocument1 page0 10/24/2022 A.N Y.S K.M 10/24/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- 300 WW 14T2 1 009 Bk1.shaDocument1 page300 WW 14T2 1 009 Bk1.shaABDERRAZZAKNo ratings yet

- Ilovepdf MergedDocument3 pagesIlovepdf MergedABDERRAZZAKNo ratings yet

- 0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionDocument1 page0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- 19PEE15Document32 pages19PEE15ABDERRAZZAKNo ratings yet

- To Match Tie-Ins Location: See SHT 200-PB-13F-219-BK1 SHT 1 F4 G5 B6Document1 pageTo Match Tie-Ins Location: See SHT 200-PB-13F-219-BK1 SHT 1 F4 G5 B6ABDERRAZZAKNo ratings yet

- Ce Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationDocument12 pagesCe Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationABDERRAZZAKNo ratings yet

- To Match Tie-Ins LocationDocument1 pageTo Match Tie-Ins LocationABDERRAZZAKNo ratings yet

- Ce Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationDocument12 pagesCe Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationABDERRAZZAKNo ratings yet

- To Match Tie-Ins LocationDocument1 pageTo Match Tie-Ins LocationABDERRAZZAKNo ratings yet

- Ce Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationDocument11 pagesCe Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationABDERRAZZAKNo ratings yet

- To Match Tie-Ins LocationDocument1 pageTo Match Tie-Ins LocationABDERRAZZAKNo ratings yet

- Ce Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationDocument6 pagesCe Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationABDERRAZZAKNo ratings yet

- Ce Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationDocument13 pagesCe Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationABDERRAZZAKNo ratings yet

- Exp. 8 Hydraulics Lab Excel FormDocument6 pagesExp. 8 Hydraulics Lab Excel FormZaher MoftyNo ratings yet

- Bobcat 175s Semi HidraulikaDocument16 pagesBobcat 175s Semi Hidraulikamarjan400No ratings yet

- 1 b1 Hydro Power Plant TurbinesDocument27 pages1 b1 Hydro Power Plant TurbinesWinston LibangaNo ratings yet

- Speed TronicDocument3 pagesSpeed Tronicscribdkhatn50% (2)

- Trailer Chassis Leveling Valve: Product FactsheetDocument4 pagesTrailer Chassis Leveling Valve: Product FactsheetLina Delgado OsorioNo ratings yet

- 994K Wheel Loader Brake System: Right RearDocument2 pages994K Wheel Loader Brake System: Right RearMed EkahNo ratings yet

- Spare Parts: LKB Automatic or Manual Butterfly ValveDocument40 pagesSpare Parts: LKB Automatic or Manual Butterfly ValveGustavo MedeirosNo ratings yet

- Valvula Relief Pruebas y Ajustes 325blDocument9 pagesValvula Relief Pruebas y Ajustes 325blcristian chuquicondor torresNo ratings yet

- Nfpa 14, 2013 - Redundance in Pressure RegulatingDocument1 pageNfpa 14, 2013 - Redundance in Pressure RegulatingDiego PovedaNo ratings yet

- GE2152 BCM Power Plant Engineering Notes 2Document13 pagesGE2152 BCM Power Plant Engineering Notes 2Alagar SamyNo ratings yet

- PNP GasDocument16 pagesPNP GasDinh Quoc SyNo ratings yet

- Hamworthy Engine Room Pumps AVTP RevisionDocument4 pagesHamworthy Engine Room Pumps AVTP RevisionВиталий КоропNo ratings yet

- ME 701 Power Plant Engineering Contact Hours: 4L Credit: 4: AdvancedDocument1 pageME 701 Power Plant Engineering Contact Hours: 4L Credit: 4: AdvancedRajib MandalNo ratings yet

- Experiment No.:-8: Study The Working and Construction of The Reciprocating Air CompressorDocument6 pagesExperiment No.:-8: Study The Working and Construction of The Reciprocating Air Compressordhirendra singhNo ratings yet

- Pipe Wall Thickness (Complete)Document40 pagesPipe Wall Thickness (Complete)Andri PutraNo ratings yet

- Training Hyd System in Cement IndustriDocument36 pagesTraining Hyd System in Cement IndustriNatsuko KayamaNo ratings yet

- Mill Interlocks: Start PermissivesDocument6 pagesMill Interlocks: Start PermissivesNikhil100% (1)

- Datasheet KOS 1060 HP - MaxDocument2 pagesDatasheet KOS 1060 HP - MaxNeil O'MalleyNo ratings yet

- Typical Laboratory VV Submittal REV U PDFDocument52 pagesTypical Laboratory VV Submittal REV U PDFERIK FLOREZ MALDONADONo ratings yet

- Chapter 5 Mass and Energy Analysis of Open SystemsDocument28 pagesChapter 5 Mass and Energy Analysis of Open Systemsrustam effendyNo ratings yet

- Hydrotest Procedure For Piping SystemsDocument6 pagesHydrotest Procedure For Piping Systemscatherine100% (1)

- Summary of Required / Installed Pumps With Accessories Churu-Bhaleri-Birmi-NiradhanuDocument35 pagesSummary of Required / Installed Pumps With Accessories Churu-Bhaleri-Birmi-NiradhanuMohit AgarwalNo ratings yet

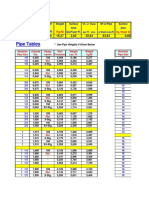

- Pipe Tables: Pipe Wall Inches Inches O.D. Thk. LBS/FTDocument12 pagesPipe Tables: Pipe Wall Inches Inches O.D. Thk. LBS/FTPedro Diaz UzcateguiNo ratings yet

- Calculator ASME B31 4Document11 pagesCalculator ASME B31 4DAYONo ratings yet

- Pumps: Bauzon, Gianpaolo B. Cabangal, DustinmarielDocument47 pagesPumps: Bauzon, Gianpaolo B. Cabangal, DustinmarielJohn Carl GuanlaoNo ratings yet

- Pump and CompressorDocument26 pagesPump and CompressorShamsol AriffinNo ratings yet

- 7.5. Cla-Val E-650-01Document4 pages7.5. Cla-Val E-650-01sigithvacNo ratings yet

- Gas Turbine-Compressor Unit For The Werne Natural Gas Compressor StationDocument6 pagesGas Turbine-Compressor Unit For The Werne Natural Gas Compressor StationscribdkhatnNo ratings yet

- Liquid Ring Compressor: KLH 47005, KLH 47105Document8 pagesLiquid Ring Compressor: KLH 47005, KLH 47105Jhon Jairo Arango MarquezNo ratings yet

To Match Tie-Ins Location: 3 Support

To Match Tie-Ins Location: 3 Support

Uploaded by

ABDERRAZZAKOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

To Match Tie-Ins Location: 3 Support

To Match Tie-Ins Location: 3 Support

Uploaded by

ABDERRAZZAKCopyright:

Available Formats

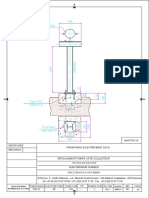

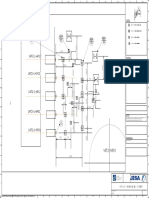

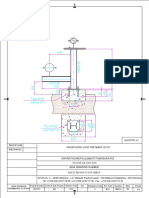

SHOP MATERIALS

PT NPD

3 NO DESCRIPTION (MM) CMDTY CODE QTY

SUPPORT 1 Pipe, FRP Filament wound, Butt wrap 200 PIPEBK1PE135 17.6 M

joint, 13.5 mm thick, Double layer of

1 Nexus Surfacing veil on all 150 PSIG

interior surfaces, Construction per

300

FRP specification

2 Equal Tee, Butt wrap joint, FRP Filament 200X200 TEEBK1BW 1

wound, Double layer of Nexus

SUPPORT 3 Surfacing veil on all interior

25 surfaces, Construction per FRP

00

TO 13GR03 14 Specification, Dimensions per Fitting

81 292 Dimension Table

SUPPORT 1 3 90 Deg Elbow, Butt wrap joint, FRP 200 90ELBK1BW 6

36 Filament wound, Double layer of Nexus

8 Surfacing veil on all interior

F4 G5 B6

73 69 surfaces, Construction per FRP

1

75 3

1316

652 Specification, Dimensions per Fitting

35 SUPPORT Dimension Table

00 7 1 292 4 FRP integral stub Flange, Butt wrap 200 FLGFF150BK1165 4

STEM UP 37

7 joint, 150#, FF, FRP hand lay-up,

F4 G5 B6 Double layer of Nexus Surfacing veil

1 on all interior surfaces. Stub end to

1 F4 G5 B6 match pipe, Flange O.D. and drilling

2

80 200X200NPD to ASME B16.5, Dimensions per FRP

0 3 EL +115186 SUPPORT Specification

50

1

12 F4 G5 B6

1316

200NPD

44 FIELD MATERIALS

3 7 66

3 STEM UP

EL +113870 PT NPD

1

SEE SHT NO DESCRIPTION (MM) CMDTY CODE QTY

200-PB-13F-219-BK1 SHT 2 5 Gasket, 150#, FF, PTFE, 3 mm thick, 200 GSKBK1SS 4

Garlok, Stress Saver 370, ASME B16.20

300 6 Stud, Stainless Steel, Threaded Full 20 STDBLTBK1 32

3 Length STUD, ASTM A193 GR B8M CL2,

With Two Heavy Hex Nuts, ASME B1.1,

ASME B18.2.2, ASTM A194 GR 8M - 110

537

mm Length

7 Plug Valve ; API 599 as Applicable ; 200 VP9AXDDFF9AAA9PZ 2

CL150 ; FF ; OS&Y, BB ; GO ; SS 904L

SUPPORT UB6PM (UNS N08904) ; Modified PTFE

Sleeve ,

3300

200NPD

1

TO 13ER03

NOTE:-

1. ALL DIMENSIONS ARE IN MM

2. ROOT GAPS FOR BUTT WELDING FITTINGS ARE NOT INCLUDED IN DIMENSIONS.

3. DIMENSIONS MAY BE SLIGHTLY DIFFERENT FROM ACTUAL DIMENSION

BY 1 MM OR 2 MM DUE TO COMPUTER ROUND-OFF CALCULATION.

Note:Dimension to be verified at site prier fabrication

4. THE SUPPORT DETAILS DEPICTED ON THE ISO DWG. ARE REFERENCE ONLY FOR

UNDERSTANDING AND DETAIL FABRICATION SHALL BE IN ACCORDANCE WITH PIPE

to match Tie-Ins location

SUPPORT STANDARD DRAWINGS.

5. FOR PIPE SIZE 1-1/2" AND BELOW.

THE FINAL ROUTING AND SUPPORTS ARE TO BE CONFIRMED BY FIELD.

6. ALL CO-ORDINATES ARE RELEVANT TO CENTRE LINE OF PIPE.

REV. DATE REVISION DESCRIPTION BY CKD APP APP PROJECT NO.

PIPING SPEC: BK1 TEST TYPE: A 04/27/22 ISSUED FOR USE / STRESS CALCULATION AG KB ONEJ ENGINEERING RECORD DATE

FLUID CODE: TEST PRESS: BY: A.GARAOUI 04/27/22

DESIGN TEMP: HEAT TRACING: CHK: K.BEIDEN 04/27/22

JPH Phase 2

DESIGN PRESS: STRESS REQ: APP: O.NEJJAR 04/27/22 ISOMETRIC DRAWINGS

OPERATING TEMP: RADIOGRAPHY: APP: LINE NO. 200-PB-13F-219-BK1 SHEET REV.

OPERATING PRESS: RAL CODE: CLIENT: ISO NO. 13F-PB-219-03 3 OF 3 A

You might also like

- Characteristic Curves KWP - KSBDocument224 pagesCharacteristic Curves KWP - KSBDaniel MilosevskiNo ratings yet

- 0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionDocument1 page0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- 0 10/24/2022 A.N Y.S K.M 10/24/2022 Issued For ConstructionDocument1 page0 10/24/2022 A.N Y.S K.M 10/24/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- Ilovepdf MergedDocument3 pagesIlovepdf MergedABDERRAZZAKNo ratings yet

- To Match Tie-Ins Location: See SHT 200-PB-13F-219-BK1 SHT 1 F4 G5 B6Document1 pageTo Match Tie-Ins Location: See SHT 200-PB-13F-219-BK1 SHT 1 F4 G5 B6ABDERRAZZAKNo ratings yet

- 0127 R8B 07 WP 311 01Document1 page0127 R8B 07 WP 311 01ABDERRAZZAKNo ratings yet

- To Match Tie-Ins LocationDocument1 pageTo Match Tie-Ins LocationABDERRAZZAKNo ratings yet

- To Match Tie-Ins LocationDocument1 pageTo Match Tie-Ins LocationABDERRAZZAKNo ratings yet

- 0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionDocument1 page0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- 300 WW 14T2 1 009 Bk1.shaDocument1 page300 WW 14T2 1 009 Bk1.shaABDERRAZZAKNo ratings yet

- 0 10/25/22 A.N Y.S K.B 10/25/22 Issued For ConstructionDocument1 page0 10/25/22 A.N Y.S K.B 10/25/22 Issued For ConstructionABDERRAZZAKNo ratings yet

- 0127 R8B 03 WP 311 01Document1 page0127 R8B 03 WP 311 01ABDERRAZZAKNo ratings yet

- To Match Tie-Ins LocationDocument1 pageTo Match Tie-Ins LocationABDERRAZZAKNo ratings yet

- 0127 R8B 06 WP 311 01Document1 page0127 R8B 06 WP 311 01ABDERRAZZAKNo ratings yet

- 0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionDocument1 page0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- 0127 R8B 04 WP 311 01Document1 page0127 R8B 04 WP 311 01ABDERRAZZAKNo ratings yet

- 0127 R8B 05 WP 311 01Document1 page0127 R8B 05 WP 311 01ABDERRAZZAKNo ratings yet

- Perspective Diagram Pentray Perspective 1: Jose Miguel BorjaDocument1 pagePerspective Diagram Pentray Perspective 1: Jose Miguel Borjajohn Patrick valinoNo ratings yet

- Notes: Roof: Concrete Roof Tiles On TrussesDocument1 pageNotes: Roof: Concrete Roof Tiles On TrussesanzaniNo ratings yet

- Pump Foundation Design PDFDocument18 pagesPump Foundation Design PDFArchana ArchuNo ratings yet

- FPSOInterface Engineering 09Document43 pagesFPSOInterface Engineering 09Ronnie Paul100% (1)

- Manual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkDocument33 pagesManual, Owner'S Drum-Export 1/1: Suffix Language Page Remarkchad tanNo ratings yet

- Selec Chart Concrete enDocument1 pageSelec Chart Concrete enRubal ShawNo ratings yet

- Transfame SDN BHD Paint Matrix Provision of Hook Up & Commissioning (Huc) Works For Murphy'S FacilitiesDocument2 pagesTransfame SDN BHD Paint Matrix Provision of Hook Up & Commissioning (Huc) Works For Murphy'S FacilitiesSupport RFZ2 EngineeringNo ratings yet

- Expansion Joint - Internal Corner: Solid Wall AT-mineral WoolDocument1 pageExpansion Joint - Internal Corner: Solid Wall AT-mineral WoolWadi Gabor100% (1)

- Sp3 MB A WPF Det - Typ 007 (Roof)Document1 pageSp3 MB A WPF Det - Typ 007 (Roof)Renaldo BunaidiNo ratings yet

- Equipment Schematic - For P5 DualDocument4 pagesEquipment Schematic - For P5 DualrahulNo ratings yet

- Precast T-Wall Alt 1Document2 pagesPrecast T-Wall Alt 1Kinantoko FauzanNo ratings yet

- Paf-Mdf Control 02Document33 pagesPaf-Mdf Control 02thanh sang đinhNo ratings yet

- MFL68723109 IndoDocument33 pagesMFL68723109 Indoarcercoa1No ratings yet

- GT1015Document1 pageGT1015Basten M H SilitongaNo ratings yet

- 66 Ihd 0003 ADocument1 page66 Ihd 0003 AMbalekelwa MpembeNo ratings yet

- MFL67284329劤틔 - hun-09-09 10Document33 pagesMFL67284329劤틔 - hun-09-09 10gyorfizsuzsi1986No ratings yet

- Paf-Mdf Control 01Document33 pagesPaf-Mdf Control 01thanh sang đinhNo ratings yet

- Gambar Listrik CilacapDocument10 pagesGambar Listrik CilacapDanang RizkiNo ratings yet

- Manual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkDocument81 pagesManual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkGuillermo SilvaNo ratings yet

- Manual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkDocument33 pagesManual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkVaniNo ratings yet

- Manual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkDocument33 pagesManual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkAndrei BogdanNo ratings yet

- 69 - IDN - 142 (Revised)Document5 pages69 - IDN - 142 (Revised)visheshssrivastavaNo ratings yet

- Step / Return: Standard Detail - Airtec Stone Natural StoneDocument1 pageStep / Return: Standard Detail - Airtec Stone Natural StoneWadi GaborNo ratings yet

- WPS MatrixDocument4 pagesWPS MatrixHarshaVeeragandham50% (2)

- L2 0910 PDFDocument1 pageL2 0910 PDFWadi GaborNo ratings yet

- Regular-Density Panel For Cost-Efficiency and Reliability: Commercial Roof FiberboardDocument2 pagesRegular-Density Panel For Cost-Efficiency and Reliability: Commercial Roof FiberboardNikola BoskovicNo ratings yet

- A2-Floor Plan, ElevationsDocument1 pageA2-Floor Plan, ElevationsRonnel John CruzNo ratings yet

- RV WU1348 Eldoret Mtungi Road - DesignDocument6 pagesRV WU1348 Eldoret Mtungi Road - DesignIKO NETWORKNo ratings yet

- 62.Tủ Điện MP-P-B2B-FAFDocument11 pages62.Tủ Điện MP-P-B2B-FAFthanh sang đinhNo ratings yet

- Thermacor Preinsulated PipesDocument6 pagesThermacor Preinsulated PipesBernard SolisNo ratings yet

- 63.Tủ Điện MP-P-B2C-FAFDocument11 pages63.Tủ Điện MP-P-B2C-FAFthanh sang đinhNo ratings yet

- PUDLO TJD GPUS 013 Slab Pipe Penetration DetailDocument1 pagePUDLO TJD GPUS 013 Slab Pipe Penetration DetailJosip MedvedNo ratings yet

- Ip 54 Ahf PDFDocument2 pagesIp 54 Ahf PDFvalay salesNo ratings yet

- Manual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkDocument33 pagesManual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkcrnimajstorNo ratings yet

- GC11 Pipe Thickness CalcDocument1 pageGC11 Pipe Thickness CalcsrinivasanNo ratings yet

- Made Easy!: 25Mm Square RangeDocument2 pagesMade Easy!: 25Mm Square RangeTonyNo ratings yet

- 10.Tủ Điện DB-B-MDFDocument7 pages10.Tủ Điện DB-B-MDFthanh sang đinhNo ratings yet

- Manual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkDocument33 pagesManual, Owner'S Drum-Export 1/1: Suffix Language Page RemarkriyadhplyNo ratings yet

- Pipe Thru Wall & Slab Detail Exhaust Air Louver Detail Door Upstand at RoofDocument1 pagePipe Thru Wall & Slab Detail Exhaust Air Louver Detail Door Upstand at RoofAdel KhalilNo ratings yet

- Grating Black Start Plan at T/G El (+) 0.300 (3 Nos) Grating Black Start Plan at T/G El (+) 0.100 (2 Nos)Document1 pageGrating Black Start Plan at T/G El (+) 0.300 (3 Nos) Grating Black Start Plan at T/G El (+) 0.100 (2 Nos)sivagnanamNo ratings yet

- 32 Gfc-P2c3-Tu02-Crp-Dr-Btn-73106-01-ADocument1 page32 Gfc-P2c3-Tu02-Crp-Dr-Btn-73106-01-ASUBHASH KUMARNo ratings yet

- FC Double Operable W - Muntins & Transom & Sidelits - Brick-to-Brick Installation Details 1Document2 pagesFC Double Operable W - Muntins & Transom & Sidelits - Brick-to-Brick Installation Details 1Payal YadavNo ratings yet

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- Rep 01Document1 pageRep 01ABDERRAZZAKNo ratings yet

- 0127 R8B 06 WP 311 01Document1 page0127 R8B 06 WP 311 01ABDERRAZZAKNo ratings yet

- Rep02 R01Document1 pageRep02 R01ABDERRAZZAKNo ratings yet

- Aspiration R01Document1 pageAspiration R01ABDERRAZZAKNo ratings yet

- Passerelle PAT150Document1 pagePasserelle PAT150ABDERRAZZAKNo ratings yet

- Plan ImplantationDocument1 pagePlan ImplantationABDERRAZZAKNo ratings yet

- IMPLANTATION Layout1Document1 pageIMPLANTATION Layout1ABDERRAZZAKNo ratings yet

- Aspiration R02Document1 pageAspiration R02ABDERRAZZAKNo ratings yet

- Support SecondaireDocument1 pageSupport SecondaireABDERRAZZAKNo ratings yet

- 0127 R8B 05 WP 311 01Document1 page0127 R8B 05 WP 311 01ABDERRAZZAKNo ratings yet

- 0127 R8B 03 WP 311 01Document1 page0127 R8B 03 WP 311 01ABDERRAZZAKNo ratings yet

- 0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionDocument1 page0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- 0127 R8B 07 WP 311 01Document1 page0127 R8B 07 WP 311 01ABDERRAZZAKNo ratings yet

- 0 10/25/22 A.N Y.S K.B 10/25/22 Issued For ConstructionDocument1 page0 10/25/22 A.N Y.S K.B 10/25/22 Issued For ConstructionABDERRAZZAKNo ratings yet

- 0127 R8B 04 WP 311 01Document1 page0127 R8B 04 WP 311 01ABDERRAZZAKNo ratings yet

- 0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionDocument1 page0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- 0 10/24/2022 A.N Y.S K.M 10/24/2022 Issued For ConstructionDocument1 page0 10/24/2022 A.N Y.S K.M 10/24/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- 300 WW 14T2 1 009 Bk1.shaDocument1 page300 WW 14T2 1 009 Bk1.shaABDERRAZZAKNo ratings yet

- Ilovepdf MergedDocument3 pagesIlovepdf MergedABDERRAZZAKNo ratings yet

- 0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionDocument1 page0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- 19PEE15Document32 pages19PEE15ABDERRAZZAKNo ratings yet

- To Match Tie-Ins Location: See SHT 200-PB-13F-219-BK1 SHT 1 F4 G5 B6Document1 pageTo Match Tie-Ins Location: See SHT 200-PB-13F-219-BK1 SHT 1 F4 G5 B6ABDERRAZZAKNo ratings yet

- Ce Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationDocument12 pagesCe Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationABDERRAZZAKNo ratings yet

- To Match Tie-Ins LocationDocument1 pageTo Match Tie-Ins LocationABDERRAZZAKNo ratings yet

- Ce Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationDocument12 pagesCe Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationABDERRAZZAKNo ratings yet

- To Match Tie-Ins LocationDocument1 pageTo Match Tie-Ins LocationABDERRAZZAKNo ratings yet

- Ce Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationDocument11 pagesCe Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationABDERRAZZAKNo ratings yet

- To Match Tie-Ins LocationDocument1 pageTo Match Tie-Ins LocationABDERRAZZAKNo ratings yet

- Ce Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationDocument6 pagesCe Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationABDERRAZZAKNo ratings yet

- Ce Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationDocument13 pagesCe Document Est La Propriété de ATLANTIQUES SOLUTIONS. Il Ne Peut Être Communiqué Ou Reproduit Sans Son AutorisationABDERRAZZAKNo ratings yet

- Exp. 8 Hydraulics Lab Excel FormDocument6 pagesExp. 8 Hydraulics Lab Excel FormZaher MoftyNo ratings yet

- Bobcat 175s Semi HidraulikaDocument16 pagesBobcat 175s Semi Hidraulikamarjan400No ratings yet

- 1 b1 Hydro Power Plant TurbinesDocument27 pages1 b1 Hydro Power Plant TurbinesWinston LibangaNo ratings yet

- Speed TronicDocument3 pagesSpeed Tronicscribdkhatn50% (2)

- Trailer Chassis Leveling Valve: Product FactsheetDocument4 pagesTrailer Chassis Leveling Valve: Product FactsheetLina Delgado OsorioNo ratings yet

- 994K Wheel Loader Brake System: Right RearDocument2 pages994K Wheel Loader Brake System: Right RearMed EkahNo ratings yet

- Spare Parts: LKB Automatic or Manual Butterfly ValveDocument40 pagesSpare Parts: LKB Automatic or Manual Butterfly ValveGustavo MedeirosNo ratings yet

- Valvula Relief Pruebas y Ajustes 325blDocument9 pagesValvula Relief Pruebas y Ajustes 325blcristian chuquicondor torresNo ratings yet

- Nfpa 14, 2013 - Redundance in Pressure RegulatingDocument1 pageNfpa 14, 2013 - Redundance in Pressure RegulatingDiego PovedaNo ratings yet

- GE2152 BCM Power Plant Engineering Notes 2Document13 pagesGE2152 BCM Power Plant Engineering Notes 2Alagar SamyNo ratings yet

- PNP GasDocument16 pagesPNP GasDinh Quoc SyNo ratings yet

- Hamworthy Engine Room Pumps AVTP RevisionDocument4 pagesHamworthy Engine Room Pumps AVTP RevisionВиталий КоропNo ratings yet

- ME 701 Power Plant Engineering Contact Hours: 4L Credit: 4: AdvancedDocument1 pageME 701 Power Plant Engineering Contact Hours: 4L Credit: 4: AdvancedRajib MandalNo ratings yet

- Experiment No.:-8: Study The Working and Construction of The Reciprocating Air CompressorDocument6 pagesExperiment No.:-8: Study The Working and Construction of The Reciprocating Air Compressordhirendra singhNo ratings yet

- Pipe Wall Thickness (Complete)Document40 pagesPipe Wall Thickness (Complete)Andri PutraNo ratings yet

- Training Hyd System in Cement IndustriDocument36 pagesTraining Hyd System in Cement IndustriNatsuko KayamaNo ratings yet

- Mill Interlocks: Start PermissivesDocument6 pagesMill Interlocks: Start PermissivesNikhil100% (1)

- Datasheet KOS 1060 HP - MaxDocument2 pagesDatasheet KOS 1060 HP - MaxNeil O'MalleyNo ratings yet

- Typical Laboratory VV Submittal REV U PDFDocument52 pagesTypical Laboratory VV Submittal REV U PDFERIK FLOREZ MALDONADONo ratings yet

- Chapter 5 Mass and Energy Analysis of Open SystemsDocument28 pagesChapter 5 Mass and Energy Analysis of Open Systemsrustam effendyNo ratings yet

- Hydrotest Procedure For Piping SystemsDocument6 pagesHydrotest Procedure For Piping Systemscatherine100% (1)

- Summary of Required / Installed Pumps With Accessories Churu-Bhaleri-Birmi-NiradhanuDocument35 pagesSummary of Required / Installed Pumps With Accessories Churu-Bhaleri-Birmi-NiradhanuMohit AgarwalNo ratings yet

- Pipe Tables: Pipe Wall Inches Inches O.D. Thk. LBS/FTDocument12 pagesPipe Tables: Pipe Wall Inches Inches O.D. Thk. LBS/FTPedro Diaz UzcateguiNo ratings yet

- Calculator ASME B31 4Document11 pagesCalculator ASME B31 4DAYONo ratings yet

- Pumps: Bauzon, Gianpaolo B. Cabangal, DustinmarielDocument47 pagesPumps: Bauzon, Gianpaolo B. Cabangal, DustinmarielJohn Carl GuanlaoNo ratings yet

- Pump and CompressorDocument26 pagesPump and CompressorShamsol AriffinNo ratings yet

- 7.5. Cla-Val E-650-01Document4 pages7.5. Cla-Val E-650-01sigithvacNo ratings yet

- Gas Turbine-Compressor Unit For The Werne Natural Gas Compressor StationDocument6 pagesGas Turbine-Compressor Unit For The Werne Natural Gas Compressor StationscribdkhatnNo ratings yet

- Liquid Ring Compressor: KLH 47005, KLH 47105Document8 pagesLiquid Ring Compressor: KLH 47005, KLH 47105Jhon Jairo Arango MarquezNo ratings yet